Corrosion-Resistant CMC Matrices For Harsh Operating Environments

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Matrices Development History and Objectives

Ceramic Matrix Composites (CMCs) have evolved significantly since their inception in the mid-20th century. Initially developed as alternatives to traditional metals and alloys for high-temperature applications, CMCs have undergone substantial transformation in their composition, manufacturing processes, and application scope. The earliest CMC matrices primarily consisted of silicon carbide (SiC) and alumina (Al2O3), offering limited corrosion resistance in extreme environments.

The 1970s marked a pivotal shift with the introduction of chemical vapor infiltration (CVI) techniques, enabling the creation of more complex matrix compositions with enhanced properties. By the 1980s, researchers had begun exploring oxide-based matrices specifically designed to withstand oxidative environments, though these early formulations struggled with mechanical stability at elevated temperatures.

The 1990s witnessed accelerated development in CMC technology, driven largely by aerospace and energy sector demands. During this period, significant advancements occurred in multi-phase matrices that combined different ceramic materials to achieve synergistic properties. The introduction of polymer infiltration and pyrolysis (PIP) methods further expanded manufacturing capabilities, allowing for more intricate matrix designs with tailored corrosion resistance.

The early 2000s brought renewed focus on environmental barrier coatings (EBCs) that work synergistically with the matrix material, providing additional protection against harsh operating conditions. Concurrently, self-healing matrix concepts emerged, incorporating phases that could react with corrosive species or fill developing microcracks during operation.

Recent developments have centered on nano-engineered matrices, where precisely controlled nanoscale structures create unprecedented corrosion resistance through mechanisms such as preferential reactivity and controlled ion transport. Advanced characterization techniques, including in-situ high-temperature testing in corrosive atmospheres, have enabled more sophisticated understanding of degradation mechanisms.

The primary objective of current research is to develop CMC matrices capable of maintaining structural integrity in increasingly extreme environments, including temperatures exceeding 1600°C, highly acidic or basic conditions, and environments containing multiple corrosive species simultaneously. Specific goals include extending component lifetimes by at least 50% compared to current state-of-the-art materials, reducing maintenance requirements in industrial applications, and enabling new capabilities in aerospace propulsion systems.

Additional objectives focus on improving manufacturing scalability to reduce production costs, developing predictive models for long-term corrosion behavior, and creating environmentally sustainable matrix compositions that minimize the use of rare or toxic elements while maintaining performance standards. These advancements aim to position CMC technology as the definitive solution for next-generation high-temperature, corrosion-resistant structural materials.

The 1970s marked a pivotal shift with the introduction of chemical vapor infiltration (CVI) techniques, enabling the creation of more complex matrix compositions with enhanced properties. By the 1980s, researchers had begun exploring oxide-based matrices specifically designed to withstand oxidative environments, though these early formulations struggled with mechanical stability at elevated temperatures.

The 1990s witnessed accelerated development in CMC technology, driven largely by aerospace and energy sector demands. During this period, significant advancements occurred in multi-phase matrices that combined different ceramic materials to achieve synergistic properties. The introduction of polymer infiltration and pyrolysis (PIP) methods further expanded manufacturing capabilities, allowing for more intricate matrix designs with tailored corrosion resistance.

The early 2000s brought renewed focus on environmental barrier coatings (EBCs) that work synergistically with the matrix material, providing additional protection against harsh operating conditions. Concurrently, self-healing matrix concepts emerged, incorporating phases that could react with corrosive species or fill developing microcracks during operation.

Recent developments have centered on nano-engineered matrices, where precisely controlled nanoscale structures create unprecedented corrosion resistance through mechanisms such as preferential reactivity and controlled ion transport. Advanced characterization techniques, including in-situ high-temperature testing in corrosive atmospheres, have enabled more sophisticated understanding of degradation mechanisms.

The primary objective of current research is to develop CMC matrices capable of maintaining structural integrity in increasingly extreme environments, including temperatures exceeding 1600°C, highly acidic or basic conditions, and environments containing multiple corrosive species simultaneously. Specific goals include extending component lifetimes by at least 50% compared to current state-of-the-art materials, reducing maintenance requirements in industrial applications, and enabling new capabilities in aerospace propulsion systems.

Additional objectives focus on improving manufacturing scalability to reduce production costs, developing predictive models for long-term corrosion behavior, and creating environmentally sustainable matrix compositions that minimize the use of rare or toxic elements while maintaining performance standards. These advancements aim to position CMC technology as the definitive solution for next-generation high-temperature, corrosion-resistant structural materials.

Market Analysis for Corrosion-Resistant CMCs

The global market for corrosion-resistant Ceramic Matrix Composites (CMCs) is experiencing robust growth, driven primarily by increasing demands in aerospace, defense, energy, and industrial sectors. Current market valuations indicate that the corrosion-resistant CMC segment represents approximately 35% of the overall CMC market, which was valued at $4.8 billion in 2022. This segment is projected to grow at a compound annual growth rate (CAGR) of 12.3% through 2030, outpacing the broader advanced ceramics market.

Aerospace and defense sectors currently dominate the demand landscape, accounting for nearly 45% of corrosion-resistant CMC applications. This is attributed to the critical need for materials that can withstand extreme temperatures, aggressive chemical environments, and mechanical stress in aircraft engines, hypersonic vehicles, and missile systems. The energy sector follows closely, representing 30% of market demand, particularly in applications related to gas turbines, fuel cells, and nuclear power systems.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 14.7% annually, driven by expanding industrial bases in China, Japan, and India, coupled with increasing investments in aerospace and defense technologies.

Customer requirements are evolving toward CMCs that can simultaneously resist multiple types of corrosion—including oxidation, hot corrosion from molten salts, and water vapor attack—while maintaining structural integrity at temperatures exceeding 1400°C. This multi-functional performance requirement is creating new market opportunities but also raising technical barriers to entry.

Price sensitivity varies significantly across application sectors. While aerospace and defense customers prioritize performance over cost, industrial and energy sectors demonstrate higher price elasticity. The average price premium for corrosion-resistant CMCs over conventional high-temperature alloys ranges from 2.5 to 4 times, depending on specific performance requirements and production volumes.

Supply chain analysis indicates potential vulnerabilities, with 68% of rare earth elements and specialty precursors required for advanced CMC matrices sourced from geopolitically sensitive regions. This has prompted increased interest in developing alternative material systems and recycling technologies, creating secondary market opportunities estimated at $650 million annually.

Market forecasts suggest that next-generation corrosion-resistant CMCs with enhanced durability in multi-corrosive environments could capture premium market segments worth $1.2 billion by 2028, particularly in hypersonic applications, advanced nuclear systems, and hydrogen energy infrastructure.

Aerospace and defense sectors currently dominate the demand landscape, accounting for nearly 45% of corrosion-resistant CMC applications. This is attributed to the critical need for materials that can withstand extreme temperatures, aggressive chemical environments, and mechanical stress in aircraft engines, hypersonic vehicles, and missile systems. The energy sector follows closely, representing 30% of market demand, particularly in applications related to gas turbines, fuel cells, and nuclear power systems.

Regional analysis reveals that North America leads the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 14.7% annually, driven by expanding industrial bases in China, Japan, and India, coupled with increasing investments in aerospace and defense technologies.

Customer requirements are evolving toward CMCs that can simultaneously resist multiple types of corrosion—including oxidation, hot corrosion from molten salts, and water vapor attack—while maintaining structural integrity at temperatures exceeding 1400°C. This multi-functional performance requirement is creating new market opportunities but also raising technical barriers to entry.

Price sensitivity varies significantly across application sectors. While aerospace and defense customers prioritize performance over cost, industrial and energy sectors demonstrate higher price elasticity. The average price premium for corrosion-resistant CMCs over conventional high-temperature alloys ranges from 2.5 to 4 times, depending on specific performance requirements and production volumes.

Supply chain analysis indicates potential vulnerabilities, with 68% of rare earth elements and specialty precursors required for advanced CMC matrices sourced from geopolitically sensitive regions. This has prompted increased interest in developing alternative material systems and recycling technologies, creating secondary market opportunities estimated at $650 million annually.

Market forecasts suggest that next-generation corrosion-resistant CMCs with enhanced durability in multi-corrosive environments could capture premium market segments worth $1.2 billion by 2028, particularly in hypersonic applications, advanced nuclear systems, and hydrogen energy infrastructure.

Current Challenges in Harsh Environment Applications

Ceramic Matrix Composites (CMCs) face significant challenges when deployed in harsh operating environments, which severely limit their performance and longevity. The most pressing challenge is the accelerated degradation of matrix materials when exposed to extreme temperatures exceeding 1200°C, particularly in aerospace and power generation applications. Under such conditions, conventional matrices experience rapid oxidation and structural deterioration, compromising the overall integrity of the composite system.

Corrosion mechanisms present another formidable obstacle, especially in environments containing molten salts, acidic compounds, or high-pressure steam. These corrosive agents penetrate the matrix through micro-cracks and pores, initiating chemical reactions that progressively weaken the material from within. The rate of corrosion is often unpredictable due to the complex interaction between multiple environmental factors, making it difficult to develop standardized protection strategies.

Thermal cycling poses a unique challenge as it induces repeated expansion and contraction of the matrix material. This cyclical stress creates fatigue at the fiber-matrix interface, eventually leading to delamination and catastrophic failure. Current matrix systems struggle to maintain consistent performance across wide temperature ranges, particularly during rapid thermal transitions common in rocket engines and hypersonic vehicles.

The synergistic effects of multiple harsh conditions simultaneously acting on CMC matrices represent perhaps the most complex challenge. For instance, materials that perform adequately under high temperature may rapidly degrade when that heat is combined with corrosive species and mechanical loading. This multi-factor degradation often occurs at rates significantly faster than predicted by single-factor testing protocols.

Manufacturing challenges further complicate the development of corrosion-resistant matrices. Current processing techniques struggle to achieve uniform distribution of corrosion inhibitors throughout the matrix, creating weak points susceptible to preferential attack. Additionally, many promising corrosion-resistant formulations exhibit poor processability, limiting their practical implementation in complex component geometries.

Economic considerations also present barriers to advancement. The high cost of specialized corrosion-resistant materials and their processing requirements often make them prohibitively expensive for widespread commercial adoption. This economic constraint has limited research investment in certain promising but costly matrix systems, creating innovation gaps in the technology landscape.

Lastly, there exists a significant knowledge gap in understanding long-term degradation mechanisms. Accelerated testing methods often fail to accurately predict real-world performance, while comprehensive field testing requires years of data collection. This uncertainty complicates material selection decisions and risk assessments for critical applications where failure is not an option.

Corrosion mechanisms present another formidable obstacle, especially in environments containing molten salts, acidic compounds, or high-pressure steam. These corrosive agents penetrate the matrix through micro-cracks and pores, initiating chemical reactions that progressively weaken the material from within. The rate of corrosion is often unpredictable due to the complex interaction between multiple environmental factors, making it difficult to develop standardized protection strategies.

Thermal cycling poses a unique challenge as it induces repeated expansion and contraction of the matrix material. This cyclical stress creates fatigue at the fiber-matrix interface, eventually leading to delamination and catastrophic failure. Current matrix systems struggle to maintain consistent performance across wide temperature ranges, particularly during rapid thermal transitions common in rocket engines and hypersonic vehicles.

The synergistic effects of multiple harsh conditions simultaneously acting on CMC matrices represent perhaps the most complex challenge. For instance, materials that perform adequately under high temperature may rapidly degrade when that heat is combined with corrosive species and mechanical loading. This multi-factor degradation often occurs at rates significantly faster than predicted by single-factor testing protocols.

Manufacturing challenges further complicate the development of corrosion-resistant matrices. Current processing techniques struggle to achieve uniform distribution of corrosion inhibitors throughout the matrix, creating weak points susceptible to preferential attack. Additionally, many promising corrosion-resistant formulations exhibit poor processability, limiting their practical implementation in complex component geometries.

Economic considerations also present barriers to advancement. The high cost of specialized corrosion-resistant materials and their processing requirements often make them prohibitively expensive for widespread commercial adoption. This economic constraint has limited research investment in certain promising but costly matrix systems, creating innovation gaps in the technology landscape.

Lastly, there exists a significant knowledge gap in understanding long-term degradation mechanisms. Accelerated testing methods often fail to accurately predict real-world performance, while comprehensive field testing requires years of data collection. This uncertainty complicates material selection decisions and risk assessments for critical applications where failure is not an option.

Existing Corrosion-Resistant Matrix Solutions

01 Ceramic Matrix Composite (CMC) materials for corrosion resistance

Ceramic Matrix Composites (CMCs) are engineered to provide superior corrosion resistance in harsh environments. These materials combine ceramic matrices with reinforcing fibers to create composites that maintain structural integrity while resisting chemical degradation. The ceramic matrices act as protective barriers against corrosive agents, while the fiber reinforcement enhances mechanical properties. These advanced materials are particularly valuable in high-temperature applications where traditional metals would deteriorate rapidly.- Ceramic Matrix Composites (CMCs) for corrosion resistance: Ceramic Matrix Composites (CMCs) are engineered materials that combine ceramic fibers within a ceramic matrix to create structures with enhanced corrosion resistance properties. These materials are particularly valuable in high-temperature and chemically aggressive environments where traditional materials would deteriorate. The ceramic matrices provide excellent resistance to oxidation, chemical attack, and thermal degradation, making them ideal for applications in harsh industrial settings.

- Protective coatings for CMC matrices: Various protective coating systems can be applied to CMC matrices to further enhance their corrosion resistance. These coatings typically consist of specialized materials such as environmental barrier coatings (EBCs), thermal barrier coatings (TBCs), or multi-layer systems designed to protect against specific corrosive agents. The coatings create an additional barrier that prevents direct contact between corrosive substances and the underlying CMC structure, thereby extending the service life of components in aggressive environments.

- CMC matrices with self-healing properties: Advanced CMC matrices can be formulated with self-healing capabilities to address corrosion damage. These innovative materials contain reactive components that activate when damage occurs, filling cracks or voids and restoring protective properties. The self-healing mechanism typically involves the formation of protective oxides or other compounds that seal damaged areas, preventing further corrosion progression and extending the operational lifetime of components exposed to corrosive environments.

- Composition optimization for corrosion resistance: The specific composition of CMC matrices can be optimized to enhance corrosion resistance in targeted environments. This involves careful selection of matrix materials, fiber types, and additives that provide superior performance against specific corrosive agents. Researchers have developed specialized formulations that incorporate elements or compounds known to resist particular forms of corrosion, such as sulfidation, oxidation, or acid attack, resulting in matrices tailored for specific industrial applications.

- Processing techniques for corrosion-resistant CMCs: Various manufacturing and processing techniques can significantly impact the corrosion resistance of CMC matrices. Advanced methods such as chemical vapor infiltration, polymer infiltration and pyrolysis, and hot pressing can create denser, more uniform matrices with fewer defects that might otherwise serve as corrosion initiation sites. Post-processing treatments, including heat treatments and surface modifications, can further enhance the corrosion resistance properties by optimizing the microstructure and surface characteristics of the final CMC components.

02 Corrosion-resistant coatings for CMC structures

Specialized coatings can be applied to CMC matrices to enhance their corrosion resistance properties. These coatings typically consist of environmental barrier layers that protect the underlying composite structure from oxidation, chemical attack, and other degradation mechanisms. The coatings can be engineered with multiple layers to address specific corrosive environments, with each layer serving a distinct protective function. Advanced deposition techniques ensure uniform coverage and strong adhesion to the CMC substrate.Expand Specific Solutions03 CMC matrices for electrical applications with corrosion resistance

CMC matrices are increasingly being utilized in electrical applications where corrosion resistance is critical. These specialized composites combine electrical functionality with the ability to withstand corrosive environments. The materials are designed to maintain electrical properties while preventing degradation from moisture, chemicals, and other environmental factors. Applications include connectors, insulators, and components for power transmission systems that must operate reliably in challenging conditions.Expand Specific Solutions04 Manufacturing processes for corrosion-resistant CMC matrices

Specialized manufacturing techniques have been developed to produce CMC matrices with enhanced corrosion resistance. These processes include innovative infiltration methods, controlled sintering, and precise fiber arrangement to optimize the material's protective properties. Advanced processing parameters ensure uniform distribution of corrosion-inhibiting compounds throughout the matrix. Post-processing treatments can further enhance the material's resistance to specific corrosive environments by sealing pores and creating protective surface layers.Expand Specific Solutions05 CMC matrices with self-healing corrosion resistance properties

Innovative CMC matrices incorporate self-healing mechanisms to provide long-term corrosion resistance. These advanced materials contain reactive components that activate when damage occurs, automatically sealing cracks and preventing corrosive agents from penetrating deeper into the structure. The self-healing process can involve phase transformations, controlled oxidation reactions, or the release of encapsulated healing agents. This technology significantly extends the service life of components in corrosive environments by maintaining protective integrity even after initial damage occurs.Expand Specific Solutions

Leading Organizations in CMC Research and Development

The corrosion-resistant CMC matrices market is in a growth phase, with increasing adoption in aerospace, defense, and energy sectors operating in extreme environments. The market is projected to expand significantly due to rising demand for high-performance materials in harsh conditions. Technologically, the field shows varying maturity levels across applications, with companies like RTX Corp., Safran Ceramics, and Rolls-Royce leading commercial implementation. Academic institutions including Northwestern Polytechnical University and Harbin Institute of Technology are advancing fundamental research, while Boeing, GE, and Siemens focus on application-specific developments. The competitive landscape features strategic partnerships between aerospace primes and specialized materials developers to overcome technical challenges in thermal stability, oxidation resistance, and manufacturing scalability.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed advanced ceramic matrix composite (CMC) matrices specifically engineered for harsh operating environments. Their proprietary SiC/SiC CMC system incorporates environmental barrier coatings (EBCs) that protect against oxidation and water vapor corrosion at temperatures exceeding 1200°C. RTX's approach involves a multi-layered matrix design with self-healing capabilities through the incorporation of boron-based additives that form protective glass phases when exposed to oxidizing environments. The company has successfully implemented silicon carbide-based matrices with rare earth silicate modifications that significantly enhance corrosion resistance in combustion environments. Their CMCs have demonstrated a 3x improvement in component life compared to conventional superalloys in gas turbine applications, while reducing weight by approximately 30%.

Strengths: Superior high-temperature performance with demonstrated durability in actual engine environments; integrated manufacturing capabilities from raw materials to finished components; extensive testing infrastructure. Weaknesses: Higher production costs compared to traditional materials; complex manufacturing processes requiring specialized equipment; longer production cycles limiting rapid deployment.

Safran Ceramics SA

Technical Solution: Safran Ceramics has pioneered innovative CMC matrix technologies specifically designed for aerospace propulsion systems operating in extreme environments. Their proprietary matrix formulations incorporate self-healing mechanisms based on multilayered SiC matrices with boron-doped interlayers that form protective borosilicate glass when exposed to oxidizing environments. This technology enables components to withstand temperatures up to 1400°C while maintaining structural integrity. Safran's approach includes the development of specialized slurry infiltration processes that create dense, low-porosity matrices with enhanced resistance to both oxidation and hot corrosion. Their CMC systems incorporate rare earth element dopants that significantly improve resistance to water vapor corrosion, a critical factor in combustion environments. Safran has successfully demonstrated these materials in actual aircraft engine components, showing a 20% reduction in specific fuel consumption compared to traditional nickel-based superalloy parts.

Strengths: Extensive experience in actual flight applications; vertically integrated production capabilities; proven performance in real-world engine environments with thousands of flight hours. Weaknesses: High initial investment costs; complex manufacturing processes requiring specialized facilities; challenges in scaling production to meet growing market demand.

Key Patents and Technical Breakthroughs

Multilayer interface coating with thermally-grown oxide for improved durability

PatentPendingUS20240018060A1

Innovation

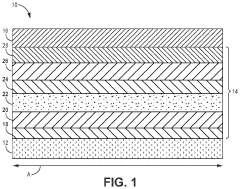

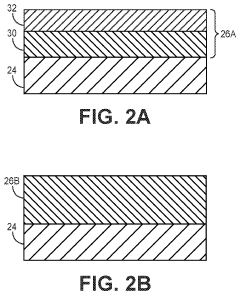

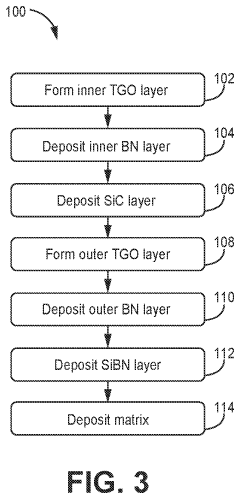

- A multi-layer coating system comprising a first boron nitride layer, a silicon carbide layer, a thermally-grown oxide layer, and a second boron nitride layer is applied to the fibers, with the silicon carbide layer promoting a smoother interface and the outer boron nitride layer providing enhanced oxidation resistance, and a silicon-doped boron nitride layer optionally added for increased stability.

Corrosion-resistant composite comprising ceramic matrix, and manufacturing process

PatentWO2018220296A1

Innovation

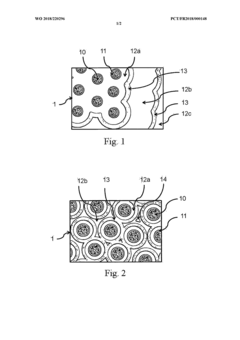

- A composite material with a multilayer ceramic matrix comprising a uniform continuous layer of boron and carbon (0.4-8% atomic percentage) and refractory layers, such as silicon carbide, where the boron-rich layer is deposited uniformly without clusters, and additional refractory layers are used to form borosilicate glasses that protect against corrosion, using a chemical vapor infiltration process with controlled infiltration rates and gas mixtures.

Environmental Impact Assessment

The development and implementation of Ceramic Matrix Composites (CMCs) with enhanced corrosion resistance for harsh operating environments necessitates a thorough environmental impact assessment. These advanced materials, while offering superior performance characteristics, may present both positive and negative environmental implications throughout their lifecycle.

CMC manufacturing processes typically involve high-temperature sintering and chemical vapor infiltration, which consume significant energy and potentially release harmful emissions. The production of ceramic precursors and reinforcement fibers may utilize hazardous chemicals that require careful handling and disposal protocols. However, compared to traditional metallic alternatives, CMCs often require fewer toxic elements such as chromium, nickel, or lead that are commonly used in high-temperature alloys, potentially reducing environmental contamination risks.

During operational use, corrosion-resistant CMCs contribute positively to environmental sustainability through extended service life and reduced maintenance requirements. This longevity translates to fewer replacement parts, diminished resource consumption, and decreased waste generation over time. In energy generation applications, CMCs enable higher operating temperatures and improved efficiency, potentially reducing overall carbon emissions and fossil fuel consumption.

The enhanced durability of these materials in harsh environments, such as those with extreme temperatures, aggressive chemicals, or high-pressure conditions, prevents catastrophic failures that could result in environmental contamination events. This is particularly relevant in nuclear, chemical processing, and aerospace applications where material failure could lead to significant environmental damage.

End-of-life considerations for CMCs present unique challenges. These materials are inherently difficult to recycle due to their composite nature and the strong chemical bonds between matrix and reinforcement components. Current recycling technologies for CMCs remain limited and energy-intensive, though research into improved recovery methods is ongoing. The non-biodegradable nature of ceramic materials means they persist in landfills indefinitely if not properly managed.

Regulatory compliance must be considered throughout the CMC lifecycle. Environmental regulations governing manufacturing emissions, workplace exposure limits, and waste disposal requirements vary globally but are generally becoming more stringent. Manufacturers must navigate these complex regulatory landscapes while developing economically viable production methods for corrosion-resistant CMC matrices.

Overall, while corrosion-resistant CMCs offer significant environmental benefits through extended service life and improved system efficiency, their environmental footprint must be holistically assessed from raw material extraction through end-of-life disposal to ensure truly sustainable implementation in harsh operating environments.

CMC manufacturing processes typically involve high-temperature sintering and chemical vapor infiltration, which consume significant energy and potentially release harmful emissions. The production of ceramic precursors and reinforcement fibers may utilize hazardous chemicals that require careful handling and disposal protocols. However, compared to traditional metallic alternatives, CMCs often require fewer toxic elements such as chromium, nickel, or lead that are commonly used in high-temperature alloys, potentially reducing environmental contamination risks.

During operational use, corrosion-resistant CMCs contribute positively to environmental sustainability through extended service life and reduced maintenance requirements. This longevity translates to fewer replacement parts, diminished resource consumption, and decreased waste generation over time. In energy generation applications, CMCs enable higher operating temperatures and improved efficiency, potentially reducing overall carbon emissions and fossil fuel consumption.

The enhanced durability of these materials in harsh environments, such as those with extreme temperatures, aggressive chemicals, or high-pressure conditions, prevents catastrophic failures that could result in environmental contamination events. This is particularly relevant in nuclear, chemical processing, and aerospace applications where material failure could lead to significant environmental damage.

End-of-life considerations for CMCs present unique challenges. These materials are inherently difficult to recycle due to their composite nature and the strong chemical bonds between matrix and reinforcement components. Current recycling technologies for CMCs remain limited and energy-intensive, though research into improved recovery methods is ongoing. The non-biodegradable nature of ceramic materials means they persist in landfills indefinitely if not properly managed.

Regulatory compliance must be considered throughout the CMC lifecycle. Environmental regulations governing manufacturing emissions, workplace exposure limits, and waste disposal requirements vary globally but are generally becoming more stringent. Manufacturers must navigate these complex regulatory landscapes while developing economically viable production methods for corrosion-resistant CMC matrices.

Overall, while corrosion-resistant CMCs offer significant environmental benefits through extended service life and improved system efficiency, their environmental footprint must be holistically assessed from raw material extraction through end-of-life disposal to ensure truly sustainable implementation in harsh operating environments.

Standardization and Testing Protocols

The standardization and testing protocols for corrosion-resistant CMC matrices represent a critical foundation for advancing research and commercial applications in harsh operating environments. Currently, the field faces significant challenges due to fragmented testing methodologies across different industries and research institutions, making direct comparisons between materials and performance claims difficult to validate.

ASTM International and ISO have established several relevant standards for ceramic matrix composites, including ASTM C1275 for monotonic tensile strength testing and ISO 20504 for compressive properties determination. However, these standards often lack specific provisions for corrosion resistance evaluation under the extreme conditions encountered in aerospace, energy generation, and chemical processing applications.

A comprehensive standardization framework must address multiple corrosion mechanisms simultaneously, including oxidation, hot corrosion from molten salts, and chemical attack from acidic or alkaline environments. The development of accelerated testing protocols that accurately predict long-term performance remains particularly challenging, as corrosion mechanisms often change with extended exposure times.

Recent collaborative efforts between industry consortia and national laboratories have yielded promising developments in standardized testing. The High Temperature Materials Testing Consortium has proposed a three-tier testing approach: screening tests for rapid material evaluation, intermediate tests simulating specific application environments, and qualification tests involving full-scale component testing under actual operating conditions.

Emerging technologies for in-situ monitoring during standardized testing are enhancing data collection capabilities. Advanced techniques such as electrochemical impedance spectroscopy (EIS) and acoustic emission monitoring provide real-time insights into corrosion progression and material degradation mechanisms, enabling more accurate lifetime predictions.

Round-robin testing programs involving multiple laboratories have become increasingly important for validating test methods and ensuring reproducibility of results. These collaborative efforts help identify variables that may affect test outcomes and establish confidence intervals for performance metrics, ultimately leading to more robust standards.

Digital material passports documenting standardized test results are gaining traction as a means to facilitate material selection and qualification processes. These comprehensive data repositories include information on corrosion resistance under various conditions, enabling engineers to make informed decisions based on standardized performance metrics rather than proprietary claims.

ASTM International and ISO have established several relevant standards for ceramic matrix composites, including ASTM C1275 for monotonic tensile strength testing and ISO 20504 for compressive properties determination. However, these standards often lack specific provisions for corrosion resistance evaluation under the extreme conditions encountered in aerospace, energy generation, and chemical processing applications.

A comprehensive standardization framework must address multiple corrosion mechanisms simultaneously, including oxidation, hot corrosion from molten salts, and chemical attack from acidic or alkaline environments. The development of accelerated testing protocols that accurately predict long-term performance remains particularly challenging, as corrosion mechanisms often change with extended exposure times.

Recent collaborative efforts between industry consortia and national laboratories have yielded promising developments in standardized testing. The High Temperature Materials Testing Consortium has proposed a three-tier testing approach: screening tests for rapid material evaluation, intermediate tests simulating specific application environments, and qualification tests involving full-scale component testing under actual operating conditions.

Emerging technologies for in-situ monitoring during standardized testing are enhancing data collection capabilities. Advanced techniques such as electrochemical impedance spectroscopy (EIS) and acoustic emission monitoring provide real-time insights into corrosion progression and material degradation mechanisms, enabling more accurate lifetime predictions.

Round-robin testing programs involving multiple laboratories have become increasingly important for validating test methods and ensuring reproducibility of results. These collaborative efforts help identify variables that may affect test outcomes and establish confidence intervals for performance metrics, ultimately leading to more robust standards.

Digital material passports documenting standardized test results are gaining traction as a means to facilitate material selection and qualification processes. These comprehensive data repositories include information on corrosion resistance under various conditions, enabling engineers to make informed decisions based on standardized performance metrics rather than proprietary claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!