Porosity Control And Densification Strategies For CMC Fabrication

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Porosity Control Background and Objectives

Ceramic Matrix Composites (CMCs) have emerged as critical materials for high-temperature applications in aerospace, energy, and defense sectors due to their exceptional thermal resistance and mechanical properties. The evolution of CMC technology spans several decades, beginning with rudimentary ceramic-fiber reinforced structures in the 1970s and progressing to today's sophisticated multi-phase systems. This technological progression has been driven by the increasing demand for materials capable of withstanding extreme environments while maintaining structural integrity.

Porosity control represents one of the most significant challenges in CMC fabrication. Historically, early CMCs suffered from excessive porosity, which compromised their mechanical properties and reliability. The technological trajectory has thus focused on developing increasingly effective densification methods to reduce porosity while preserving the beneficial properties of the composite structure.

The primary objective of porosity control in CMC fabrication is to achieve an optimal balance between necessary porosity for crack deflection and toughening mechanisms, while minimizing detrimental voids that compromise structural integrity. This delicate balance directly impacts the material's performance characteristics including strength, toughness, thermal conductivity, and oxidation resistance.

Current technological trends in CMC porosity control are moving toward more precise, controllable processes that allow for tailored porosity distributions within the material. Advanced techniques such as pressure-assisted processes, reactive melt infiltration, and hybrid approaches represent the cutting edge of this field. These methods aim to achieve near-theoretical density in critical regions while maintaining engineered porosity where beneficial.

The evolution of computational modeling and simulation tools has significantly enhanced our understanding of porosity formation mechanisms during processing. These advancements enable more predictive approaches to porosity control, moving beyond empirical methods toward science-based manufacturing protocols.

Looking forward, the technological objectives for CMC porosity control include developing processes capable of creating gradient porosity structures, improving process repeatability and yield, reducing manufacturing costs, and enabling complex geometries with controlled internal architectures. Additionally, there is growing interest in understanding the long-term effects of service conditions on porosity evolution and its impact on component lifetime.

The ultimate goal remains the development of CMCs with precisely engineered porosity distributions that maximize performance while ensuring reliability in extreme operating environments. This objective drives current research efforts and shapes the technological roadmap for next-generation CMC materials and processing methods.

Porosity control represents one of the most significant challenges in CMC fabrication. Historically, early CMCs suffered from excessive porosity, which compromised their mechanical properties and reliability. The technological trajectory has thus focused on developing increasingly effective densification methods to reduce porosity while preserving the beneficial properties of the composite structure.

The primary objective of porosity control in CMC fabrication is to achieve an optimal balance between necessary porosity for crack deflection and toughening mechanisms, while minimizing detrimental voids that compromise structural integrity. This delicate balance directly impacts the material's performance characteristics including strength, toughness, thermal conductivity, and oxidation resistance.

Current technological trends in CMC porosity control are moving toward more precise, controllable processes that allow for tailored porosity distributions within the material. Advanced techniques such as pressure-assisted processes, reactive melt infiltration, and hybrid approaches represent the cutting edge of this field. These methods aim to achieve near-theoretical density in critical regions while maintaining engineered porosity where beneficial.

The evolution of computational modeling and simulation tools has significantly enhanced our understanding of porosity formation mechanisms during processing. These advancements enable more predictive approaches to porosity control, moving beyond empirical methods toward science-based manufacturing protocols.

Looking forward, the technological objectives for CMC porosity control include developing processes capable of creating gradient porosity structures, improving process repeatability and yield, reducing manufacturing costs, and enabling complex geometries with controlled internal architectures. Additionally, there is growing interest in understanding the long-term effects of service conditions on porosity evolution and its impact on component lifetime.

The ultimate goal remains the development of CMCs with precisely engineered porosity distributions that maximize performance while ensuring reliability in extreme operating environments. This objective drives current research efforts and shapes the technological roadmap for next-generation CMC materials and processing methods.

Market Analysis for High-Density CMC Applications

The global market for high-density Ceramic Matrix Composites (CMCs) has experienced significant growth in recent years, driven primarily by increasing demand in aerospace, defense, and energy sectors. The market value for CMCs reached approximately $4.5 billion in 2022, with high-density applications accounting for nearly 40% of this value. Industry analysts project a compound annual growth rate of 12.3% through 2030, potentially pushing the market beyond $11 billion.

Aerospace remains the dominant application sector, representing over 50% of the high-density CMC market. This dominance stems from the critical need for lightweight yet durable materials capable of withstanding extreme temperatures in aircraft engines and hypersonic vehicles. Major aerospace manufacturers have increased their CMC utilization by 35% since 2018, with GE Aviation's LEAP engine program serving as a prime example of successful commercial implementation.

The defense sector constitutes approximately 25% of the market, with applications in missile systems, radar components, and thermal protection systems. Government defense spending on advanced materials has shown consistent growth, with CMC-specific allocations increasing by 18% annually since 2020.

Energy applications, particularly in gas turbines and nuclear power systems, represent about 15% of the market. The push for more efficient energy generation has accelerated adoption of high-density CMCs in these applications, with implementation rates growing at 22% annually.

Regional analysis reveals North America leads with 42% market share, followed by Europe (28%) and Asia-Pacific (23%). China has demonstrated the most aggressive growth trajectory, increasing its CMC production capacity by 65% between 2019 and 2023.

Customer requirements across these sectors consistently emphasize three key performance metrics: temperature resistance (typically >1200°C), mechanical strength (particularly under cyclic loading), and service lifetime. High-density CMCs with porosity levels below 5% command premium pricing, often 30-40% higher than their standard-density counterparts.

Supply chain analysis indicates potential bottlenecks in raw material sourcing, particularly for high-purity silicon carbide and specialized ceramic fibers. These constraints have contributed to price volatility, with raw material costs fluctuating by up to 25% annually.

Market penetration remains challenged by production costs, which typically exceed traditional materials by 3-5 times. However, lifecycle cost analysis demonstrates that high-density CMCs can achieve cost parity or advantage when accounting for extended service life and reduced maintenance requirements, particularly in high-temperature applications where traditional materials require frequent replacement.

Aerospace remains the dominant application sector, representing over 50% of the high-density CMC market. This dominance stems from the critical need for lightweight yet durable materials capable of withstanding extreme temperatures in aircraft engines and hypersonic vehicles. Major aerospace manufacturers have increased their CMC utilization by 35% since 2018, with GE Aviation's LEAP engine program serving as a prime example of successful commercial implementation.

The defense sector constitutes approximately 25% of the market, with applications in missile systems, radar components, and thermal protection systems. Government defense spending on advanced materials has shown consistent growth, with CMC-specific allocations increasing by 18% annually since 2020.

Energy applications, particularly in gas turbines and nuclear power systems, represent about 15% of the market. The push for more efficient energy generation has accelerated adoption of high-density CMCs in these applications, with implementation rates growing at 22% annually.

Regional analysis reveals North America leads with 42% market share, followed by Europe (28%) and Asia-Pacific (23%). China has demonstrated the most aggressive growth trajectory, increasing its CMC production capacity by 65% between 2019 and 2023.

Customer requirements across these sectors consistently emphasize three key performance metrics: temperature resistance (typically >1200°C), mechanical strength (particularly under cyclic loading), and service lifetime. High-density CMCs with porosity levels below 5% command premium pricing, often 30-40% higher than their standard-density counterparts.

Supply chain analysis indicates potential bottlenecks in raw material sourcing, particularly for high-purity silicon carbide and specialized ceramic fibers. These constraints have contributed to price volatility, with raw material costs fluctuating by up to 25% annually.

Market penetration remains challenged by production costs, which typically exceed traditional materials by 3-5 times. However, lifecycle cost analysis demonstrates that high-density CMCs can achieve cost parity or advantage when accounting for extended service life and reduced maintenance requirements, particularly in high-temperature applications where traditional materials require frequent replacement.

Current Challenges in CMC Densification Technology

Despite significant advancements in Ceramic Matrix Composite (CMC) fabrication technologies, achieving optimal densification while controlling porosity remains one of the most challenging aspects in the manufacturing process. Current CMC densification technologies face several critical limitations that impede widespread industrial adoption and performance optimization.

The primary challenge lies in the inherent trade-off between porosity control and mechanical properties. While lower porosity generally yields higher strength and oxidation resistance, some level of controlled porosity is essential for toughness and crack deflection mechanisms. Achieving this delicate balance consistently across complex geometries presents significant technical difficulties, particularly for components with varying thickness or intricate internal features.

Manufacturing scale-up represents another substantial hurdle. Laboratory-scale densification processes often fail to translate effectively to industrial production environments. The Chemical Vapor Infiltration (CVI) process, while capable of producing high-quality CMCs, suffers from extremely long processing times (often weeks or months) and significant cost implications. This time-intensive nature creates production bottlenecks that limit commercial viability.

Melt Infiltration (MI) techniques offer faster processing but struggle with uniform infiltration throughout the preform, frequently resulting in residual porosity gradients or localized densification inconsistencies. These heterogeneities create weak points in the final component that can lead to premature failure under service conditions.

Energy consumption during densification processes presents both economic and environmental challenges. Current technologies, particularly those requiring multiple infiltration-pyrolysis cycles or extended high-temperature treatments, demand substantial energy inputs. This not only increases production costs but also contributes to the carbon footprint of CMC manufacturing.

Quality control and non-destructive evaluation (NDE) of densification present additional complications. Current inspection technologies struggle to accurately characterize internal porosity distribution in complex CMC components, making it difficult to validate densification quality without destructive testing.

Material compatibility issues further complicate densification strategies. The chemical interactions between matrix precursors and fiber reinforcements during high-temperature processing can lead to degradation of fiber properties or formation of undesirable interfacial reactions, compromising the overall composite performance.

Recent research has highlighted the challenge of achieving consistent densification in next-generation CMCs designed for ultra-high temperature applications (>1600°C). Traditional densification approaches often prove inadequate for these advanced material systems, necessitating novel processing methodologies and matrix precursors.

The primary challenge lies in the inherent trade-off between porosity control and mechanical properties. While lower porosity generally yields higher strength and oxidation resistance, some level of controlled porosity is essential for toughness and crack deflection mechanisms. Achieving this delicate balance consistently across complex geometries presents significant technical difficulties, particularly for components with varying thickness or intricate internal features.

Manufacturing scale-up represents another substantial hurdle. Laboratory-scale densification processes often fail to translate effectively to industrial production environments. The Chemical Vapor Infiltration (CVI) process, while capable of producing high-quality CMCs, suffers from extremely long processing times (often weeks or months) and significant cost implications. This time-intensive nature creates production bottlenecks that limit commercial viability.

Melt Infiltration (MI) techniques offer faster processing but struggle with uniform infiltration throughout the preform, frequently resulting in residual porosity gradients or localized densification inconsistencies. These heterogeneities create weak points in the final component that can lead to premature failure under service conditions.

Energy consumption during densification processes presents both economic and environmental challenges. Current technologies, particularly those requiring multiple infiltration-pyrolysis cycles or extended high-temperature treatments, demand substantial energy inputs. This not only increases production costs but also contributes to the carbon footprint of CMC manufacturing.

Quality control and non-destructive evaluation (NDE) of densification present additional complications. Current inspection technologies struggle to accurately characterize internal porosity distribution in complex CMC components, making it difficult to validate densification quality without destructive testing.

Material compatibility issues further complicate densification strategies. The chemical interactions between matrix precursors and fiber reinforcements during high-temperature processing can lead to degradation of fiber properties or formation of undesirable interfacial reactions, compromising the overall composite performance.

Recent research has highlighted the challenge of achieving consistent densification in next-generation CMCs designed for ultra-high temperature applications (>1600°C). Traditional densification approaches often prove inadequate for these advanced material systems, necessitating novel processing methodologies and matrix precursors.

State-of-the-Art Densification Methods for CMCs

01 Porosity control methods in CMCs

Various methods can be employed to control porosity in Ceramic Matrix Composites, including the use of specific precursors, processing techniques, and infiltration methods. These approaches allow for tailored porosity levels that can enhance specific properties of the composite. Controlled porosity can improve thermal shock resistance, reduce weight, and provide pathways for subsequent infiltration processes. The porosity can be engineered at different scales from micro to macro levels depending on the intended application.- Porosity control methods in CMCs: Various methods can be employed to control porosity in Ceramic Matrix Composites, including the use of specific precursors, processing techniques, and infiltration methods. These approaches allow for tailored porosity levels which directly impact the mechanical and thermal properties of the final composite. Controlled porosity can enhance certain performance characteristics while maintaining structural integrity, making it crucial for applications requiring specific property profiles.

- Porosity measurement and characterization techniques: Advanced techniques for measuring and characterizing porosity in Ceramic Matrix Composites include non-destructive testing methods, imaging analysis, and computational modeling. These techniques provide accurate assessment of pore size distribution, total porosity volume, and pore connectivity within the composite structure. Such characterization is essential for quality control and understanding the relationship between processing parameters and resultant porosity features.

- Porosity effects on mechanical properties: The presence and distribution of porosity significantly influences the mechanical properties of Ceramic Matrix Composites. While excessive porosity can reduce strength and stiffness, controlled porosity can enhance fracture toughness and damage tolerance by providing crack deflection paths. Understanding this relationship allows for designing CMCs with optimized mechanical performance for specific applications, particularly in high-temperature and high-stress environments.

- Porosity-tailored CMCs for thermal applications: Ceramic Matrix Composites with engineered porosity structures offer enhanced thermal insulation properties and controlled thermal conductivity. By manipulating pore size, distribution, and connectivity, thermal expansion behavior and thermal shock resistance can be optimized. These porosity-tailored CMCs are particularly valuable in high-temperature applications where thermal management is critical, such as in aerospace components and energy systems.

- Novel infiltration techniques for porosity reduction: Innovative infiltration techniques have been developed to reduce unwanted porosity in Ceramic Matrix Composites while maintaining desired microstructural features. These include chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration processes. Multiple infiltration cycles can progressively reduce porosity to achieve near-theoretical density in critical regions while preserving engineered porosity where beneficial for performance characteristics.

02 Porosity measurement and characterization techniques

Advanced techniques for measuring and characterizing porosity in Ceramic Matrix Composites include non-destructive testing methods, image analysis, mercury porosimetry, and computational modeling. These techniques allow for accurate determination of pore size distribution, total porosity volume, and pore connectivity. Characterization of porosity is essential for quality control and understanding the relationship between processing parameters and final composite properties. Modern approaches can provide three-dimensional visualization of pore networks within the composite structure.Expand Specific Solutions03 Porosity effects on mechanical properties

The presence and distribution of porosity significantly impact the mechanical properties of Ceramic Matrix Composites. While controlled porosity can enhance toughness and thermal shock resistance, excessive or uncontrolled porosity typically reduces strength and stiffness. The relationship between porosity and mechanical performance depends on pore size, shape, distribution, and interconnectivity. Optimizing porosity levels is crucial for achieving the desired balance of properties such as strength, toughness, and damage tolerance in high-temperature applications.Expand Specific Solutions04 Infiltration techniques to reduce porosity

Various infiltration techniques are employed to reduce or control porosity in Ceramic Matrix Composites, including chemical vapor infiltration (CVI), polymer infiltration and pyrolysis (PIP), and melt infiltration (MI). These processes involve filling the porous preform with matrix material to achieve desired density levels. Multiple infiltration cycles may be required to reach target porosity levels. The choice of infiltration method depends on factors such as the desired final properties, component geometry, and economic considerations.Expand Specific Solutions05 Functional porosity for specific applications

In certain applications, engineered porosity in Ceramic Matrix Composites provides functional benefits beyond structural considerations. Controlled porosity can enhance thermal insulation properties, improve acoustic damping, enable fluid transport, or facilitate integration of functional elements. For high-temperature applications, strategically designed porosity can accommodate thermal expansion, prevent catastrophic failure, and improve thermal shock resistance. Environmental barrier coatings may be applied to protect porous CMCs in harsh operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CMC Development

The ceramic matrix composite (CMC) fabrication market is currently in a growth phase, characterized by increasing demand for high-performance materials in aerospace and industrial applications. The global CMC market is expanding rapidly, with projections indicating significant growth driven by aerospace and defense sectors. Technologically, porosity control and densification remain critical challenges, with varying maturity levels across different approaches. Leading players like Safran Ceramics and GE have established advanced capabilities in chemical vapor infiltration and reactive melt infiltration processes, while research institutions such as Northwestern Polytechnical University and the Institute of Mechanics (CAS) are developing next-generation densification techniques. Companies including RTX, BAE Systems, and Toyota are actively pursuing proprietary densification strategies to overcome the porosity-performance trade-off that currently limits wider CMC adoption in critical applications.

Safran SA

Technical Solution: Safran has developed advanced Ceramic Matrix Composite (CMC) fabrication techniques focusing on porosity control through multi-stage infiltration processes. Their proprietary Chemical Vapor Infiltration (CVI) method allows precise control of pore size distribution and overall porosity levels in CMC components. The company employs a hybrid approach combining CVI with Polymer Infiltration and Pyrolysis (PIP), where initial infiltration creates a controlled porous structure that is subsequently densified through multiple PIP cycles. Safran's technology incorporates in-situ monitoring systems that analyze gas flow dynamics during infiltration to optimize processing parameters in real-time, achieving porosity levels below 10% in complex geometries. Their densification strategy includes pressure-assisted sintering techniques that apply controlled mechanical pressure during thermal processing to collapse micro-porosity while maintaining structural integrity of the ceramic fibers.

Strengths: Exceptional control over porosity distribution allowing tailored properties for specific aerospace applications; integrated quality control systems ensuring consistent production. Weaknesses: Process requires multiple time-consuming infiltration cycles; high energy consumption during extended high-temperature processing phases.

General Electric Company

Technical Solution: GE has pioneered a comprehensive porosity control system for CMC fabrication centered around their proprietary melt infiltration (MI) technology. Their approach begins with precisely engineered fiber preforms with controlled inter-tow spacing to create predetermined porosity channels. GE's process incorporates a multi-step densification strategy where initial matrix formation occurs through slurry infiltration with nano-scale ceramic particles suspended in carefully formulated carriers. This creates a controlled initial porosity structure that is subsequently infiltrated with molten silicon at temperatures exceeding 1400°C. The silicon reacts with carbon in the matrix to form silicon carbide, filling micro-pores and achieving near-theoretical density in critical regions. GE has developed specialized surface treatments that modify the wetting characteristics of the molten silicon, allowing it to penetrate deeper into the structure while preventing fiber damage. Their process achieves final porosity levels of 1-3% in production components, with the ability to create engineered porosity gradients for thermal management.

Strengths: Achieves exceptionally high densification levels (>97%) in production components; relatively faster processing cycle compared to traditional CVI methods; excellent mechanical properties retention. Weaknesses: Residual free silicon can limit maximum use temperature; process requires precise temperature control to prevent fiber degradation during infiltration.

Critical Patents and Research on Porosity Control

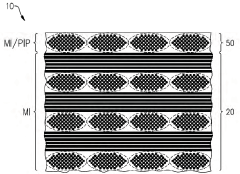

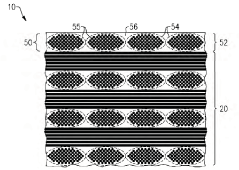

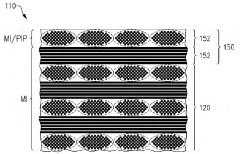

Ceramic matrix composite articles and methods for forming same

PatentInactiveIN201644006330A

Innovation

- A ceramic matrix composite article and method involving a substrate with a first free silicon proportion formed by melt infiltration, accompanied by a surface layer with a second, lower free silicon proportion achieved through melt infiltration or polymer impregnation and pyrolysis, enhancing creep resistance and temperature capability.

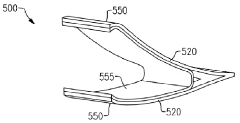

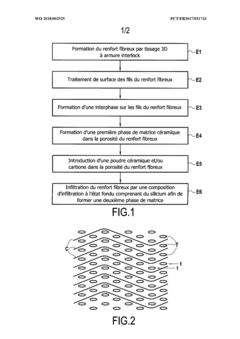

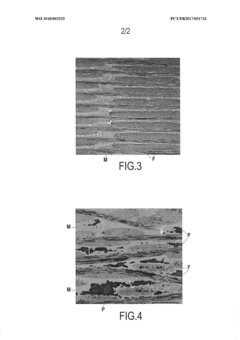

Process for manufacturing a ceramic matrix composite part

PatentWO2018002525A1

Innovation

- A method involving three-dimensional weaving of ceramic yarns with an interlock weave, followed by the formation of a first ceramic matrix phase, introduction of ceramic or carbon particles, and infiltration with a molten silicon composition to form a second matrix phase, enhancing penetration and reducing porosity.

Environmental Impact of CMC Manufacturing Processes

The manufacturing processes of Ceramic Matrix Composites (CMCs) present significant environmental considerations that must be addressed as these materials gain wider industrial adoption. Traditional CMC fabrication methods, particularly those focused on porosity control and densification, often involve energy-intensive processes operating at extremely high temperatures (1000-1800°C) for extended periods. This substantial energy consumption contributes significantly to carbon emissions, especially when powered by non-renewable energy sources.

Chemical vapor infiltration (CVI), a common densification technique, utilizes precursor gases that may include toxic compounds such as methyltrichlorosilane and various chlorinated hydrocarbons. These substances pose potential environmental hazards through atmospheric emissions and require sophisticated abatement systems to prevent air pollution. Similarly, polymer infiltration and pyrolysis (PIP) processes employ organic resins containing solvents that can release volatile organic compounds (VOCs) during curing and pyrolysis stages.

Water consumption represents another environmental concern, particularly in slurry-based processes where substantial volumes are required for material preparation and equipment cleaning. The resulting wastewater often contains ceramic particles, binders, and processing aids that necessitate treatment before discharge to prevent water pollution and ecosystem damage.

Raw material extraction for CMC production also carries environmental implications. Mining operations for silicon carbide, alumina, and rare earth elements used in CMCs can lead to habitat disruption, soil erosion, and potential groundwater contamination. The sustainability of these resource extraction practices becomes increasingly important as CMC production scales up to meet growing demand.

Recent advancements in green manufacturing technologies offer promising pathways to mitigate these environmental impacts. Microwave-assisted sintering and spark plasma sintering significantly reduce energy consumption and processing times compared to conventional methods. Additionally, water-based processing systems are replacing solvent-based approaches, while closed-loop manufacturing systems are being developed to recycle process water and recover valuable materials from waste streams.

Life cycle assessment (LCA) studies indicate that despite these environmental challenges during manufacturing, CMCs can provide net environmental benefits through their application. Their lightweight properties contribute to fuel efficiency in transportation applications, while their exceptional durability extends product lifespans, reducing the environmental burden of replacement and maintenance activities.

Chemical vapor infiltration (CVI), a common densification technique, utilizes precursor gases that may include toxic compounds such as methyltrichlorosilane and various chlorinated hydrocarbons. These substances pose potential environmental hazards through atmospheric emissions and require sophisticated abatement systems to prevent air pollution. Similarly, polymer infiltration and pyrolysis (PIP) processes employ organic resins containing solvents that can release volatile organic compounds (VOCs) during curing and pyrolysis stages.

Water consumption represents another environmental concern, particularly in slurry-based processes where substantial volumes are required for material preparation and equipment cleaning. The resulting wastewater often contains ceramic particles, binders, and processing aids that necessitate treatment before discharge to prevent water pollution and ecosystem damage.

Raw material extraction for CMC production also carries environmental implications. Mining operations for silicon carbide, alumina, and rare earth elements used in CMCs can lead to habitat disruption, soil erosion, and potential groundwater contamination. The sustainability of these resource extraction practices becomes increasingly important as CMC production scales up to meet growing demand.

Recent advancements in green manufacturing technologies offer promising pathways to mitigate these environmental impacts. Microwave-assisted sintering and spark plasma sintering significantly reduce energy consumption and processing times compared to conventional methods. Additionally, water-based processing systems are replacing solvent-based approaches, while closed-loop manufacturing systems are being developed to recycle process water and recover valuable materials from waste streams.

Life cycle assessment (LCA) studies indicate that despite these environmental challenges during manufacturing, CMCs can provide net environmental benefits through their application. Their lightweight properties contribute to fuel efficiency in transportation applications, while their exceptional durability extends product lifespans, reducing the environmental burden of replacement and maintenance activities.

Cost-Benefit Analysis of Advanced Densification Strategies

The implementation of advanced densification strategies for Ceramic Matrix Composites (CMCs) requires careful evaluation of economic factors alongside technical performance. Current industry analysis indicates that while Chemical Vapor Infiltration (CVI) offers excellent microstructural control, its operational costs exceed $1,000 per kilogram of finished component, primarily due to extended processing times (often 4-6 weeks) and specialized equipment requirements.

Polymer Infiltration and Pyrolysis (PIP) presents a more economical alternative at approximately $600-800 per kilogram, with significantly reduced processing times of 1-2 weeks. However, this cost advantage must be weighed against the typically higher residual porosity (5-15%) compared to CVI methods (1-5%), which may compromise mechanical properties in high-stress applications.

Melt Infiltration (MI) demonstrates the most favorable cost structure at $400-600 per kilogram with processing times under one week, representing a 50-60% cost reduction compared to traditional CVI approaches. This economic advantage has driven increased industrial adoption, particularly in aerospace propulsion components where production volume is increasing.

Recent innovations in hybrid densification approaches combining initial PIP cycles with final CVI treatment have shown promising cost-optimization results. Data from industrial implementation indicates a 30-35% cost reduction compared to pure CVI while maintaining comparable mechanical properties. These hybrid methods effectively balance the economic advantages of faster processes with the quality requirements of high-performance applications.

Energy consumption analysis reveals significant differences between densification methods, with CVI requiring 150-200 kWh per kilogram of finished component, compared to 80-120 kWh for PIP and 60-90 kWh for MI processes. As energy costs continue to rise globally, this factor increasingly influences total production economics.

Scaling considerations further impact cost structures, with MI showing the most favorable economies of scale. Production volume increases from prototype to full-scale manufacturing can reduce per-unit costs by up to 40% for MI systems, compared to only 15-20% for CVI processes. This scalability advantage makes MI particularly attractive for emerging high-volume applications in automotive and energy sectors.

Investment recovery timelines also differ significantly, with MI and hybrid approaches typically achieving return on capital investment within 3-4 years, while pure CVI systems often require 6-8 years to reach profitability thresholds. This financial metric has become increasingly important as manufacturers face pressure to demonstrate shorter paths to commercial viability.

Polymer Infiltration and Pyrolysis (PIP) presents a more economical alternative at approximately $600-800 per kilogram, with significantly reduced processing times of 1-2 weeks. However, this cost advantage must be weighed against the typically higher residual porosity (5-15%) compared to CVI methods (1-5%), which may compromise mechanical properties in high-stress applications.

Melt Infiltration (MI) demonstrates the most favorable cost structure at $400-600 per kilogram with processing times under one week, representing a 50-60% cost reduction compared to traditional CVI approaches. This economic advantage has driven increased industrial adoption, particularly in aerospace propulsion components where production volume is increasing.

Recent innovations in hybrid densification approaches combining initial PIP cycles with final CVI treatment have shown promising cost-optimization results. Data from industrial implementation indicates a 30-35% cost reduction compared to pure CVI while maintaining comparable mechanical properties. These hybrid methods effectively balance the economic advantages of faster processes with the quality requirements of high-performance applications.

Energy consumption analysis reveals significant differences between densification methods, with CVI requiring 150-200 kWh per kilogram of finished component, compared to 80-120 kWh for PIP and 60-90 kWh for MI processes. As energy costs continue to rise globally, this factor increasingly influences total production economics.

Scaling considerations further impact cost structures, with MI showing the most favorable economies of scale. Production volume increases from prototype to full-scale manufacturing can reduce per-unit costs by up to 40% for MI systems, compared to only 15-20% for CVI processes. This scalability advantage makes MI particularly attractive for emerging high-volume applications in automotive and energy sectors.

Investment recovery timelines also differ significantly, with MI and hybrid approaches typically achieving return on capital investment within 3-4 years, while pure CVI systems often require 6-8 years to reach profitability thresholds. This financial metric has become increasingly important as manufacturers face pressure to demonstrate shorter paths to commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!