Environmental Barrier Coatings For SiC/SiC CMC Turbine Components

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EBC Technology Background and Objectives

Environmental Barrier Coatings (EBCs) have emerged as a critical technology for protecting Silicon Carbide/Silicon Carbide Ceramic Matrix Composites (SiC/SiC CMCs) in advanced gas turbine engines. The development of EBCs can be traced back to the 1990s when researchers at NASA Glenn Research Center pioneered the first-generation coatings to address the vulnerability of silicon-based ceramics to water vapor corrosion in combustion environments.

The evolution of EBC technology has been primarily driven by the aerospace and power generation industries' pursuit of higher operating temperatures to improve engine efficiency and reduce emissions. Traditional superalloy components have reached their thermal limits, prompting the transition to SiC/SiC CMCs which offer superior temperature capability, reduced weight, and improved durability. However, these materials suffer from accelerated oxidation and recession in the presence of water vapor at high temperatures.

Current technological trends indicate a shift from simple barrier designs to multi-layered, multifunctional coating systems that provide protection against multiple degradation mechanisms simultaneously. The integration of rare earth silicates and advanced bond coat materials has significantly extended coating lifetimes under extreme conditions. Recent developments also focus on self-healing capabilities and improved strain tolerance to accommodate the thermal expansion mismatch between coating layers and substrates.

The primary technical objective for next-generation EBCs is to enable SiC/SiC CMC components to operate reliably at temperatures exceeding 1400°C for thousands of hours in aggressive turbine environments. This requires coatings that can withstand thermal cycling, resist calcium-magnesium-alumino-silicate (CMAS) infiltration, maintain phase stability, and provide effective protection against oxidation and volatilization.

Secondary objectives include developing manufacturing processes that can consistently produce high-quality coatings on complex-shaped components, reducing coating thickness to minimize weight penalties, and ensuring compatibility with existing turbine designs and materials. Cost-effective deposition methods such as air plasma spray, suspension plasma spray, and directed vapor deposition are being explored to enable widespread commercial adoption.

The successful development of advanced EBCs represents a transformative opportunity for the gas turbine industry, potentially enabling efficiency improvements of 5-7% and corresponding reductions in fuel consumption and emissions. This technology is increasingly viewed as an enabling factor for meeting future environmental regulations and sustainability goals in both aviation and power generation sectors.

The evolution of EBC technology has been primarily driven by the aerospace and power generation industries' pursuit of higher operating temperatures to improve engine efficiency and reduce emissions. Traditional superalloy components have reached their thermal limits, prompting the transition to SiC/SiC CMCs which offer superior temperature capability, reduced weight, and improved durability. However, these materials suffer from accelerated oxidation and recession in the presence of water vapor at high temperatures.

Current technological trends indicate a shift from simple barrier designs to multi-layered, multifunctional coating systems that provide protection against multiple degradation mechanisms simultaneously. The integration of rare earth silicates and advanced bond coat materials has significantly extended coating lifetimes under extreme conditions. Recent developments also focus on self-healing capabilities and improved strain tolerance to accommodate the thermal expansion mismatch between coating layers and substrates.

The primary technical objective for next-generation EBCs is to enable SiC/SiC CMC components to operate reliably at temperatures exceeding 1400°C for thousands of hours in aggressive turbine environments. This requires coatings that can withstand thermal cycling, resist calcium-magnesium-alumino-silicate (CMAS) infiltration, maintain phase stability, and provide effective protection against oxidation and volatilization.

Secondary objectives include developing manufacturing processes that can consistently produce high-quality coatings on complex-shaped components, reducing coating thickness to minimize weight penalties, and ensuring compatibility with existing turbine designs and materials. Cost-effective deposition methods such as air plasma spray, suspension plasma spray, and directed vapor deposition are being explored to enable widespread commercial adoption.

The successful development of advanced EBCs represents a transformative opportunity for the gas turbine industry, potentially enabling efficiency improvements of 5-7% and corresponding reductions in fuel consumption and emissions. This technology is increasingly viewed as an enabling factor for meeting future environmental regulations and sustainability goals in both aviation and power generation sectors.

Market Analysis for SiC/SiC CMC Applications

The global market for SiC/SiC CMC applications has experienced significant growth in recent years, primarily driven by the aerospace and power generation sectors. The market value for SiC/SiC CMC components in gas turbines reached approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 8.7% through 2030.

The aerospace sector currently dominates the application landscape, accounting for roughly 65% of the total market share. This dominance stems from the critical need for lightweight, high-temperature resistant materials in next-generation aircraft engines. Major aerospace manufacturers including GE Aviation, Rolls-Royce, and Safran have made substantial investments in SiC/SiC CMC technology, recognizing its potential to significantly improve fuel efficiency and reduce emissions.

Power generation represents the second-largest market segment at 25%, with industrial applications comprising the remaining 10%. The power generation sector's interest is primarily focused on land-based gas turbines, where efficiency improvements of 1-2% translate to substantial operational cost savings and reduced carbon emissions over the equipment lifecycle.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (31%), Asia-Pacific (22%), and rest of the world (5%). The United States maintains technological leadership through significant defense and aerospace investments, while Japan and Germany have established strong positions in industrial applications of these materials.

Market drivers include increasingly stringent environmental regulations, particularly in aviation where the International Civil Aviation Organization has mandated a 50% reduction in CO2 emissions by 2050 compared to 2005 levels. Additionally, the push for higher operating temperatures in gas turbines to improve thermodynamic efficiency creates natural demand for SiC/SiC CMC components protected by advanced environmental barrier coatings.

Supply chain constraints represent a significant market challenge, with limited raw material suppliers and specialized manufacturing capabilities creating bottlenecks. The high production costs associated with these advanced materials have restricted their application primarily to high-value sectors where performance benefits justify the premium.

Looking forward, market penetration is expected to accelerate as manufacturing processes mature and economies of scale reduce costs. The automotive sector, particularly for high-performance and electric vehicles, represents an emerging opportunity as these materials find applications in brake systems and powertrain components requiring exceptional thermal stability.

The aerospace sector currently dominates the application landscape, accounting for roughly 65% of the total market share. This dominance stems from the critical need for lightweight, high-temperature resistant materials in next-generation aircraft engines. Major aerospace manufacturers including GE Aviation, Rolls-Royce, and Safran have made substantial investments in SiC/SiC CMC technology, recognizing its potential to significantly improve fuel efficiency and reduce emissions.

Power generation represents the second-largest market segment at 25%, with industrial applications comprising the remaining 10%. The power generation sector's interest is primarily focused on land-based gas turbines, where efficiency improvements of 1-2% translate to substantial operational cost savings and reduced carbon emissions over the equipment lifecycle.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (31%), Asia-Pacific (22%), and rest of the world (5%). The United States maintains technological leadership through significant defense and aerospace investments, while Japan and Germany have established strong positions in industrial applications of these materials.

Market drivers include increasingly stringent environmental regulations, particularly in aviation where the International Civil Aviation Organization has mandated a 50% reduction in CO2 emissions by 2050 compared to 2005 levels. Additionally, the push for higher operating temperatures in gas turbines to improve thermodynamic efficiency creates natural demand for SiC/SiC CMC components protected by advanced environmental barrier coatings.

Supply chain constraints represent a significant market challenge, with limited raw material suppliers and specialized manufacturing capabilities creating bottlenecks. The high production costs associated with these advanced materials have restricted their application primarily to high-value sectors where performance benefits justify the premium.

Looking forward, market penetration is expected to accelerate as manufacturing processes mature and economies of scale reduce costs. The automotive sector, particularly for high-performance and electric vehicles, represents an emerging opportunity as these materials find applications in brake systems and powertrain components requiring exceptional thermal stability.

Current EBC Technical Challenges

Environmental Barrier Coatings (EBCs) for SiC/SiC ceramic matrix composites (CMCs) face several critical technical challenges that currently limit their widespread implementation in turbine components. The primary challenge remains the achievement of long-term durability under extreme operating conditions, where temperatures can exceed 1400°C in modern high-efficiency turbine systems. These harsh environments create complex degradation mechanisms that conventional coating systems struggle to withstand.

Water vapor corrosion represents one of the most significant challenges for EBCs. In combustion environments, silicon-based ceramics react with water vapor to form volatile silicon hydroxide species, leading to recession rates that can compromise component integrity. Current EBC systems provide only partial protection against this phenomenon, particularly at the elevated temperatures required for next-generation turbines.

Coefficient of thermal expansion (CTE) mismatch between the coating layers and the SiC/SiC substrate continues to be a persistent issue. This mismatch generates substantial thermal stresses during thermal cycling, resulting in coating delamination and spallation after extended service. Despite significant research efforts, achieving compatible CTE values across the entire coating system while maintaining other required properties remains elusive.

Interface stability presents another major technical hurdle. The chemical reactions occurring at the interfaces between different coating layers and the substrate can form undesirable reaction products that compromise adhesion and mechanical integrity. These reactions are accelerated at higher operating temperatures, creating a significant barrier to achieving the 30,000+ hour durability required for commercial aviation applications.

Erosion resistance is increasingly recognized as a critical challenge for EBC systems. Particulates in the gas stream can cause progressive material removal through impact damage, especially at the leading edges of turbine components. Current coating compositions that excel in thermal and chemical protection often exhibit insufficient mechanical properties to withstand this erosion damage.

Manufacturing scalability and reproducibility constitute significant technical barriers. Advanced EBC systems typically require complex deposition processes such as plasma spraying or chemical vapor deposition, which present challenges in achieving uniform coating thickness and microstructure across geometrically complex turbine components. The industry still lacks standardized, cost-effective manufacturing protocols for consistent high-quality EBC application.

Diagnostic and prognostic capabilities for in-service EBC health monitoring remain underdeveloped. Non-destructive evaluation techniques capable of detecting early-stage coating degradation before catastrophic failure occurs are limited, hampering the implementation of condition-based maintenance strategies for CMC components with EBCs.

Water vapor corrosion represents one of the most significant challenges for EBCs. In combustion environments, silicon-based ceramics react with water vapor to form volatile silicon hydroxide species, leading to recession rates that can compromise component integrity. Current EBC systems provide only partial protection against this phenomenon, particularly at the elevated temperatures required for next-generation turbines.

Coefficient of thermal expansion (CTE) mismatch between the coating layers and the SiC/SiC substrate continues to be a persistent issue. This mismatch generates substantial thermal stresses during thermal cycling, resulting in coating delamination and spallation after extended service. Despite significant research efforts, achieving compatible CTE values across the entire coating system while maintaining other required properties remains elusive.

Interface stability presents another major technical hurdle. The chemical reactions occurring at the interfaces between different coating layers and the substrate can form undesirable reaction products that compromise adhesion and mechanical integrity. These reactions are accelerated at higher operating temperatures, creating a significant barrier to achieving the 30,000+ hour durability required for commercial aviation applications.

Erosion resistance is increasingly recognized as a critical challenge for EBC systems. Particulates in the gas stream can cause progressive material removal through impact damage, especially at the leading edges of turbine components. Current coating compositions that excel in thermal and chemical protection often exhibit insufficient mechanical properties to withstand this erosion damage.

Manufacturing scalability and reproducibility constitute significant technical barriers. Advanced EBC systems typically require complex deposition processes such as plasma spraying or chemical vapor deposition, which present challenges in achieving uniform coating thickness and microstructure across geometrically complex turbine components. The industry still lacks standardized, cost-effective manufacturing protocols for consistent high-quality EBC application.

Diagnostic and prognostic capabilities for in-service EBC health monitoring remain underdeveloped. Non-destructive evaluation techniques capable of detecting early-stage coating degradation before catastrophic failure occurs are limited, hampering the implementation of condition-based maintenance strategies for CMC components with EBCs.

Current EBC Solutions for SiC/SiC CMCs

01 Composition and structure of EBCs for enhanced durability

Environmental Barrier Coatings can be formulated with specific compositions and structures to enhance their durability and protection capabilities. These coatings typically consist of multiple layers with different materials such as rare earth silicates, mullite, or zirconia. The layered structure helps to provide thermal protection, resist environmental degradation, and improve overall coating lifespan. The composition can be tailored to resist specific environmental challenges such as water vapor, calcium-magnesium-alumino-silicate (CMAS) infiltration, and thermal cycling.- Composition of Environmental Barrier Coatings: Environmental Barrier Coatings (EBCs) can be formulated with various materials to enhance protection and durability. These compositions typically include ceramic materials, rare earth silicates, and multi-layered structures that provide resistance against environmental degradation. The specific composition of the coating plays a crucial role in determining its effectiveness in protecting underlying substrates from high-temperature oxidation, water vapor corrosion, and other environmental factors.

- Advanced manufacturing techniques for EBCs: Various manufacturing techniques are employed to produce high-performance Environmental Barrier Coatings with enhanced durability. These include plasma spraying, chemical vapor deposition, physical vapor deposition, and solution-based methods. Advanced processing techniques can create coatings with optimized microstructures, reduced porosity, and improved adhesion to substrates, resulting in superior protection against environmental degradation and extended service life in harsh operating conditions.

- Self-healing and damage-resistant EBC systems: Self-healing Environmental Barrier Coating systems incorporate mechanisms that allow the coating to repair damage during operation. These innovative systems may include phase-transforming materials, sacrificial layers, or reactive components that can fill cracks and voids when exposed to high temperatures. By incorporating self-healing capabilities, these coatings can maintain their protective function even after experiencing mechanical damage or thermal cycling, significantly extending component life in harsh environments.

- Testing and evaluation methods for EBC durability: Specialized testing methodologies have been developed to evaluate the durability and protective capabilities of Environmental Barrier Coatings. These include thermal cycling tests, steam exposure tests, erosion resistance evaluations, and accelerated aging protocols. Advanced characterization techniques such as electron microscopy, spectroscopy, and non-destructive testing are employed to assess coating integrity, identify failure mechanisms, and predict service life under various operating conditions.

- Multi-functional EBC systems for extreme environments: Multi-functional Environmental Barrier Coating systems are designed to provide protection against multiple degradation mechanisms simultaneously. These advanced systems combine thermal insulation, oxidation resistance, water vapor protection, and mechanical durability in a single coating architecture. By incorporating multiple functional layers or composite materials with complementary properties, these coatings can protect components in extreme environments such as gas turbines, hypersonic vehicles, and advanced energy systems where components are exposed to combinations of high temperature, pressure, and corrosive species.

02 Self-healing mechanisms in EBCs

Self-healing mechanisms can be incorporated into Environmental Barrier Coatings to improve their longevity and performance. These mechanisms involve the inclusion of materials that can react to damage by filling cracks or voids that form during service. For example, certain glass-forming additives can melt and flow into cracks at high temperatures, effectively sealing them and preventing further environmental attack. Other approaches include the use of reactive phases that expand upon oxidation to fill damaged areas, or the incorporation of nanoparticles that can migrate to damaged regions.Expand Specific Solutions03 Advanced deposition techniques for EBCs

Various advanced deposition techniques can be employed to create Environmental Barrier Coatings with superior protection and durability characteristics. These include plasma spraying, physical vapor deposition, chemical vapor deposition, and solution precursor methods. Each technique offers different advantages in terms of coating density, adhesion, thickness control, and microstructure. For instance, plasma spraying allows for rapid deposition of thick coatings, while vapor deposition methods can produce denser coatings with better controlled microstructures. The choice of deposition technique significantly impacts the coating's resistance to environmental degradation.Expand Specific Solutions04 CMAS resistance strategies for EBCs

Calcium-Magnesium-Alumino-Silicate (CMAS) infiltration is a major degradation mechanism for Environmental Barrier Coatings in high-temperature applications. Various strategies can be employed to enhance CMAS resistance, including the development of rare earth-based coatings that form apatite phases upon reaction with CMAS, creating a protective barrier that prevents further infiltration. Other approaches include designing coatings with low wettability to molten CMAS, incorporating sacrificial layers that react with CMAS to form high-melting point compounds, and creating dense microstructures that physically impede CMAS penetration.Expand Specific Solutions05 Testing and evaluation methods for EBC durability

Specialized testing and evaluation methods are crucial for assessing the durability and protection capabilities of Environmental Barrier Coatings. These include thermal cycling tests to evaluate resistance to temperature fluctuations, steam exposure tests to simulate water vapor environments, erosion testing to assess mechanical durability, and long-term high-temperature exposure tests. Advanced characterization techniques such as electron microscopy, X-ray diffraction, and spectroscopic methods are employed to analyze coating microstructure, phase composition, and degradation mechanisms. These testing protocols help in predicting coating performance and lifespan in actual service conditions.Expand Specific Solutions

Leading Companies in EBC Technology

Environmental Barrier Coatings (EBCs) for SiC/SiC CMC turbine components are in a growth phase, with the market expanding as aerospace and power generation industries seek higher efficiency and durability. The global market is projected to reach significant scale as gas turbine technologies advance toward higher operating temperatures. Leading players include established aerospace giants like General Electric, Rolls-Royce, RTX (formerly United Technologies), and Safran, who are investing heavily in EBC technology development. Research institutions such as Northwestern Polytechnical University and CNRS collaborate with industry to advance coating technologies. Technical maturity varies, with first-generation EBCs already deployed while more advanced multi-layer systems are still under development, particularly for extreme temperature applications exceeding 1400°C.

General Electric Company

Technical Solution: GE has developed a multi-layered Environmental Barrier Coating (EBC) system specifically designed for SiC/SiC ceramic matrix composites used in turbine components. Their approach typically consists of a bond coat (often silicon-based), an intermediate layer (rare earth silicates), and a top coat (gadolinium zirconate or other rare earth zirconates). GE's EBC technology incorporates self-healing capabilities through the addition of secondary phases that can flow and seal cracks during thermal cycling. Their coatings are applied using both atmospheric plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) techniques, with the latter providing superior strain tolerance through a columnar microstructure. GE has demonstrated that their EBCs can protect SiC/SiC CMCs at temperatures exceeding 1316°C (2400°F) for thousands of hours, significantly extending component life in harsh combustion environments where water vapor would otherwise rapidly degrade unprotected SiC surfaces.

Strengths: Industry-leading experience with implementation in actual engine environments; proprietary self-healing coating formulations; advanced manufacturing capabilities for complex geometries. Weaknesses: Higher manufacturing costs compared to conventional materials; potential rare earth material supply chain vulnerabilities; requires specialized application equipment and expertise.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed a sophisticated multi-layer EBC system for SiC/SiC CMC turbine components featuring a silicon bond coat, rare earth silicate intermediate layers, and an erosion-resistant top coat. Their proprietary "SMART" (Self-Monitoring Analysis and Reporting Technology) EBC incorporates embedded sensors that enable real-time monitoring of coating degradation and remaining useful life. Rolls-Royce utilizes a combination of air plasma spray (APS) and suspension plasma spray (SPS) techniques to achieve precise microstructural control, with particular focus on porosity management to enhance thermal cycling resistance. Their EBC system is designed to withstand temperatures up to 1400°C while providing protection against calcium-magnesium-alumino-silicate (CMAS) infiltration through the incorporation of sacrificial reaction layers that form stable crystalline phases upon CMAS interaction. Recent developments include graded compositions throughout the coating thickness to minimize thermal expansion mismatch stresses and improve overall durability in engine operating conditions.

Strengths: Advanced health monitoring capabilities integrated into coating systems; superior CMAS resistance; extensive engine testing experience with demonstrated durability. Weaknesses: Complex manufacturing process with multiple specialized steps; higher initial implementation costs; requires sophisticated quality control systems to ensure coating consistency.

Key Patents and Technical Literature

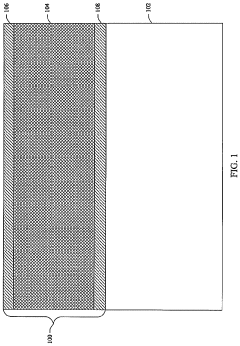

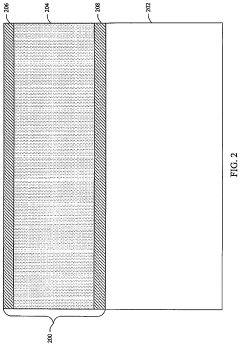

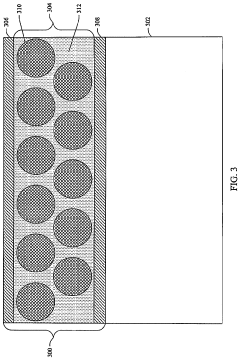

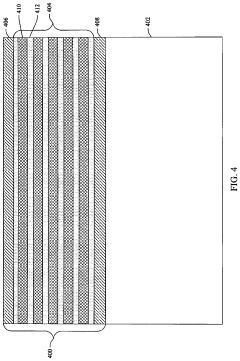

Advanced high temperature environmental barrier coating for SiC/SiC ceramic matrix composites

PatentActiveUS10604454B1

Innovation

- The development of advanced high-temperature environmental barrier coating systems featuring a bond coat system with silicon/silicide or oxide/silicate components, including rare earth doped silicon alloys and highly stable oxide/silicate materials, which provide enhanced adhesion, oxidation resistance, and self-healing capabilities, enabling operation up to 2700°F (1482°C) with reduced oxygen activity and thermal expansion matching Si-based ceramics.

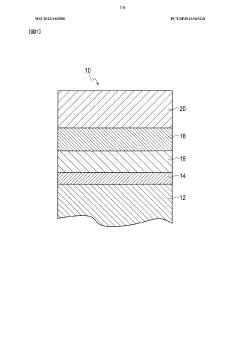

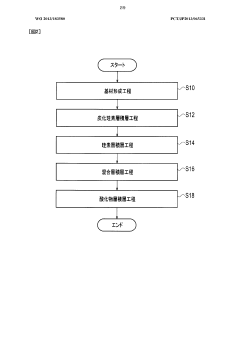

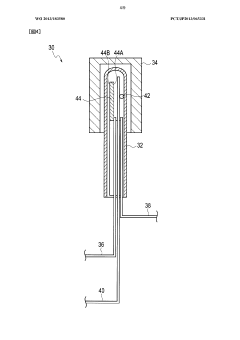

Environmental barrier coated ceramic matrix composite component and method for manufacturing same

PatentWO2013183580A1

Innovation

- A ceramic matrix composite material with a multilayer coating comprising a silicon carbide layer, a silicon layer, a mixed layer of mullite and ytterbium silicate, and an oxide layer, where each layer is carefully thickness-controlled and formed using specific deposition methods to enhance adhesion and thermal expansion matching, thereby improving durability and resistance.

Environmental Impact Assessment

The environmental impact of Environmental Barrier Coatings (EBCs) for SiC/SiC Ceramic Matrix Composite (CMC) turbine components extends across multiple dimensions of sustainability and ecological considerations. These advanced coating systems, while primarily designed to protect CMC components from harsh operating environments, also contribute significantly to environmental conservation efforts through improved engine efficiency and reduced emissions.

The implementation of EBCs on SiC/SiC CMC turbine components enables higher operating temperatures in gas turbine engines, directly translating to improved thermal efficiency. This efficiency gain results in reduced fuel consumption per unit of power output, which consequently decreases the carbon footprint of aircraft and power generation systems. Studies indicate that advanced turbine systems utilizing EBC-protected CMC components can achieve 5-8% improvement in fuel efficiency compared to conventional metal-based systems.

Emissions reduction represents another critical environmental benefit of EBC technology. The higher temperature capabilities facilitated by these coatings lead to more complete combustion processes, reducing the formation of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Environmental monitoring data from test engines shows potential NOx reduction of up to 30% when operating with EBC-protected CMC components at optimal conditions.

From a life cycle perspective, EBCs contribute to sustainability through extended component lifespans. The protective nature of these coatings significantly reduces the degradation rate of SiC/SiC CMC components, potentially doubling or tripling their operational lifetime compared to uncoated alternatives. This longevity reduces the environmental burden associated with component manufacturing, replacement, and disposal processes.

The manufacturing processes for EBCs do present certain environmental challenges that warrant consideration. Techniques such as plasma spraying, chemical vapor deposition, and slurry processes involve energy-intensive operations and may utilize materials with environmental implications. Recent advancements in water-based slurry systems and reduced-temperature deposition techniques have begun addressing these concerns, lowering the environmental footprint of coating production.

End-of-life management for EBC-coated components remains an evolving field. The multi-material nature of these systems presents recycling challenges, as separation of coating layers from the CMC substrate requires specialized processes. Research into recovery methods for rare earth elements and other valuable materials used in EBCs shows promising potential for closing the material loop and reducing waste.

Regulatory frameworks increasingly recognize the environmental benefits of advanced turbine technologies incorporating EBCs. Carbon credit systems and emissions standards in both aviation and power generation sectors provide incentives for adoption of these more efficient systems, accelerating their implementation and associated environmental benefits.

The implementation of EBCs on SiC/SiC CMC turbine components enables higher operating temperatures in gas turbine engines, directly translating to improved thermal efficiency. This efficiency gain results in reduced fuel consumption per unit of power output, which consequently decreases the carbon footprint of aircraft and power generation systems. Studies indicate that advanced turbine systems utilizing EBC-protected CMC components can achieve 5-8% improvement in fuel efficiency compared to conventional metal-based systems.

Emissions reduction represents another critical environmental benefit of EBC technology. The higher temperature capabilities facilitated by these coatings lead to more complete combustion processes, reducing the formation of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Environmental monitoring data from test engines shows potential NOx reduction of up to 30% when operating with EBC-protected CMC components at optimal conditions.

From a life cycle perspective, EBCs contribute to sustainability through extended component lifespans. The protective nature of these coatings significantly reduces the degradation rate of SiC/SiC CMC components, potentially doubling or tripling their operational lifetime compared to uncoated alternatives. This longevity reduces the environmental burden associated with component manufacturing, replacement, and disposal processes.

The manufacturing processes for EBCs do present certain environmental challenges that warrant consideration. Techniques such as plasma spraying, chemical vapor deposition, and slurry processes involve energy-intensive operations and may utilize materials with environmental implications. Recent advancements in water-based slurry systems and reduced-temperature deposition techniques have begun addressing these concerns, lowering the environmental footprint of coating production.

End-of-life management for EBC-coated components remains an evolving field. The multi-material nature of these systems presents recycling challenges, as separation of coating layers from the CMC substrate requires specialized processes. Research into recovery methods for rare earth elements and other valuable materials used in EBCs shows promising potential for closing the material loop and reducing waste.

Regulatory frameworks increasingly recognize the environmental benefits of advanced turbine technologies incorporating EBCs. Carbon credit systems and emissions standards in both aviation and power generation sectors provide incentives for adoption of these more efficient systems, accelerating their implementation and associated environmental benefits.

Durability and Lifecycle Analysis

The durability and lifecycle analysis of Environmental Barrier Coatings (EBCs) for SiC/SiC Ceramic Matrix Composite (CMC) turbine components represents a critical aspect of their implementation in advanced gas turbine engines. Current generation EBCs typically demonstrate operational lifetimes ranging from 5,000 to 10,000 hours under standard engine conditions, falling significantly short of the desired 30,000+ hours required for commercial aviation applications.

Accelerated testing methodologies have been developed to evaluate long-term performance, including thermal cycling tests, steam-jet exposure, and CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance assessments. These tests reveal that coating failure typically occurs through multiple degradation mechanisms acting simultaneously, including thermochemical recession, interfacial debonding, and thermomechanical fatigue.

Field data analysis from experimental engines shows that EBC degradation rates are highly dependent on operational parameters. Components experiencing frequent thermal cycling exhibit significantly reduced coating lifespans compared to those operating under steady-state conditions. Statistical modeling suggests that thermal gradient cycling contributes approximately 60% to overall coating degradation, while chemical attack accounts for roughly 30%, with the remainder attributed to erosion and foreign object damage.

Lifecycle cost analysis indicates that despite their higher initial manufacturing costs, advanced multi-layered EBC systems can provide substantial economic benefits through extended component lifespans. The implementation of self-healing EBC variants has demonstrated potential to extend service intervals by up to 40% in laboratory conditions, though field validation remains limited.

Predictive modeling tools have been developed to forecast EBC degradation based on operational parameters. These models incorporate materials science fundamentals with empirical data to provide reasonably accurate lifespan predictions, typically within ±15% of actual observed lifetimes. Such tools enable condition-based maintenance strategies rather than time-based approaches, optimizing component utilization.

Recent advancements in non-destructive evaluation techniques, including infrared thermography and acoustic emission monitoring, have improved in-service inspection capabilities. These methods can detect subsurface delamination and crack formation before catastrophic coating failure occurs, enabling more precise remaining useful life assessments and maintenance planning.

Accelerated testing methodologies have been developed to evaluate long-term performance, including thermal cycling tests, steam-jet exposure, and CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance assessments. These tests reveal that coating failure typically occurs through multiple degradation mechanisms acting simultaneously, including thermochemical recession, interfacial debonding, and thermomechanical fatigue.

Field data analysis from experimental engines shows that EBC degradation rates are highly dependent on operational parameters. Components experiencing frequent thermal cycling exhibit significantly reduced coating lifespans compared to those operating under steady-state conditions. Statistical modeling suggests that thermal gradient cycling contributes approximately 60% to overall coating degradation, while chemical attack accounts for roughly 30%, with the remainder attributed to erosion and foreign object damage.

Lifecycle cost analysis indicates that despite their higher initial manufacturing costs, advanced multi-layered EBC systems can provide substantial economic benefits through extended component lifespans. The implementation of self-healing EBC variants has demonstrated potential to extend service intervals by up to 40% in laboratory conditions, though field validation remains limited.

Predictive modeling tools have been developed to forecast EBC degradation based on operational parameters. These models incorporate materials science fundamentals with empirical data to provide reasonably accurate lifespan predictions, typically within ±15% of actual observed lifetimes. Such tools enable condition-based maintenance strategies rather than time-based approaches, optimizing component utilization.

Recent advancements in non-destructive evaluation techniques, including infrared thermography and acoustic emission monitoring, have improved in-service inspection capabilities. These methods can detect subsurface delamination and crack formation before catastrophic coating failure occurs, enabling more precise remaining useful life assessments and maintenance planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!