Mechanical Property Variability: Statistical Process Control For CMCs

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Property Variability Background and Objectives

Ceramic Matrix Composites (CMCs) have emerged as critical materials in high-temperature applications across aerospace, energy, and defense sectors due to their exceptional thermal resistance and mechanical properties. The development of CMCs dates back to the 1970s, with significant advancements occurring in the 1990s and 2000s as manufacturing processes matured. These materials represent a sophisticated evolution beyond traditional ceramics, incorporating reinforcing fibers within a ceramic matrix to overcome inherent brittleness while maintaining thermal stability.

The evolution of CMC technology has followed a trajectory from laboratory curiosity to commercial viability, with recent years seeing accelerated adoption in turbine engines, hypersonic vehicles, and nuclear applications. This progression has been enabled by improvements in fiber technology, matrix formulations, and interface engineering. However, a persistent challenge throughout this evolution has been the control and prediction of property variability, which directly impacts component reliability and service life.

Current technical trends in CMC development focus on process optimization, computational modeling, and non-destructive evaluation techniques to better understand and control variability. The industry is moving toward digital manufacturing approaches that incorporate real-time monitoring and feedback systems to ensure consistent material properties. Additionally, there is growing interest in tailoring CMC microstructures for specific applications through precise control of processing parameters.

The primary objective of implementing Statistical Process Control (SPC) for CMC property variability is to establish robust methodologies for monitoring, controlling, and predicting mechanical property variations throughout the manufacturing process. This includes developing statistical models that can accurately correlate processing parameters with final material properties, enabling manufacturers to maintain consistent quality while reducing rejection rates and production costs.

Secondary objectives include identifying critical process variables that most significantly influence property variability, establishing appropriate control limits for these variables, and developing early warning systems for process deviations. Furthermore, the implementation of SPC aims to create a framework for continuous improvement in CMC manufacturing, allowing for systematic refinement of processes based on accumulated data and statistical insights.

The long-term technical goal is to achieve a level of process understanding and control that enables "right-first-time" manufacturing of CMCs with predictable properties, reducing the current reliance on extensive post-production testing. This would represent a paradigm shift from the traditional quality control approach to a more proactive quality assurance methodology, ultimately enabling broader adoption of these advanced materials across industries where reliability and consistency are paramount.

The evolution of CMC technology has followed a trajectory from laboratory curiosity to commercial viability, with recent years seeing accelerated adoption in turbine engines, hypersonic vehicles, and nuclear applications. This progression has been enabled by improvements in fiber technology, matrix formulations, and interface engineering. However, a persistent challenge throughout this evolution has been the control and prediction of property variability, which directly impacts component reliability and service life.

Current technical trends in CMC development focus on process optimization, computational modeling, and non-destructive evaluation techniques to better understand and control variability. The industry is moving toward digital manufacturing approaches that incorporate real-time monitoring and feedback systems to ensure consistent material properties. Additionally, there is growing interest in tailoring CMC microstructures for specific applications through precise control of processing parameters.

The primary objective of implementing Statistical Process Control (SPC) for CMC property variability is to establish robust methodologies for monitoring, controlling, and predicting mechanical property variations throughout the manufacturing process. This includes developing statistical models that can accurately correlate processing parameters with final material properties, enabling manufacturers to maintain consistent quality while reducing rejection rates and production costs.

Secondary objectives include identifying critical process variables that most significantly influence property variability, establishing appropriate control limits for these variables, and developing early warning systems for process deviations. Furthermore, the implementation of SPC aims to create a framework for continuous improvement in CMC manufacturing, allowing for systematic refinement of processes based on accumulated data and statistical insights.

The long-term technical goal is to achieve a level of process understanding and control that enables "right-first-time" manufacturing of CMCs with predictable properties, reducing the current reliance on extensive post-production testing. This would represent a paradigm shift from the traditional quality control approach to a more proactive quality assurance methodology, ultimately enabling broader adoption of these advanced materials across industries where reliability and consistency are paramount.

Market Analysis for SPC in Advanced Ceramics

The global market for Statistical Process Control (SPC) in advanced ceramics, particularly Ceramic Matrix Composites (CMCs), has been experiencing significant growth driven by increasing demand across aerospace, defense, energy, and automotive sectors. The market size for SPC solutions in advanced ceramics was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2028, representing a compound annual growth rate of 13.2% during the forecast period.

The aerospace and defense sectors currently dominate the market demand, accounting for nearly 45% of the total market share. This dominance is attributed to the stringent quality requirements and the critical nature of CMC components used in these industries. The implementation of SPC methodologies has become essential for manufacturers to meet the exacting standards required for high-temperature, high-stress applications in aircraft engines and defense systems.

Energy sector applications, particularly in gas turbines and nuclear power generation, represent the fastest-growing segment with a projected growth rate of 16.8% annually. This growth is driven by the increasing adoption of CMCs in harsh operating environments where traditional materials fail to deliver optimal performance. The automotive industry is also emerging as a significant market for SPC in advanced ceramics, particularly with the transition toward electric vehicles and more efficient internal combustion engines.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate of 15.7% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investments in aerospace and defense industries.

The market is characterized by a growing demand for integrated SPC solutions that combine real-time monitoring, advanced analytics, and machine learning capabilities. End-users are increasingly seeking comprehensive platforms that can not only detect variations in mechanical properties but also predict potential failures and recommend corrective actions. This trend is driving the development of more sophisticated SPC tools specifically tailored for the unique challenges of CMC production.

Cost considerations remain a significant factor influencing market dynamics. The implementation of advanced SPC systems requires substantial initial investment, ranging from $50,000 to $500,000 depending on the scale and complexity of operations. However, the long-term benefits in terms of reduced scrap rates, improved product consistency, and enhanced customer satisfaction are driving adoption despite the high initial costs. Studies indicate that effective SPC implementation can reduce quality-related costs by up to 30% within two years of deployment.

The aerospace and defense sectors currently dominate the market demand, accounting for nearly 45% of the total market share. This dominance is attributed to the stringent quality requirements and the critical nature of CMC components used in these industries. The implementation of SPC methodologies has become essential for manufacturers to meet the exacting standards required for high-temperature, high-stress applications in aircraft engines and defense systems.

Energy sector applications, particularly in gas turbines and nuclear power generation, represent the fastest-growing segment with a projected growth rate of 16.8% annually. This growth is driven by the increasing adoption of CMCs in harsh operating environments where traditional materials fail to deliver optimal performance. The automotive industry is also emerging as a significant market for SPC in advanced ceramics, particularly with the transition toward electric vehicles and more efficient internal combustion engines.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate of 15.7% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investments in aerospace and defense industries.

The market is characterized by a growing demand for integrated SPC solutions that combine real-time monitoring, advanced analytics, and machine learning capabilities. End-users are increasingly seeking comprehensive platforms that can not only detect variations in mechanical properties but also predict potential failures and recommend corrective actions. This trend is driving the development of more sophisticated SPC tools specifically tailored for the unique challenges of CMC production.

Cost considerations remain a significant factor influencing market dynamics. The implementation of advanced SPC systems requires substantial initial investment, ranging from $50,000 to $500,000 depending on the scale and complexity of operations. However, the long-term benefits in terms of reduced scrap rates, improved product consistency, and enhanced customer satisfaction are driving adoption despite the high initial costs. Studies indicate that effective SPC implementation can reduce quality-related costs by up to 30% within two years of deployment.

Current SPC Challenges in CMC Manufacturing

The implementation of Statistical Process Control (SPC) in Ceramic Matrix Composites (CMCs) manufacturing faces several significant challenges that impede effective quality control and process optimization. Traditional SPC methods developed for conventional materials often prove inadequate when applied to CMCs due to their complex microstructure and manufacturing processes.

One primary challenge is the inherent material variability in CMCs. Unlike metals or polymers, CMCs exhibit substantial heterogeneity at multiple scales, from fiber distribution to matrix porosity. This natural variability makes it difficult to establish appropriate control limits and distinguish between normal process variation and actual defects or quality issues.

Data scarcity presents another major obstacle. CMC production volumes remain relatively low compared to traditional materials, resulting in limited historical data for establishing robust statistical models. This scarcity is particularly problematic for high-temperature or specialized applications where each component may have slightly different requirements or operating conditions.

The multi-stage manufacturing process of CMCs introduces additional complexity. Each stage—from fiber preparation to matrix infiltration and final heat treatment—contributes to the final properties, creating a complex web of process variables that interact in ways that are difficult to model statistically. Traditional SPC tools struggle to capture these complex interactions and their cumulative effects on final properties.

Non-destructive evaluation (NDE) limitations further complicate SPC implementation. Many critical CMC properties cannot be measured without destroying the component, forcing manufacturers to rely on surrogate measurements or limited sampling. This creates significant uncertainty in process monitoring and makes real-time adjustments challenging.

The high cost of testing and inspection compounds these challenges. Comprehensive mechanical property testing of CMCs is expensive and time-consuming, limiting the frequency and extent of quality checks. This economic constraint often leads to reduced sampling rates, which further weakens statistical confidence in process control decisions.

Measurement system variability also introduces significant noise into SPC systems for CMCs. The specialized equipment and techniques required for CMC testing often have their own variability, which must be distinguished from actual material and process variation. Gauge R&R (Repeatability and Reproducibility) studies for CMC testing systems frequently reveal high measurement uncertainty.

Finally, there is a notable knowledge gap in applying advanced statistical methods to CMC manufacturing. Traditional SPC approaches like X-bar and R charts may be insufficient for capturing the complex property distributions in CMCs, while more sophisticated multivariate methods require statistical expertise that is often lacking in production environments.

One primary challenge is the inherent material variability in CMCs. Unlike metals or polymers, CMCs exhibit substantial heterogeneity at multiple scales, from fiber distribution to matrix porosity. This natural variability makes it difficult to establish appropriate control limits and distinguish between normal process variation and actual defects or quality issues.

Data scarcity presents another major obstacle. CMC production volumes remain relatively low compared to traditional materials, resulting in limited historical data for establishing robust statistical models. This scarcity is particularly problematic for high-temperature or specialized applications where each component may have slightly different requirements or operating conditions.

The multi-stage manufacturing process of CMCs introduces additional complexity. Each stage—from fiber preparation to matrix infiltration and final heat treatment—contributes to the final properties, creating a complex web of process variables that interact in ways that are difficult to model statistically. Traditional SPC tools struggle to capture these complex interactions and their cumulative effects on final properties.

Non-destructive evaluation (NDE) limitations further complicate SPC implementation. Many critical CMC properties cannot be measured without destroying the component, forcing manufacturers to rely on surrogate measurements or limited sampling. This creates significant uncertainty in process monitoring and makes real-time adjustments challenging.

The high cost of testing and inspection compounds these challenges. Comprehensive mechanical property testing of CMCs is expensive and time-consuming, limiting the frequency and extent of quality checks. This economic constraint often leads to reduced sampling rates, which further weakens statistical confidence in process control decisions.

Measurement system variability also introduces significant noise into SPC systems for CMCs. The specialized equipment and techniques required for CMC testing often have their own variability, which must be distinguished from actual material and process variation. Gauge R&R (Repeatability and Reproducibility) studies for CMC testing systems frequently reveal high measurement uncertainty.

Finally, there is a notable knowledge gap in applying advanced statistical methods to CMC manufacturing. Traditional SPC approaches like X-bar and R charts may be insufficient for capturing the complex property distributions in CMCs, while more sophisticated multivariate methods require statistical expertise that is often lacking in production environments.

Existing SPC Methodologies for CMC Production

01 Processing methods affecting mechanical property variability

Various processing methods can significantly impact the mechanical property variability of Ceramic Matrix Composites (CMCs). Techniques such as chemical vapor infiltration, melt infiltration, and polymer infiltration and pyrolysis each introduce different levels of variability in the final composite properties. Controlling processing parameters like temperature, pressure, and infiltration time is crucial for reducing variability and achieving consistent mechanical properties in CMCs.- Factors affecting mechanical property variability in CMCs: Various factors contribute to the mechanical property variability in Ceramic Matrix Composites (CMCs), including processing parameters, raw material quality, fiber architecture, and environmental conditions during manufacturing. Understanding these factors is crucial for predicting and controlling the mechanical behavior of CMCs in different applications. The variability in mechanical properties can be attributed to microstructural heterogeneity, interfacial characteristics between fibers and matrix, and the presence of defects such as pores and microcracks.

- Testing and characterization methods for CMC mechanical properties: Various testing and characterization methods are employed to evaluate the mechanical properties of Ceramic Matrix Composites and understand their variability. These include tensile, compression, flexural, and shear testing, as well as non-destructive evaluation techniques such as ultrasonic testing, X-ray computed tomography, and acoustic emission monitoring. Advanced microscopy techniques are also used to analyze microstructural features that influence mechanical property variability, enabling better quality control and performance prediction.

- Manufacturing processes to reduce mechanical property variability: Specialized manufacturing processes have been developed to reduce mechanical property variability in Ceramic Matrix Composites. These include controlled infiltration techniques, precise fiber preform preparation, optimized pyrolysis cycles, and advanced sintering methods. Process monitoring and control systems help maintain consistency in manufacturing parameters, resulting in more uniform microstructures and mechanical properties. Post-processing treatments can also be applied to enhance uniformity and reduce variability in the final composite materials.

- Computational modeling for predicting CMC mechanical property variability: Computational modeling approaches are used to predict and understand mechanical property variability in Ceramic Matrix Composites. These include finite element analysis, micromechanical modeling, statistical methods, and machine learning techniques. Such models incorporate microstructural features, processing parameters, and material properties to simulate the mechanical behavior of CMCs under various conditions. These computational tools help in designing more reliable CMCs with reduced property variability and enable the development of uncertainty quantification methods for performance prediction.

- Interface engineering to control mechanical property variability: Interface engineering between fibers and matrix plays a crucial role in controlling mechanical property variability in Ceramic Matrix Composites. Various coating techniques and interface design strategies are employed to create optimal fiber-matrix interfaces that provide consistent mechanical performance. These interfaces control crack propagation, load transfer, and failure mechanisms in the composite. By carefully engineering these interfaces through controlled coating thickness, composition, and microstructure, manufacturers can achieve more consistent mechanical properties and reduce variability in CMC performance.

02 Fiber architecture and interface design

The architecture of reinforcing fibers and the design of fiber-matrix interfaces play critical roles in determining the mechanical property variability of CMCs. Factors such as fiber orientation, weave pattern, fiber volume fraction, and interface coating thickness can all contribute to variability in mechanical properties. Optimizing these parameters can lead to more consistent mechanical performance and reduced property scatter in CMC components.Expand Specific Solutions03 Testing and characterization methods

Advanced testing and characterization methods are essential for accurately assessing the mechanical property variability in CMCs. Non-destructive evaluation techniques, microstructural analysis, and standardized mechanical testing protocols help in quantifying variability and identifying its sources. Statistical approaches to data analysis enable better understanding of property distributions and confidence intervals, which is crucial for design allowables in critical applications.Expand Specific Solutions04 Environmental effects on property variability

Environmental conditions significantly influence the mechanical property variability of CMCs. Factors such as high temperature exposure, oxidative environments, moisture, and thermal cycling can alter the microstructure and mechanical behavior of these composites over time. Understanding these environmental effects is crucial for predicting long-term performance variability and developing CMCs with consistent properties under service conditions.Expand Specific Solutions05 Computational modeling of property variability

Computational modeling approaches are increasingly used to predict and understand mechanical property variability in CMCs. Multi-scale modeling techniques, from atomistic to continuum levels, help in relating microstructural features to macroscopic property variations. These models incorporate statistical methods to account for inherent material variability and manufacturing uncertainties, enabling more robust design of CMC components with predictable mechanical performance.Expand Specific Solutions

Leading CMC Manufacturers and Research Institutions

The Statistical Process Control (SPC) for Ceramic Matrix Composites (CMCs) market is currently in a growth phase, with increasing adoption across aerospace and defense sectors. The global CMC market is projected to reach significant scale due to superior mechanical properties and high-temperature resistance capabilities. Leading aerospace companies including Rolls-Royce Corp., RTX Corp. (formerly United Technologies), and Safran Ceramics demonstrate advanced technical maturity in CMC applications, while research institutions like Nanjing University of Aeronautics & Astronautics and Northwestern Polytechnical University contribute fundamental research. Specialized manufacturers such as COI Ceramics and Rolls-Royce High Temperature Composites have developed proprietary SPC methodologies, though standardization remains challenging. The technology shows varying maturity levels across different applications, with aerospace implementations being most advanced while industrial applications remain emerging.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive SPC framework for CMCs that integrates traditional statistical methods with advanced machine learning techniques. Their approach focuses on identifying critical process parameters that most significantly impact mechanical property variability through Design of Experiments (DoE) methodologies. Honeywell's system employs multivariate analysis techniques including Principal Component Analysis (PCA) and Partial Least Squares (PLS) to monitor complex relationships between process variables and mechanical properties. The company has implemented an adaptive control system that automatically adjusts process parameters based on real-time statistical analysis of incoming material properties, processing conditions, and in-process measurements. Their SPC methodology incorporates a unique risk-based approach that prioritizes monitoring efforts on parameters with the highest potential impact on critical mechanical properties, optimizing resource allocation while maintaining strict quality control.

Strengths: Integration of machine learning with traditional SPC methods provides robust detection of complex patterns affecting mechanical properties. Risk-based approach optimizes monitoring resources for maximum effectiveness. Weaknesses: Requires extensive initial characterization and modeling to implement effectively. May be less sensitive to rare or unexpected process variations not captured in training data.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has pioneered an advanced statistical process control methodology specifically tailored for CMC components used in high-temperature aerospace applications. Their approach centers on a hierarchical Bayesian framework that accounts for the inherent variability in CMC manufacturing processes. The system monitors over 200 process variables across the entire manufacturing workflow, from fiber production to final component testing. Rolls-Royce employs a unique "fingerprinting" technique that establishes statistical correlations between manufacturing parameters and mechanical properties, allowing for early detection of potential variability issues. Their SPC implementation includes specialized control charts that account for the anisotropic nature of CMCs and the complex interactions between matrix and fiber properties. The company has developed proprietary algorithms that can predict mechanical property variations based on subtle changes in manufacturing conditions, enabling real-time process adjustments to maintain consistent component quality.

Strengths: Hierarchical Bayesian approach effectively handles the complex variability inherent in CMC production. Extensive database of historical process data enables highly accurate predictive modeling. Weaknesses: System is highly specialized for aerospace applications and may require significant adaptation for other industries. Heavy reliance on proprietary algorithms creates potential vendor lock-in.

Key Statistical Models for CMC Property Prediction

Ceramic matrix composite structures and methods for manufacture thereof

PatentPendingUS20250170751A1

Innovation

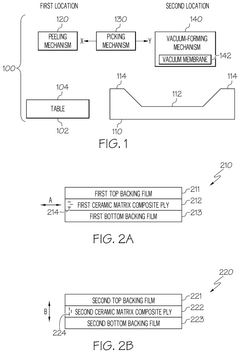

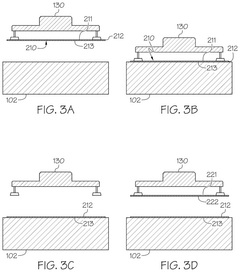

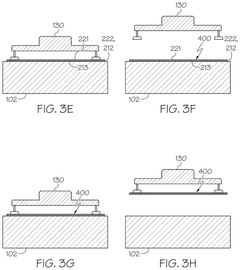

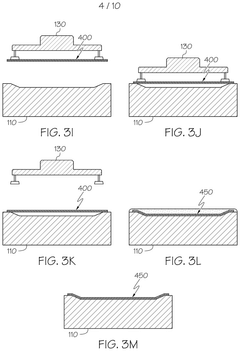

- An electronically-controlled method for manufacturing ceramic matrix composite structures involves processing ceramic matrix composite plies at one location, transporting the stack to a remote location, and further processing to achieve the desired shape and consistency.

Ceramic matrix composite material

PatentWO2019235624A1

Innovation

- A ceramic matrix composite material is developed with a silicon carbide fiber bundle coated with a silicon carbide film, where the average film thickness ratio between the surface and inner layers is controlled between 1.0 and 1.3, with a minimum of 2.6 μm in the inner layer, using chemical vapor deposition (CVD) or chemical vapor impregnation (CVI) methods, ensuring excellent mechanical properties.

Material Characterization Techniques for CMCs

Material characterization techniques for Ceramic Matrix Composites (CMCs) play a crucial role in understanding and controlling property variability during manufacturing processes. Non-destructive evaluation (NDE) methods such as X-ray computed tomography (CT) and ultrasonic testing provide valuable insights into internal structures without compromising the integrity of components. X-ray CT specifically offers three-dimensional visualization of fiber architecture, matrix distribution, and defect locations with resolution capabilities reaching the micron scale, essential for identifying structural inconsistencies.

Mechanical property assessment techniques include flexural testing, tensile testing, and fracture toughness evaluation. These standardized methods follow ASTM guidelines to ensure consistency across different manufacturing batches. Tensile testing with digital image correlation (DIC) has emerged as particularly valuable for CMCs, as it allows for real-time strain mapping across the specimen surface, revealing localized deformation patterns that conventional extensometers might miss.

Microstructural analysis through scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provides detailed examination of fiber-matrix interfaces, which significantly influence the mechanical behavior of CMCs. Energy-dispersive X-ray spectroscopy (EDS) coupled with these microscopy techniques enables elemental mapping to track compositional variations that may contribute to property inconsistencies.

Thermal characterization methods including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) help evaluate the thermal stability and phase transformations in CMCs. These techniques are particularly important for applications in high-temperature environments where thermal cycling can induce property changes over time.

Advanced spectroscopic techniques such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) provide information about chemical bonding and crystalline structures at different stages of processing. These non-destructive methods can be implemented in-line during manufacturing to monitor chemical reactions and crystallization processes that affect final properties.

Porosity and density measurements using mercury intrusion porosimetry and Archimedes' principle offer quantitative data on void content and distribution. Since porosity significantly impacts mechanical properties, these measurements serve as critical quality control parameters in statistical process control frameworks for CMCs.

Emerging characterization technologies including acoustic emission monitoring and in-situ mechanical testing within environmental chambers allow for real-time observation of damage progression under simulated service conditions. These approaches provide valuable data for developing predictive models of CMC behavior and identifying early indicators of property variability.

Mechanical property assessment techniques include flexural testing, tensile testing, and fracture toughness evaluation. These standardized methods follow ASTM guidelines to ensure consistency across different manufacturing batches. Tensile testing with digital image correlation (DIC) has emerged as particularly valuable for CMCs, as it allows for real-time strain mapping across the specimen surface, revealing localized deformation patterns that conventional extensometers might miss.

Microstructural analysis through scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provides detailed examination of fiber-matrix interfaces, which significantly influence the mechanical behavior of CMCs. Energy-dispersive X-ray spectroscopy (EDS) coupled with these microscopy techniques enables elemental mapping to track compositional variations that may contribute to property inconsistencies.

Thermal characterization methods including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) help evaluate the thermal stability and phase transformations in CMCs. These techniques are particularly important for applications in high-temperature environments where thermal cycling can induce property changes over time.

Advanced spectroscopic techniques such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) provide information about chemical bonding and crystalline structures at different stages of processing. These non-destructive methods can be implemented in-line during manufacturing to monitor chemical reactions and crystallization processes that affect final properties.

Porosity and density measurements using mercury intrusion porosimetry and Archimedes' principle offer quantitative data on void content and distribution. Since porosity significantly impacts mechanical properties, these measurements serve as critical quality control parameters in statistical process control frameworks for CMCs.

Emerging characterization technologies including acoustic emission monitoring and in-situ mechanical testing within environmental chambers allow for real-time observation of damage progression under simulated service conditions. These approaches provide valuable data for developing predictive models of CMC behavior and identifying early indicators of property variability.

Regulatory Standards for CMC Quality Assurance

The regulatory landscape for Ceramic Matrix Composites (CMCs) quality assurance is governed by a comprehensive framework of standards established by various international and national bodies. The Aerospace Materials Specification (AMS) committee has developed AMS 6071 specifically for CMC components in aerospace applications, detailing stringent requirements for statistical process control methodologies. This standard mandates continuous monitoring of key mechanical properties including tensile strength, interlaminar shear strength, and fracture toughness with specified control limits and sampling frequencies.

The National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specialized audit criteria for CMC manufacturing processes, requiring manufacturers to implement robust statistical process control systems that can detect and address property variability before it impacts final component quality. These requirements include documentation of process capability indices (Cpk) exceeding 1.33 for critical mechanical properties.

ASTM International has developed several standards relevant to CMC quality assurance, including ASTM C1341 for flexural properties testing and ASTM C1275 for tensile testing of CMCs. These standards provide detailed methodologies for property measurement and statistical analysis of test results. The ASTM E2587 standard specifically addresses statistical process control implementation for advanced ceramics manufacturing.

In the automotive sector, the International Automotive Task Force (IATF) 16949 quality management system includes provisions for CMC components used in high-temperature applications, requiring manufacturers to establish process control plans with appropriate statistical techniques for monitoring property variability. This standard emphasizes the use of measurement system analysis (MSA) to validate testing methodologies before implementing statistical process control.

The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have established certification requirements for CMC components in aircraft engines through Advisory Circulars and Certification Specifications. These documents mandate the implementation of statistical process control for critical mechanical properties and require demonstration of process stability before certification approval.

ISO 21948:2019 provides guidelines for non-destructive testing of CMCs, complementing statistical process control by enabling 100% inspection of critical components. This standard is increasingly referenced in regulatory frameworks as a means to validate statistical sampling approaches and provide additional quality assurance for high-risk applications.

Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive requirements, allowing manufacturers flexibility in implementing statistical process control methodologies provided they can demonstrate effective control of mechanical property variability. This trend is reflected in recent updates to standards from the SAE International G-3 Committee on Aerospace Couplings, Fittings, Hose, and Tubing Assemblies, which now incorporate risk-based approaches to quality assurance for CMC components.

The National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specialized audit criteria for CMC manufacturing processes, requiring manufacturers to implement robust statistical process control systems that can detect and address property variability before it impacts final component quality. These requirements include documentation of process capability indices (Cpk) exceeding 1.33 for critical mechanical properties.

ASTM International has developed several standards relevant to CMC quality assurance, including ASTM C1341 for flexural properties testing and ASTM C1275 for tensile testing of CMCs. These standards provide detailed methodologies for property measurement and statistical analysis of test results. The ASTM E2587 standard specifically addresses statistical process control implementation for advanced ceramics manufacturing.

In the automotive sector, the International Automotive Task Force (IATF) 16949 quality management system includes provisions for CMC components used in high-temperature applications, requiring manufacturers to establish process control plans with appropriate statistical techniques for monitoring property variability. This standard emphasizes the use of measurement system analysis (MSA) to validate testing methodologies before implementing statistical process control.

The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have established certification requirements for CMC components in aircraft engines through Advisory Circulars and Certification Specifications. These documents mandate the implementation of statistical process control for critical mechanical properties and require demonstration of process stability before certification approval.

ISO 21948:2019 provides guidelines for non-destructive testing of CMCs, complementing statistical process control by enabling 100% inspection of critical components. This standard is increasingly referenced in regulatory frameworks as a means to validate statistical sampling approaches and provide additional quality assurance for high-risk applications.

Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive requirements, allowing manufacturers flexibility in implementing statistical process control methodologies provided they can demonstrate effective control of mechanical property variability. This trend is reflected in recent updates to standards from the SAE International G-3 Committee on Aerospace Couplings, Fittings, Hose, and Tubing Assemblies, which now incorporate risk-based approaches to quality assurance for CMC components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!