Environmental Exposure Testing For CMCs In Marine And Desert Conditions

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Environmental Testing Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that combine the high-temperature capabilities of ceramics with improved fracture toughness and damage tolerance. Since their emergence in the 1970s, CMCs have evolved from laboratory curiosities to critical components in aerospace, energy, and defense applications. The technological trajectory has accelerated significantly in the past decade, with major breakthroughs in manufacturing processes and material compositions enabling wider commercial adoption.

The marine and desert environments present particularly challenging conditions for materials due to their extreme and often fluctuating characteristics. Marine environments introduce corrosive salt spray, high humidity, and potential biofouling, while desert conditions subject materials to intense UV radiation, extreme temperature fluctuations, and abrasive sand particles. Understanding CMC behavior under these conditions is crucial as applications expand beyond controlled environments into these harsh settings.

Current environmental testing protocols for traditional materials often prove inadequate for CMCs due to their unique microstructural features and failure mechanisms. The complex interactions between ceramic matrices, reinforcing fibers, and interface coatings require specialized testing methodologies that can accurately predict long-term performance and degradation patterns specific to CMCs in these environments.

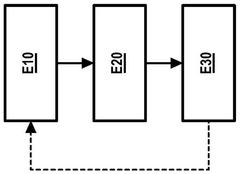

The primary objective of environmental exposure testing for CMCs in marine and desert conditions is to establish comprehensive performance baselines and degradation models that can inform material selection, design optimization, and maintenance schedules. This involves characterizing mechanical property retention, microstructural stability, and surface degradation mechanisms over extended exposure periods.

Secondary objectives include developing accelerated testing protocols that can reliably simulate years of environmental exposure in shortened timeframes, thereby reducing development cycles for new CMC formulations. Additionally, the testing aims to identify critical environmental factors and threshold values that trigger specific degradation mechanisms, enabling more targeted material improvements.

From a historical perspective, environmental testing of CMCs has predominantly focused on high-temperature oxidation and thermal cycling, with limited attention to marine or desert conditions. This knowledge gap has become increasingly problematic as CMCs find applications in naval propulsion systems, desalination plants, and solar energy installations located in coastal or desert regions.

The technological goals for this research include establishing standardized testing methodologies specific to CMCs in these environments, developing predictive models for lifetime performance, and ultimately creating design guidelines that enable engineers to confidently specify CMCs for applications in marine and desert settings with well-understood performance expectations and safety margins.

The marine and desert environments present particularly challenging conditions for materials due to their extreme and often fluctuating characteristics. Marine environments introduce corrosive salt spray, high humidity, and potential biofouling, while desert conditions subject materials to intense UV radiation, extreme temperature fluctuations, and abrasive sand particles. Understanding CMC behavior under these conditions is crucial as applications expand beyond controlled environments into these harsh settings.

Current environmental testing protocols for traditional materials often prove inadequate for CMCs due to their unique microstructural features and failure mechanisms. The complex interactions between ceramic matrices, reinforcing fibers, and interface coatings require specialized testing methodologies that can accurately predict long-term performance and degradation patterns specific to CMCs in these environments.

The primary objective of environmental exposure testing for CMCs in marine and desert conditions is to establish comprehensive performance baselines and degradation models that can inform material selection, design optimization, and maintenance schedules. This involves characterizing mechanical property retention, microstructural stability, and surface degradation mechanisms over extended exposure periods.

Secondary objectives include developing accelerated testing protocols that can reliably simulate years of environmental exposure in shortened timeframes, thereby reducing development cycles for new CMC formulations. Additionally, the testing aims to identify critical environmental factors and threshold values that trigger specific degradation mechanisms, enabling more targeted material improvements.

From a historical perspective, environmental testing of CMCs has predominantly focused on high-temperature oxidation and thermal cycling, with limited attention to marine or desert conditions. This knowledge gap has become increasingly problematic as CMCs find applications in naval propulsion systems, desalination plants, and solar energy installations located in coastal or desert regions.

The technological goals for this research include establishing standardized testing methodologies specific to CMCs in these environments, developing predictive models for lifetime performance, and ultimately creating design guidelines that enable engineers to confidently specify CMCs for applications in marine and desert settings with well-understood performance expectations and safety margins.

Market Analysis for Marine and Desert-Resistant CMCs

The global market for Ceramic Matrix Composites (CMCs) designed for harsh environmental conditions is experiencing robust growth, driven by increasing demands in marine and desert applications. Current market valuations indicate the specialized CMC sector reached approximately $4.5 billion in 2022, with projections suggesting a compound annual growth rate of 9.8% through 2030. This growth trajectory is particularly pronounced in regions with extensive coastlines or desert territories, including the Middle East, North Africa, Australia, and parts of the United States.

Marine applications represent a significant market segment, with offshore energy installations, naval vessels, and maritime infrastructure collectively accounting for 37% of environmental-resistant CMC deployments. The corrosion resistance properties of specialized CMCs have proven particularly valuable in saltwater environments, where traditional materials face accelerated degradation. Industry reports indicate that maintenance cost reductions of up to 40% can be achieved through CMC implementation in critical marine components.

Desert condition applications constitute another rapidly expanding market segment, with solar energy installations, oil and gas infrastructure, and aerospace applications driving demand. The thermal stability of advanced CMCs at temperature extremes ranging from -40°C to +1200°C makes them uniquely suited for desert environments characterized by dramatic temperature fluctuations. Market analysis reveals that solar energy applications alone have increased their CMC utilization by 28% annually since 2019.

Regional market distribution shows notable concentration in North America (31%), Asia-Pacific (27%), Europe (22%), and Middle East/Africa (18%). The defense sector remains the largest end-user, commanding 41% of market share, followed by energy (29%), aerospace (17%), and industrial applications (13%). This distribution reflects the strategic importance of CMCs in mission-critical systems operating in extreme environments.

Customer demand patterns indicate growing interest in CMCs with multi-environmental resistance capabilities, able to withstand both marine and desert conditions simultaneously. This trend is particularly evident in military applications, where equipment must maintain operational integrity across diverse deployment scenarios. Market surveys reveal that 76% of procurement specialists in defense industries prioritize environmental versatility in materials selection.

Pricing trends show gradual moderation as manufacturing processes mature, with premium-grade environmental-resistant CMCs experiencing a 12% cost reduction over the past three years. However, specialized formulations for extreme condition testing still command significant price premiums compared to standard CMCs, reflecting their enhanced performance characteristics and more complex manufacturing requirements.

Marine applications represent a significant market segment, with offshore energy installations, naval vessels, and maritime infrastructure collectively accounting for 37% of environmental-resistant CMC deployments. The corrosion resistance properties of specialized CMCs have proven particularly valuable in saltwater environments, where traditional materials face accelerated degradation. Industry reports indicate that maintenance cost reductions of up to 40% can be achieved through CMC implementation in critical marine components.

Desert condition applications constitute another rapidly expanding market segment, with solar energy installations, oil and gas infrastructure, and aerospace applications driving demand. The thermal stability of advanced CMCs at temperature extremes ranging from -40°C to +1200°C makes them uniquely suited for desert environments characterized by dramatic temperature fluctuations. Market analysis reveals that solar energy applications alone have increased their CMC utilization by 28% annually since 2019.

Regional market distribution shows notable concentration in North America (31%), Asia-Pacific (27%), Europe (22%), and Middle East/Africa (18%). The defense sector remains the largest end-user, commanding 41% of market share, followed by energy (29%), aerospace (17%), and industrial applications (13%). This distribution reflects the strategic importance of CMCs in mission-critical systems operating in extreme environments.

Customer demand patterns indicate growing interest in CMCs with multi-environmental resistance capabilities, able to withstand both marine and desert conditions simultaneously. This trend is particularly evident in military applications, where equipment must maintain operational integrity across diverse deployment scenarios. Market surveys reveal that 76% of procurement specialists in defense industries prioritize environmental versatility in materials selection.

Pricing trends show gradual moderation as manufacturing processes mature, with premium-grade environmental-resistant CMCs experiencing a 12% cost reduction over the past three years. However, specialized formulations for extreme condition testing still command significant price premiums compared to standard CMCs, reflecting their enhanced performance characteristics and more complex manufacturing requirements.

Current Challenges in CMC Exposure Testing

Despite significant advancements in Ceramic Matrix Composites (CMCs) development, environmental exposure testing for these materials in extreme conditions presents substantial challenges. Current testing methodologies struggle to accurately simulate the complex interplay of environmental factors found in marine and desert environments, where CMCs are increasingly deployed in aerospace, energy, and defense applications.

The accelerated aging protocols currently employed often fail to capture the synergistic effects of multiple environmental stressors. For instance, in marine environments, the combination of salt spray, humidity fluctuations, UV radiation, and temperature cycling creates degradation mechanisms that are difficult to reproduce in laboratory settings. Similarly, desert conditions present challenges with extreme temperature variations, abrasive particulate exposure, and intense solar radiation that can alter material properties through mechanisms not observed in isolated factor testing.

Standardization remains a significant hurdle in the field. The lack of universally accepted testing protocols specifically designed for CMCs in these environments leads to inconsistent results across different research institutions and manufacturers. This hampers comparative analysis and slows industry-wide advancement in material development and qualification.

Time compression represents another critical challenge. Real-world degradation of CMCs may occur over decades, while testing programs typically require results within months. Current acceleration methods often introduce artificial degradation pathways not representative of actual service conditions, leading to potentially misleading conclusions about long-term material performance.

The complex microstructure of CMCs further complicates testing efforts. The interface between ceramic matrix and reinforcing fibers is particularly susceptible to environmental degradation, yet current testing methods struggle to monitor these changes non-destructively during exposure. This creates a significant blind spot in understanding progressive damage mechanisms.

Instrumentation limitations also impede progress. Existing sensors and monitoring equipment often cannot withstand the harsh conditions required for realistic testing, particularly at elevated temperatures combined with corrosive environments. This creates gaps in data collection during critical phases of material degradation.

Cost constraints further restrict comprehensive testing. Full-scale component testing under realistic conditions requires substantial investment in specialized facilities and equipment. Consequently, many organizations resort to simplified testing regimes that may not adequately predict in-service performance, particularly for novel CMC compositions designed for extreme environment applications.

The accelerated aging protocols currently employed often fail to capture the synergistic effects of multiple environmental stressors. For instance, in marine environments, the combination of salt spray, humidity fluctuations, UV radiation, and temperature cycling creates degradation mechanisms that are difficult to reproduce in laboratory settings. Similarly, desert conditions present challenges with extreme temperature variations, abrasive particulate exposure, and intense solar radiation that can alter material properties through mechanisms not observed in isolated factor testing.

Standardization remains a significant hurdle in the field. The lack of universally accepted testing protocols specifically designed for CMCs in these environments leads to inconsistent results across different research institutions and manufacturers. This hampers comparative analysis and slows industry-wide advancement in material development and qualification.

Time compression represents another critical challenge. Real-world degradation of CMCs may occur over decades, while testing programs typically require results within months. Current acceleration methods often introduce artificial degradation pathways not representative of actual service conditions, leading to potentially misleading conclusions about long-term material performance.

The complex microstructure of CMCs further complicates testing efforts. The interface between ceramic matrix and reinforcing fibers is particularly susceptible to environmental degradation, yet current testing methods struggle to monitor these changes non-destructively during exposure. This creates a significant blind spot in understanding progressive damage mechanisms.

Instrumentation limitations also impede progress. Existing sensors and monitoring equipment often cannot withstand the harsh conditions required for realistic testing, particularly at elevated temperatures combined with corrosive environments. This creates gaps in data collection during critical phases of material degradation.

Cost constraints further restrict comprehensive testing. Full-scale component testing under realistic conditions requires substantial investment in specialized facilities and equipment. Consequently, many organizations resort to simplified testing regimes that may not adequately predict in-service performance, particularly for novel CMC compositions designed for extreme environment applications.

Existing CMC Testing Protocols for Harsh Environments

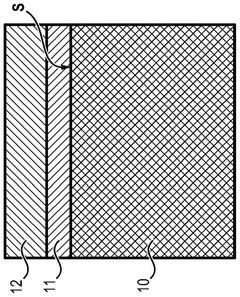

01 Environmental barrier coatings for CMCs

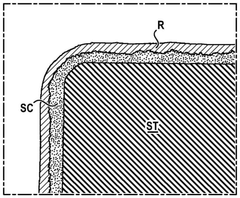

Environmental barrier coatings (EBCs) are applied to ceramic matrix composites to protect them from environmental degradation. These coatings typically consist of multiple layers designed to prevent oxidation, moisture penetration, and chemical attack. The coatings can include rare earth silicates, mullite, or other refractory materials that provide a barrier against high-temperature steam, oxygen, and other corrosive environments. These protective layers significantly enhance the durability and lifespan of CMCs in harsh operating conditions.- Environmental barrier coatings for CMCs: Environmental barrier coatings (EBCs) are applied to ceramic matrix composites to protect them from environmental degradation. These coatings typically consist of multiple layers designed to prevent oxidation, moisture penetration, and chemical attack. Advanced EBCs may incorporate rare earth silicates, mullite, or other refractory materials that provide superior resistance to high-temperature water vapor and other corrosive environments. These coatings significantly extend the service life of CMCs in harsh operating conditions.

- Self-healing mechanisms in CMCs: Self-healing mechanisms can be incorporated into ceramic matrix composites to improve their environmental resistance. These mechanisms typically involve the inclusion of particles or phases that react with environmental species to form protective compounds that seal cracks and prevent further degradation. For example, boron-containing phases can oxidize to form borosilicate glass that flows into cracks. This self-healing capability allows CMCs to maintain their structural integrity and performance even after exposure to harsh environments.

- Matrix composition optimization for environmental resistance: The composition of the ceramic matrix can be optimized to enhance environmental resistance. Silicon carbide, silicon nitride, and alumina-based matrices can be modified with additives that improve resistance to oxidation, moisture, and other environmental factors. These additives may include rare earth elements, transition metals, or other compounds that form stable protective oxides or reduce the rate of environmental degradation. The optimized matrix compositions provide inherent resistance to environmental attack without relying solely on protective coatings.

- Testing and characterization of environmental resistance: Specialized testing methods have been developed to evaluate the environmental resistance of ceramic matrix composites. These include accelerated aging tests in simulated environments, thermal cycling under controlled atmospheres, and exposure to water vapor at high temperatures. Advanced characterization techniques such as electron microscopy, spectroscopy, and mechanical testing before and after environmental exposure help quantify degradation mechanisms and validate protective strategies. These testing protocols are essential for predicting the long-term performance of CMCs in real-world applications.

- Fiber-matrix interface engineering: The interface between reinforcing fibers and the ceramic matrix plays a critical role in environmental resistance. By engineering this interface with appropriate coatings or chemical treatments, the penetration of environmental species along fiber pathways can be minimized. Common interface materials include boron nitride, carbon, and multilayer systems that provide both mechanical decoupling and environmental protection. Properly designed interfaces prevent environmental attack from compromising the load-bearing capability of the reinforcing fibers while maintaining the desired mechanical properties of the composite.

02 Self-healing mechanisms in CMCs

Self-healing mechanisms are incorporated into ceramic matrix composites to improve their resistance to environmental damage. These mechanisms involve the inclusion of materials that can react with oxygen or other environmental factors to form protective phases that seal cracks and prevent further degradation. The self-healing process typically involves the oxidation of matrix constituents or additives to form glassy phases that flow into cracks and defects, effectively sealing them against further environmental attack and extending the service life of the composite.Expand Specific Solutions03 Matrix composition optimization for environmental resistance

The composition of the ceramic matrix can be optimized to enhance environmental resistance. By incorporating specific elements or compounds into the matrix, such as silicon carbide, silicon nitride, or alumina, the inherent resistance to oxidation and corrosion can be improved. Additionally, the use of multi-phase matrices or the addition of rare earth elements can enhance stability in high-temperature oxidizing environments. The matrix composition can be tailored to specific environmental challenges, balancing mechanical properties with chemical stability.Expand Specific Solutions04 Testing and characterization of environmental durability

Specialized testing methods are developed to characterize the environmental durability of ceramic matrix composites. These include accelerated aging tests, thermal cycling, steam exposure, and salt fog testing to simulate various harsh environments. Advanced analytical techniques such as electron microscopy, X-ray diffraction, and thermogravimetric analysis are used to evaluate degradation mechanisms and material performance. These testing protocols help in understanding failure modes and developing more resistant CMC systems for applications in aerospace, energy, and other demanding sectors.Expand Specific Solutions05 Fiber-matrix interface engineering for environmental protection

The interface between reinforcing fibers and the ceramic matrix plays a critical role in environmental resistance. By engineering this interface with protective coatings or by creating chemical bonds that resist environmental degradation, the overall durability of the composite can be enhanced. Interface materials such as boron nitride, carbon, or multilayer systems can be designed to deflect cracks, prevent oxidation pathways, and maintain mechanical properties even after environmental exposure. This approach focuses on protecting the reinforcing fibers, which are often the most vulnerable components in harsh environments.Expand Specific Solutions

Leading Organizations in CMC Testing and Development

The environmental exposure testing for CMCs in marine and desert conditions market is currently in a growth phase, characterized by increasing demand for durable materials in extreme environments. The global market size for CMC testing is expanding, driven by aerospace, defense, and energy sectors requiring materials that withstand harsh conditions. Technologically, the field shows moderate maturity with established testing protocols, though innovation continues. Key players include research institutions like University of Science & Technology Beijing and Ocean University of China, which focus on fundamental research, while commercial entities such as Exxonmobil Upstream Research, Halliburton Energy Services, and China National Petroleum Corp. are developing application-specific solutions. Chinese institutions dominate the research landscape, with Western companies like Schlumberger and Chevron focusing on energy applications, creating a competitive yet collaborative global ecosystem for advancing CMC testing methodologies.

China Institute of Electronic Product Reliability and Environmental Testing

Technical Solution: China Institute of Electronic Product Reliability and Environmental Testing has pioneered advanced environmental exposure methodologies for CMCs in extreme conditions. Their marine testing protocol incorporates cyclic immersion in synthetic seawater with precisely controlled salinity (3.5±0.1%) and pH levels (8.2±0.2), combined with tidal simulation systems that alternate wet/dry cycles at 6-hour intervals. Their desert condition testing chambers can maintain temperatures between 20-85°C with rapid cycling capabilities and controlled humidity levels down to 5% RH. The institute has developed specialized instrumentation for in-situ monitoring of CMC degradation, including electrochemical impedance spectroscopy systems that track corrosion progression in real-time. Their testing regimes incorporate standardized procedures aligned with ISO 9142 and ASTM C1368 but modified to account for the unique properties of modern CMC materials used in marine infrastructure and desert-deployed electronics housing.

Strengths: Comprehensive testing facilities with precise environmental control capabilities; strong integration of electrochemical analysis techniques for corrosion monitoring. Weaknesses: Testing methodologies may emphasize electronic component protection over structural applications; limited experience with high-temperature CMC variants used in advanced propulsion systems.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a multi-parameter environmental exposure testing system for CMCs that simultaneously evaluates mechanical, thermal, and chemical degradation mechanisms in marine and desert environments. Their approach employs custom-designed environmental chambers capable of reproducing complex exposure conditions including salt fog concentration gradients (15-35 g/L), UV radiation intensities up to 180 W/m², and sand particle impingement at controlled angles (15-90°). The university's research team has pioneered the use of in-situ acoustic emission monitoring during environmental exposure to detect microcracking and interfacial debonding in real-time. Their testing protocols incorporate cyclic loading during environmental exposure to simulate service conditions more accurately, with stress levels ranging from 30-70% of ultimate strength. The university has established correlations between accelerated laboratory testing and actual field performance through their network of exposure sites along China's coastline and northwestern desert regions, developing mathematical models that predict CMC service life based on accelerated test data.

Strengths: Strong integration of mechanical testing during environmental exposure; sophisticated modeling capabilities for lifetime prediction based on accelerated testing. Weaknesses: Research focus may be more academic than application-oriented; limited experience with qualification testing for specific industrial standards.

Key Technical Innovations in CMC Exposure Assessment

Method for electrophoretic coating of ceramic matrix composite component with environmental barrier

PatentPendingCN118339128A

Innovation

- Electrophoretic deposition is carried out using a rare earth silicate powder suspension containing selected from aluminum, yttrium and ytterbium nitrates, and a sintering agent is added after the sintering heat treatment to improve the density of the coating, and the conductivity is adjusted to reduce the electric field concentration effect and form a uniform Thickness of coating.

Composite material component with silicon-containing ceramic matrix, protected against corrosion

PatentActiveEP2002031A2

Innovation

- A composite environmental barrier is formed on the CMC substrate with a bonding sub-layer that gradates from pure silicon to mullite, providing enhanced adhesion and chemical barrier functions, reducing sensitivity to thermal shocks and chemical interactions, and an outer aluminosilicate layer for corrosion protection, with optional thermal protection layers.

Material Degradation Mechanisms in Extreme Conditions

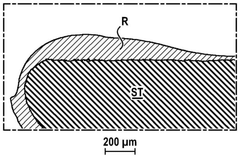

Ceramic Matrix Composites (CMCs) exposed to extreme environmental conditions undergo several complex degradation mechanisms that significantly impact their structural integrity and performance. In marine environments, the primary degradation pathway involves salt-induced corrosion, where sodium chloride and other sea salts penetrate the material matrix, leading to accelerated oxidation of the ceramic fibers and matrix interfaces. This process is particularly aggressive at elevated temperatures, creating a synergistic effect between thermal and chemical degradation.

Water vapor in marine atmospheres presents another critical challenge, as it can react with certain ceramic constituents to form hydroxides, weakening the material's mechanical properties. The cyclic nature of moisture exposure in coastal environments—with repeated wetting and drying—creates additional stress on the material structure, promoting microcrack formation and propagation through the composite.

In desert conditions, CMCs face a different set of degradation mechanisms dominated by thermal cycling and particulate erosion. The extreme temperature variations between day and night (often exceeding 50°C differential) induce thermal fatigue, creating mismatches in thermal expansion between the ceramic matrix and reinforcing fibers. This mismatch generates internal stresses that eventually lead to delamination and matrix cracking.

Sand and dust particles carried by desert winds cause progressive surface erosion through mechanical abrasion. These particles, often containing silica and other hard minerals, impact the CMC surface at high velocities, removing protective oxide layers and exposing fresh material to further oxidation. The combination of mechanical erosion and subsequent oxidation creates a self-accelerating degradation cycle.

Ultraviolet radiation, particularly intense in desert environments, catalyzes photo-oxidation reactions in any polymer components present in the composite system, such as interphase materials or surface coatings. This degradation alters the interfacial properties between fibers and matrix, compromising load transfer efficiency and overall mechanical performance.

Both environments share common degradation mechanisms related to oxidation, where oxygen penetrates through pores and microcracks to react with non-oxide ceramics (such as SiC or Si3N4), forming volatile species or expansive oxides that disrupt the material's microstructure. The rate and extent of oxidation are significantly influenced by temperature, moisture content, and the presence of catalytic contaminants specific to each environment.

Understanding these degradation mechanisms is essential for developing effective protective systems and predicting service life in these challenging environments. The complex interplay between chemical, thermal, and mechanical degradation processes necessitates comprehensive testing protocols that accurately simulate real-world exposure conditions.

Water vapor in marine atmospheres presents another critical challenge, as it can react with certain ceramic constituents to form hydroxides, weakening the material's mechanical properties. The cyclic nature of moisture exposure in coastal environments—with repeated wetting and drying—creates additional stress on the material structure, promoting microcrack formation and propagation through the composite.

In desert conditions, CMCs face a different set of degradation mechanisms dominated by thermal cycling and particulate erosion. The extreme temperature variations between day and night (often exceeding 50°C differential) induce thermal fatigue, creating mismatches in thermal expansion between the ceramic matrix and reinforcing fibers. This mismatch generates internal stresses that eventually lead to delamination and matrix cracking.

Sand and dust particles carried by desert winds cause progressive surface erosion through mechanical abrasion. These particles, often containing silica and other hard minerals, impact the CMC surface at high velocities, removing protective oxide layers and exposing fresh material to further oxidation. The combination of mechanical erosion and subsequent oxidation creates a self-accelerating degradation cycle.

Ultraviolet radiation, particularly intense in desert environments, catalyzes photo-oxidation reactions in any polymer components present in the composite system, such as interphase materials or surface coatings. This degradation alters the interfacial properties between fibers and matrix, compromising load transfer efficiency and overall mechanical performance.

Both environments share common degradation mechanisms related to oxidation, where oxygen penetrates through pores and microcracks to react with non-oxide ceramics (such as SiC or Si3N4), forming volatile species or expansive oxides that disrupt the material's microstructure. The rate and extent of oxidation are significantly influenced by temperature, moisture content, and the presence of catalytic contaminants specific to each environment.

Understanding these degradation mechanisms is essential for developing effective protective systems and predicting service life in these challenging environments. The complex interplay between chemical, thermal, and mechanical degradation processes necessitates comprehensive testing protocols that accurately simulate real-world exposure conditions.

Standardization and Certification Requirements for CMCs

The standardization and certification landscape for Ceramic Matrix Composites (CMCs) in extreme environmental conditions requires robust frameworks to ensure material performance and reliability. Currently, several international standards organizations have established protocols specifically addressing CMCs in marine and desert environments, including ASTM C1341 for cyclic fatigue testing and ISO 20504 for compressive properties at elevated temperatures.

For marine environment certification, standards must address salt spray resistance (ASTM B117), moisture absorption rates, and electrochemical corrosion resistance. These standards typically require 1000-5000 hour exposure tests with subsequent mechanical property evaluation to determine degradation patterns. The Naval Sea Systems Command (NAVSEA) has additional requirements for CMCs intended for maritime applications, mandating specific salt fog cycling protocols and biofouling resistance metrics.

Desert condition certification focuses on thermal cycling durability (ASTM C1368), sand erosion resistance (ASTM G76), and UV stability testing. These standards typically require materials to withstand temperature fluctuations between -10°C and 70°C while maintaining at least 85% of original mechanical properties. Additionally, sand particulate testing must demonstrate erosion rates below established thresholds at wind speeds up to 20 m/s.

Certification pathways for CMCs vary by application sector. Aerospace applications follow FAA and EASA guidelines requiring compliance with specific fire resistance standards (FAR 25.853) and lightning strike protection metrics. Industrial applications typically adhere to ISO 20507 for general technical specifications of ceramic composites, with additional requirements based on specific use cases.

The certification process generally involves three phases: preliminary qualification testing, accelerated environmental exposure, and long-term validation testing. This process typically spans 18-36 months depending on the application criticality. Third-party certification bodies including Underwriters Laboratories (UL), TÜV, and DNV GL provide independent verification of compliance.

Emerging standardization trends include the development of digital twin methodologies for predicting long-term environmental degradation, harmonization of international testing protocols, and the incorporation of sustainability metrics into certification requirements. The CMC industry is actively working through consortia such as the Composites Materials Handbook (CMH-17) to establish unified testing methodologies that address the unique challenges of environmental exposure in extreme conditions.

Cost considerations for certification are significant, with comprehensive testing programs ranging from $250,000 to over $1 million depending on application requirements and certification scope. These costs represent a substantial barrier to market entry for new CMC formulations and drive industry efforts toward more efficient testing methodologies and international standard harmonization.

For marine environment certification, standards must address salt spray resistance (ASTM B117), moisture absorption rates, and electrochemical corrosion resistance. These standards typically require 1000-5000 hour exposure tests with subsequent mechanical property evaluation to determine degradation patterns. The Naval Sea Systems Command (NAVSEA) has additional requirements for CMCs intended for maritime applications, mandating specific salt fog cycling protocols and biofouling resistance metrics.

Desert condition certification focuses on thermal cycling durability (ASTM C1368), sand erosion resistance (ASTM G76), and UV stability testing. These standards typically require materials to withstand temperature fluctuations between -10°C and 70°C while maintaining at least 85% of original mechanical properties. Additionally, sand particulate testing must demonstrate erosion rates below established thresholds at wind speeds up to 20 m/s.

Certification pathways for CMCs vary by application sector. Aerospace applications follow FAA and EASA guidelines requiring compliance with specific fire resistance standards (FAR 25.853) and lightning strike protection metrics. Industrial applications typically adhere to ISO 20507 for general technical specifications of ceramic composites, with additional requirements based on specific use cases.

The certification process generally involves three phases: preliminary qualification testing, accelerated environmental exposure, and long-term validation testing. This process typically spans 18-36 months depending on the application criticality. Third-party certification bodies including Underwriters Laboratories (UL), TÜV, and DNV GL provide independent verification of compliance.

Emerging standardization trends include the development of digital twin methodologies for predicting long-term environmental degradation, harmonization of international testing protocols, and the incorporation of sustainability metrics into certification requirements. The CMC industry is actively working through consortia such as the Composites Materials Handbook (CMH-17) to establish unified testing methodologies that address the unique challenges of environmental exposure in extreme conditions.

Cost considerations for certification are significant, with comprehensive testing programs ranging from $250,000 to over $1 million depending on application requirements and certification scope. These costs represent a substantial barrier to market entry for new CMC formulations and drive industry efforts toward more efficient testing methodologies and international standard harmonization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!