Predictive Maintenance Signals For In-Service CMC Components

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Components Predictive Maintenance Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that have transformed high-temperature applications across aerospace, energy, and industrial sectors. Since their commercial introduction in the 1990s, CMCs have evolved from experimental materials to critical components in the most demanding environments, offering superior temperature resistance, reduced weight, and enhanced durability compared to traditional metal alloys. The technological evolution of CMCs has accelerated significantly over the past decade, driven by increasing demands for more efficient and environmentally friendly turbine engines, power generation systems, and industrial equipment.

The primary objective of predictive maintenance for in-service CMC components is to develop robust methodologies for detecting early signs of degradation before catastrophic failure occurs. This proactive approach aims to maximize component lifespan while minimizing unscheduled downtime, which can cost millions of dollars per day in industries like aerospace and power generation. By identifying subtle changes in material properties and performance characteristics, predictive maintenance strategies seek to optimize maintenance schedules and reduce lifecycle costs.

Current predictive maintenance approaches for CMCs face unique challenges due to the complex failure mechanisms of these materials. Unlike metals, which typically exhibit gradual degradation patterns, CMCs can maintain near-pristine performance until shortly before failure. This "cliff-edge" behavior makes traditional predictive maintenance signals less effective for CMCs, necessitating more sophisticated monitoring techniques and analytical models.

The technological trajectory for CMC predictive maintenance is moving toward integrated sensor systems that can monitor multiple parameters simultaneously, including acoustic emissions, thermal signatures, and microstructural changes. Advanced data analytics and machine learning algorithms are increasingly being employed to identify subtle patterns in sensor data that may indicate impending failure, even when individual signals remain within normal operating parameters.

Industry projections indicate that the market for CMC components will grow at a CAGR of approximately 12% through 2030, with the predictive maintenance segment expected to expand even faster as operators seek to maximize the return on their investment in these premium materials. This growth is further driven by regulatory pressures for increased fuel efficiency and reduced emissions in aerospace and energy applications, where CMCs offer significant performance advantages.

The ultimate goal of this technological evolution is to establish a comprehensive predictive maintenance framework that can accurately forecast the remaining useful life of CMC components under varying operational conditions, enabling truly condition-based maintenance rather than time-based replacement schedules.

The primary objective of predictive maintenance for in-service CMC components is to develop robust methodologies for detecting early signs of degradation before catastrophic failure occurs. This proactive approach aims to maximize component lifespan while minimizing unscheduled downtime, which can cost millions of dollars per day in industries like aerospace and power generation. By identifying subtle changes in material properties and performance characteristics, predictive maintenance strategies seek to optimize maintenance schedules and reduce lifecycle costs.

Current predictive maintenance approaches for CMCs face unique challenges due to the complex failure mechanisms of these materials. Unlike metals, which typically exhibit gradual degradation patterns, CMCs can maintain near-pristine performance until shortly before failure. This "cliff-edge" behavior makes traditional predictive maintenance signals less effective for CMCs, necessitating more sophisticated monitoring techniques and analytical models.

The technological trajectory for CMC predictive maintenance is moving toward integrated sensor systems that can monitor multiple parameters simultaneously, including acoustic emissions, thermal signatures, and microstructural changes. Advanced data analytics and machine learning algorithms are increasingly being employed to identify subtle patterns in sensor data that may indicate impending failure, even when individual signals remain within normal operating parameters.

Industry projections indicate that the market for CMC components will grow at a CAGR of approximately 12% through 2030, with the predictive maintenance segment expected to expand even faster as operators seek to maximize the return on their investment in these premium materials. This growth is further driven by regulatory pressures for increased fuel efficiency and reduced emissions in aerospace and energy applications, where CMCs offer significant performance advantages.

The ultimate goal of this technological evolution is to establish a comprehensive predictive maintenance framework that can accurately forecast the remaining useful life of CMC components under varying operational conditions, enabling truly condition-based maintenance rather than time-based replacement schedules.

Market Analysis for CMC Predictive Maintenance Solutions

The global market for Ceramic Matrix Composite (CMC) predictive maintenance solutions is experiencing significant growth, driven by increasing adoption of CMC components in high-temperature applications across aerospace, defense, and industrial sectors. The market size for CMC-specific predictive maintenance was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2030, representing a compound annual growth rate of 14.3%.

Aerospace remains the dominant market segment, accounting for nearly 45% of the total market share. This is primarily due to the extensive use of CMC components in aircraft engines, where predictive maintenance solutions offer substantial cost savings by preventing unscheduled downtime. The defense sector follows closely at 30%, with industrial applications comprising the remaining 25%.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and the rest of the world (9%). The United States dominates the North American market due to its advanced aerospace industry and significant defense spending. In Europe, France, Germany, and the UK are key markets, while in Asia-Pacific, Japan and China are rapidly expanding their capabilities.

Key market drivers include increasing safety regulations in aerospace, rising operational costs, and growing emphasis on extending component lifecycles. The Federal Aviation Administration and European Union Aviation Safety Agency have implemented stringent requirements for monitoring critical components, creating regulatory pressure for advanced predictive maintenance solutions.

Customer demand is shifting toward integrated systems that combine sensor technologies, data analytics, and artificial intelligence to provide real-time monitoring of CMC components. End-users are particularly interested in solutions that can detect early signs of delamination, matrix cracking, and oxidation—common failure modes in CMC components.

The market faces challenges including high implementation costs, technical complexity in signal processing for CMC-specific degradation patterns, and integration issues with existing maintenance systems. The average implementation cost for a comprehensive CMC predictive maintenance system ranges from $500,000 to $2 million, depending on the scale and complexity of operations.

Future market growth will be driven by advancements in non-destructive testing technologies, machine learning algorithms specifically trained on CMC degradation patterns, and the development of more affordable sensor systems that can withstand extreme operating environments. The emergence of subscription-based predictive maintenance services is expected to lower entry barriers for smaller operators.

Aerospace remains the dominant market segment, accounting for nearly 45% of the total market share. This is primarily due to the extensive use of CMC components in aircraft engines, where predictive maintenance solutions offer substantial cost savings by preventing unscheduled downtime. The defense sector follows closely at 30%, with industrial applications comprising the remaining 25%.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and the rest of the world (9%). The United States dominates the North American market due to its advanced aerospace industry and significant defense spending. In Europe, France, Germany, and the UK are key markets, while in Asia-Pacific, Japan and China are rapidly expanding their capabilities.

Key market drivers include increasing safety regulations in aerospace, rising operational costs, and growing emphasis on extending component lifecycles. The Federal Aviation Administration and European Union Aviation Safety Agency have implemented stringent requirements for monitoring critical components, creating regulatory pressure for advanced predictive maintenance solutions.

Customer demand is shifting toward integrated systems that combine sensor technologies, data analytics, and artificial intelligence to provide real-time monitoring of CMC components. End-users are particularly interested in solutions that can detect early signs of delamination, matrix cracking, and oxidation—common failure modes in CMC components.

The market faces challenges including high implementation costs, technical complexity in signal processing for CMC-specific degradation patterns, and integration issues with existing maintenance systems. The average implementation cost for a comprehensive CMC predictive maintenance system ranges from $500,000 to $2 million, depending on the scale and complexity of operations.

Future market growth will be driven by advancements in non-destructive testing technologies, machine learning algorithms specifically trained on CMC degradation patterns, and the development of more affordable sensor systems that can withstand extreme operating environments. The emergence of subscription-based predictive maintenance services is expected to lower entry barriers for smaller operators.

Current Challenges in CMC Component Health Monitoring

Despite significant advancements in Ceramic Matrix Composite (CMC) materials for high-temperature applications, health monitoring of in-service CMC components remains a complex challenge. Current monitoring systems struggle with the unique degradation mechanisms of CMCs, which differ substantially from traditional metallic components. The heterogeneous microstructure of CMCs, consisting of ceramic fibers, matrix, and interface coatings, creates multiple failure modes that conventional sensors cannot adequately detect or predict.

One primary challenge is the limited accessibility of critical components during operation. CMC components in aerospace engines, power generation systems, and hypersonic vehicles operate in extreme environments with temperatures exceeding 1200°C, making real-time monitoring exceptionally difficult. Conventional sensors often fail under such conditions, creating significant blind spots in health assessment capabilities.

Signal interpretation presents another major hurdle. The complex damage progression in CMCs—including matrix cracking, fiber fracture, interface debonding, and environmental degradation—produces subtle and often overlapping signals. Current algorithms struggle to differentiate between normal operational variations and early indicators of component degradation, leading to both false positives and missed detection of critical failure precursors.

Data integration across multiple sensor modalities remains problematic. While acoustic emission, thermography, electrical resistance, and vibration analysis each provide valuable insights, the industry lacks standardized approaches for fusing these disparate data streams into coherent health assessments. This fragmentation impedes the development of comprehensive monitoring solutions.

Environmental interference further complicates monitoring efforts. High temperatures, aggressive chemical environments, and electromagnetic interference in operational settings distort sensor readings, reducing reliability. Current filtering techniques are often inadequate for isolating meaningful signals from environmental noise in CMC applications.

The absence of comprehensive degradation models specifically calibrated for CMCs hinders predictive capabilities. Unlike metals with well-established fatigue and creep models, CMCs exhibit complex progressive failure mechanisms that current models cannot accurately predict, especially when considering the synergistic effects of mechanical loading, thermal cycling, and environmental attack.

Retrofitting existing CMC components with monitoring systems presents significant design challenges. Most monitoring solutions require substantial modification to component design or manufacturing processes, limiting their applicability to components already in service and increasing implementation costs.

AI and machine learning approaches show promise but are hampered by insufficient training data. The relatively limited deployment history of CMCs means that comprehensive failure datasets are scarce, limiting the effectiveness of data-driven predictive approaches that could otherwise overcome many analytical limitations.

One primary challenge is the limited accessibility of critical components during operation. CMC components in aerospace engines, power generation systems, and hypersonic vehicles operate in extreme environments with temperatures exceeding 1200°C, making real-time monitoring exceptionally difficult. Conventional sensors often fail under such conditions, creating significant blind spots in health assessment capabilities.

Signal interpretation presents another major hurdle. The complex damage progression in CMCs—including matrix cracking, fiber fracture, interface debonding, and environmental degradation—produces subtle and often overlapping signals. Current algorithms struggle to differentiate between normal operational variations and early indicators of component degradation, leading to both false positives and missed detection of critical failure precursors.

Data integration across multiple sensor modalities remains problematic. While acoustic emission, thermography, electrical resistance, and vibration analysis each provide valuable insights, the industry lacks standardized approaches for fusing these disparate data streams into coherent health assessments. This fragmentation impedes the development of comprehensive monitoring solutions.

Environmental interference further complicates monitoring efforts. High temperatures, aggressive chemical environments, and electromagnetic interference in operational settings distort sensor readings, reducing reliability. Current filtering techniques are often inadequate for isolating meaningful signals from environmental noise in CMC applications.

The absence of comprehensive degradation models specifically calibrated for CMCs hinders predictive capabilities. Unlike metals with well-established fatigue and creep models, CMCs exhibit complex progressive failure mechanisms that current models cannot accurately predict, especially when considering the synergistic effects of mechanical loading, thermal cycling, and environmental attack.

Retrofitting existing CMC components with monitoring systems presents significant design challenges. Most monitoring solutions require substantial modification to component design or manufacturing processes, limiting their applicability to components already in service and increasing implementation costs.

AI and machine learning approaches show promise but are hampered by insufficient training data. The relatively limited deployment history of CMCs means that comprehensive failure datasets are scarce, limiting the effectiveness of data-driven predictive approaches that could otherwise overcome many analytical limitations.

Existing Signal Processing Methods for CMC Degradation Detection

01 Condition Monitoring and Control (CMC) systems for turbine components

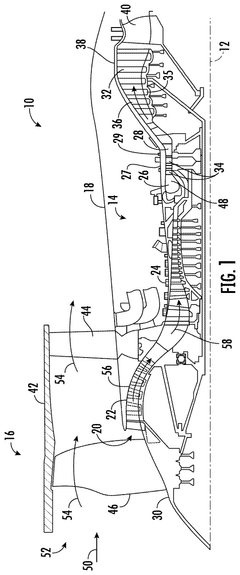

CMC systems are implemented in turbine engines to monitor and control the condition of various components. These systems collect data on component performance, detect abnormalities, and generate maintenance signals when issues are identified. The systems help optimize maintenance schedules, prevent catastrophic failures, and extend the operational life of turbine components through predictive maintenance approaches.- Condition Monitoring Systems for Turbine Components: Advanced monitoring systems for turbine components that detect maintenance signals through sensors and data analysis. These systems track operational parameters, vibration patterns, and thermal conditions to identify potential failures before they occur. The monitoring solutions enable predictive maintenance strategies for critical components in gas and wind turbines, improving reliability and reducing downtime.

- Signal Processing for Component Health Assessment: Methods for processing maintenance signals from mechanical components to assess their health status. These techniques involve analyzing vibration signatures, acoustic emissions, and operational data through algorithms that can identify degradation patterns. The signal processing approaches enable accurate diagnosis of component conditions, facilitating timely maintenance interventions and extending equipment lifespan.

- Automated Maintenance Systems with Component Monitoring: Integrated systems that automate the monitoring and maintenance of critical mechanical components. These solutions combine sensors, communication modules, and control systems to continuously track component performance, automatically generate maintenance alerts, and in some cases, initiate corrective actions. The automated approach optimizes maintenance scheduling and reduces human intervention requirements.

- Blade and Rotor Component Monitoring Technologies: Specialized technologies for monitoring the condition of blade and rotor components in turbines and other rotating machinery. These technologies employ strain gauges, optical sensors, and accelerometers to detect early signs of wear, cracking, or imbalance. The monitoring systems help prevent catastrophic failures by identifying subtle changes in blade performance or structural integrity.

- Data Integration Systems for Maintenance Decision Support: Comprehensive data integration platforms that collect, analyze, and visualize maintenance signals from multiple component sources. These systems consolidate information from various sensors and monitoring devices to provide holistic insights into equipment health. The integrated approach supports informed maintenance decision-making through trend analysis, anomaly detection, and predictive modeling capabilities.

02 Signal processing for component health monitoring

Advanced signal processing techniques are employed to analyze maintenance signals from components. These techniques include filtering algorithms, pattern recognition, and anomaly detection to identify deviations from normal operating conditions. The processed signals provide insights into component degradation, allowing for early detection of potential failures and enabling condition-based maintenance strategies.Expand Specific Solutions03 Integrated maintenance management systems

Comprehensive maintenance management systems integrate component monitoring signals with maintenance planning and execution. These systems collect data from multiple sources, analyze component health indicators, and generate maintenance recommendations. The integration enables efficient resource allocation, optimized maintenance scheduling, and improved component reliability through systematic maintenance approaches.Expand Specific Solutions04 Wireless transmission of component maintenance signals

Wireless technologies are utilized for transmitting maintenance signals from components to monitoring systems. These technologies enable real-time data collection from remote or hard-to-access components, facilitating continuous monitoring without physical connections. The wireless transmission systems enhance monitoring capabilities, reduce installation complexity, and allow for more comprehensive component health assessment.Expand Specific Solutions05 Predictive analytics for component maintenance

Advanced predictive analytics algorithms are applied to component maintenance signals to forecast potential failures before they occur. These algorithms analyze historical data, identify trends, and predict future component behavior based on current operating conditions. The predictive capabilities enable proactive maintenance interventions, minimize unplanned downtime, and optimize component lifecycle management through data-driven decision making.Expand Specific Solutions

Leading Organizations in CMC Predictive Maintenance Industry

The predictive maintenance signals market for CMC components is in a growth phase, characterized by increasing adoption across aerospace, energy, and manufacturing sectors. The market size is expanding rapidly due to the rising demand for condition monitoring systems that reduce downtime and maintenance costs. Technologically, the field is advancing from basic monitoring to sophisticated AI-driven predictive analytics. Leading players like Siemens AG demonstrate mature capabilities with comprehensive industrial IoT platforms, while companies such as Lam Research and Hitachi are developing specialized solutions for semiconductor and heavy machinery applications. Other significant contributors include SAP SE with enterprise-level analytics integration and Xerox with sensor technology innovations. The competitive landscape shows a mix of established industrial giants and specialized technology providers working to enhance real-time monitoring capabilities for ceramic matrix composite components.

Siemens AG

Technical Solution: Siemens has developed an integrated predictive maintenance platform for CMC components that combines IoT sensors, digital twins, and AI analytics. Their solution employs high-temperature resistant sensors embedded within or attached to CMC components to continuously monitor critical parameters including thermal gradients, mechanical stress, and chemical degradation markers. The collected data is processed through Siemens' MindSphere IoT operating system, where advanced machine learning algorithms analyze patterns to detect early signs of material degradation. Their system particularly excels at identifying microstructural changes in CMC matrices before visible damage occurs, using proprietary acoustic emission analysis techniques that can distinguish between normal thermal cycling responses and actual material deterioration. The platform incorporates physics-based models that account for the unique properties of silicon carbide and oxide-based CMCs under various operational conditions, enabling more accurate remaining useful life predictions.

Strengths: Comprehensive integration with existing industrial control systems; extensive experience with high-temperature applications; sophisticated digital twin capabilities that accurately model complex CMC behavior. Weaknesses: Higher implementation costs compared to standalone solutions; requires significant customization for specific CMC compositions; system complexity necessitates specialized training for maintenance personnel.

Lam Research Corp.

Technical Solution: Lam Research has pioneered a specialized predictive maintenance system for CMC components used in semiconductor manufacturing equipment. Their approach focuses on monitoring the degradation patterns of CMC parts exposed to plasma environments and corrosive chemicals. The system employs a multi-modal sensing framework that combines thermal imaging, spectroscopic analysis, and electrical impedance measurements to detect early signs of material degradation. Lam's proprietary algorithms can identify subtle changes in CMC surface properties that precede catastrophic failure, particularly in components subjected to cyclic thermal loading and chemical etching. Their solution incorporates real-time monitoring capabilities that track the evolution of protective oxide layers on SiC-based CMCs, which are critical indicators of remaining component life. The system also features adaptive maintenance scheduling that optimizes replacement timing based on actual component condition rather than fixed time intervals, significantly reducing unnecessary downtime while preventing unexpected failures.

Strengths: Highly specialized for semiconductor manufacturing environments; exceptional sensitivity to early-stage degradation markers; seamless integration with existing fab monitoring systems. Weaknesses: Limited applicability outside semiconductor manufacturing contexts; requires highly controlled environmental conditions for optimal sensor performance; significant initial calibration period needed for new CMC compositions.

Key Sensor Technologies for In-Service CMC Monitoring

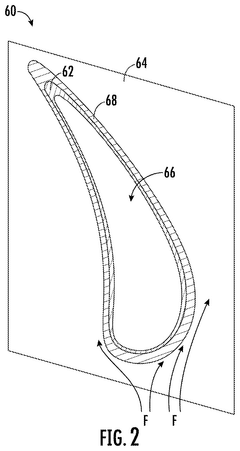

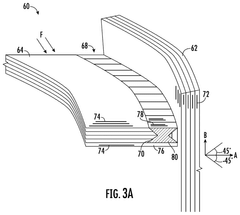

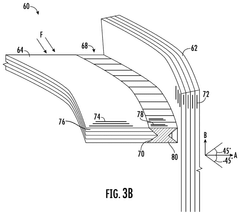

Ceramic matrix composites and methods for producing ceramic matrix composites

PatentWO2014150394A2

Innovation

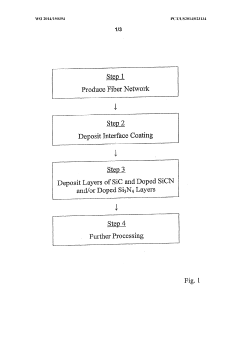

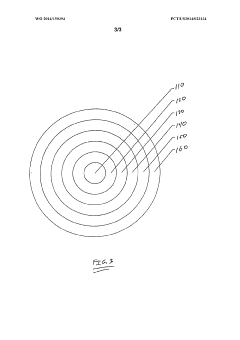

- A method for producing CMCs involves forming a network of fibers and depositing a matrix material with specific component ratios and additional elements to match creep rates, using techniques like chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration, with the option of applying interface layers such as boron nitride or silicon doped boron nitride to optimize properties.

Ceramic matrix composite component repairing and joining

PatentPendingUS20250243125A1

Innovation

- The method involves placing joining plies with off-plane fiber directions relative to adjacent plies to improve laminar organization and structural integrity, using a ply stack configuration that alternates fiber directions to enhance infiltration and retention mechanisms.

Implementation Costs and ROI Analysis for CMC Monitoring Systems

Implementing predictive maintenance systems for Ceramic Matrix Composite (CMC) components requires significant initial investment, but offers substantial long-term financial benefits. The initial implementation costs typically range from $150,000 to $500,000 depending on the scale of operations and complexity of the monitoring system. These costs encompass sensor hardware (approximately 30% of total cost), data acquisition systems (20%), software platforms (25%), integration with existing systems (15%), and staff training (10%).

For aerospace applications, where CMC components are increasingly critical, the installation of comprehensive monitoring systems represents approximately 3-5% of the total maintenance budget but can reduce overall maintenance costs by 15-25% within three years of implementation. The most significant cost drivers include high-temperature sensors capable of withstanding extreme operating conditions and specialized signal processing algorithms designed to interpret complex CMC degradation patterns.

Return on investment calculations demonstrate that most CMC monitoring systems achieve breakeven within 18-24 months of deployment. This ROI is primarily realized through three channels: extended component lifespan (contributing approximately 40% of savings), reduced unplanned downtime (35% of savings), and optimized maintenance scheduling (25% of savings). For a typical aerospace engine application, the financial benefits can exceed $2 million annually for a fleet of 50 aircraft.

Case studies from leading aerospace manufacturers indicate that advanced CMC monitoring systems have reduced in-service failures by up to 70% and extended component lifespan by 30-40%. These improvements translate to approximately $15,000-$25,000 in savings per component over its operational lifetime. Additionally, the reduction in unplanned maintenance events significantly decreases operational disruptions, with airlines reporting 15-20% fewer flight cancellations related to engine maintenance issues.

Implementation strategies that optimize ROI include phased deployment approaches, beginning with critical components and gradually expanding to the entire CMC ecosystem. Organizations that adopt a modular implementation strategy report 30% lower initial costs while maintaining 80% of the benefits. Cloud-based monitoring solutions further reduce infrastructure costs by approximately 40% compared to fully on-premises systems, though they introduce additional considerations regarding data security and latency.

For aerospace applications, where CMC components are increasingly critical, the installation of comprehensive monitoring systems represents approximately 3-5% of the total maintenance budget but can reduce overall maintenance costs by 15-25% within three years of implementation. The most significant cost drivers include high-temperature sensors capable of withstanding extreme operating conditions and specialized signal processing algorithms designed to interpret complex CMC degradation patterns.

Return on investment calculations demonstrate that most CMC monitoring systems achieve breakeven within 18-24 months of deployment. This ROI is primarily realized through three channels: extended component lifespan (contributing approximately 40% of savings), reduced unplanned downtime (35% of savings), and optimized maintenance scheduling (25% of savings). For a typical aerospace engine application, the financial benefits can exceed $2 million annually for a fleet of 50 aircraft.

Case studies from leading aerospace manufacturers indicate that advanced CMC monitoring systems have reduced in-service failures by up to 70% and extended component lifespan by 30-40%. These improvements translate to approximately $15,000-$25,000 in savings per component over its operational lifetime. Additionally, the reduction in unplanned maintenance events significantly decreases operational disruptions, with airlines reporting 15-20% fewer flight cancellations related to engine maintenance issues.

Implementation strategies that optimize ROI include phased deployment approaches, beginning with critical components and gradually expanding to the entire CMC ecosystem. Organizations that adopt a modular implementation strategy report 30% lower initial costs while maintaining 80% of the benefits. Cloud-based monitoring solutions further reduce infrastructure costs by approximately 40% compared to fully on-premises systems, though they introduce additional considerations regarding data security and latency.

Safety Standards and Certification Requirements for CMC Components

The implementation of Ceramic Matrix Composites (CMCs) in critical aerospace and industrial applications necessitates adherence to stringent safety standards and certification requirements. Currently, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive frameworks for certifying CMC components, with specific focus on their unique failure modes and degradation mechanisms.

These regulatory bodies require extensive validation through standardized testing protocols, including ASTM C1341 for flexural properties and ASTM C1275 for tensile strength at elevated temperatures. Additionally, components must demonstrate compliance with damage tolerance requirements outlined in FAA Advisory Circular 20-107B, which has been adapted to address the specific characteristics of CMC materials.

For predictive maintenance applications, certification standards mandate continuous monitoring capabilities that can detect early signs of material degradation. The SAE Aerospace Standard AS6081 provides guidelines for implementing health monitoring systems in composite structures, while MIL-HDBK-17 offers specific protocols for data collection and interpretation related to CMC performance monitoring.

Risk assessment methodologies for CMC components follow the framework established in ISO 31000, with particular emphasis on failure mode and effects analysis (FMEA) tailored to ceramic composite degradation patterns. Certification processes require manufacturers to demonstrate that their predictive maintenance signals can reliably identify potential failures before they reach critical thresholds, with a minimum probability of detection (POD) of 90% at a 95% confidence level.

Environmental factors significantly impact certification requirements, with standards specifying performance criteria under various operational conditions. RTCA DO-160 environmental conditions testing has been adapted for CMC applications, requiring validation of monitoring systems across temperature ranges from -65°C to 1200°C and in various humidity, vibration, and chemical exposure scenarios.

Recent updates to certification frameworks have begun incorporating machine learning validation protocols, such as those outlined in the emerging ISO/IEC TR 24028:2020 standard, which addresses artificial intelligence reliability in safety-critical applications. These standards require extensive validation of predictive algorithms using representative datasets that encompass the full spectrum of potential degradation signals.

Compliance documentation for CMC components must include comprehensive material property databases, validated degradation models, and statistical reliability assessments of the predictive maintenance system. The certification process typically requires a minimum of 5,000 hours of operational data across diverse conditions to establish baseline performance metrics and validate signal thresholds for maintenance interventions.

These regulatory bodies require extensive validation through standardized testing protocols, including ASTM C1341 for flexural properties and ASTM C1275 for tensile strength at elevated temperatures. Additionally, components must demonstrate compliance with damage tolerance requirements outlined in FAA Advisory Circular 20-107B, which has been adapted to address the specific characteristics of CMC materials.

For predictive maintenance applications, certification standards mandate continuous monitoring capabilities that can detect early signs of material degradation. The SAE Aerospace Standard AS6081 provides guidelines for implementing health monitoring systems in composite structures, while MIL-HDBK-17 offers specific protocols for data collection and interpretation related to CMC performance monitoring.

Risk assessment methodologies for CMC components follow the framework established in ISO 31000, with particular emphasis on failure mode and effects analysis (FMEA) tailored to ceramic composite degradation patterns. Certification processes require manufacturers to demonstrate that their predictive maintenance signals can reliably identify potential failures before they reach critical thresholds, with a minimum probability of detection (POD) of 90% at a 95% confidence level.

Environmental factors significantly impact certification requirements, with standards specifying performance criteria under various operational conditions. RTCA DO-160 environmental conditions testing has been adapted for CMC applications, requiring validation of monitoring systems across temperature ranges from -65°C to 1200°C and in various humidity, vibration, and chemical exposure scenarios.

Recent updates to certification frameworks have begun incorporating machine learning validation protocols, such as those outlined in the emerging ISO/IEC TR 24028:2020 standard, which addresses artificial intelligence reliability in safety-critical applications. These standards require extensive validation of predictive algorithms using representative datasets that encompass the full spectrum of potential degradation signals.

Compliance documentation for CMC components must include comprehensive material property databases, validated degradation models, and statistical reliability assessments of the predictive maintenance system. The certification process typically requires a minimum of 5,000 hours of operational data across diverse conditions to establish baseline performance metrics and validate signal thresholds for maintenance interventions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!