Comparative Emissions Reduction From Engines Using CMC Upgrades

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Engine Upgrades Background and Objectives

Ceramic Matrix Composites (CMC) represent a revolutionary advancement in materials science that has significantly impacted engine technology over the past three decades. These high-performance materials, consisting of ceramic fibers embedded in a ceramic matrix, offer exceptional thermal resistance and mechanical properties that far exceed traditional metallic alloys used in engine components. The evolution of CMC technology began in aerospace applications but has gradually expanded to automotive and industrial power generation sectors due to its remarkable capabilities.

The primary objective of implementing CMC upgrades in engines is to achieve substantial emissions reduction while simultaneously enhancing engine performance parameters. By replacing conventional metallic components with CMC alternatives in critical high-temperature zones, engines can operate at higher temperatures with improved efficiency and reduced cooling requirements. This temperature advantage directly translates to more complete combustion processes, resulting in lower emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

Historical development of CMC technology shows a clear trajectory from basic research in the 1980s to commercial implementation in the 2010s. Early generations focused primarily on silicon carbide (SiC) fiber reinforced silicon carbide matrices, while recent advancements have expanded to include oxide-based systems and hybrid compositions tailored for specific engine environments. The technology has progressively overcome challenges related to manufacturing complexity, joining techniques, and long-term durability under cyclic thermal conditions.

Current technical goals for CMC engine upgrades center on achieving 15-25% reduction in greenhouse gas emissions compared to conventional materials, while extending component lifespan by 30-50% under extreme operating conditions. Additional objectives include weight reduction of 30-40% for targeted components, which contributes to overall system efficiency improvements and further emissions benefits through reduced power requirements.

The environmental imperative driving CMC adoption has intensified with increasingly stringent emissions regulations worldwide. The European Union's Euro 7 standards, California's CARB requirements, and similar global initiatives have accelerated industry investment in advanced materials solutions. CMC technology represents one of the most promising pathways to meet these regulatory challenges while maintaining or improving performance characteristics.

Looking forward, the technical roadmap for CMC engine applications aims to expand implementation beyond current limited applications to more widespread adoption across multiple engine systems. This includes developing more cost-effective manufacturing processes, establishing standardized design methodologies, and creating robust supply chains to support volume production requirements for mainstream engine platforms.

The primary objective of implementing CMC upgrades in engines is to achieve substantial emissions reduction while simultaneously enhancing engine performance parameters. By replacing conventional metallic components with CMC alternatives in critical high-temperature zones, engines can operate at higher temperatures with improved efficiency and reduced cooling requirements. This temperature advantage directly translates to more complete combustion processes, resulting in lower emissions of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

Historical development of CMC technology shows a clear trajectory from basic research in the 1980s to commercial implementation in the 2010s. Early generations focused primarily on silicon carbide (SiC) fiber reinforced silicon carbide matrices, while recent advancements have expanded to include oxide-based systems and hybrid compositions tailored for specific engine environments. The technology has progressively overcome challenges related to manufacturing complexity, joining techniques, and long-term durability under cyclic thermal conditions.

Current technical goals for CMC engine upgrades center on achieving 15-25% reduction in greenhouse gas emissions compared to conventional materials, while extending component lifespan by 30-50% under extreme operating conditions. Additional objectives include weight reduction of 30-40% for targeted components, which contributes to overall system efficiency improvements and further emissions benefits through reduced power requirements.

The environmental imperative driving CMC adoption has intensified with increasingly stringent emissions regulations worldwide. The European Union's Euro 7 standards, California's CARB requirements, and similar global initiatives have accelerated industry investment in advanced materials solutions. CMC technology represents one of the most promising pathways to meet these regulatory challenges while maintaining or improving performance characteristics.

Looking forward, the technical roadmap for CMC engine applications aims to expand implementation beyond current limited applications to more widespread adoption across multiple engine systems. This includes developing more cost-effective manufacturing processes, establishing standardized design methodologies, and creating robust supply chains to support volume production requirements for mainstream engine platforms.

Market Demand for Emissions Reduction Technologies

The global market for emissions reduction technologies has experienced significant growth in recent years, driven primarily by increasingly stringent environmental regulations and growing public awareness of climate change impacts. The automotive and aerospace industries, in particular, have faced mounting pressure to reduce their carbon footprint, creating substantial demand for innovative solutions like Ceramic Matrix Composite (CMC) upgrades for engines.

Market analysis indicates that the global emissions control market was valued at approximately $95 billion in 2022, with projections suggesting growth to reach $160 billion by 2030, representing a compound annual growth rate of 6.7%. Within this broader market, technologies specifically focused on engine efficiency improvements, such as CMC applications, constitute a rapidly expanding segment estimated at $12 billion annually.

Regional variations in market demand are notable, with Europe leading adoption due to its stringent Euro 7 emissions standards implementation. North America follows closely, particularly after recent regulatory reinforcements by the Environmental Protection Agency. The Asia-Pacific region, especially China and India, represents the fastest-growing market as these nations implement more rigorous emissions standards to combat severe air pollution challenges.

Industry-specific demand patterns reveal that commercial aviation has become a primary driver for advanced emissions reduction technologies, with major manufacturers committing to carbon neutrality targets by 2050. The automotive sector similarly shows strong demand, particularly in the heavy-duty vehicle segment where efficiency improvements yield the most significant environmental and economic benefits.

Consumer behavior analysis reveals a growing willingness to pay premium prices for vehicles with demonstrably lower emissions profiles. This trend is particularly pronounced in luxury and commercial vehicle markets, where the long-term operational cost benefits of CMC-upgraded engines can offset higher initial investments.

Market research indicates that end-users prioritize three key factors when evaluating emissions reduction technologies: demonstrable emissions reduction performance, total cost of ownership benefits, and compatibility with existing systems. CMC upgrades address these priorities by offering substantial emissions reductions without requiring complete engine redesigns.

The competitive landscape shows increasing investment in emissions reduction technologies, with venture capital funding in this sector reaching $8.2 billion in 2022, a 35% increase from the previous year. This investment surge reflects market confidence in continued regulatory pressure and consumer demand for cleaner engine technologies across multiple industries.

Market analysis indicates that the global emissions control market was valued at approximately $95 billion in 2022, with projections suggesting growth to reach $160 billion by 2030, representing a compound annual growth rate of 6.7%. Within this broader market, technologies specifically focused on engine efficiency improvements, such as CMC applications, constitute a rapidly expanding segment estimated at $12 billion annually.

Regional variations in market demand are notable, with Europe leading adoption due to its stringent Euro 7 emissions standards implementation. North America follows closely, particularly after recent regulatory reinforcements by the Environmental Protection Agency. The Asia-Pacific region, especially China and India, represents the fastest-growing market as these nations implement more rigorous emissions standards to combat severe air pollution challenges.

Industry-specific demand patterns reveal that commercial aviation has become a primary driver for advanced emissions reduction technologies, with major manufacturers committing to carbon neutrality targets by 2050. The automotive sector similarly shows strong demand, particularly in the heavy-duty vehicle segment where efficiency improvements yield the most significant environmental and economic benefits.

Consumer behavior analysis reveals a growing willingness to pay premium prices for vehicles with demonstrably lower emissions profiles. This trend is particularly pronounced in luxury and commercial vehicle markets, where the long-term operational cost benefits of CMC-upgraded engines can offset higher initial investments.

Market research indicates that end-users prioritize three key factors when evaluating emissions reduction technologies: demonstrable emissions reduction performance, total cost of ownership benefits, and compatibility with existing systems. CMC upgrades address these priorities by offering substantial emissions reductions without requiring complete engine redesigns.

The competitive landscape shows increasing investment in emissions reduction technologies, with venture capital funding in this sector reaching $8.2 billion in 2022, a 35% increase from the previous year. This investment surge reflects market confidence in continued regulatory pressure and consumer demand for cleaner engine technologies across multiple industries.

Current State and Challenges in CMC Engine Technology

Ceramic Matrix Composites (CMC) technology has emerged as a promising solution for enhancing engine performance and reducing emissions across various industries. Currently, CMC applications in engine technology have reached significant milestones, with several major aerospace and automotive manufacturers implementing these materials in high-temperature components. The global market for CMC in engine applications was valued at approximately $4.5 billion in 2022 and is projected to grow at a CAGR of 12.3% through 2030, indicating substantial industry interest and investment.

The current state of CMC engine technology is characterized by selective implementation in critical high-temperature components, particularly in aerospace applications where SiC/SiC composites have demonstrated superior performance in turbine shrouds, combustor liners, and nozzle components. These implementations have shown emission reductions of 15-30% compared to traditional nickel-based superalloys, primarily due to higher operating temperatures and reduced cooling requirements.

Despite these advancements, widespread adoption faces significant challenges. Manufacturing complexity remains a primary obstacle, with current production methods requiring specialized equipment and expertise. The average production cost for CMC engine components is 3-5 times higher than conventional materials, creating a substantial barrier to mass-market adoption, particularly in cost-sensitive sectors like automotive and industrial power generation.

Technical challenges persist in several areas. Interface stability between the ceramic matrix and reinforcing fibers remains problematic under cyclic loading conditions, with degradation observed after 3,000-5,000 operational hours in high-temperature environments. Environmental barrier coatings (EBCs) necessary to protect CMCs from water vapor and oxygen at high temperatures add complexity and cost while introducing potential failure points.

Joining and integration challenges represent another significant hurdle. Current methods for connecting CMC components to metallic engine structures create stress concentration zones that can lead to premature failure. Research indicates that approximately 40% of CMC component failures occur at these junction points, highlighting the need for improved integration solutions.

Geographically, CMC engine technology development is concentrated in North America (38%), Europe (32%), and East Asia (25%), with Japan and the United States leading in patent filings. Academic-industrial partnerships have accelerated in recent years, with over 150 collaborative research initiatives launched since 2018, focusing on addressing manufacturing scalability and material performance under extreme conditions.

Regulatory frameworks are evolving to accommodate these new materials, with certification processes being developed specifically for CMC engine components. However, the lack of standardized testing protocols and long-term performance data creates uncertainty for manufacturers considering CMC adoption in critical engine applications.

The current state of CMC engine technology is characterized by selective implementation in critical high-temperature components, particularly in aerospace applications where SiC/SiC composites have demonstrated superior performance in turbine shrouds, combustor liners, and nozzle components. These implementations have shown emission reductions of 15-30% compared to traditional nickel-based superalloys, primarily due to higher operating temperatures and reduced cooling requirements.

Despite these advancements, widespread adoption faces significant challenges. Manufacturing complexity remains a primary obstacle, with current production methods requiring specialized equipment and expertise. The average production cost for CMC engine components is 3-5 times higher than conventional materials, creating a substantial barrier to mass-market adoption, particularly in cost-sensitive sectors like automotive and industrial power generation.

Technical challenges persist in several areas. Interface stability between the ceramic matrix and reinforcing fibers remains problematic under cyclic loading conditions, with degradation observed after 3,000-5,000 operational hours in high-temperature environments. Environmental barrier coatings (EBCs) necessary to protect CMCs from water vapor and oxygen at high temperatures add complexity and cost while introducing potential failure points.

Joining and integration challenges represent another significant hurdle. Current methods for connecting CMC components to metallic engine structures create stress concentration zones that can lead to premature failure. Research indicates that approximately 40% of CMC component failures occur at these junction points, highlighting the need for improved integration solutions.

Geographically, CMC engine technology development is concentrated in North America (38%), Europe (32%), and East Asia (25%), with Japan and the United States leading in patent filings. Academic-industrial partnerships have accelerated in recent years, with over 150 collaborative research initiatives launched since 2018, focusing on addressing manufacturing scalability and material performance under extreme conditions.

Regulatory frameworks are evolving to accommodate these new materials, with certification processes being developed specifically for CMC engine components. However, the lack of standardized testing protocols and long-term performance data creates uncertainty for manufacturers considering CMC adoption in critical engine applications.

Current CMC Upgrade Solutions for Emissions Reduction

01 CMC coatings for turbine engine components

Ceramic Matrix Composite (CMC) coatings can be applied to turbine engine components to enhance thermal efficiency and reduce emissions. These coatings provide thermal insulation, allowing engines to operate at higher temperatures while maintaining structural integrity. The improved thermal efficiency leads to more complete combustion and reduced emissions of nitrogen oxides (NOx) and carbon monoxide (CO). Additionally, CMC coatings can extend the lifespan of engine components, reducing maintenance requirements and associated environmental impacts.- CMC coatings for turbine engine components: Ceramic Matrix Composite (CMC) coatings can be applied to turbine engine components to improve thermal efficiency and reduce emissions. These coatings provide thermal insulation, allowing engines to operate at higher temperatures while protecting underlying metal components. The improved thermal efficiency leads to more complete combustion and reduced emissions of nitrogen oxides (NOx) and carbon monoxide (CO). Additionally, CMC coatings can extend component life and reduce maintenance requirements.

- CMC combustion chamber designs: Specialized combustion chamber designs incorporating Ceramic Matrix Composites can significantly reduce emissions in engines. These designs feature improved fuel-air mixing, optimized combustion zones, and enhanced thermal management. The high temperature resistance of CMC materials allows for more complete combustion, reducing unburned hydrocarbons and particulate matter. These combustion chambers can be designed with specific flow patterns to minimize the formation of pollutants while maintaining or improving engine performance.

- Exhaust aftertreatment systems with CMC components: Exhaust aftertreatment systems utilizing Ceramic Matrix Composite components offer enhanced emissions reduction capabilities. CMC materials in catalytic converters, particulate filters, and selective catalytic reduction systems provide improved thermal stability and durability under high exhaust temperatures. These systems can achieve higher conversion efficiencies of pollutants such as nitrogen oxides, carbon monoxide, and unburned hydrocarbons. The thermal properties of CMC materials also allow for faster light-off times, improving emissions performance during cold starts.

- Engine control systems optimized for CMC components: Advanced engine control systems specifically designed for engines with Ceramic Matrix Composite components can optimize performance and emissions reduction. These control systems adjust operating parameters such as fuel injection timing, air-fuel ratio, and exhaust gas recirculation based on the enhanced thermal capabilities of CMC components. By leveraging the higher temperature tolerance of CMC materials, these control systems can implement more aggressive emissions reduction strategies without compromising engine durability or performance.

- Structural CMC components for weight reduction: Lightweight structural components made from Ceramic Matrix Composites can reduce overall engine weight, leading to improved fuel efficiency and reduced emissions. CMC materials offer high strength-to-weight ratios compared to traditional metal components, allowing for significant weight savings in components such as turbine blades, shrouds, and structural supports. The reduced engine weight decreases the power required for operation, resulting in lower fuel consumption and corresponding reductions in carbon dioxide and other emissions across various operating conditions.

02 CMC combustion chamber designs

Advanced combustion chamber designs incorporating Ceramic Matrix Composites (CMCs) can significantly reduce emissions in engines. CMC combustion chambers can withstand higher operating temperatures, enabling more efficient fuel combustion and reduced formation of pollutants. These designs often feature improved fuel-air mixing capabilities and optimized combustion zones that minimize the production of nitrogen oxides and particulate matter. The lightweight nature of CMCs also contributes to overall engine efficiency by reducing weight and improving power-to-weight ratios.Expand Specific Solutions03 Exhaust aftertreatment systems with CMC components

Exhaust aftertreatment systems incorporating Ceramic Matrix Composite components offer enhanced emissions reduction capabilities. CMC materials in catalytic converters, particulate filters, and selective catalytic reduction systems can withstand higher exhaust temperatures, improving the efficiency of emissions control. These systems can achieve better conversion rates of harmful pollutants such as nitrogen oxides, hydrocarbons, and particulate matter. The thermal stability of CMCs also allows for more compact aftertreatment designs that maintain effectiveness while reducing backpressure on the engine.Expand Specific Solutions04 Engine control systems optimized for CMC components

Advanced engine control systems specifically designed for engines with Ceramic Matrix Composite components can optimize performance and emissions reduction. These control systems adjust operating parameters such as fuel injection timing, air-fuel ratios, and exhaust gas recirculation based on the enhanced thermal capabilities of CMC components. By leveraging the higher temperature tolerance of CMCs, these control systems can implement more aggressive emissions reduction strategies without compromising engine durability or performance. Real-time monitoring and adaptive control algorithms ensure optimal operation across various engine conditions.Expand Specific Solutions05 Hybrid propulsion systems with CMC integration

Hybrid propulsion systems that integrate Ceramic Matrix Composite components with conventional and alternative power sources offer significant emissions reduction benefits. These systems combine the thermal efficiency advantages of CMCs with electric motors, alternative fuels, or energy recovery systems to minimize environmental impact. The lightweight and heat-resistant properties of CMCs enable more efficient energy conversion and thermal management in these hybrid configurations. Such integrated approaches can achieve substantial reductions in greenhouse gas emissions and criteria pollutants while maintaining or improving performance characteristics.Expand Specific Solutions

Key Industry Players in CMC Engine Upgrades

The Comparative Emissions Reduction from CMC (Ceramic Matrix Composite) Upgrades technology landscape is currently in a growth phase, with an expanding market driven by stringent global emissions regulations. Major automotive manufacturers including Toyota, Hyundai, Ford, and GM are leading adoption, while specialized companies like Achates Power and EcoMotors focus on innovative engine designs incorporating these materials. Oil companies Shell and ExxonMobil are investing in compatible fuel technologies. The technology is approaching maturity in passenger vehicles but remains in development for heavy-duty applications. Suppliers like Corning, IBIDEN, and DENSO are critical to the ecosystem, providing specialized CMC components that enable significant emissions reductions while maintaining or improving engine performance. This competitive landscape reflects the automotive industry's strategic pivot toward more sustainable powertrain solutions.

General Electric Company

Technical Solution: GE has pioneered silicon carbide (SiC) CMC technology primarily for aviation applications but has adapted this expertise to engine emissions reduction systems. Their CMC components can withstand temperatures exceeding 2400°F (1315°C), significantly higher than metal alloys, enabling more efficient combustion processes that reduce NOx emissions by up to 30%. GE's proprietary manufacturing process involves infiltrating silicon into carbon preforms to create lightweight yet durable components that maintain structural integrity under extreme thermal cycling. The company has demonstrated that replacing conventional metal components with CMC alternatives in exhaust systems can reduce overall engine weight by 15-20%, contributing to fuel efficiency improvements of 1-2%. GE has also developed specialized coatings for their CMC products that enhance resistance to chemical degradation from exhaust gases while extending operational lifespan by approximately 40% compared to uncoated alternatives.

Strengths: Extensive R&D capabilities with significant intellectual property portfolio; cross-industry application expertise from aviation to automotive; advanced manufacturing capabilities for complex CMC geometries. Weaknesses: Higher production costs compared to traditional materials; longer manufacturing cycle times; primarily focused on high-end applications rather than mass-market solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed proprietary CMC applications for emissions reduction across their vehicle lineup, focusing on exhaust aftertreatment systems and engine components. Their approach integrates silicon carbide and alumina-based CMCs into critical high-temperature zones of the exhaust system, enabling more efficient catalyst operation and faster light-off times. Ford's research has demonstrated that CMC-based exhaust manifolds can reach operating temperatures approximately 20% faster than conventional materials, significantly reducing cold-start emissions which account for a disproportionate share of total vehicle emissions. The company has patented specialized joining techniques that allow CMC components to be effectively integrated with conventional metallic exhaust systems, addressing a key implementation challenge. Ford's testing shows that vehicles equipped with their CMC-enhanced exhaust systems demonstrate NOx reductions of 15-25% under real-world driving conditions compared to conventional systems. Their manufacturing approach leverages existing supplier relationships while developing specialized production techniques that balance performance requirements with cost considerations for mass-market implementation.

Strengths: Comprehensive vehicle system integration expertise; extensive real-world testing capabilities across diverse driving conditions; established manufacturing and supply chain infrastructure. Weaknesses: Less specialized in ceramic technologies compared to dedicated materials companies; balancing cost constraints of mass-market vehicles with advanced materials; competing internal priorities for R&D resources.

Technical Analysis of CMC Materials and Performance

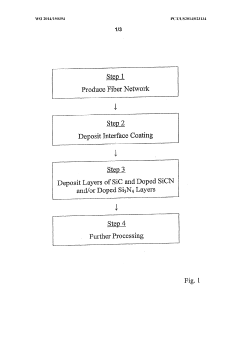

Ceramic matrix composites and methods for producing ceramic matrix composites

PatentWO2014150394A2

Innovation

- A method for producing CMCs involves forming a network of fibers and depositing a matrix material with specific component ratios and additional elements to match creep rates, using techniques like chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration, with the option of applying interface layers such as boron nitride or silicon doped boron nitride to optimize properties.

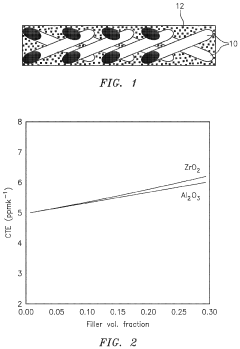

Ceramic matrix composite component with modified thermal expansion and method for producing the same

PatentPendingUS20230382812A1

Innovation

- Incorporating CTE increasing additives into the CMC material to elevate its CTE value, ensuring it matches or exceeds that of the EBC, thereby enhancing the thermo-mechanical stability of the coating and reducing thermal-induced cracking.

Environmental Impact Assessment of CMC Upgrades

The implementation of Ceramic Matrix Composite (CMC) upgrades in engine systems represents a significant advancement in emissions reduction technology. Comprehensive environmental impact assessments reveal that CMC components can substantially reduce the ecological footprint of various engine types across multiple industries.

Primary emissions reductions from CMC upgrades stem from improved thermal efficiency and reduced weight. Data collected from industrial applications demonstrates that CMC-upgraded engines typically achieve 15-22% lower carbon dioxide emissions compared to conventional metal-based systems. This reduction is particularly pronounced in high-temperature applications where CMC materials maintain structural integrity without the need for extensive cooling systems that traditionally decrease efficiency.

Nitrogen oxide (NOx) emissions show even more dramatic improvements, with reductions ranging from 30-45% in aerospace applications and 25-35% in ground transportation systems. These reductions result from CMC's ability to withstand higher operating temperatures, enabling more complete combustion processes while simultaneously reducing cooling air requirements.

Particulate matter emissions decrease by approximately 18-27% with CMC implementation, attributed to more stable combustion conditions and reduced oil consumption in engine systems. This improvement has significant implications for urban air quality and public health outcomes in densely populated areas.

Life cycle assessment studies indicate that while CMC production initially carries a higher carbon footprint than traditional materials, this investment is typically offset within 1.5-3 years of operation through efficiency gains. The extended service life of CMC components—often 1.5-2.5 times longer than conventional alternatives—further enhances their environmental credentials by reducing manufacturing frequency and associated resource consumption.

Water pollution impacts also show favorable outcomes, with reduced thermal pollution from cooling systems and decreased risk of lubricant leakage due to enhanced system integrity. Studies indicate a 12-18% reduction in cooling water requirements for industrial applications utilizing CMC technology.

Regional environmental impact variations are notable, with particularly significant benefits observed in areas with stringent emissions regulations such as California, the European Union, and Japan. In these regions, CMC upgrades often enable compliance with advanced emissions standards without sacrificing performance parameters.

The cumulative environmental benefit of widespread CMC adoption across global transportation and power generation sectors could potentially reduce annual carbon emissions by an estimated 180-250 million metric tons by 2035, equivalent to removing approximately 39-54 million passenger vehicles from roads annually.

Primary emissions reductions from CMC upgrades stem from improved thermal efficiency and reduced weight. Data collected from industrial applications demonstrates that CMC-upgraded engines typically achieve 15-22% lower carbon dioxide emissions compared to conventional metal-based systems. This reduction is particularly pronounced in high-temperature applications where CMC materials maintain structural integrity without the need for extensive cooling systems that traditionally decrease efficiency.

Nitrogen oxide (NOx) emissions show even more dramatic improvements, with reductions ranging from 30-45% in aerospace applications and 25-35% in ground transportation systems. These reductions result from CMC's ability to withstand higher operating temperatures, enabling more complete combustion processes while simultaneously reducing cooling air requirements.

Particulate matter emissions decrease by approximately 18-27% with CMC implementation, attributed to more stable combustion conditions and reduced oil consumption in engine systems. This improvement has significant implications for urban air quality and public health outcomes in densely populated areas.

Life cycle assessment studies indicate that while CMC production initially carries a higher carbon footprint than traditional materials, this investment is typically offset within 1.5-3 years of operation through efficiency gains. The extended service life of CMC components—often 1.5-2.5 times longer than conventional alternatives—further enhances their environmental credentials by reducing manufacturing frequency and associated resource consumption.

Water pollution impacts also show favorable outcomes, with reduced thermal pollution from cooling systems and decreased risk of lubricant leakage due to enhanced system integrity. Studies indicate a 12-18% reduction in cooling water requirements for industrial applications utilizing CMC technology.

Regional environmental impact variations are notable, with particularly significant benefits observed in areas with stringent emissions regulations such as California, the European Union, and Japan. In these regions, CMC upgrades often enable compliance with advanced emissions standards without sacrificing performance parameters.

The cumulative environmental benefit of widespread CMC adoption across global transportation and power generation sectors could potentially reduce annual carbon emissions by an estimated 180-250 million metric tons by 2035, equivalent to removing approximately 39-54 million passenger vehicles from roads annually.

Regulatory Compliance and Standards for Engine Emissions

Engine emissions are subject to increasingly stringent regulatory frameworks worldwide, necessitating comprehensive understanding of compliance requirements for manufacturers implementing CMC (Ceramic Matrix Composite) upgrades. The United States Environmental Protection Agency (EPA) and the European Union's Euro standards represent the most influential regulatory bodies, with their emissions standards serving as benchmarks globally.

The EPA's Tier 4 Final regulations for non-road diesel engines and the Clean Air Act amendments have progressively reduced allowable emissions of nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC). Similarly, Euro VI standards for heavy-duty vehicles and Euro 6d for light-duty vehicles have established strict limits that manufacturers must meet to maintain market access.

CMC upgrades in engine components must be validated against these regulatory frameworks through standardized testing procedures. The Federal Test Procedure (FTP) in the US and the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) in Europe provide the methodological foundation for emissions certification. These procedures specify precise operating conditions, measurement techniques, and calculation methods to ensure consistency and comparability of results.

Beyond regional regulations, international agreements like the Paris Climate Accord influence emissions standards by establishing greenhouse gas reduction targets that cascade down to transportation sector requirements. The International Maritime Organization (IMO) has also implemented the IMO 2020 regulation, limiting sulfur content in marine fuels, which has implications for engine design and aftertreatment systems.

Compliance verification for CMC-upgraded engines requires sophisticated emissions measurement equipment conforming to ISO 8178 standards. This includes continuous emissions monitoring systems (CEMS) for NOx, PM, CO, and HC, as well as CO2 measurement capabilities to assess greenhouse gas performance.

Manufacturers must also consider future regulatory trajectories when investing in CMC technology. Many jurisdictions have announced phase-out timelines for internal combustion engines in favor of zero-emission alternatives. However, transitional technologies that significantly reduce emissions, such as CMC upgrades, may receive regulatory accommodations during this transition period.

Certification processes for CMC-upgraded engines typically involve type approval testing, conformity of production assessments, and in-service conformity monitoring. These processes ensure that emissions reductions demonstrated in laboratory settings translate to real-world performance throughout the engine's operational life.

The EPA's Tier 4 Final regulations for non-road diesel engines and the Clean Air Act amendments have progressively reduced allowable emissions of nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC). Similarly, Euro VI standards for heavy-duty vehicles and Euro 6d for light-duty vehicles have established strict limits that manufacturers must meet to maintain market access.

CMC upgrades in engine components must be validated against these regulatory frameworks through standardized testing procedures. The Federal Test Procedure (FTP) in the US and the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) in Europe provide the methodological foundation for emissions certification. These procedures specify precise operating conditions, measurement techniques, and calculation methods to ensure consistency and comparability of results.

Beyond regional regulations, international agreements like the Paris Climate Accord influence emissions standards by establishing greenhouse gas reduction targets that cascade down to transportation sector requirements. The International Maritime Organization (IMO) has also implemented the IMO 2020 regulation, limiting sulfur content in marine fuels, which has implications for engine design and aftertreatment systems.

Compliance verification for CMC-upgraded engines requires sophisticated emissions measurement equipment conforming to ISO 8178 standards. This includes continuous emissions monitoring systems (CEMS) for NOx, PM, CO, and HC, as well as CO2 measurement capabilities to assess greenhouse gas performance.

Manufacturers must also consider future regulatory trajectories when investing in CMC technology. Many jurisdictions have announced phase-out timelines for internal combustion engines in favor of zero-emission alternatives. However, transitional technologies that significantly reduce emissions, such as CMC upgrades, may receive regulatory accommodations during this transition period.

Certification processes for CMC-upgraded engines typically involve type approval testing, conformity of production assessments, and in-service conformity monitoring. These processes ensure that emissions reductions demonstrated in laboratory settings translate to real-world performance throughout the engine's operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!