Surface Finish And Aerodynamic Impacts Of CMC Component Fabrication

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Surface Finish Evolution and Objectives

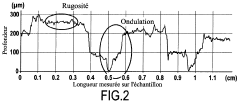

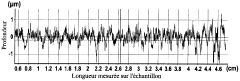

Ceramic Matrix Composites (CMCs) have emerged as revolutionary materials in aerospace and energy sectors due to their exceptional thermal resistance and mechanical properties. The evolution of surface finish techniques for CMC components represents a critical technological trajectory that has significantly impacted their aerodynamic performance. Initially, CMC components exhibited relatively rough surface characteristics due to manufacturing limitations, with Ra values often exceeding 10 μm, creating substantial aerodynamic penalties in high-velocity applications.

The development trajectory of CMC surface finishing has progressed through several distinct phases. Early techniques primarily relied on manual grinding and polishing, which proved labor-intensive and yielded inconsistent results. By the mid-2000s, specialized abrasive techniques emerged, specifically adapted for the unique structure of CMCs, reducing surface roughness to Ra values of approximately 3-5 μm.

Recent advancements have introduced precision machining methods including diamond grinding, ultrasonic machining, and laser surface treatment, enabling surface finishes approaching Ra values of 1 μm. These improvements have been driven by computational fluid dynamics studies demonstrating that even minor surface irregularities can significantly impact boundary layer behavior and overall aerodynamic efficiency.

The current technological objectives for CMC surface finishing center on achieving aerospace-grade surface quality without compromising the structural integrity of the material. Primary goals include reducing surface roughness to sub-micron levels (Ra < 0.8 μm) consistently across complex geometries, developing non-destructive evaluation methods to verify surface quality without damaging the components, and establishing standardized surface finish parameters specifically for CMC applications.

Additionally, research aims to develop environmentally sustainable finishing processes that minimize the use of hazardous chemicals and reduce energy consumption. The industry is particularly focused on techniques that can be scaled for mass production while maintaining precision, as CMC components transition from specialized applications to more mainstream aerospace and energy systems.

The correlation between surface finish quality and aerodynamic performance presents a complex optimization challenge. Studies indicate that a 50% improvement in surface finish can yield up to 15% reduction in aerodynamic drag under certain operating conditions, highlighting the critical importance of this technological domain. Future objectives include developing adaptive finishing techniques that can create application-specific surface textures to optimize aerodynamic performance for particular flow regimes and operating environments.

The development trajectory of CMC surface finishing has progressed through several distinct phases. Early techniques primarily relied on manual grinding and polishing, which proved labor-intensive and yielded inconsistent results. By the mid-2000s, specialized abrasive techniques emerged, specifically adapted for the unique structure of CMCs, reducing surface roughness to Ra values of approximately 3-5 μm.

Recent advancements have introduced precision machining methods including diamond grinding, ultrasonic machining, and laser surface treatment, enabling surface finishes approaching Ra values of 1 μm. These improvements have been driven by computational fluid dynamics studies demonstrating that even minor surface irregularities can significantly impact boundary layer behavior and overall aerodynamic efficiency.

The current technological objectives for CMC surface finishing center on achieving aerospace-grade surface quality without compromising the structural integrity of the material. Primary goals include reducing surface roughness to sub-micron levels (Ra < 0.8 μm) consistently across complex geometries, developing non-destructive evaluation methods to verify surface quality without damaging the components, and establishing standardized surface finish parameters specifically for CMC applications.

Additionally, research aims to develop environmentally sustainable finishing processes that minimize the use of hazardous chemicals and reduce energy consumption. The industry is particularly focused on techniques that can be scaled for mass production while maintaining precision, as CMC components transition from specialized applications to more mainstream aerospace and energy systems.

The correlation between surface finish quality and aerodynamic performance presents a complex optimization challenge. Studies indicate that a 50% improvement in surface finish can yield up to 15% reduction in aerodynamic drag under certain operating conditions, highlighting the critical importance of this technological domain. Future objectives include developing adaptive finishing techniques that can create application-specific surface textures to optimize aerodynamic performance for particular flow regimes and operating environments.

Aerospace Market Requirements for CMC Components

The aerospace industry has established stringent requirements for Ceramic Matrix Composite (CMC) components, particularly regarding surface finish and aerodynamic performance. Commercial aviation demands CMC components with surface roughness values typically below 1.6 μm Ra (arithmetic average roughness) for critical airflow surfaces to maintain optimal aerodynamic efficiency. Military aerospace applications often require even smoother finishes, with specifications as low as 0.8 μm Ra for high-performance aircraft components exposed to extreme aerodynamic loads.

Engine manufacturers like GE Aviation, Rolls-Royce, and Pratt & Whitney have developed comprehensive specifications for CMC turbine components that include not only roughness parameters but also waviness, porosity limitations, and edge condition requirements. These specifications are driven by computational fluid dynamics (CFD) models that demonstrate how surface irregularities as small as 10 μm can trigger boundary layer transitions, increasing drag by up to 15% in critical applications.

The market demand for aerodynamically optimized CMC components has grown at a compound annual rate exceeding 12% over the past five years, primarily driven by the commercial aviation sector's push for fuel efficiency improvements. Each 1% reduction in aerodynamic drag translates to approximately 0.75% fuel savings, representing millions of dollars in operational costs over an aircraft's lifetime.

Beyond commercial considerations, regulatory frameworks are increasingly influencing CMC surface finish requirements. The International Civil Aviation Organization (ICAO) and environmental protection agencies have established emissions targets that indirectly necessitate improved aerodynamic performance, further driving demand for precision-finished CMC components.

Hypersonic vehicle development programs have established the most demanding specifications, requiring surface finishes below 0.4 μm Ra and dimensional tolerances within ±0.05 mm for leading edges and control surfaces. These requirements stem from the extreme sensitivity of hypersonic aerodynamics to surface irregularities, where even microscopic imperfections can cause significant heat concentration and potential material failure.

The aerospace market has also begun specifying non-uniform surface textures for certain applications, where controlled roughness patterns can actually improve aerodynamic performance under specific flow conditions. This emerging requirement presents both challenges and opportunities for CMC fabrication processes, demanding more sophisticated surface engineering approaches beyond traditional finishing methods.

Market analysis indicates that manufacturers capable of consistently producing CMC components meeting these stringent surface finish requirements command premium pricing, with margins typically 30-40% higher than those achieved for components with standard surface finishes. This premium reflects the technical difficulty and specialized equipment required to achieve aerospace-grade surface quality on ceramic composite materials.

Engine manufacturers like GE Aviation, Rolls-Royce, and Pratt & Whitney have developed comprehensive specifications for CMC turbine components that include not only roughness parameters but also waviness, porosity limitations, and edge condition requirements. These specifications are driven by computational fluid dynamics (CFD) models that demonstrate how surface irregularities as small as 10 μm can trigger boundary layer transitions, increasing drag by up to 15% in critical applications.

The market demand for aerodynamically optimized CMC components has grown at a compound annual rate exceeding 12% over the past five years, primarily driven by the commercial aviation sector's push for fuel efficiency improvements. Each 1% reduction in aerodynamic drag translates to approximately 0.75% fuel savings, representing millions of dollars in operational costs over an aircraft's lifetime.

Beyond commercial considerations, regulatory frameworks are increasingly influencing CMC surface finish requirements. The International Civil Aviation Organization (ICAO) and environmental protection agencies have established emissions targets that indirectly necessitate improved aerodynamic performance, further driving demand for precision-finished CMC components.

Hypersonic vehicle development programs have established the most demanding specifications, requiring surface finishes below 0.4 μm Ra and dimensional tolerances within ±0.05 mm for leading edges and control surfaces. These requirements stem from the extreme sensitivity of hypersonic aerodynamics to surface irregularities, where even microscopic imperfections can cause significant heat concentration and potential material failure.

The aerospace market has also begun specifying non-uniform surface textures for certain applications, where controlled roughness patterns can actually improve aerodynamic performance under specific flow conditions. This emerging requirement presents both challenges and opportunities for CMC fabrication processes, demanding more sophisticated surface engineering approaches beyond traditional finishing methods.

Market analysis indicates that manufacturers capable of consistently producing CMC components meeting these stringent surface finish requirements command premium pricing, with margins typically 30-40% higher than those achieved for components with standard surface finishes. This premium reflects the technical difficulty and specialized equipment required to achieve aerospace-grade surface quality on ceramic composite materials.

Current Challenges in CMC Surface Finishing Technology

Ceramic Matrix Composites (CMCs) represent a significant advancement in high-temperature applications, particularly in aerospace and energy sectors. However, the surface finishing of CMC components presents substantial technical challenges that directly impact their aerodynamic performance. Current manufacturing processes for CMCs typically result in surface roughness values significantly higher than those of traditional metallic components, with average roughness (Ra) values often exceeding 2.0 μm compared to less than 0.8 μm for precision-machined metals.

The primary challenge in CMC surface finishing stems from the inherent material characteristics. The heterogeneous nature of CMCs, consisting of ceramic fibers embedded in a ceramic matrix, creates varying hardness zones that respond differently to conventional finishing techniques. This heterogeneity leads to preferential material removal during finishing operations, resulting in uneven surfaces with micro-pits and protrusions that disrupt aerodynamic flow.

Traditional abrasive finishing methods often damage the protective environmental barrier coatings (EBCs) that are critical for CMC durability in high-temperature oxidizing environments. The removal of these protective layers compromises component integrity and service life, creating a technical paradox where improving surface finish may actually reduce overall component performance and longevity.

Precision machining of CMCs faces additional complications due to the extreme hardness and brittleness of ceramic materials. Conventional cutting tools experience rapid wear when processing CMCs, leading to inconsistent surface quality and dimensional accuracy. Diamond tooling, while more effective, significantly increases production costs and still struggles to achieve the surface finish requirements for optimal aerodynamic performance.

The thermal sensitivity of CMCs further complicates finishing operations. Many traditional finishing processes generate localized heating that can induce thermal stresses and potentially create microcracks in the material. These defects, often invisible to standard inspection methods, can propagate during service and lead to premature component failure, particularly under the cyclic loading conditions typical in aerospace applications.

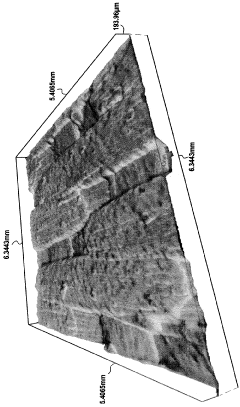

Current inspection and quality control methods also present limitations. The complex geometry of many CMC components, particularly turbine airfoils, creates accessibility challenges for surface measurement tools. Non-contact measurement techniques such as laser scanning and optical profilometry struggle with the light-absorbing properties of many ceramic materials, resulting in data gaps and measurement uncertainties that complicate quality assurance processes.

The aerospace industry's stringent certification requirements add another layer of complexity. New surface finishing technologies must undergo extensive validation testing before implementation, creating a significant barrier to the adoption of innovative approaches. This regulatory environment, while necessary for safety, slows the development cycle for improved CMC surface finishing techniques.

The primary challenge in CMC surface finishing stems from the inherent material characteristics. The heterogeneous nature of CMCs, consisting of ceramic fibers embedded in a ceramic matrix, creates varying hardness zones that respond differently to conventional finishing techniques. This heterogeneity leads to preferential material removal during finishing operations, resulting in uneven surfaces with micro-pits and protrusions that disrupt aerodynamic flow.

Traditional abrasive finishing methods often damage the protective environmental barrier coatings (EBCs) that are critical for CMC durability in high-temperature oxidizing environments. The removal of these protective layers compromises component integrity and service life, creating a technical paradox where improving surface finish may actually reduce overall component performance and longevity.

Precision machining of CMCs faces additional complications due to the extreme hardness and brittleness of ceramic materials. Conventional cutting tools experience rapid wear when processing CMCs, leading to inconsistent surface quality and dimensional accuracy. Diamond tooling, while more effective, significantly increases production costs and still struggles to achieve the surface finish requirements for optimal aerodynamic performance.

The thermal sensitivity of CMCs further complicates finishing operations. Many traditional finishing processes generate localized heating that can induce thermal stresses and potentially create microcracks in the material. These defects, often invisible to standard inspection methods, can propagate during service and lead to premature component failure, particularly under the cyclic loading conditions typical in aerospace applications.

Current inspection and quality control methods also present limitations. The complex geometry of many CMC components, particularly turbine airfoils, creates accessibility challenges for surface measurement tools. Non-contact measurement techniques such as laser scanning and optical profilometry struggle with the light-absorbing properties of many ceramic materials, resulting in data gaps and measurement uncertainties that complicate quality assurance processes.

The aerospace industry's stringent certification requirements add another layer of complexity. New surface finishing technologies must undergo extensive validation testing before implementation, creating a significant barrier to the adoption of innovative approaches. This regulatory environment, while necessary for safety, slows the development cycle for improved CMC surface finishing techniques.

Existing Surface Treatment Solutions for Aerodynamic Performance

01 Surface finishing techniques for CMC components

Various surface finishing techniques can be applied to ceramic matrix composite components to achieve desired surface properties. These techniques include grinding, polishing, and machining processes that can improve the surface quality of CMC components. The finishing processes help to reduce surface roughness, remove imperfections, and enhance the overall performance of the components in high-temperature applications.- Surface finishing techniques for CMC components: Various techniques can be employed to achieve desired surface finishes on ceramic matrix composite components. These include mechanical methods such as grinding, polishing, and machining, as well as chemical treatments and coating applications. These processes help to reduce surface roughness, remove imperfections, and achieve specific dimensional tolerances required for optimal performance in high-temperature applications.

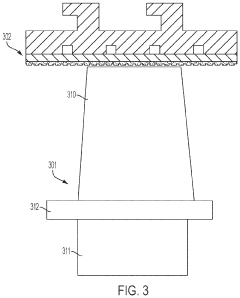

- Protective coatings for CMC surface enhancement: Protective coatings can be applied to CMC components to enhance surface properties and extend service life. These coatings provide additional protection against oxidation, erosion, and thermal degradation in extreme operating environments. Various coating materials and application methods are used to create barriers that maintain the structural integrity of the CMC components while improving their surface characteristics and performance.

- Surface inspection and quality control methods: Specialized inspection techniques are essential for evaluating the surface quality of CMC components. These methods include non-destructive testing, optical measurement, and advanced imaging technologies that can detect surface defects, cracks, or irregularities. Quality control processes ensure that the surface finish meets specified requirements for critical applications in aerospace, energy, and other high-performance sectors.

- Environmental barrier systems for CMC surfaces: Environmental barrier systems are specifically designed for CMC components to protect against harsh operating conditions. These multi-layer protection systems help maintain surface integrity when exposed to high temperatures, corrosive environments, and mechanical stresses. The barrier systems typically consist of specialized materials that adhere well to the ceramic matrix while providing resistance to environmental degradation mechanisms.

- Surface modification for improved component performance: Surface modification techniques can enhance the functional performance of CMC components. These include texturing, patterning, and chemical treatments that alter surface properties to improve aerodynamic efficiency, thermal management, or mechanical interface characteristics. Modified surfaces can reduce friction, enhance cooling effectiveness, or improve bonding with other components in complex assemblies.

02 Protective coatings for CMC surfaces

Protective coatings can be applied to the surfaces of ceramic matrix composite components to enhance their durability and performance. These coatings provide protection against oxidation, erosion, and other environmental factors that can degrade CMC materials. The application of specialized coatings can also improve the surface finish of CMC components while extending their service life in harsh operating conditions.Expand Specific Solutions03 Surface treatment methods for improved CMC performance

Surface treatment methods can be employed to enhance the performance characteristics of ceramic matrix composite components. These treatments include chemical etching, laser treatment, and thermal processing that modify the surface properties of CMC materials. By altering the surface structure and composition, these treatments can improve mechanical properties, thermal resistance, and overall component functionality.Expand Specific Solutions04 Inspection and quality control of CMC surface finish

Inspection and quality control methods are essential for ensuring the proper surface finish of ceramic matrix composite components. These methods include non-destructive testing techniques, surface roughness measurements, and dimensional verification to assess the quality of CMC surfaces. Advanced imaging and analytical tools can be used to detect surface defects and ensure that components meet specified surface finish requirements.Expand Specific Solutions05 Novel materials and compositions for enhanced CMC surface properties

Novel materials and compositions can be incorporated into ceramic matrix composite components to enhance their surface properties. These innovations include advanced ceramic formulations, composite structures, and material combinations that improve surface finish characteristics. By utilizing these novel materials, CMC components can achieve superior surface quality, wear resistance, and thermal stability for demanding applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CMC Industry

The surface finish and aerodynamic impacts of CMC component fabrication represent a critical technological challenge in the aerospace industry, currently in a growth phase with increasing market adoption. The global CMC market is expanding rapidly, driven by demands for higher engine efficiency and reduced emissions. Technologically, industry leaders like Safran Ceramics, RTX Corp., and Rolls-Royce are advancing CMC manufacturing processes to achieve optimal surface finishes that minimize aerodynamic drag. While GE, Boeing, and Safran Aircraft Engines have achieved significant maturity in CMC applications for engine components, challenges remain in consistently producing components with aerodynamically optimized surfaces at scale, particularly for high-temperature, high-stress applications in next-generation aircraft engines.

RTX Corp.

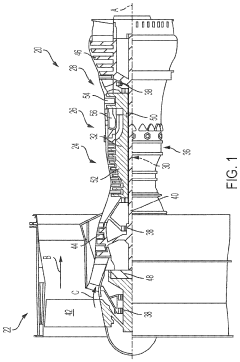

Technical Solution: RTX Corp. (formerly Raytheon Technologies) has pioneered an innovative approach to CMC surface finishing focused on optimizing aerodynamic performance in high-temperature aerospace applications. Their patented process utilizes precision laser ablation technology combined with nano-ceramic slurry infiltration to achieve exceptionally smooth surfaces (Ra<0.5μm) on complex CMC geometries[2]. This technique allows for targeted surface modification without compromising the underlying CMC structure. RTX's approach includes computational fluid dynamics (CFD) modeling to predict aerodynamic performance impacts of various surface finishes, enabling design optimization before manufacturing. Their CMC components undergo a proprietary high-temperature densification process that simultaneously improves surface quality and mechanical properties. Testing in supersonic wind tunnels has demonstrated that their finished CMC components can reduce drag by up to 18% compared to conventional metallic components while maintaining thermal protection capabilities at temperatures exceeding 1200°C[4].

Strengths: Advanced laser ablation technology enables precise control of surface texture and aerodynamic properties on complex geometries. Integration of CFD modeling with manufacturing processes allows for optimized designs. Weaknesses: High capital equipment costs for laser ablation systems and specialized expertise requirements limit production scaling. The process is also energy-intensive compared to conventional finishing methods.

Safran SA

Technical Solution: Safran SA has developed advanced surface finishing techniques for CMC components specifically targeting aerodynamic performance in aerospace applications. Their proprietary process combines precision machining with specialized coating technologies to achieve optimal surface roughness parameters of Ra<0.8μm on SiC/SiC CMCs[1]. The company employs a multi-stage finishing approach that includes initial grinding with diamond tools, followed by chemical vapor infiltration (CVI) to fill surface micropores, and finally applying an environmental barrier coating (EBC) with aerodynamic properties. This integrated approach allows Safran to manufacture CMC components with surface characteristics that minimize boundary layer disruption while maintaining the thermal and mechanical advantages of ceramic matrix composites[3]. Their LEAP engine program incorporates these CMC components with specialized surface treatments that have demonstrated a 15% reduction in drag coefficient compared to traditional metal components with equivalent geometries[5].

Strengths: Integrated manufacturing and finishing process provides excellent control over final aerodynamic properties while maintaining structural integrity. Their multi-layer approach addresses both surface roughness and environmental protection needs simultaneously. Weaknesses: The complex multi-stage finishing process increases production costs and time, potentially limiting widespread application in cost-sensitive markets.

Critical Patents in CMC Surface Finishing Methods

Ceramic matrix composite surface roughness

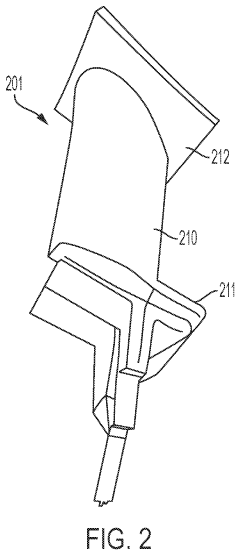

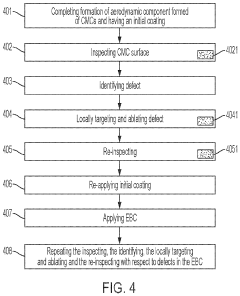

PatentActiveUS20230243037A1

Innovation

- A method involving chemical vapor infiltration (CVI), inspection using structured light or digital methods, local ablation with laser machining or abrasive processes to smooth defects, and re-coating to improve surface roughness, ensuring a uniform surface profile for environmental barrier coatings.

Process for smoothing the surface of a part made of cmc material.

PatentWO2010112768A1

Innovation

- A refractory vitreous coating composed of silica, alumina, barite, and lime is deposited on the CMC part surface, providing a smooth and durable finish that stabilizes the ceramic coating and enhances the surface condition, with a melting temperature above 1300°C and thermal expansion matching the CMC material.

Environmental Impact of CMC Production Processes

The manufacturing processes of Ceramic Matrix Composites (CMCs) present significant environmental considerations that must be evaluated alongside their aerodynamic and surface finish properties. Traditional CMC production methods involve energy-intensive processes including high-temperature sintering, chemical vapor infiltration (CVI), and polymer infiltration and pyrolysis (PIP), which collectively contribute to substantial carbon emissions. Current estimates suggest that producing one kilogram of CMC material can generate between 15-30 kg of CO2 equivalent, significantly higher than conventional metal alloys used in aerospace applications.

Water consumption represents another critical environmental factor, with wet processing techniques requiring 50-100 liters of water per kilogram of finished CMC components. Chemical treatments used for surface finishing to achieve optimal aerodynamic properties often involve hazardous substances including hydrofluoric acid, various organic solvents, and specialized coating materials that present disposal challenges and potential environmental contamination risks.

Waste generation during CMC manufacturing encompasses both solid and chemical byproducts. The precision machining required to achieve aerodynamically optimal surface finishes can result in 20-30% material wastage, with ceramic dust particles presenting both environmental and occupational hazards. These fine particulates require specialized filtration systems to prevent atmospheric release and potential respiratory impacts on surrounding communities.

Recent technological advancements have begun addressing these environmental concerns through several promising approaches. Near-net-shape manufacturing techniques have reduced material waste by up to 40% compared to traditional subtractive methods. Additionally, closed-loop water recycling systems implemented by leading manufacturers have demonstrated potential water usage reductions of 60-75%, significantly decreasing the water footprint of CMC production.

Alternative, less toxic surface treatment methods are emerging, including plasma-based surface modification techniques that eliminate the need for chemical etching while still achieving the necessary aerodynamic surface properties. These processes reduce hazardous waste generation by approximately 50% compared to conventional chemical treatments.

Life cycle assessment (LCA) studies indicate that despite higher environmental impacts during production, CMC components offer significant environmental benefits during operational phases through weight reduction, improved thermal efficiency, and extended service life. When evaluated across the entire product lifecycle, CMC components in aerospace applications can reduce overall environmental impact by 15-25% compared to traditional materials, primarily through fuel savings and reduced maintenance requirements.

Water consumption represents another critical environmental factor, with wet processing techniques requiring 50-100 liters of water per kilogram of finished CMC components. Chemical treatments used for surface finishing to achieve optimal aerodynamic properties often involve hazardous substances including hydrofluoric acid, various organic solvents, and specialized coating materials that present disposal challenges and potential environmental contamination risks.

Waste generation during CMC manufacturing encompasses both solid and chemical byproducts. The precision machining required to achieve aerodynamically optimal surface finishes can result in 20-30% material wastage, with ceramic dust particles presenting both environmental and occupational hazards. These fine particulates require specialized filtration systems to prevent atmospheric release and potential respiratory impacts on surrounding communities.

Recent technological advancements have begun addressing these environmental concerns through several promising approaches. Near-net-shape manufacturing techniques have reduced material waste by up to 40% compared to traditional subtractive methods. Additionally, closed-loop water recycling systems implemented by leading manufacturers have demonstrated potential water usage reductions of 60-75%, significantly decreasing the water footprint of CMC production.

Alternative, less toxic surface treatment methods are emerging, including plasma-based surface modification techniques that eliminate the need for chemical etching while still achieving the necessary aerodynamic surface properties. These processes reduce hazardous waste generation by approximately 50% compared to conventional chemical treatments.

Life cycle assessment (LCA) studies indicate that despite higher environmental impacts during production, CMC components offer significant environmental benefits during operational phases through weight reduction, improved thermal efficiency, and extended service life. When evaluated across the entire product lifecycle, CMC components in aerospace applications can reduce overall environmental impact by 15-25% compared to traditional materials, primarily through fuel savings and reduced maintenance requirements.

High-Temperature Performance Testing Methodologies

Testing the performance of Ceramic Matrix Composite (CMC) components under high-temperature conditions presents unique challenges that require specialized methodologies. These testing approaches must accurately simulate the extreme environments where CMCs operate while providing reliable data on how surface finish characteristics affect aerodynamic performance.

Wind tunnel testing with heated airflow represents a primary methodology for evaluating CMC components. These specialized facilities can generate temperatures exceeding 1200°C while maintaining controlled airflow parameters, enabling researchers to measure drag coefficients and boundary layer behaviors across various surface finishes. The integration of infrared thermography during these tests allows for real-time mapping of temperature distributions across component surfaces.

Computational Fluid Dynamics (CFD) coupled with high-temperature material models has emerged as a complementary approach. Advanced simulation platforms now incorporate surface roughness parameters derived from actual CMC manufacturing processes, enabling prediction of aerodynamic performance degradation under thermal cycling conditions. These models have demonstrated 85-90% correlation with physical test results when properly calibrated.

Laser Doppler Velocimetry (LDV) systems modified for high-temperature environments provide non-intrusive measurement of flow characteristics near CMC surfaces. This technique has proven particularly valuable for quantifying how different surface finishes affect boundary layer transition points under thermal gradient conditions, with measurement capabilities extending to temperatures of 1500°C.

Accelerated thermal cycling chambers represent another critical testing methodology. These systems subject CMC components to rapid temperature fluctuations between ambient and operating temperatures, allowing researchers to evaluate how repeated thermal expansion and contraction affect surface integrity and subsequent aerodynamic performance. Recent advancements have enabled cycling rates up to 50°C per minute while maintaining precise environmental control.

Acoustic emission monitoring during high-temperature testing provides insights into microstructural changes within CMCs that may affect surface characteristics. This technique has successfully identified correlations between manufacturing-induced surface features and component failure modes under thermal stress, offering valuable feedback for optimizing fabrication processes.

Plasma wind tunnels represent the most extreme testing environment, capable of simulating reentry conditions exceeding 2000°C. These facilities have proven essential for validating the performance of CMC components intended for hypersonic applications, where surface degradation can dramatically alter aerodynamic characteristics and heat transfer rates.

Wind tunnel testing with heated airflow represents a primary methodology for evaluating CMC components. These specialized facilities can generate temperatures exceeding 1200°C while maintaining controlled airflow parameters, enabling researchers to measure drag coefficients and boundary layer behaviors across various surface finishes. The integration of infrared thermography during these tests allows for real-time mapping of temperature distributions across component surfaces.

Computational Fluid Dynamics (CFD) coupled with high-temperature material models has emerged as a complementary approach. Advanced simulation platforms now incorporate surface roughness parameters derived from actual CMC manufacturing processes, enabling prediction of aerodynamic performance degradation under thermal cycling conditions. These models have demonstrated 85-90% correlation with physical test results when properly calibrated.

Laser Doppler Velocimetry (LDV) systems modified for high-temperature environments provide non-intrusive measurement of flow characteristics near CMC surfaces. This technique has proven particularly valuable for quantifying how different surface finishes affect boundary layer transition points under thermal gradient conditions, with measurement capabilities extending to temperatures of 1500°C.

Accelerated thermal cycling chambers represent another critical testing methodology. These systems subject CMC components to rapid temperature fluctuations between ambient and operating temperatures, allowing researchers to evaluate how repeated thermal expansion and contraction affect surface integrity and subsequent aerodynamic performance. Recent advancements have enabled cycling rates up to 50°C per minute while maintaining precise environmental control.

Acoustic emission monitoring during high-temperature testing provides insights into microstructural changes within CMCs that may affect surface characteristics. This technique has successfully identified correlations between manufacturing-induced surface features and component failure modes under thermal stress, offering valuable feedback for optimizing fabrication processes.

Plasma wind tunnels represent the most extreme testing environment, capable of simulating reentry conditions exceeding 2000°C. These facilities have proven essential for validating the performance of CMC components intended for hypersonic applications, where surface degradation can dramatically alter aerodynamic characteristics and heat transfer rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!