EBC Repair And Re-Coating Methods For Field Maintenance

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EBC Repair Technology Background and Objectives

Environmental Barrier Coatings (EBCs) have emerged as a critical technology for protecting ceramic matrix composites (CMCs) in high-temperature gas turbine environments. The development of EBCs began in the 1990s as a response to the limitations of traditional thermal barrier coatings when applied to silicon-based ceramics. Initially designed to protect against water vapor-induced corrosion, EBCs have evolved significantly over the past three decades to address multiple degradation mechanisms in increasingly demanding operational environments.

The evolution of EBC technology has progressed through several distinct generations. First-generation EBCs consisted primarily of mullite-based systems, which provided basic protection but suffered from volatilization issues at high temperatures. Second-generation coatings introduced barium strontium aluminosilicate (BSAS) compositions, offering improved durability. Current third-generation systems incorporate rare earth silicates and more complex multilayer architectures to withstand temperatures exceeding 1400°C while providing enhanced resistance to calcium-magnesium-aluminosilicate (CMAS) infiltration.

Field maintenance of EBC-coated components represents a significant technical challenge that has gained increasing attention as these materials transition from experimental to widespread commercial deployment. Unlike traditional metallic components, which have well-established repair protocols, EBC repair methodologies are still in their developmental stages. The primary objective of EBC repair technology is to restore protective functionality to damaged coatings without necessitating complete component replacement, thereby extending service life and reducing operational costs.

The technical goals for effective EBC repair methods encompass several critical requirements. First, repair techniques must restore the environmental protection capabilities of the original coating system. Second, they must be applicable in field conditions with minimal specialized equipment. Third, repaired areas must maintain thermal cycling resistance comparable to the original coating. Fourth, the repair process must not compromise the underlying CMC substrate integrity. Finally, repaired coatings should ideally match the lifetime expectancy of the original coating system.

Current research trends are focusing on developing field-deployable repair solutions that can address various damage modes, from minor surface erosion to more significant spallation events. Emerging approaches include localized thermal spray techniques, slurry-based repair methods, and preceramic polymer infiltration processes. The ultimate aim is to establish standardized repair protocols that can be implemented during routine maintenance cycles, thereby enhancing the economic viability of CMC components in aerospace and power generation applications.

The evolution of EBC technology has progressed through several distinct generations. First-generation EBCs consisted primarily of mullite-based systems, which provided basic protection but suffered from volatilization issues at high temperatures. Second-generation coatings introduced barium strontium aluminosilicate (BSAS) compositions, offering improved durability. Current third-generation systems incorporate rare earth silicates and more complex multilayer architectures to withstand temperatures exceeding 1400°C while providing enhanced resistance to calcium-magnesium-aluminosilicate (CMAS) infiltration.

Field maintenance of EBC-coated components represents a significant technical challenge that has gained increasing attention as these materials transition from experimental to widespread commercial deployment. Unlike traditional metallic components, which have well-established repair protocols, EBC repair methodologies are still in their developmental stages. The primary objective of EBC repair technology is to restore protective functionality to damaged coatings without necessitating complete component replacement, thereby extending service life and reducing operational costs.

The technical goals for effective EBC repair methods encompass several critical requirements. First, repair techniques must restore the environmental protection capabilities of the original coating system. Second, they must be applicable in field conditions with minimal specialized equipment. Third, repaired areas must maintain thermal cycling resistance comparable to the original coating. Fourth, the repair process must not compromise the underlying CMC substrate integrity. Finally, repaired coatings should ideally match the lifetime expectancy of the original coating system.

Current research trends are focusing on developing field-deployable repair solutions that can address various damage modes, from minor surface erosion to more significant spallation events. Emerging approaches include localized thermal spray techniques, slurry-based repair methods, and preceramic polymer infiltration processes. The ultimate aim is to establish standardized repair protocols that can be implemented during routine maintenance cycles, thereby enhancing the economic viability of CMC components in aerospace and power generation applications.

Market Analysis for Field Maintenance Solutions

The Environmental Barrier Coating (EBC) repair and re-coating market for field maintenance is experiencing significant growth, driven by the expanding deployment of ceramic matrix composites (CMCs) in aerospace and power generation sectors. Current market valuations indicate the global EBC repair services market reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030.

The aerospace sector dominates demand, accounting for roughly 65% of the total market share, with commercial and military aviation being the primary consumers of field maintenance solutions. Power generation follows at 28%, while industrial applications constitute the remaining 7%. This distribution reflects the critical nature of EBC integrity in high-temperature, high-stress operating environments where component failure can result in catastrophic consequences.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (31%), Asia-Pacific (21%), and rest of the world (6%). This distribution correlates strongly with the concentration of aerospace manufacturing and maintenance facilities. However, the Asia-Pacific region is demonstrating the fastest growth rate at 9.3% annually, driven by China's and India's expanding aerospace industries and power generation infrastructure.

Customer segmentation shows original equipment manufacturers (OEMs) represent 55% of the market, while third-party maintenance, repair, and overhaul (MRO) providers account for 35%. The remaining 10% consists of in-house maintenance operations at end-user facilities. This distribution highlights the technical complexity of EBC repair processes, which often require specialized equipment and expertise typically available through OEMs.

Market drivers include increasing service life expectations for components, rising fuel efficiency demands, and stricter emission regulations that necessitate higher operating temperatures in engines. Additionally, the cost differential between component replacement and repair—with repairs typically costing 30-40% of new component prices—creates strong economic incentives for maintenance solutions.

Challenges facing the market include limited field repair capabilities for complex EBC systems, inconsistent quality control in non-standardized field environments, and intellectual property restrictions that limit third-party repair options. The technical complexity of newer multi-layer EBC systems presents additional barriers to market entry for smaller service providers.

Future market trends point toward increased demand for portable repair technologies, development of rapid-cure coating systems for field applications, and integration of non-destructive evaluation techniques with repair processes. The emergence of subscription-based maintenance programs and predictive maintenance solutions is also reshaping customer expectations and service delivery models in this specialized market.

The aerospace sector dominates demand, accounting for roughly 65% of the total market share, with commercial and military aviation being the primary consumers of field maintenance solutions. Power generation follows at 28%, while industrial applications constitute the remaining 7%. This distribution reflects the critical nature of EBC integrity in high-temperature, high-stress operating environments where component failure can result in catastrophic consequences.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (31%), Asia-Pacific (21%), and rest of the world (6%). This distribution correlates strongly with the concentration of aerospace manufacturing and maintenance facilities. However, the Asia-Pacific region is demonstrating the fastest growth rate at 9.3% annually, driven by China's and India's expanding aerospace industries and power generation infrastructure.

Customer segmentation shows original equipment manufacturers (OEMs) represent 55% of the market, while third-party maintenance, repair, and overhaul (MRO) providers account for 35%. The remaining 10% consists of in-house maintenance operations at end-user facilities. This distribution highlights the technical complexity of EBC repair processes, which often require specialized equipment and expertise typically available through OEMs.

Market drivers include increasing service life expectations for components, rising fuel efficiency demands, and stricter emission regulations that necessitate higher operating temperatures in engines. Additionally, the cost differential between component replacement and repair—with repairs typically costing 30-40% of new component prices—creates strong economic incentives for maintenance solutions.

Challenges facing the market include limited field repair capabilities for complex EBC systems, inconsistent quality control in non-standardized field environments, and intellectual property restrictions that limit third-party repair options. The technical complexity of newer multi-layer EBC systems presents additional barriers to market entry for smaller service providers.

Future market trends point toward increased demand for portable repair technologies, development of rapid-cure coating systems for field applications, and integration of non-destructive evaluation techniques with repair processes. The emergence of subscription-based maintenance programs and predictive maintenance solutions is also reshaping customer expectations and service delivery models in this specialized market.

Current EBC Repair Challenges and Limitations

Environmental Barrier Coatings (EBCs) deployed in field conditions face significant repair challenges that limit maintenance effectiveness. Current repair methods struggle with the complex microstructure of EBCs, which typically consist of multiple layers with distinct compositions and functions. When damage occurs in field settings, accurately replicating this layered structure becomes exceptionally difficult without specialized equipment available in manufacturing facilities.

Field repair operations contend with environmental contamination issues that can compromise coating integrity. Dust, moisture, and other atmospheric contaminants readily infiltrate damaged areas, creating adhesion problems between the original coating and repair materials. These contaminants often lead to premature failure of repaired sections, with delamination occurring at the interface between original and repaired areas.

Temperature control presents another major limitation in field repairs. Optimal EBC application requires precise thermal management during deposition and curing processes. Field conditions rarely permit the controlled heating and cooling cycles necessary for proper phase formation and microstructural development. Consequently, field-repaired coatings frequently exhibit inferior crystallinity, higher porosity, and reduced erosion resistance compared to factory-applied counterparts.

The dimensional accuracy of repairs poses significant challenges. Current field repair methods struggle to maintain uniform thickness across repaired areas, creating aerodynamic inconsistencies and potential stress concentration points. These irregularities can accelerate degradation of the repaired regions and potentially initiate new failure mechanisms in surrounding intact coating areas.

Equipment portability severely constrains field repair capabilities. Most advanced coating technologies—such as plasma spraying, physical vapor deposition, and controlled atmosphere heat treatment—rely on bulky equipment not readily transportable to field locations. Portable alternatives typically produce inferior coating quality with compromised microstructural properties and reduced service life.

Quality assessment of field repairs remains problematic. Non-destructive evaluation techniques suitable for field deployment lack the resolution to detect subtle defects in repaired coatings. This diagnostic limitation means that many repair defects remain undetected until they progress to visible damage, by which point more extensive repairs become necessary.

Chemical compatibility between repair materials and aged EBCs presents another significant challenge. Field-exposed coatings undergo compositional changes through service exposure, making them chemically different from their as-manufactured state. Current repair materials are typically formulated to match new coating compositions rather than aged ones, creating potential phase incompatibilities and diffusion-related failures at repair interfaces.

Field repair operations contend with environmental contamination issues that can compromise coating integrity. Dust, moisture, and other atmospheric contaminants readily infiltrate damaged areas, creating adhesion problems between the original coating and repair materials. These contaminants often lead to premature failure of repaired sections, with delamination occurring at the interface between original and repaired areas.

Temperature control presents another major limitation in field repairs. Optimal EBC application requires precise thermal management during deposition and curing processes. Field conditions rarely permit the controlled heating and cooling cycles necessary for proper phase formation and microstructural development. Consequently, field-repaired coatings frequently exhibit inferior crystallinity, higher porosity, and reduced erosion resistance compared to factory-applied counterparts.

The dimensional accuracy of repairs poses significant challenges. Current field repair methods struggle to maintain uniform thickness across repaired areas, creating aerodynamic inconsistencies and potential stress concentration points. These irregularities can accelerate degradation of the repaired regions and potentially initiate new failure mechanisms in surrounding intact coating areas.

Equipment portability severely constrains field repair capabilities. Most advanced coating technologies—such as plasma spraying, physical vapor deposition, and controlled atmosphere heat treatment—rely on bulky equipment not readily transportable to field locations. Portable alternatives typically produce inferior coating quality with compromised microstructural properties and reduced service life.

Quality assessment of field repairs remains problematic. Non-destructive evaluation techniques suitable for field deployment lack the resolution to detect subtle defects in repaired coatings. This diagnostic limitation means that many repair defects remain undetected until they progress to visible damage, by which point more extensive repairs become necessary.

Chemical compatibility between repair materials and aged EBCs presents another significant challenge. Field-exposed coatings undergo compositional changes through service exposure, making them chemically different from their as-manufactured state. Current repair materials are typically formulated to match new coating compositions rather than aged ones, creating potential phase incompatibilities and diffusion-related failures at repair interfaces.

Current Field Maintenance Technical Solutions

01 Repair methods for damaged EBC coatings

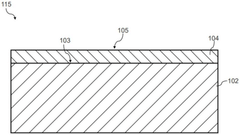

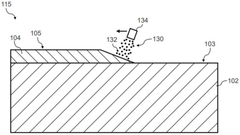

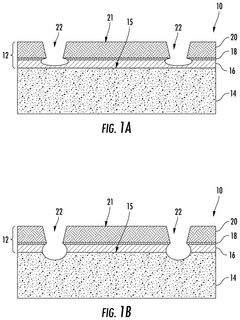

Various methods are employed to repair damaged Environmental Barrier Coatings (EBCs) on components. These include localized repair techniques that target specific damaged areas without requiring complete removal of the existing coating. Repair processes may involve cleaning the damaged area, applying repair material compatible with the original coating, and curing under controlled conditions. These methods help restore the protective function of the EBC while minimizing downtime and extending component life.- Repair methods for damaged EBC coatings: Various methods have been developed to repair damaged environmental barrier coatings on components. These methods include localized repair techniques that target specific damaged areas without requiring complete removal of the existing coating. The repair processes typically involve cleaning the damaged area, applying repair materials compatible with the original coating, and curing under controlled conditions. These techniques help restore the protective properties of the EBC while minimizing downtime and extending component life.

- Novel EBC compositions for repair applications: Specialized environmental barrier coating compositions have been formulated specifically for repair applications. These compositions often feature enhanced adhesion properties to bond with existing coatings, improved thermal shock resistance, and compatibility with base materials. Some formulations include rare earth silicates, mullite-based materials, or specialized ceramic compounds that provide excellent protection against environmental degradation while being suitable for localized application during repair processes.

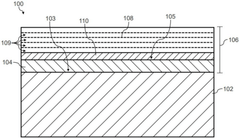

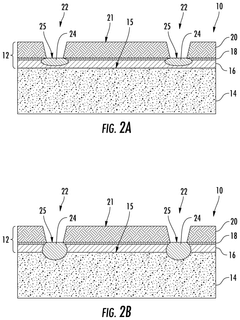

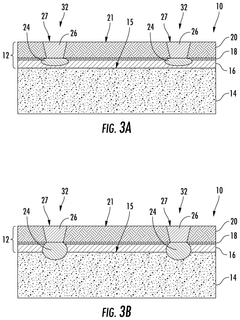

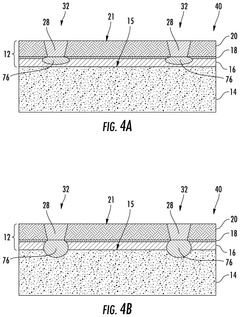

- Multi-layer EBC repair systems: Multi-layer approaches for EBC repair and recoating involve the application of several distinct functional layers to restore damaged coatings. These systems typically include a bond coat to ensure adhesion to the substrate, intermediate layers providing environmental protection, and a top coat that offers resistance against environmental factors such as water vapor, oxygen, and particulate erosion. The multi-layer approach allows for customization of the repair system to address specific damage mechanisms while maintaining overall coating integrity.

- Thermal spray techniques for EBC repair: Thermal spray methods represent a significant approach for repairing and recoating environmental barrier coatings. These techniques include plasma spraying, high-velocity oxygen fuel spraying, and suspension plasma spraying, which enable the deposition of repair materials onto damaged areas. The processes allow for controlled application of coating materials with specific particle sizes and distribution, resulting in repaired coatings with optimized microstructure and enhanced durability against high-temperature oxidation and corrosion.

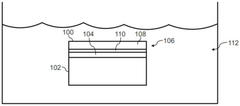

- In-situ repair technologies for EBC systems: In-situ repair technologies enable the restoration of environmental barrier coatings without complete disassembly of components or systems. These methods include portable thermal spray equipment, localized heating systems, and specialized application tools that can access confined spaces. Some approaches incorporate laser-assisted deposition or curing processes to achieve precise repairs with minimal heat-affected zones. These technologies are particularly valuable for maintaining components in field conditions or when complete removal for repair is impractical.

02 Novel EBC compositions for repair applications

Specialized compositions have been developed specifically for EBC repair applications. These formulations often include rare earth silicates, mullite, barium strontium aluminosilicate (BSAS), and other ceramic materials designed to match the thermal expansion properties of the substrate. Some compositions incorporate self-healing mechanisms or enhanced crack resistance properties. These advanced materials ensure compatibility with existing coatings while providing improved durability and protection against environmental degradation.Expand Specific Solutions03 Application techniques for EBC repair and recoating

Various application techniques are used for EBC repair and recoating, including thermal spray methods, slurry-based applications, and vapor deposition processes. These techniques can be tailored to specific damage types, component geometries, and operating conditions. Some methods allow for in-situ repairs, while others require component removal. The selection of application technique significantly impacts the quality, adhesion, and performance of the repaired coating.Expand Specific Solutions04 Heat treatment and curing processes for repaired EBCs

After application of repair materials, specific heat treatment and curing processes are essential to ensure proper bonding, densification, and performance of the repaired EBC. These processes may include controlled heating rates, specific temperature holds, and specialized atmospheres to prevent oxidation. Some advanced techniques incorporate laser sintering or microwave processing for localized repairs. Proper heat treatment is critical for achieving the desired microstructure and ensuring long-term durability of the repaired coating.Expand Specific Solutions05 Quality assessment and performance testing of repaired EBCs

Various methods are employed to assess the quality and performance of repaired EBC coatings. These include non-destructive testing techniques such as thermal imaging, ultrasonic inspection, and X-ray analysis to detect defects or delamination. Performance testing may involve thermal cycling, erosion resistance evaluation, and simulated environmental exposure. These assessment methods help ensure that repaired coatings meet the required specifications and will provide adequate protection under operating conditions.Expand Specific Solutions

Key Industry Players in EBC Repair Technology

The EBC (Environmental Barrier Coating) repair and re-coating methods for field maintenance market is currently in a growth phase, with increasing demand driven by the expanding gas turbine industry. The market size is estimated to reach significant value as power generation companies seek cost-effective maintenance solutions. Leading players include General Electric and Rolls-Royce, who have developed advanced repair technologies, while RTX Corp. (formerly United Technologies) and Safran Ceramics are investing in innovative coating methods. Chinese institutions like Xi'an Jiaotong University and Beihang University are emerging as important research centers. Oerlikon Metco and Directed Vapor Technologies offer specialized coating solutions, creating a competitive landscape where technological differentiation is key to market leadership. The technology is approaching maturity but continues to evolve with new materials and application methods.

General Electric Company

Technical Solution: GE has pioneered a comprehensive EBC repair system for field maintenance applications, particularly focused on their advanced gas turbine components. Their technology employs a modular approach to EBC repair that can be adapted to various field conditions. The system utilizes specialized portable thermal spray equipment with modified parameters to accommodate field constraints while maintaining coating quality. GE's method incorporates a proprietary two-layer repair approach: first applying a specially formulated bond coat that can adhere to partially degraded original coatings, followed by a nanostructured ceramic topcoat with enhanced erosion resistance. The company has developed field-deployable surface preparation techniques that combine mechanical cleaning with chemical treatments to ensure optimal substrate conditions prior to recoating. GE's repair methodology includes in-situ curing processes that use controlled heating elements to achieve proper coating consolidation without requiring component removal or factory processing.

Strengths: Extensive field validation across multiple engine platforms; modular repair approach that can be tailored to specific damage types and severity; integration with digital inspection tools for precise damage assessment and repair verification. Weaknesses: Higher initial equipment investment compared to some competing solutions; requires more extensive field infrastructure setup; repair process has longer downtime requirements than some alternative methods.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced field repair solutions for Environmental Barrier Coatings (EBCs) on ceramic matrix composite (CMC) components used in their aero engines. Their approach combines portable plasma spray systems with proprietary slurry-based repair methods that can be applied in field maintenance environments. The technology utilizes specialized ceramic powders with controlled particle size distribution to achieve optimal adhesion and durability when applied to damaged EBC areas. Rolls-Royce's repair methodology includes a multi-step process: surface preparation through controlled abrasive techniques, application of bond coat materials compatible with field conditions, deposition of the ceramic topcoat, and a field-viable heat treatment process to ensure proper coating consolidation. Their system includes quality control protocols using portable inspection equipment to verify coating thickness and integrity without requiring component removal from the engine.

Strengths: Highly portable repair equipment designed specifically for field maintenance scenarios; proprietary slurry formulations that achieve excellent adhesion without requiring high-temperature processing; comprehensive repair protocols that can be executed by trained field technicians. Weaknesses: Limited repair area size capability compared to factory repairs; field repairs may have shorter service life than original coatings due to processing constraints; requires specialized training for maintenance personnel.

Critical Patents and Innovations in EBC Repair

Method for removing EBC from substrate and repairing coated parts

PatentPendingCN120453163A

Innovation

- The etching solution is used to contact the coating component, which contains 5-70% by volume of hydrogen fluoride and solvent, and the hydrogen fluoride reacts with the silicon oxide in the thermally grown oxide layer, removes the thermally grown oxide layer and the environmental barrier coating, exposes the adhesive coating to form the intermediate part, and forms an alternative environmental barrier coating thereon.

Repair of a silicon-based bondcoat

PatentPendingUS20250100945A1

Innovation

- A liquid phase sintering method using a powder mixture of silicon and germanium is employed, where germanium acts as a transient liquid to facilitate fast densification of the silicon-based powder mixture at relatively low temperatures, allowing for in-situ repair of defects in the bondcoat and EBC.

Environmental Impact Assessment of Repair Methods

The environmental impact of EBC (Environmental Barrier Coating) repair and re-coating methods represents a critical consideration in the aerospace and power generation industries. Current field maintenance procedures often involve chemical processes, abrasive techniques, and thermal applications that can generate significant environmental concerns if not properly managed.

Traditional repair methods frequently utilize chemical stripping agents containing volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air quality degradation and pose potential health risks to maintenance personnel. These chemicals may contaminate soil and water systems when improperly disposed of, creating long-term environmental liabilities for organizations.

Mechanical repair techniques, while reducing chemical exposure, generate particulate matter that may contain toxic elements from the coating materials, including rare earth elements and heavy metals. Without proper containment systems, these particles can disperse into the surrounding environment, affecting local ecosystems and potentially entering the food chain through bioaccumulation processes.

Energy consumption represents another significant environmental factor in EBC repair operations. Thermal methods require substantial energy inputs, contributing to carbon emissions when powered by non-renewable sources. Field maintenance operations often rely on portable generators or other high-emission power sources, further increasing the carbon footprint of repair activities.

Water usage and wastewater management present additional challenges, particularly for wet processing techniques. Cooling systems and cleaning processes may consume substantial water resources, while the resulting wastewater often contains contaminants requiring specialized treatment before discharge.

Recent life cycle assessments of various EBC repair methodologies indicate that vacuum plasma spray repairs typically generate 30-45% lower environmental impact compared to traditional wet chemical processes, primarily due to reduced chemical waste generation and more efficient material utilization. However, these benefits must be balanced against the higher energy requirements of plasma-based systems.

Emerging environmentally-conscious repair technologies show promising developments, including water-based stripping agents, supercritical CO2 cleaning systems, and laser ablation techniques that minimize waste generation. These approaches demonstrate potential reductions in environmental impact ranging from 40-70% across multiple ecological indicators compared to conventional methods.

Regulatory frameworks increasingly mandate environmental impact mitigation strategies for maintenance operations, with particular emphasis on waste reduction, emissions control, and resource conservation. Organizations implementing comprehensive environmental management systems for repair operations report average compliance cost reductions of 25-35% through improved process efficiency and waste minimization.

Traditional repair methods frequently utilize chemical stripping agents containing volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air quality degradation and pose potential health risks to maintenance personnel. These chemicals may contaminate soil and water systems when improperly disposed of, creating long-term environmental liabilities for organizations.

Mechanical repair techniques, while reducing chemical exposure, generate particulate matter that may contain toxic elements from the coating materials, including rare earth elements and heavy metals. Without proper containment systems, these particles can disperse into the surrounding environment, affecting local ecosystems and potentially entering the food chain through bioaccumulation processes.

Energy consumption represents another significant environmental factor in EBC repair operations. Thermal methods require substantial energy inputs, contributing to carbon emissions when powered by non-renewable sources. Field maintenance operations often rely on portable generators or other high-emission power sources, further increasing the carbon footprint of repair activities.

Water usage and wastewater management present additional challenges, particularly for wet processing techniques. Cooling systems and cleaning processes may consume substantial water resources, while the resulting wastewater often contains contaminants requiring specialized treatment before discharge.

Recent life cycle assessments of various EBC repair methodologies indicate that vacuum plasma spray repairs typically generate 30-45% lower environmental impact compared to traditional wet chemical processes, primarily due to reduced chemical waste generation and more efficient material utilization. However, these benefits must be balanced against the higher energy requirements of plasma-based systems.

Emerging environmentally-conscious repair technologies show promising developments, including water-based stripping agents, supercritical CO2 cleaning systems, and laser ablation techniques that minimize waste generation. These approaches demonstrate potential reductions in environmental impact ranging from 40-70% across multiple ecological indicators compared to conventional methods.

Regulatory frameworks increasingly mandate environmental impact mitigation strategies for maintenance operations, with particular emphasis on waste reduction, emissions control, and resource conservation. Organizations implementing comprehensive environmental management systems for repair operations report average compliance cost reductions of 25-35% through improved process efficiency and waste minimization.

Quality Control Standards for Field Repairs

Quality control is paramount in field repair operations for Environmental Barrier Coatings (EBC), as these repairs directly impact the performance and longevity of critical components. Establishing comprehensive quality control standards ensures consistency, reliability, and effectiveness of repair procedures across different field environments and conditions.

The foundation of quality control for EBC field repairs begins with standardized inspection protocols. These protocols must include pre-repair assessment, in-process verification, and post-repair evaluation. Surface preparation quality must be verified through roughness measurements, cleanliness tests, and contamination detection methods. Industry standards typically require Ra values between 3-5 μm for optimal coating adhesion, with cleanliness levels meeting ISO 8502 standards.

Temperature and environmental monitoring represent critical quality control parameters during field repairs. Ambient conditions must be continuously tracked, with humidity levels maintained below 65% and temperatures within 10°C of the dew point to prevent moisture-related defects. Advanced portable monitoring equipment with data logging capabilities enables real-time tracking and documentation of these parameters throughout the repair process.

Coating thickness verification forms another essential quality control element. Non-destructive testing methods such as eddy current or ultrasonic thickness gauges provide accurate measurements without damaging the newly applied coating. Acceptable thickness variations typically range within ±10% of specified values, with measurements taken at multiple points across the repaired area to ensure uniformity.

Adhesion testing protocols must be established to verify the mechanical bond between the substrate and repair coating. Field-applicable methods include portable pull-off adhesion testers (conforming to ASTM D4541) and cross-hatch testing for thinner coatings. Minimum adhesion strength requirements typically range from 20-30 MPa depending on the specific EBC system and application environment.

Documentation and traceability systems form the backbone of effective quality control. Each repair must be thoroughly documented with standardized forms capturing environmental conditions, surface preparation parameters, coating application details, and post-repair inspection results. Digital documentation systems with cloud storage capabilities facilitate real-time data sharing between field technicians and engineering support teams, enabling prompt intervention when deviations occur.

Certification requirements for field repair technicians represent the human element of quality control. Personnel must undergo specialized training programs covering both theoretical knowledge and practical skills, with periodic recertification to ensure continued competence. Industry-recognized certifications such as NACE coating inspector or equivalent qualifications provide a standardized benchmark for technician capabilities.

The foundation of quality control for EBC field repairs begins with standardized inspection protocols. These protocols must include pre-repair assessment, in-process verification, and post-repair evaluation. Surface preparation quality must be verified through roughness measurements, cleanliness tests, and contamination detection methods. Industry standards typically require Ra values between 3-5 μm for optimal coating adhesion, with cleanliness levels meeting ISO 8502 standards.

Temperature and environmental monitoring represent critical quality control parameters during field repairs. Ambient conditions must be continuously tracked, with humidity levels maintained below 65% and temperatures within 10°C of the dew point to prevent moisture-related defects. Advanced portable monitoring equipment with data logging capabilities enables real-time tracking and documentation of these parameters throughout the repair process.

Coating thickness verification forms another essential quality control element. Non-destructive testing methods such as eddy current or ultrasonic thickness gauges provide accurate measurements without damaging the newly applied coating. Acceptable thickness variations typically range within ±10% of specified values, with measurements taken at multiple points across the repaired area to ensure uniformity.

Adhesion testing protocols must be established to verify the mechanical bond between the substrate and repair coating. Field-applicable methods include portable pull-off adhesion testers (conforming to ASTM D4541) and cross-hatch testing for thinner coatings. Minimum adhesion strength requirements typically range from 20-30 MPa depending on the specific EBC system and application environment.

Documentation and traceability systems form the backbone of effective quality control. Each repair must be thoroughly documented with standardized forms capturing environmental conditions, surface preparation parameters, coating application details, and post-repair inspection results. Digital documentation systems with cloud storage capabilities facilitate real-time data sharing between field technicians and engineering support teams, enabling prompt intervention when deviations occur.

Certification requirements for field repair technicians represent the human element of quality control. Personnel must undergo specialized training programs covering both theoretical knowledge and practical skills, with periodic recertification to ensure continued competence. Industry-recognized certifications such as NACE coating inspector or equivalent qualifications provide a standardized benchmark for technician capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!