Coating-to-Substrate Compatibility: EBC Design For Long-Life CMCs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EBC-CMC Interface Technology Background and Objectives

Environmental Barrier Coatings (EBCs) have emerged as a critical technology for protecting Ceramic Matrix Composites (CMCs) in extreme operating environments, particularly in aerospace and energy generation applications. The evolution of this technology began in the 1990s when researchers recognized the vulnerability of silicon-based CMCs to water vapor oxidation at high temperatures. Early EBC systems consisted of simple single-layer coatings, which have progressively evolved into sophisticated multi-layered architectures designed to address multiple degradation mechanisms simultaneously.

The technological trajectory of EBC development has been driven by increasingly demanding performance requirements in gas turbine engines, where higher operating temperatures directly correlate with improved efficiency and reduced emissions. This push toward extreme environments has accelerated research into advanced coating systems capable of withstanding temperatures exceeding 1400°C while maintaining chemical compatibility with the underlying CMC substrate.

Current EBC technology faces significant challenges at the coating-substrate interface, where coefficient of thermal expansion mismatches, chemical reactions during thermal cycling, and interdiffusion phenomena can lead to premature coating failure. These interface issues represent the primary limiting factor in achieving the desired 30,000+ hour service life required for next-generation turbine components.

The primary technical objective of advanced EBC development is to create coating systems with enhanced durability through improved interface compatibility. This includes designing compositionally graded transition layers that minimize thermal expansion stresses, developing diffusion barrier layers that prevent detrimental chemical interactions, and engineering interface architectures that accommodate inevitable crack formation without catastrophic failure.

Another critical objective is to establish standardized testing methodologies that accurately predict long-term coating performance under realistic operating conditions. Current accelerated testing protocols often fail to capture the complex degradation mechanisms that occur at the EBC-CMC interface over extended service periods.

Recent technological breakthroughs in atomic-level deposition techniques and computational materials science have opened new avenues for interface engineering. Researchers are now exploring nanoscale modifications to interface chemistry and structure that can dramatically improve coating adhesion and durability without compromising the mechanical properties of the underlying CMC.

The ultimate goal of this technological pursuit is to develop EBC systems capable of protecting CMCs throughout their entire service life without requiring replacement or repair, thereby enabling transformative advances in engine efficiency, performance, and reliability while reducing lifecycle maintenance costs and environmental impact.

The technological trajectory of EBC development has been driven by increasingly demanding performance requirements in gas turbine engines, where higher operating temperatures directly correlate with improved efficiency and reduced emissions. This push toward extreme environments has accelerated research into advanced coating systems capable of withstanding temperatures exceeding 1400°C while maintaining chemical compatibility with the underlying CMC substrate.

Current EBC technology faces significant challenges at the coating-substrate interface, where coefficient of thermal expansion mismatches, chemical reactions during thermal cycling, and interdiffusion phenomena can lead to premature coating failure. These interface issues represent the primary limiting factor in achieving the desired 30,000+ hour service life required for next-generation turbine components.

The primary technical objective of advanced EBC development is to create coating systems with enhanced durability through improved interface compatibility. This includes designing compositionally graded transition layers that minimize thermal expansion stresses, developing diffusion barrier layers that prevent detrimental chemical interactions, and engineering interface architectures that accommodate inevitable crack formation without catastrophic failure.

Another critical objective is to establish standardized testing methodologies that accurately predict long-term coating performance under realistic operating conditions. Current accelerated testing protocols often fail to capture the complex degradation mechanisms that occur at the EBC-CMC interface over extended service periods.

Recent technological breakthroughs in atomic-level deposition techniques and computational materials science have opened new avenues for interface engineering. Researchers are now exploring nanoscale modifications to interface chemistry and structure that can dramatically improve coating adhesion and durability without compromising the mechanical properties of the underlying CMC.

The ultimate goal of this technological pursuit is to develop EBC systems capable of protecting CMCs throughout their entire service life without requiring replacement or repair, thereby enabling transformative advances in engine efficiency, performance, and reliability while reducing lifecycle maintenance costs and environmental impact.

Market Analysis for High-Temperature Ceramic Coating Applications

The global market for high-temperature ceramic coatings, particularly Environmental Barrier Coatings (EBCs) for Ceramic Matrix Composites (CMCs), has experienced significant growth driven by increasing demands in aerospace, power generation, and industrial sectors. The market value reached approximately $2.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2030, potentially reaching $4.3 billion by the end of the forecast period.

Aerospace applications currently dominate the market share, accounting for nearly 45% of the total demand. This is primarily due to the critical need for high-performance materials in aircraft engines that can withstand extreme temperatures while maintaining structural integrity. The commercial aviation segment, in particular, has shown robust growth as manufacturers seek to improve fuel efficiency and reduce emissions through lightweight, heat-resistant components.

The power generation sector represents the second-largest market segment at 28%, with significant adoption in gas turbines and emerging applications in concentrated solar power systems. Industrial applications, including chemical processing and waste incineration, constitute approximately 18% of the market, while automotive and defense applications make up the remaining 9%.

Regionally, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.1% annually, driven by expanding aerospace and energy sectors in China, Japan, and India, coupled with increasing industrial manufacturing capabilities.

Customer requirements are increasingly focused on coating longevity and reliability under thermal cycling conditions. End-users are willing to pay premium prices for coatings that can demonstrate extended service life beyond the current industry standard of 10,000-15,000 hours for critical applications. Market research indicates that coatings capable of extending component life by 20% command price premiums of up to 35%.

The market is also witnessing a shift toward customized coating solutions tailored to specific operating environments. This trend is particularly evident in the aerospace sector, where manufacturers are seeking coatings optimized for specific engine components and flight profiles. Additionally, there is growing demand for coatings that can accommodate the thermal expansion mismatch between ceramic substrates and protective layers, a critical factor in preventing coating delamination and failure.

Environmental regulations and sustainability concerns are emerging as significant market drivers, with customers increasingly valuing coatings that enable more efficient combustion processes and reduce overall emissions. This trend is expected to accelerate as global carbon reduction targets become more stringent, potentially opening new market opportunities for advanced EBC technologies that support cleaner energy generation.

Aerospace applications currently dominate the market share, accounting for nearly 45% of the total demand. This is primarily due to the critical need for high-performance materials in aircraft engines that can withstand extreme temperatures while maintaining structural integrity. The commercial aviation segment, in particular, has shown robust growth as manufacturers seek to improve fuel efficiency and reduce emissions through lightweight, heat-resistant components.

The power generation sector represents the second-largest market segment at 28%, with significant adoption in gas turbines and emerging applications in concentrated solar power systems. Industrial applications, including chemical processing and waste incineration, constitute approximately 18% of the market, while automotive and defense applications make up the remaining 9%.

Regionally, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.1% annually, driven by expanding aerospace and energy sectors in China, Japan, and India, coupled with increasing industrial manufacturing capabilities.

Customer requirements are increasingly focused on coating longevity and reliability under thermal cycling conditions. End-users are willing to pay premium prices for coatings that can demonstrate extended service life beyond the current industry standard of 10,000-15,000 hours for critical applications. Market research indicates that coatings capable of extending component life by 20% command price premiums of up to 35%.

The market is also witnessing a shift toward customized coating solutions tailored to specific operating environments. This trend is particularly evident in the aerospace sector, where manufacturers are seeking coatings optimized for specific engine components and flight profiles. Additionally, there is growing demand for coatings that can accommodate the thermal expansion mismatch between ceramic substrates and protective layers, a critical factor in preventing coating delamination and failure.

Environmental regulations and sustainability concerns are emerging as significant market drivers, with customers increasingly valuing coatings that enable more efficient combustion processes and reduce overall emissions. This trend is expected to accelerate as global carbon reduction targets become more stringent, potentially opening new market opportunities for advanced EBC technologies that support cleaner energy generation.

Current EBC Technology Challenges and Limitations

Environmental Barrier Coatings (EBCs) for Ceramic Matrix Composites (CMCs) face significant technological challenges that limit their widespread implementation and long-term performance. The primary challenge lies in achieving optimal coating-to-substrate compatibility across varying operational conditions. Current EBC systems experience coefficient of thermal expansion (CTE) mismatches between the coating layers and the CMC substrate, leading to residual stresses during thermal cycling that ultimately result in coating delamination and spallation.

The chemical compatibility between EBCs and CMCs presents another critical limitation. Silicon-based CMCs undergo oxidation at high temperatures, forming silica scales that can react with water vapor to form volatile silicon hydroxide species. While current EBC materials like rare-earth silicates provide some protection, they often exhibit insufficient chemical stability when exposed to calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash in engine environments.

Phase stability of EBC materials represents a significant technical hurdle. Many promising coating materials undergo phase transformations during thermal cycling, causing volume changes that compromise coating integrity. For instance, ytterbium disilicate experiences polymorphic transformations that induce microcracking and accelerate coating degradation, particularly in the temperature range of 1200-1400°C where many advanced turbine engines operate.

Processing limitations further constrain EBC development. Current deposition techniques like air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) struggle to produce uniform, defect-free coatings on complex CMC geometries. These methods often introduce porosity and microcracks that serve as pathways for environmental species to reach the substrate, compromising the protective function of the coating system.

Bond coat technology represents another limitation in current EBC systems. Silicon-based bond coats, while providing good adhesion, are susceptible to oxidation and volatilization at temperatures above 1300°C. Alternative bond coat materials with improved high-temperature stability often exhibit poor adhesion to the CMC substrate or incompatibility with the top coat layers.

Lifetime prediction and accelerated testing methodologies remain underdeveloped for EBC-CMC systems. Current models fail to accurately predict coating degradation mechanisms under complex operational conditions, making it difficult to design systems with predictable service lives. The lack of standardized testing protocols that can simulate the combined effects of thermal cycling, mechanical loading, and environmental attack further complicates the development of reliable EBC systems for long-life CMC applications.

The chemical compatibility between EBCs and CMCs presents another critical limitation. Silicon-based CMCs undergo oxidation at high temperatures, forming silica scales that can react with water vapor to form volatile silicon hydroxide species. While current EBC materials like rare-earth silicates provide some protection, they often exhibit insufficient chemical stability when exposed to calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash in engine environments.

Phase stability of EBC materials represents a significant technical hurdle. Many promising coating materials undergo phase transformations during thermal cycling, causing volume changes that compromise coating integrity. For instance, ytterbium disilicate experiences polymorphic transformations that induce microcracking and accelerate coating degradation, particularly in the temperature range of 1200-1400°C where many advanced turbine engines operate.

Processing limitations further constrain EBC development. Current deposition techniques like air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) struggle to produce uniform, defect-free coatings on complex CMC geometries. These methods often introduce porosity and microcracks that serve as pathways for environmental species to reach the substrate, compromising the protective function of the coating system.

Bond coat technology represents another limitation in current EBC systems. Silicon-based bond coats, while providing good adhesion, are susceptible to oxidation and volatilization at temperatures above 1300°C. Alternative bond coat materials with improved high-temperature stability often exhibit poor adhesion to the CMC substrate or incompatibility with the top coat layers.

Lifetime prediction and accelerated testing methodologies remain underdeveloped for EBC-CMC systems. Current models fail to accurately predict coating degradation mechanisms under complex operational conditions, making it difficult to design systems with predictable service lives. The lack of standardized testing protocols that can simulate the combined effects of thermal cycling, mechanical loading, and environmental attack further complicates the development of reliable EBC systems for long-life CMC applications.

State-of-the-Art EBC Design Approaches for CMCs

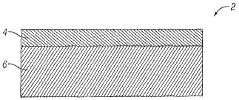

01 Material composition for EBC compatibility

Environmental Barrier Coatings can be formulated with specific material compositions to enhance compatibility with substrates. These compositions typically include rare earth silicates, mullite, and other ceramic materials that provide thermal expansion matching with the substrate. The careful selection of materials ensures good adhesion, reduces thermal stresses, and prevents delamination during thermal cycling, which is crucial for long-term performance in high-temperature environments.- Material composition for EBC compatibility: Environmental Barrier Coatings can be formulated with specific material compositions to enhance compatibility with substrates. These compositions typically include rare earth silicates, mullite, and other ceramic materials that provide thermal expansion matching with the substrate. The careful selection of materials ensures good adhesion, reduces thermal stresses, and prevents delamination during thermal cycling, which is crucial for long-term performance in high-temperature environments.

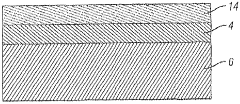

- Interlayer design for improved EBC adhesion: Incorporating specialized interlayers between the substrate and the environmental barrier coating significantly improves compatibility and adhesion. These transition layers can be graded in composition or consist of multiple discrete layers with varying properties to bridge the differences between substrate and coating. Such interlayer designs help manage thermal expansion mismatches, enhance bonding strength, and prevent crack propagation across interfaces during thermal cycling.

- Processing techniques for EBC application: Various processing techniques can be employed to enhance the compatibility of environmental barrier coatings with substrates. Methods such as plasma spraying, chemical vapor deposition, and sol-gel processing can be optimized to control microstructure, porosity, and interface characteristics. The selection of appropriate processing parameters affects coating density, residual stress, and ultimately the compatibility and durability of the coating system in harsh environments.

- Self-healing mechanisms for EBC durability: Environmental barrier coatings can be designed with self-healing capabilities to improve long-term compatibility and performance. These mechanisms involve incorporating phases that can flow and seal cracks at high temperatures or including reactive components that form protective products when exposed to environmental contaminants. Self-healing features extend coating lifetime by addressing damage that would otherwise lead to premature failure through substrate oxidation or coating delamination.

- Environmental resistance optimization: Enhancing the environmental resistance of barrier coatings involves tailoring their composition and structure to withstand specific operational conditions. This includes developing coatings resistant to water vapor, molten salts, CMAS (calcium-magnesium-alumino-silicate) infiltration, and other corrosive environments. Optimized environmental resistance ensures coating-substrate compatibility is maintained throughout the component lifecycle, preventing chemical reactions at interfaces that could compromise coating adhesion and performance.

02 Interlayer design for improved EBC adhesion

Incorporating specialized interlayers between the substrate and the main EBC layer significantly improves coating compatibility. These transition layers typically feature gradient compositions or functionally graded materials that bridge the property differences between the substrate and the outer coating. Such designs minimize thermal expansion mismatches, enhance bonding strength, and improve overall coating durability when exposed to extreme temperature fluctuations and environmental contaminants.Expand Specific Solutions03 Surface treatment techniques for EBC application

Various surface treatment methods can be employed to prepare substrates for EBC application, enhancing compatibility between the coating and base material. These techniques include plasma treatment, chemical etching, grit blasting, and laser texturing to create optimal surface roughness and chemical activation. Proper surface preparation removes contaminants, creates mechanical interlocking features, and promotes chemical bonding, resulting in superior coating adhesion and performance in harsh operating environments.Expand Specific Solutions04 EBC deposition methods for compatibility optimization

The choice of deposition method significantly impacts EBC compatibility with substrates. Techniques such as plasma spraying, chemical vapor deposition, physical vapor deposition, and solution precursor methods can be optimized to control coating microstructure, density, and interface characteristics. Each method offers distinct advantages in terms of coating adhesion, uniformity, and defect minimization, allowing tailored approaches for specific substrate materials and operating conditions.Expand Specific Solutions05 Environmental durability enhancements for EBCs

Specialized additives and compositional modifications can be incorporated into EBCs to enhance their environmental durability and compatibility under extreme conditions. These enhancements include water vapor resistance additives, CMAS (calcium-magnesium-alumino-silicate) infiltration inhibitors, and oxidation-resistant compounds. Such modifications protect the underlying substrate from environmental degradation while maintaining coating integrity, extending component life in applications involving high temperatures, corrosive environments, and thermal cycling.Expand Specific Solutions

Leading Companies and Research Institutions in EBC-CMC Technology

The Environmental Barrier Coating (EBC) market for Ceramic Matrix Composites (CMCs) is in a growth phase, with increasing adoption in high-temperature aerospace applications. The market is projected to expand significantly as gas turbine efficiency demands rise, particularly in aviation. Leading the technological development are major aerospace propulsion companies including Rolls-Royce, General Electric, and RTX Corp. (formerly United Technologies), who have established advanced coating capabilities for CMC components. Research institutions like the Institute of Metal Research Chinese Academy of Sciences and Shanghai Institute of Ceramics are contributing fundamental innovations, while specialized surface technology providers such as Oerlikon Surface Solutions are developing commercial coating solutions. The technology is approaching maturity for first-generation applications but continues to evolve for more demanding thermal and environmental conditions.

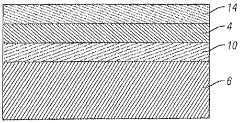

General Electric Company

Technical Solution: GE has developed a multi-layered EBC system specifically designed for SiC/SiC CMCs used in high-temperature turbine applications. Their approach utilizes a three-layer architecture: (1) a silicon bond coat that forms a protective silica scale, (2) an intermediate rare-earth silicate layer (typically based on ytterbium or yttrium disilicates), and (3) an outer rare-earth monosilicate top coat. GE's system incorporates controlled porosity gradients and compositional tailoring to manage thermal expansion mismatches between the coating and substrate. Their proprietary CMAS (Calcium-Magnesium-Alumino-Silicate) resistant top coat formulations have demonstrated significant improvements in resistance to environmental degradation in engine-relevant conditions. GE has also pioneered advanced deposition techniques combining vapor deposition for dense inner layers with plasma spray for outer layers, creating optimized microstructures that enhance coating durability while maintaining strong interfacial bonding.

Strengths: Industry-leading integration of EBC technology with CMC components in actual engine applications; extensive field testing data; sophisticated multi-layer architecture optimized for thermal cycling. Weaknesses: Higher manufacturing costs compared to traditional materials; complex processing requirements; potential challenges with repair and maintenance of coated components.

RTX Corp.

Technical Solution: RTX (formerly Raytheon Technologies) has developed an advanced EBC system for CMCs that employs a multi-layered approach with specific focus on coating-substrate compatibility for long-term durability. Their technology utilizes a modified silicon bond coat with rare-earth dopants to improve oxidation resistance and adhesion to the SiC/SiC substrate. The intermediate layers consist of rare-earth disilicates (primarily ytterbium and yttrium-based) with engineered porosity gradients to accommodate thermal expansion differences. RTX's system features a unique top coat formulation incorporating hafnium and zirconium compounds to enhance CMAS resistance while maintaining phase stability at temperatures exceeding 1400°C. Their manufacturing approach combines controlled atmosphere plasma spray techniques with targeted infiltration processes to seal interconnected porosity. A distinguishing aspect of RTX's technology is their focus on interface engineering between coating layers, utilizing nanoscale transition zones to improve mechanical bonding while minimizing diffusion-related degradation mechanisms. Recent advancements include the development of self-diagnosing coating systems with embedded sensors for real-time monitoring of coating integrity.

Strengths: Superior CMAS resistance; excellent thermal shock resistance; innovative interface engineering between layers; advanced monitoring capabilities. Weaknesses: Higher production costs; complex quality control requirements; limited field service data compared to some competitors; challenges in scaling to complex geometries.

Key Patents and Technical Innovations in EBC-CMC Interface Engineering

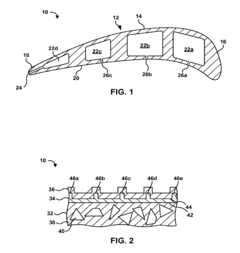

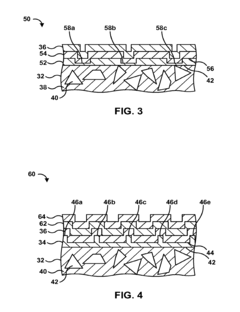

Long life low cost environmental barrier coating for ceramic matrix composites

PatentWO2014137804A1

Innovation

- A doped rare earth disilicate layer, comprising specific rare earth elements and dopants like Al2O3, alkali oxides, and alkali earth oxides, is applied over the CMCs to form a long-life, low-cost environmental barrier coating, which reduces silica scale growth and enhances chemical bonding.

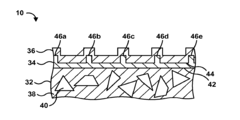

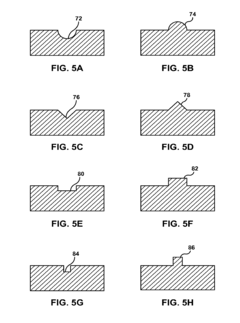

Features for mitigating thermal or mechanical stress on an environmental barrier coating

PatentActiveUS20130122259A1

Innovation

- Forming features on the surface of layers within the system, such as grooves or ridges, to disrupt planarity and impede crack growth, segregating the substrate and EBC into smaller domains, thereby mitigating thermal and mechanical stress and preventing delamination.

Material Selection Criteria for Optimized EBC-CMC Systems

The selection of materials for Environmental Barrier Coatings (EBCs) and Ceramic Matrix Composites (CMCs) systems requires a systematic approach that considers multiple interdependent factors to ensure optimal performance and longevity. The primary criterion is thermal expansion compatibility between the coating and substrate, as mismatches can lead to residual stresses, cracking, and premature failure during thermal cycling. Ideally, the coefficient of thermal expansion (CTE) of the EBC should closely match that of the CMC substrate, typically within ±1 ppm/K to minimize interfacial stress accumulation.

Chemical compatibility represents another critical selection parameter, as adverse reactions at elevated temperatures can compromise coating integrity. Materials must be selected to prevent the formation of low-melting eutectics or volatile species that could accelerate degradation. For silicon-based CMCs, rare-earth silicates and disilicates have demonstrated superior chemical stability in high-temperature steam environments, with ytterbium and yttrium-based compounds showing particularly promising results.

Phase stability across the operational temperature range (typically 1200-1500°C) is essential for maintaining coating integrity. Materials that undergo significant phase transformations, volume changes, or crystallization during service should be avoided. Multi-phase systems must be carefully engineered to ensure phase compatibility throughout the temperature cycling experienced in turbine applications.

Mechanical property matching between the EBC and CMC substrate significantly influences system durability. The elastic modulus ratio between coating and substrate should be optimized to distribute stresses effectively. Additionally, fracture toughness values above 3-5 MPa·m^1/2 are generally desirable for EBC materials to resist crack propagation under thermal and mechanical loading conditions.

Processing compatibility must also be considered, as the deposition method (typically plasma spray, chemical vapor deposition, or slurry-based approaches) influences microstructure development and adhesion strength. The selected materials must be amenable to the chosen processing route while maintaining their protective capabilities and interfacial integrity.

Environmental resistance criteria include stability in water vapor, resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration, and oxidation protection. Rare-earth monosilicates with low silica activity have demonstrated superior resistance to volatilization in high-velocity steam environments, while gadolinium zirconate compositions show enhanced CMAS resistance through rapid crystallization mechanisms that limit melt penetration.

Cost-effectiveness and material availability represent practical considerations that cannot be overlooked, particularly for large-scale industrial applications. The development of multi-layer architectures with tailored compositions at each interface has emerged as a promising approach to optimize the overall EBC-CMC system performance while managing material costs.

Chemical compatibility represents another critical selection parameter, as adverse reactions at elevated temperatures can compromise coating integrity. Materials must be selected to prevent the formation of low-melting eutectics or volatile species that could accelerate degradation. For silicon-based CMCs, rare-earth silicates and disilicates have demonstrated superior chemical stability in high-temperature steam environments, with ytterbium and yttrium-based compounds showing particularly promising results.

Phase stability across the operational temperature range (typically 1200-1500°C) is essential for maintaining coating integrity. Materials that undergo significant phase transformations, volume changes, or crystallization during service should be avoided. Multi-phase systems must be carefully engineered to ensure phase compatibility throughout the temperature cycling experienced in turbine applications.

Mechanical property matching between the EBC and CMC substrate significantly influences system durability. The elastic modulus ratio between coating and substrate should be optimized to distribute stresses effectively. Additionally, fracture toughness values above 3-5 MPa·m^1/2 are generally desirable for EBC materials to resist crack propagation under thermal and mechanical loading conditions.

Processing compatibility must also be considered, as the deposition method (typically plasma spray, chemical vapor deposition, or slurry-based approaches) influences microstructure development and adhesion strength. The selected materials must be amenable to the chosen processing route while maintaining their protective capabilities and interfacial integrity.

Environmental resistance criteria include stability in water vapor, resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration, and oxidation protection. Rare-earth monosilicates with low silica activity have demonstrated superior resistance to volatilization in high-velocity steam environments, while gadolinium zirconate compositions show enhanced CMAS resistance through rapid crystallization mechanisms that limit melt penetration.

Cost-effectiveness and material availability represent practical considerations that cannot be overlooked, particularly for large-scale industrial applications. The development of multi-layer architectures with tailored compositions at each interface has emerged as a promising approach to optimize the overall EBC-CMC system performance while managing material costs.

Environmental and Thermal Cycling Effects on Coating Performance

Environmental and thermal cycling conditions represent critical challenges for Environmental Barrier Coatings (EBCs) applied to Ceramic Matrix Composites (CMCs). These coatings experience significant performance degradation when subjected to the harsh operational environments typical in aerospace and power generation applications. Temperature fluctuations ranging from ambient to over 1300°C create substantial thermal expansion mismatches between coating layers and the CMC substrate, resulting in thermal stresses that can lead to coating delamination and spallation.

Water vapor exposure presents another significant challenge, particularly in combustion environments where steam content can exceed 10% by volume. Studies have demonstrated that silica-based protective scales formed on silicon-containing EBCs undergo accelerated volatilization in high-temperature steam environments, transforming solid SiO2 into gaseous Si(OH)4. This reaction occurs at rates approximately 100 times faster than oxidation in dry air at equivalent temperatures, severely compromising coating integrity.

Thermal cycling effects manifest through several degradation mechanisms. Repeated heating and cooling cycles induce fatigue damage at coating interfaces, with crack initiation typically occurring at stress concentration points. Research by NASA Glenn Research Center has documented that most EBC systems show significant performance deterioration after 500-1000 thermal cycles, with degradation rates accelerating as cycle count increases. The thermal gradient across coating thickness further complicates this issue, creating non-uniform expansion that exacerbates interfacial stress.

Chemical compatibility under cycling conditions represents another critical concern. At elevated temperatures, interdiffusion between coating layers and substrates accelerates, potentially forming brittle reaction products at interfaces. Rare-earth silicates, while offering excellent high-temperature stability, have demonstrated problematic chemical interactions with silicon bond coats during prolonged thermal cycling, forming low-melting eutectics that compromise structural integrity.

Environmental contaminants further compound these challenges. Calcium-magnesium-aluminosilicate (CMAS) deposits from ingested sand, dust, and volcanic ash melt at high temperatures and infiltrate coating porosity. Upon cooling, these deposits solidify and create additional stress points. Research indicates that CMAS attack becomes particularly severe above 1200°C, with infiltration depths increasing exponentially with temperature and exposure time.

Recent testing protocols have evolved to better simulate these combined effects. Advanced thermal gradient mechanical fatigue (TGMF) testing now incorporates water vapor exposure and CMAS contamination to provide more realistic performance predictions. These integrated testing approaches have revealed synergistic degradation mechanisms that were not apparent when evaluating individual environmental factors in isolation.

Water vapor exposure presents another significant challenge, particularly in combustion environments where steam content can exceed 10% by volume. Studies have demonstrated that silica-based protective scales formed on silicon-containing EBCs undergo accelerated volatilization in high-temperature steam environments, transforming solid SiO2 into gaseous Si(OH)4. This reaction occurs at rates approximately 100 times faster than oxidation in dry air at equivalent temperatures, severely compromising coating integrity.

Thermal cycling effects manifest through several degradation mechanisms. Repeated heating and cooling cycles induce fatigue damage at coating interfaces, with crack initiation typically occurring at stress concentration points. Research by NASA Glenn Research Center has documented that most EBC systems show significant performance deterioration after 500-1000 thermal cycles, with degradation rates accelerating as cycle count increases. The thermal gradient across coating thickness further complicates this issue, creating non-uniform expansion that exacerbates interfacial stress.

Chemical compatibility under cycling conditions represents another critical concern. At elevated temperatures, interdiffusion between coating layers and substrates accelerates, potentially forming brittle reaction products at interfaces. Rare-earth silicates, while offering excellent high-temperature stability, have demonstrated problematic chemical interactions with silicon bond coats during prolonged thermal cycling, forming low-melting eutectics that compromise structural integrity.

Environmental contaminants further compound these challenges. Calcium-magnesium-aluminosilicate (CMAS) deposits from ingested sand, dust, and volcanic ash melt at high temperatures and infiltrate coating porosity. Upon cooling, these deposits solidify and create additional stress points. Research indicates that CMAS attack becomes particularly severe above 1200°C, with infiltration depths increasing exponentially with temperature and exposure time.

Recent testing protocols have evolved to better simulate these combined effects. Advanced thermal gradient mechanical fatigue (TGMF) testing now incorporates water vapor exposure and CMAS contamination to provide more realistic performance predictions. These integrated testing approaches have revealed synergistic degradation mechanisms that were not apparent when evaluating individual environmental factors in isolation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!