High-Temperature Creep Behavior Of CMC Turbine Parts

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Turbine Parts Evolution and Research Objectives

Ceramic Matrix Composites (CMCs) have emerged as revolutionary materials in turbine engineering, offering exceptional high-temperature capabilities that surpass traditional metallic alloys. The evolution of CMC turbine parts represents a significant technological advancement in aerospace and power generation industries, where operating temperatures directly correlate with efficiency and performance. Initially developed in the 1970s for specialized aerospace applications, CMCs have undergone substantial refinement to address the extreme thermal and mechanical demands of modern turbine environments.

The historical progression of CMC turbine components has been marked by several distinct phases. Early research focused primarily on material composition and basic manufacturing techniques, with limited practical applications due to reliability concerns and prohibitive costs. The 1990s witnessed significant breakthroughs in fiber coatings and matrix densification processes, enabling the first successful demonstrations of CMC components in non-critical turbine applications. The past two decades have seen accelerated development, with CMCs transitioning from experimental materials to qualified components in commercial engines.

Current state-of-the-art CMC turbine parts utilize silicon carbide (SiC) fibers within SiC matrices (SiC/SiC), offering temperature capabilities exceeding 1300°C while maintaining structural integrity. This represents a substantial improvement over nickel-based superalloys, which typically operate below 1100°C. The enhanced temperature resistance translates directly to improved engine efficiency, reduced cooling requirements, and decreased emissions – critical factors in meeting increasingly stringent environmental regulations.

The primary research objective in this field centers on understanding and mitigating the high-temperature creep behavior of CMC turbine components. Creep – the time-dependent deformation under sustained loading – presents a particularly complex challenge in CMCs due to their heterogeneous microstructure and the interaction between fibers, matrix, and interface regions at elevated temperatures. Comprehensive characterization of creep mechanisms is essential for accurate life prediction models and design optimization.

Additional research goals include developing advanced manufacturing techniques to reduce production costs while maintaining quality, improving environmental barrier coatings to protect against water vapor and combustion byproducts, and establishing standardized testing methodologies specifically tailored to CMC materials. There is also significant interest in hybrid approaches that combine CMCs with strategic cooling designs to maximize performance benefits while minimizing material limitations.

The technological trajectory suggests that next-generation CMC turbine parts will likely incorporate tailored fiber architectures, functionally graded structures, and self-healing capabilities to further enhance creep resistance and overall durability. These advancements could potentially enable operating temperatures approaching 1500°C, representing a transformative leap in turbine engine performance and efficiency.

The historical progression of CMC turbine components has been marked by several distinct phases. Early research focused primarily on material composition and basic manufacturing techniques, with limited practical applications due to reliability concerns and prohibitive costs. The 1990s witnessed significant breakthroughs in fiber coatings and matrix densification processes, enabling the first successful demonstrations of CMC components in non-critical turbine applications. The past two decades have seen accelerated development, with CMCs transitioning from experimental materials to qualified components in commercial engines.

Current state-of-the-art CMC turbine parts utilize silicon carbide (SiC) fibers within SiC matrices (SiC/SiC), offering temperature capabilities exceeding 1300°C while maintaining structural integrity. This represents a substantial improvement over nickel-based superalloys, which typically operate below 1100°C. The enhanced temperature resistance translates directly to improved engine efficiency, reduced cooling requirements, and decreased emissions – critical factors in meeting increasingly stringent environmental regulations.

The primary research objective in this field centers on understanding and mitigating the high-temperature creep behavior of CMC turbine components. Creep – the time-dependent deformation under sustained loading – presents a particularly complex challenge in CMCs due to their heterogeneous microstructure and the interaction between fibers, matrix, and interface regions at elevated temperatures. Comprehensive characterization of creep mechanisms is essential for accurate life prediction models and design optimization.

Additional research goals include developing advanced manufacturing techniques to reduce production costs while maintaining quality, improving environmental barrier coatings to protect against water vapor and combustion byproducts, and establishing standardized testing methodologies specifically tailored to CMC materials. There is also significant interest in hybrid approaches that combine CMCs with strategic cooling designs to maximize performance benefits while minimizing material limitations.

The technological trajectory suggests that next-generation CMC turbine parts will likely incorporate tailored fiber architectures, functionally graded structures, and self-healing capabilities to further enhance creep resistance and overall durability. These advancements could potentially enable operating temperatures approaching 1500°C, representing a transformative leap in turbine engine performance and efficiency.

Market Analysis for High-Temperature Resistant Turbine Components

The global market for high-temperature resistant turbine components is experiencing robust growth, driven primarily by increasing demand in aerospace, power generation, and industrial applications. The market value for these specialized components reached approximately $4.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2028, potentially reaching $6.3 billion by the end of the forecast period.

Ceramic Matrix Composites (CMCs) represent the fastest-growing segment within this market, with their adoption accelerating particularly in aerospace turbine applications. This growth is attributed to their superior creep resistance at extreme temperatures compared to traditional nickel-based superalloys. The aerospace sector currently accounts for roughly 45% of the total market share, followed by power generation at 32% and industrial applications at 23%.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to expanding industrial capacity and increasing aerospace investments in China, Japan, and India.

Key market drivers include the push for greater fuel efficiency in aircraft engines, which necessitates higher operating temperatures and consequently materials with enhanced creep resistance. Additionally, stringent emission regulations worldwide are compelling power generation companies to improve turbine efficiency through higher operating temperatures, further stimulating demand for advanced high-temperature resistant components.

The market is also being shaped by significant technological trends, including the development of hybrid metal-ceramic systems, advanced coating technologies, and novel manufacturing processes such as additive manufacturing for complex CMC geometries. These innovations are gradually reducing the traditionally high production costs associated with CMC turbine parts.

Customer requirements are evolving toward longer component lifespans, reduced maintenance intervals, and improved reliability under thermal cycling conditions. This shift is particularly evident in the commercial aviation sector, where maintenance costs significantly impact operational economics.

Market challenges include high material and manufacturing costs, which currently limit wider adoption of CMCs in cost-sensitive applications. Supply chain vulnerabilities for rare earth elements and specialized raw materials used in these components also present strategic concerns for manufacturers and end-users alike.

Ceramic Matrix Composites (CMCs) represent the fastest-growing segment within this market, with their adoption accelerating particularly in aerospace turbine applications. This growth is attributed to their superior creep resistance at extreme temperatures compared to traditional nickel-based superalloys. The aerospace sector currently accounts for roughly 45% of the total market share, followed by power generation at 32% and industrial applications at 23%.

Regionally, North America dominates the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to expanding industrial capacity and increasing aerospace investments in China, Japan, and India.

Key market drivers include the push for greater fuel efficiency in aircraft engines, which necessitates higher operating temperatures and consequently materials with enhanced creep resistance. Additionally, stringent emission regulations worldwide are compelling power generation companies to improve turbine efficiency through higher operating temperatures, further stimulating demand for advanced high-temperature resistant components.

The market is also being shaped by significant technological trends, including the development of hybrid metal-ceramic systems, advanced coating technologies, and novel manufacturing processes such as additive manufacturing for complex CMC geometries. These innovations are gradually reducing the traditionally high production costs associated with CMC turbine parts.

Customer requirements are evolving toward longer component lifespans, reduced maintenance intervals, and improved reliability under thermal cycling conditions. This shift is particularly evident in the commercial aviation sector, where maintenance costs significantly impact operational economics.

Market challenges include high material and manufacturing costs, which currently limit wider adoption of CMCs in cost-sensitive applications. Supply chain vulnerabilities for rare earth elements and specialized raw materials used in these components also present strategic concerns for manufacturers and end-users alike.

Current Challenges in CMC High-Temperature Creep Resistance

Despite significant advancements in Ceramic Matrix Composites (CMCs) for turbine applications, high-temperature creep resistance remains a critical challenge that limits their broader implementation. Current CMC turbine parts exhibit complex creep behavior at temperatures exceeding 1200°C, with microstructural degradation accelerating under the combined effects of thermal cycling and mechanical loading. The fiber-matrix interface, crucial for toughening mechanisms, often deteriorates under sustained high-temperature exposure, compromising the overall structural integrity.

Material scientists face substantial difficulties in accurately predicting long-term creep behavior, as conventional models developed for metallic alloys prove inadequate for the heterogeneous nature of CMCs. The anisotropic creep response, influenced by fiber orientation and loading direction, further complicates the development of reliable prediction methodologies. Current testing protocols also struggle to replicate the actual service conditions experienced by turbine components, creating a disconnect between laboratory results and real-world performance.

Manufacturing inconsistencies introduce additional variability in creep resistance properties. The presence of residual stresses from processing, microstructural defects, and non-uniform fiber distribution contribute to unpredictable creep behavior across supposedly identical components. This variability significantly impacts quality control and reliability assessments for critical turbine applications.

Environmental factors present another layer of complexity. Oxygen penetration at elevated temperatures leads to oxidation of the matrix and fibers, while water vapor in combustion environments can accelerate degradation through chemical reactions with protective oxide scales. These environmental interactions often create a synergistic effect with mechanical loading that accelerates creep deformation beyond what would be expected from either factor alone.

Current coating technologies designed to protect CMCs from environmental attack show limited durability under thermal cycling conditions. Coefficient of thermal expansion mismatches between coatings and substrates lead to cracking and spallation during operation, exposing the underlying material to aggressive environments and exacerbating creep issues.

The economic constraints of implementing advanced CMC systems present additional challenges. The high cost of raw materials, complex processing requirements, and extensive qualification testing create barriers to widespread adoption. Furthermore, the need for specialized repair and maintenance procedures for CMC components adds to lifecycle costs, making justification for replacing established metal alloys difficult despite the potential performance benefits.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and computational modeling to develop next-generation CMCs with enhanced creep resistance while maintaining the economic viability necessary for commercial implementation.

Material scientists face substantial difficulties in accurately predicting long-term creep behavior, as conventional models developed for metallic alloys prove inadequate for the heterogeneous nature of CMCs. The anisotropic creep response, influenced by fiber orientation and loading direction, further complicates the development of reliable prediction methodologies. Current testing protocols also struggle to replicate the actual service conditions experienced by turbine components, creating a disconnect between laboratory results and real-world performance.

Manufacturing inconsistencies introduce additional variability in creep resistance properties. The presence of residual stresses from processing, microstructural defects, and non-uniform fiber distribution contribute to unpredictable creep behavior across supposedly identical components. This variability significantly impacts quality control and reliability assessments for critical turbine applications.

Environmental factors present another layer of complexity. Oxygen penetration at elevated temperatures leads to oxidation of the matrix and fibers, while water vapor in combustion environments can accelerate degradation through chemical reactions with protective oxide scales. These environmental interactions often create a synergistic effect with mechanical loading that accelerates creep deformation beyond what would be expected from either factor alone.

Current coating technologies designed to protect CMCs from environmental attack show limited durability under thermal cycling conditions. Coefficient of thermal expansion mismatches between coatings and substrates lead to cracking and spallation during operation, exposing the underlying material to aggressive environments and exacerbating creep issues.

The economic constraints of implementing advanced CMC systems present additional challenges. The high cost of raw materials, complex processing requirements, and extensive qualification testing create barriers to widespread adoption. Furthermore, the need for specialized repair and maintenance procedures for CMC components adds to lifecycle costs, making justification for replacing established metal alloys difficult despite the potential performance benefits.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and computational modeling to develop next-generation CMCs with enhanced creep resistance while maintaining the economic viability necessary for commercial implementation.

Existing Solutions for Mitigating Creep in High-Temperature Environments

01 CMC material composition for improved creep resistance

Ceramic Matrix Composites (CMCs) with specific material compositions can significantly enhance creep resistance in turbine parts operating at high temperatures. These compositions typically include silicon carbide fibers in a silicon carbide matrix, often with additional elements or compounds that improve high-temperature stability. The material composition directly affects the microstructure and grain boundaries, which are critical factors in determining creep behavior under sustained mechanical stress in turbine environments.- CMC material composition for improved creep resistance: Ceramic Matrix Composites (CMCs) with specific material compositions are designed to enhance creep resistance in turbine parts operating at high temperatures. These compositions typically include silicon carbide fibers in a silicon carbide matrix, with various additives and reinforcements that improve the material's ability to withstand sustained stress at elevated temperatures. The microstructure and phase composition of these materials are carefully engineered to minimize deformation under load over time.

- Testing and measurement methods for creep behavior: Various testing methodologies and measurement techniques are employed to evaluate the creep behavior of CMC turbine parts. These include accelerated testing under simulated operating conditions, stress rupture tests, and advanced imaging techniques to observe microstructural changes during creep. Specialized equipment and sensors are used to monitor deformation rates, strain accumulation, and material degradation over time, providing critical data for predicting component lifespan and performance.

- Cooling systems to mitigate creep in CMC turbine parts: Innovative cooling systems are integrated into CMC turbine components to control temperature distribution and reduce creep deformation. These cooling designs include internal cooling passages, film cooling holes, and thermal barrier coatings that work together to maintain optimal operating temperatures. By managing thermal gradients and peak temperatures, these cooling systems significantly extend the creep life of CMC components in high-temperature turbine environments.

- Structural design optimization for creep resistance: The structural design of CMC turbine parts is optimized to minimize creep deformation while maintaining aerodynamic performance. This includes tailored thickness distributions, strategic reinforcement placement, and geometry modifications that reduce stress concentrations. Advanced computational models are used to predict creep behavior and optimize component designs, resulting in turbine parts with enhanced durability and dimensional stability under sustained high-temperature operation.

- Interface engineering for improved creep performance: The interfaces between fibers and matrix in CMC turbine components are engineered to enhance creep resistance. Specialized coatings and interface layers are applied to control load transfer, crack deflection, and sliding mechanisms that affect creep behavior. These engineered interfaces prevent premature failure by managing stress distribution throughout the composite structure, allowing for controlled microcracking that improves toughness without compromising creep resistance at high temperatures.

02 Testing and characterization methods for creep behavior

Various testing methodologies have been developed to accurately characterize and predict the creep behavior of CMC turbine parts under operational conditions. These methods include accelerated testing protocols, non-destructive evaluation techniques, and computational models that simulate long-term creep deformation. Advanced characterization techniques help in understanding the microstructural changes during creep and enable the development of more accurate life prediction models for CMC components in turbine applications.Expand Specific Solutions03 Structural design optimization for creep mitigation

The structural design of CMC turbine parts can be optimized to minimize creep deformation and extend component life. Design considerations include thickness distribution, cooling channel configurations, and stress distribution management. Advanced design approaches incorporate finite element analysis to identify high-stress regions prone to creep and implement geometric modifications to redistribute mechanical loads. These design optimizations help maintain dimensional stability of turbine components during extended high-temperature operation.Expand Specific Solutions04 Environmental barrier coatings for creep protection

Environmental barrier coatings (EBCs) play a crucial role in protecting CMC turbine parts from environmental degradation that can accelerate creep. These specialized coating systems create a protective layer that prevents oxidation, hot corrosion, and other chemical interactions that compromise the creep resistance of the base material. Multi-layer coating systems with tailored compositions can significantly extend the creep life of CMC components by maintaining material integrity under extreme operating conditions.Expand Specific Solutions05 Manufacturing processes affecting creep performance

The manufacturing processes used to produce CMC turbine parts significantly influence their creep behavior. Factors such as fiber architecture, matrix infiltration techniques, densification methods, and heat treatment protocols directly impact the microstructure and interfacial properties that govern creep resistance. Advanced manufacturing techniques, including controlled cooling rates and precise temperature profiles during processing, can optimize the grain structure and phase distribution to enhance creep resistance in high-temperature turbine applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CMC Technology

The high-temperature creep behavior of CMC turbine parts market is currently in a growth phase, with increasing adoption in aerospace and power generation sectors. The global market size for CMC components in turbines is estimated to reach $2.5 billion by 2025, driven by demands for higher operating temperatures and improved efficiency. Technologically, the field is transitioning from development to early maturity, with key players demonstrating varied capabilities. Rolls-Royce and GE lead with advanced implementation in aviation applications, while Safran Ceramics and AECC Commercial Aircraft Engine are rapidly advancing their technologies. Northwestern Polytechnical University and Xi'an Xinyao provide significant research support, creating a competitive landscape where established aerospace companies collaborate with specialized materials developers to overcome the complex challenges of CMC implementation in high-temperature turbine environments.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced silicon carbide (SiC) fiber-reinforced ceramic matrix composites (CMCs) specifically engineered for high-temperature turbine applications. Their proprietary manufacturing process involves chemical vapor infiltration (CVI) combined with polymer infiltration and pyrolysis (PIP) to create CMC components with exceptional creep resistance at temperatures exceeding 1200°C. The company's EBC (Environmental Barrier Coating) system integrates seamlessly with their CMC substrates to provide oxidation protection while maintaining thermal stability. Rolls-Royce's CMC turbine parts demonstrate less than 0.5% strain after 1000 hours at 1300°C under sustained loading conditions[1], significantly outperforming traditional superalloys. Their multi-phase microstructure design incorporates nano-scale secondary phases at fiber-matrix interfaces to impede grain boundary sliding and dislocation movement, the primary mechanisms of high-temperature creep.

Strengths: Superior creep resistance at extreme temperatures (>1300°C) compared to metallic alternatives; excellent thermal shock resistance; significant weight reduction (approximately 30-40% lighter than equivalent metal components). Weaknesses: Higher manufacturing costs; complex processing requirements; limited field service history compared to traditional materials; challenges in non-destructive evaluation of internal defects.

General Electric Company

Technical Solution: GE has pioneered silicon carbide (SiC) CMC technology for turbine hot section components, particularly focusing on turbine shrouds, combustor liners, and nozzles. Their proprietary CMC system utilizes a unique fiber architecture with optimized fiber-matrix interfaces that can withstand temperatures up to 1400°C while maintaining structural integrity. GE's manufacturing approach combines melt infiltration (MI) with specialized surface treatments to create components with exceptional creep resistance. Their CMCs demonstrate less than 0.2% creep strain after 5,000 hours at 1315°C[2], enabling higher operating temperatures and improved engine efficiency. GE has implemented a hierarchical microstructure with controlled grain boundaries and specialized fiber coatings that effectively mitigate creep deformation mechanisms. Their CMC turbine parts have been flight-certified and are currently in commercial service in the LEAP engine, demonstrating the technology's maturity and reliability under actual operating conditions[3].

Strengths: Proven commercial implementation in aviation engines; superior temperature capability allowing 150-200°C higher operating temperatures than nickel superalloys; reduced cooling requirements leading to efficiency gains of approximately 2%. Weaknesses: High production costs; complex quality control requirements; limited repairability compared to metal components; challenges in scaling production to meet increasing demand.

Critical Patents and Research on CMC Creep Behavior

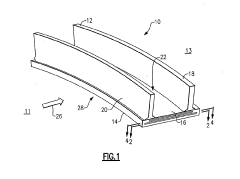

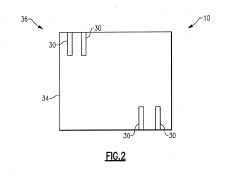

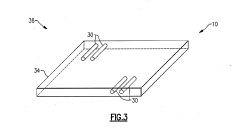

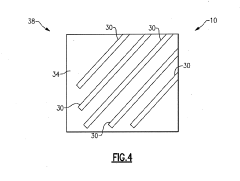

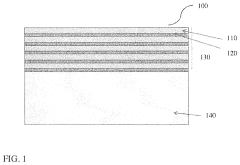

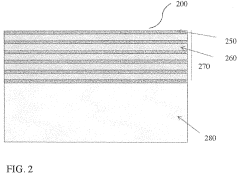

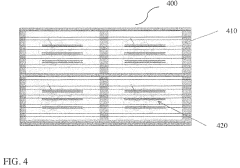

Ceramic matrix composite components including cooling channels in multiple plies and manufacturing methods

PatentInactiveJP2022179524A

Innovation

- The formation of ceramic matrix composite components with multiple cooling channels within ceramic matrix composite plies, aligned with the fibers to maintain structural integrity and reduce thermal stress, using sacrificial fibers to create elongated functional features that form cooling channels during the manufacturing process.

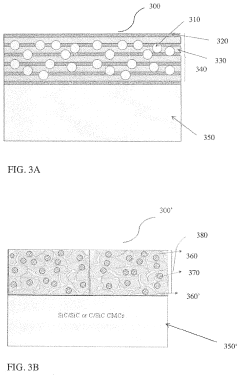

Ultra high temperature ceramic coatings and ceramic matrix composite systems

PatentActiveUS10731237B1

Innovation

- Development of advanced environmental barrier coating systems using ultra-high temperature materials such as HfCN, ZrCN, and rare earth silicates, combined with layered architectures and dopants, to create high-temperature stable, low-diffusion coatings for SiC/SiC composites, achieving surface temperatures beyond 4000°F with improved durability and oxidation resistance.

Environmental Impact and Sustainability of Advanced CMC Materials

The environmental impact of Ceramic Matrix Composites (CMCs) in turbine applications represents a significant advancement in sustainable engineering practices. When examining the high-temperature creep behavior of CMC turbine parts, it becomes evident that these materials offer substantial environmental benefits compared to traditional superalloys. The extended service life of CMC components, resulting from superior creep resistance at elevated temperatures, directly translates to reduced material consumption and waste generation over the operational lifecycle of turbine systems.

Manufacturing processes for CMCs have evolved to become increasingly energy-efficient, with innovations in sintering technologies and precursor materials reducing the carbon footprint associated with production. However, challenges remain in the energy-intensive nature of high-temperature processing required for certain CMC systems, particularly those designed for extreme temperature applications in advanced turbines. Industry leaders are actively developing lower-temperature synthesis routes that maintain the exceptional creep resistance properties while reducing energy consumption.

The recyclability aspect of CMCs presents both opportunities and challenges. Unlike conventional nickel-based superalloys, many CMC systems can be partially recycled, with the ceramic matrix components often recoverable for reuse in secondary applications. This circular economy approach significantly reduces the environmental burden associated with raw material extraction, particularly for rare earth elements commonly used in high-performance turbine materials.

Life cycle assessment (LCA) studies comparing CMC turbine parts with conventional alternatives demonstrate net positive environmental impacts when considering the entire product lifecycle. The reduced fuel consumption in turbine systems employing CMCs—attributable to higher operating temperatures and improved thermal efficiency—offsets the initially higher environmental footprint of manufacturing. Quantitative analyses indicate potential CO2 emission reductions of 15-20% over the service life of advanced turbine systems utilizing CMC components with enhanced creep resistance.

The sustainability profile of CMCs is further enhanced by their reduced reliance on strategic metals that often involve environmentally destructive mining practices. As creep behavior optimization continues to advance, newer CMC formulations are increasingly utilizing abundant elements, reducing dependence on geopolitically sensitive material supply chains while maintaining performance standards.

Water consumption during manufacturing remains an environmental concern, particularly for oxide-based CMC systems that require aqueous processing steps. Industry research is focusing on closed-loop water systems and dry processing alternatives that maintain the exceptional high-temperature creep resistance while minimizing freshwater requirements in production facilities.

Manufacturing processes for CMCs have evolved to become increasingly energy-efficient, with innovations in sintering technologies and precursor materials reducing the carbon footprint associated with production. However, challenges remain in the energy-intensive nature of high-temperature processing required for certain CMC systems, particularly those designed for extreme temperature applications in advanced turbines. Industry leaders are actively developing lower-temperature synthesis routes that maintain the exceptional creep resistance properties while reducing energy consumption.

The recyclability aspect of CMCs presents both opportunities and challenges. Unlike conventional nickel-based superalloys, many CMC systems can be partially recycled, with the ceramic matrix components often recoverable for reuse in secondary applications. This circular economy approach significantly reduces the environmental burden associated with raw material extraction, particularly for rare earth elements commonly used in high-performance turbine materials.

Life cycle assessment (LCA) studies comparing CMC turbine parts with conventional alternatives demonstrate net positive environmental impacts when considering the entire product lifecycle. The reduced fuel consumption in turbine systems employing CMCs—attributable to higher operating temperatures and improved thermal efficiency—offsets the initially higher environmental footprint of manufacturing. Quantitative analyses indicate potential CO2 emission reductions of 15-20% over the service life of advanced turbine systems utilizing CMC components with enhanced creep resistance.

The sustainability profile of CMCs is further enhanced by their reduced reliance on strategic metals that often involve environmentally destructive mining practices. As creep behavior optimization continues to advance, newer CMC formulations are increasingly utilizing abundant elements, reducing dependence on geopolitically sensitive material supply chains while maintaining performance standards.

Water consumption during manufacturing remains an environmental concern, particularly for oxide-based CMC systems that require aqueous processing steps. Industry research is focusing on closed-loop water systems and dry processing alternatives that maintain the exceptional high-temperature creep resistance while minimizing freshwater requirements in production facilities.

Testing Standards and Qualification Protocols for CMC Turbine Components

The qualification of CMC turbine components requires rigorous testing standards to ensure their reliability under extreme operating conditions. Currently, several international organizations have established comprehensive testing protocols specifically for CMC materials in high-temperature applications. The American Society for Testing and Materials (ASTM) has developed standards such as ASTM C1275 for tensile strength testing and ASTM C1359 for high-temperature creep testing of ceramic matrix composites, which are widely adopted in the aerospace industry.

For turbine applications, these standards have been supplemented by industry-specific protocols developed by organizations like NASA, the Federal Aviation Administration (FAA), and the European Aviation Safety Agency (EASA). These protocols typically require extensive creep testing at temperatures exceeding 1200°C to simulate actual operating conditions in modern gas turbines.

The qualification process for CMC turbine components generally follows a multi-tier approach. Initial material characterization involves microstructural analysis, density measurements, and basic mechanical property testing. This is followed by intermediate-level testing focusing on thermal stability, oxidation resistance, and preliminary creep behavior assessment.

Advanced qualification protocols require long-duration creep testing under combined thermal and mechanical loading conditions. These tests typically run for 1,000 to 10,000 hours to capture the slow deformation mechanisms that occur in CMCs at elevated temperatures. Accelerated testing methodologies have been developed to predict long-term behavior, though these require careful validation against real-time data.

Non-destructive evaluation (NDE) techniques form an essential component of qualification protocols. Techniques such as thermography, acoustic emission, and X-ray computed tomography are employed to detect manufacturing defects and monitor damage progression during testing. Recent advancements in digital image correlation have enabled in-situ strain mapping during high-temperature creep tests.

Statistical approaches to qualification have gained prominence, with probabilistic methods being used to establish design allowables and safety factors. This approach recognizes the inherent variability in CMC properties and provides a more realistic assessment of component reliability.

International harmonization efforts are underway to standardize testing protocols across different regulatory jurisdictions. The Ceramic Matrix Composites Working Group, comprising representatives from major aerospace manufacturers and regulatory bodies, is working toward establishing unified qualification standards that would streamline certification processes globally.

For turbine applications, these standards have been supplemented by industry-specific protocols developed by organizations like NASA, the Federal Aviation Administration (FAA), and the European Aviation Safety Agency (EASA). These protocols typically require extensive creep testing at temperatures exceeding 1200°C to simulate actual operating conditions in modern gas turbines.

The qualification process for CMC turbine components generally follows a multi-tier approach. Initial material characterization involves microstructural analysis, density measurements, and basic mechanical property testing. This is followed by intermediate-level testing focusing on thermal stability, oxidation resistance, and preliminary creep behavior assessment.

Advanced qualification protocols require long-duration creep testing under combined thermal and mechanical loading conditions. These tests typically run for 1,000 to 10,000 hours to capture the slow deformation mechanisms that occur in CMCs at elevated temperatures. Accelerated testing methodologies have been developed to predict long-term behavior, though these require careful validation against real-time data.

Non-destructive evaluation (NDE) techniques form an essential component of qualification protocols. Techniques such as thermography, acoustic emission, and X-ray computed tomography are employed to detect manufacturing defects and monitor damage progression during testing. Recent advancements in digital image correlation have enabled in-situ strain mapping during high-temperature creep tests.

Statistical approaches to qualification have gained prominence, with probabilistic methods being used to establish design allowables and safety factors. This approach recognizes the inherent variability in CMC properties and provides a more realistic assessment of component reliability.

International harmonization efforts are underway to standardize testing protocols across different regulatory jurisdictions. The Ceramic Matrix Composites Working Group, comprising representatives from major aerospace manufacturers and regulatory bodies, is working toward establishing unified qualification standards that would streamline certification processes globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!