Advanced Alloy Use in Plate Heat Exchanger Manufacturing

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alloy Evolution in Heat Exchangers

The evolution of alloys in heat exchangers represents a significant journey of technological advancement, driven by the need for improved efficiency, durability, and performance in heat transfer applications. Initially, heat exchangers primarily utilized basic metals such as copper and aluminum due to their thermal conductivity and availability. However, as industrial processes became more demanding, the limitations of these materials became apparent, particularly in corrosive environments and high-temperature applications.

The 1950s and 1960s saw the introduction of stainless steel alloys in heat exchanger manufacturing, marking a significant milestone. These alloys offered superior corrosion resistance and mechanical strength, enabling heat exchangers to operate in more aggressive environments. The development of austenitic stainless steels, such as 304 and 316 grades, provided a balance between cost-effectiveness and performance, becoming industry standards for many applications.

As the chemical and petrochemical industries expanded in the 1970s and 1980s, the demand for more specialized alloys grew. This period witnessed the emergence of high-performance nickel-based alloys, such as Inconel and Hastelloy. These materials offered exceptional resistance to both high temperatures and corrosive media, allowing heat exchangers to function in extreme conditions previously deemed impossible.

The 1990s brought about a focus on energy efficiency and sustainability, leading to the development of titanium alloys for heat exchanger applications. Titanium's excellent corrosion resistance, coupled with its lightweight properties, made it an ideal choice for seawater applications and industries requiring high purity, such as pharmaceuticals and food processing.

In the early 2000s, the advent of duplex stainless steels revolutionized the field. These alloys combined the strength of ferritic steels with the corrosion resistance of austenitic grades, offering a cost-effective solution for many challenging environments. This period also saw increased research into super duplex and hyper duplex grades, pushing the boundaries of alloy performance even further.

Recent years have witnessed a surge in the development of advanced aluminum alloys, particularly for compact heat exchangers in automotive and aerospace applications. These alloys offer enhanced thermal conductivity and reduced weight, contributing to overall system efficiency. Additionally, the exploration of novel materials such as metal matrix composites and high-entropy alloys represents the cutting edge of heat exchanger material science, promising unprecedented combinations of properties for future applications.

The 1950s and 1960s saw the introduction of stainless steel alloys in heat exchanger manufacturing, marking a significant milestone. These alloys offered superior corrosion resistance and mechanical strength, enabling heat exchangers to operate in more aggressive environments. The development of austenitic stainless steels, such as 304 and 316 grades, provided a balance between cost-effectiveness and performance, becoming industry standards for many applications.

As the chemical and petrochemical industries expanded in the 1970s and 1980s, the demand for more specialized alloys grew. This period witnessed the emergence of high-performance nickel-based alloys, such as Inconel and Hastelloy. These materials offered exceptional resistance to both high temperatures and corrosive media, allowing heat exchangers to function in extreme conditions previously deemed impossible.

The 1990s brought about a focus on energy efficiency and sustainability, leading to the development of titanium alloys for heat exchanger applications. Titanium's excellent corrosion resistance, coupled with its lightweight properties, made it an ideal choice for seawater applications and industries requiring high purity, such as pharmaceuticals and food processing.

In the early 2000s, the advent of duplex stainless steels revolutionized the field. These alloys combined the strength of ferritic steels with the corrosion resistance of austenitic grades, offering a cost-effective solution for many challenging environments. This period also saw increased research into super duplex and hyper duplex grades, pushing the boundaries of alloy performance even further.

Recent years have witnessed a surge in the development of advanced aluminum alloys, particularly for compact heat exchangers in automotive and aerospace applications. These alloys offer enhanced thermal conductivity and reduced weight, contributing to overall system efficiency. Additionally, the exploration of novel materials such as metal matrix composites and high-entropy alloys represents the cutting edge of heat exchanger material science, promising unprecedented combinations of properties for future applications.

Market Demand Analysis

The market demand for advanced alloys in plate heat exchanger manufacturing has been steadily increasing due to the growing need for more efficient and durable heat transfer solutions across various industries. This trend is driven by the rising emphasis on energy efficiency, sustainability, and the need for equipment that can withstand harsh operating conditions.

In the industrial sector, particularly in chemical processing, oil and gas, and power generation, there is a significant demand for plate heat exchangers that can handle corrosive fluids and high-temperature applications. Advanced alloys, such as high-grade stainless steel, titanium, and nickel-based alloys, are increasingly sought after for their superior corrosion resistance and thermal properties. This demand is further amplified by stringent environmental regulations and the push for more sustainable industrial processes.

The food and beverage industry represents another key market for advanced alloy plate heat exchangers. With the increasing focus on food safety and hygiene, manufacturers are seeking materials that offer better resistance to bacterial growth and are easier to clean. Advanced alloys that meet these requirements while also providing excellent heat transfer capabilities are in high demand.

In the HVAC sector, the trend towards more energy-efficient buildings is driving the adoption of advanced alloy plate heat exchangers. These exchangers offer better performance in terms of heat transfer efficiency and longevity, contributing to reduced energy consumption and lower maintenance costs over the lifecycle of HVAC systems.

The pharmaceutical and biotechnology industries are also significant contributors to the market demand for advanced alloy plate heat exchangers. These sectors require materials that can maintain purity in sensitive processes and withstand frequent cleaning and sterilization cycles. Advanced alloys that offer both corrosion resistance and biocompatibility are particularly valued in these applications.

Geographically, the demand for advanced alloy plate heat exchangers is strongest in regions with developed industrial bases and stringent environmental regulations, such as North America, Europe, and parts of Asia. However, emerging economies are also showing increased interest as they upgrade their industrial infrastructure and adopt more advanced manufacturing processes.

The market size for advanced alloy plate heat exchangers is expected to grow significantly in the coming years. This growth is fueled by the ongoing industrialization in developing countries, the global focus on energy efficiency, and the continuous innovation in alloy technologies that enable new applications and improved performance.

In the industrial sector, particularly in chemical processing, oil and gas, and power generation, there is a significant demand for plate heat exchangers that can handle corrosive fluids and high-temperature applications. Advanced alloys, such as high-grade stainless steel, titanium, and nickel-based alloys, are increasingly sought after for their superior corrosion resistance and thermal properties. This demand is further amplified by stringent environmental regulations and the push for more sustainable industrial processes.

The food and beverage industry represents another key market for advanced alloy plate heat exchangers. With the increasing focus on food safety and hygiene, manufacturers are seeking materials that offer better resistance to bacterial growth and are easier to clean. Advanced alloys that meet these requirements while also providing excellent heat transfer capabilities are in high demand.

In the HVAC sector, the trend towards more energy-efficient buildings is driving the adoption of advanced alloy plate heat exchangers. These exchangers offer better performance in terms of heat transfer efficiency and longevity, contributing to reduced energy consumption and lower maintenance costs over the lifecycle of HVAC systems.

The pharmaceutical and biotechnology industries are also significant contributors to the market demand for advanced alloy plate heat exchangers. These sectors require materials that can maintain purity in sensitive processes and withstand frequent cleaning and sterilization cycles. Advanced alloys that offer both corrosion resistance and biocompatibility are particularly valued in these applications.

Geographically, the demand for advanced alloy plate heat exchangers is strongest in regions with developed industrial bases and stringent environmental regulations, such as North America, Europe, and parts of Asia. However, emerging economies are also showing increased interest as they upgrade their industrial infrastructure and adopt more advanced manufacturing processes.

The market size for advanced alloy plate heat exchangers is expected to grow significantly in the coming years. This growth is fueled by the ongoing industrialization in developing countries, the global focus on energy efficiency, and the continuous innovation in alloy technologies that enable new applications and improved performance.

Current Alloy Challenges

The use of advanced alloys in plate heat exchanger manufacturing faces several significant challenges. One of the primary issues is the need for materials that can withstand increasingly extreme operating conditions. As industries push for higher efficiency and performance, plate heat exchangers are required to function under higher temperatures and pressures, as well as in more corrosive environments. This demand puts considerable stress on the alloys used, necessitating the development of materials with enhanced thermal stability, mechanical strength, and corrosion resistance.

Another challenge lies in the balance between performance and cost-effectiveness. While high-performance alloys such as titanium and nickel-based superalloys offer excellent properties, their high cost can make them prohibitively expensive for widespread use in plate heat exchangers. Manufacturers must navigate the trade-off between material performance and economic viability, often leading to compromises in design or the need for innovative material solutions.

The complexity of alloy composition and processing also presents significant hurdles. Achieving the desired properties often requires precise control over alloy composition, heat treatment, and manufacturing processes. Even minor variations can lead to substantial differences in performance, making consistent production challenging. This complexity is further compounded by the need for alloys that can be easily formed into thin plates with intricate patterns, a crucial requirement for efficient heat transfer in plate heat exchangers.

Corrosion resistance remains a persistent challenge, particularly in applications involving aggressive media or marine environments. While stainless steels are commonly used, they may not provide adequate protection in all scenarios. The development of alloys with improved corrosion resistance, without sacrificing other critical properties, is an ongoing area of research and development.

The long-term stability and reliability of advanced alloys in plate heat exchangers also pose significant challenges. Over time, materials may experience degradation due to thermal cycling, mechanical stress, and chemical interactions. Predicting and mitigating these long-term effects is crucial for ensuring the longevity and safety of heat exchanger systems, particularly in critical applications such as power generation or chemical processing.

Lastly, the manufacturing processes for advanced alloys in plate heat exchangers face their own set of challenges. Techniques such as brazing or welding must be optimized to maintain the integrity of the alloy properties while ensuring leak-tight joints. Additionally, the increasing focus on sustainability and environmental impact necessitates the development of alloys and manufacturing processes that minimize waste, energy consumption, and environmental footprint.

Another challenge lies in the balance between performance and cost-effectiveness. While high-performance alloys such as titanium and nickel-based superalloys offer excellent properties, their high cost can make them prohibitively expensive for widespread use in plate heat exchangers. Manufacturers must navigate the trade-off between material performance and economic viability, often leading to compromises in design or the need for innovative material solutions.

The complexity of alloy composition and processing also presents significant hurdles. Achieving the desired properties often requires precise control over alloy composition, heat treatment, and manufacturing processes. Even minor variations can lead to substantial differences in performance, making consistent production challenging. This complexity is further compounded by the need for alloys that can be easily formed into thin plates with intricate patterns, a crucial requirement for efficient heat transfer in plate heat exchangers.

Corrosion resistance remains a persistent challenge, particularly in applications involving aggressive media or marine environments. While stainless steels are commonly used, they may not provide adequate protection in all scenarios. The development of alloys with improved corrosion resistance, without sacrificing other critical properties, is an ongoing area of research and development.

The long-term stability and reliability of advanced alloys in plate heat exchangers also pose significant challenges. Over time, materials may experience degradation due to thermal cycling, mechanical stress, and chemical interactions. Predicting and mitigating these long-term effects is crucial for ensuring the longevity and safety of heat exchanger systems, particularly in critical applications such as power generation or chemical processing.

Lastly, the manufacturing processes for advanced alloys in plate heat exchangers face their own set of challenges. Techniques such as brazing or welding must be optimized to maintain the integrity of the alloy properties while ensuring leak-tight joints. Additionally, the increasing focus on sustainability and environmental impact necessitates the development of alloys and manufacturing processes that minimize waste, energy consumption, and environmental footprint.

Advanced Alloy Solutions

01 Composition and processing of advanced alloys

Advanced alloys are developed through innovative compositions and processing techniques to enhance their properties. This includes precise control of alloying elements, heat treatments, and manufacturing methods to achieve desired characteristics such as improved strength, corrosion resistance, or thermal stability.- Composition and processing of advanced alloys: Advanced alloys are developed through careful composition control and specialized processing techniques. These may include precise alloying element additions, heat treatments, and thermomechanical processing to achieve desired properties such as high strength, corrosion resistance, or specific magnetic characteristics.

- Novel manufacturing methods for advanced alloys: Innovative manufacturing methods are employed to produce advanced alloys with enhanced properties. These may include powder metallurgy, rapid solidification, additive manufacturing, or other non-traditional techniques that allow for precise control of microstructure and composition.

- Advanced alloys for specific applications: Specialized alloys are developed for particular applications such as aerospace, automotive, energy, or medical industries. These alloys are tailored to meet specific performance requirements like high temperature strength, wear resistance, or biocompatibility.

- Surface treatments and coatings for advanced alloys: Various surface treatments and coating technologies are applied to advanced alloys to enhance their properties. These may include nitriding, carburizing, or the application of protective coatings to improve wear resistance, corrosion protection, or other surface-dependent properties.

- Characterization and testing of advanced alloys: Advanced techniques for characterizing and testing alloy properties are crucial in the development and quality control of these materials. This may include advanced microscopy, spectroscopy, mechanical testing, and in-situ testing methods to understand and optimize alloy performance.

02 High-performance alloys for specific applications

Specialized alloys are engineered for particular industries or applications, such as aerospace, automotive, or energy sectors. These alloys are tailored to meet specific performance requirements under extreme conditions, including high temperatures, pressures, or corrosive environments.Expand Specific Solutions03 Novel manufacturing techniques for advanced alloys

Innovative manufacturing processes are developed to produce advanced alloys with unique microstructures or properties. These may include additive manufacturing, powder metallurgy, or rapid solidification techniques that allow for precise control over alloy composition and structure.Expand Specific Solutions04 Surface treatments and coatings for advanced alloys

Various surface modification techniques and coatings are applied to advanced alloys to enhance their surface properties. These treatments can improve wear resistance, corrosion protection, or thermal barrier properties, extending the lifespan and performance of alloy components.Expand Specific Solutions05 Characterization and testing of advanced alloys

Advanced techniques for analyzing and testing alloy properties are crucial for their development and quality control. This includes methods for evaluating microstructure, mechanical properties, and performance under simulated operating conditions to ensure the alloys meet required specifications.Expand Specific Solutions

Key Manufacturers Analysis

The advanced alloy use in plate heat exchanger manufacturing is in a mature stage of development, with a substantial global market size driven by increasing demand in various industries. The technology's maturity is evident from the involvement of established players like DENSO Corp., Kobe Steel, Ltd., and UACJ Corp., who have extensive experience in metallurgy and heat exchanger technologies. These companies, along with others such as Marelli Corp. and MAHLE International GmbH, are continuously innovating to improve alloy performance and manufacturing processes. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, with ongoing research and development efforts at institutions like Chongqing University and South China University of Technology contributing to technological advancements in the field.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed advanced aluminum alloys specifically for plate heat exchangers (PHEs). Their proprietary alloy, named "KPAL", offers superior corrosion resistance and high thermal conductivity. The alloy composition is optimized to withstand aggressive environments while maintaining excellent heat transfer properties. Kobe Steel employs a unique manufacturing process that involves precise control of alloying elements and heat treatment to achieve the desired microstructure. This results in plates with improved strength and formability, allowing for more efficient heat exchanger designs[1][3]. The company has also implemented advanced surface treatment techniques to enhance the brazeability of the alloy, ensuring reliable joints in the PHE assembly process.

Strengths: Superior corrosion resistance, high thermal conductivity, and improved formability. Weaknesses: Potentially higher cost compared to standard alloys, and may require specialized manufacturing equipment.

UACJ Corp.

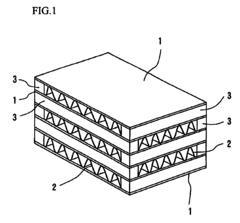

Technical Solution: UACJ Corporation has developed a range of high-performance aluminum alloys for plate heat exchangers. Their advanced alloy series, known as "UALEX", is designed to meet the demanding requirements of modern PHE applications. UACJ's alloys feature a carefully balanced composition that provides excellent thermal conductivity while maintaining high strength and corrosion resistance. The company utilizes a sophisticated rolling process that ensures uniform thickness and surface quality across large plate dimensions. UACJ has also developed proprietary cladding techniques that allow for the creation of multi-layer plates, combining the benefits of different alloys in a single product[2][5]. This innovation enables the optimization of both internal and external surfaces of the heat exchanger plates for specific operating conditions.

Innovative Alloy Patents

Plate type heat exchanger and method for manufacture thereof

PatentInactiveUS7179540B2

Innovation

- A nickel-based alloy with a composition of 25-35% chromium, 5-7% phosphorus, 3-5% silicon, and 0.001-0.1% of aluminum, calcium, or yttrium, with a binder applied via spray coating, is used to cover the plate and fin surfaces, enhancing brazing strength, fluidity, and corrosion resistance, and allowing for uniform adhesion of the brazing alloy powder.

Aluminum alloy material and plate heat exchanger with superior corrosion resistance

PatentInactiveUS8225851B2

Innovation

- An aluminum alloy material with a surface anodic oxide layer and a fluorocarbon resin coating, specifically a trifluoroethylene polymer-based coating, is applied using an organic phosphonic acid primer to enhance adhesion and corrosion resistance, with the anodic oxide layer thickness ranging from 1 to 20 μm and the fluorocarbon resin coating thickness from 1 to 100 μm.

Corrosion Resistance Advancements

Corrosion resistance advancements in plate heat exchanger manufacturing have seen significant progress in recent years, driven by the need for more durable and efficient heat transfer solutions in various industries. The use of advanced alloys has played a crucial role in enhancing the corrosion resistance of plate heat exchangers, particularly in aggressive environments such as chemical processing, oil and gas, and marine applications.

One of the most notable advancements in corrosion resistance has been the development and implementation of high-performance stainless steel alloys. These alloys, such as super austenitic stainless steels (e.g., 254 SMO, AL-6XN) and duplex stainless steels (e.g., 2205, 2507), offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking compared to traditional austenitic grades like 316L.

Nickel-based alloys have also gained prominence in plate heat exchanger manufacturing due to their exceptional corrosion resistance in highly aggressive media. Alloys such as Inconel 625, Hastelloy C-276, and Alloy 59 have demonstrated excellent performance in environments containing chlorides, sulfuric acid, and other corrosive substances. These materials have enabled the use of plate heat exchangers in applications previously considered too challenging for conventional materials.

Surface modification techniques have further enhanced the corrosion resistance of plate heat exchangers. Advanced coating technologies, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), have been employed to apply thin, protective layers of corrosion-resistant materials onto the plate surfaces. These coatings can significantly extend the service life of heat exchangers in corrosive environments while maintaining optimal heat transfer efficiency.

Nanotechnology has also contributed to corrosion resistance advancements in plate heat exchanger manufacturing. Nanostructured materials and nanocomposite coatings have shown promise in providing enhanced protection against various forms of corrosion. These innovations offer the potential for improved performance and longevity in challenging operating conditions.

The integration of computational modeling and simulation tools has greatly accelerated the development of corrosion-resistant alloys and coatings for plate heat exchangers. Advanced software packages allow engineers to predict corrosion behavior under different operating conditions, optimize material selection, and design more effective corrosion protection strategies. This approach has led to more targeted and efficient research and development efforts in the field of corrosion-resistant materials for heat exchanger applications.

One of the most notable advancements in corrosion resistance has been the development and implementation of high-performance stainless steel alloys. These alloys, such as super austenitic stainless steels (e.g., 254 SMO, AL-6XN) and duplex stainless steels (e.g., 2205, 2507), offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking compared to traditional austenitic grades like 316L.

Nickel-based alloys have also gained prominence in plate heat exchanger manufacturing due to their exceptional corrosion resistance in highly aggressive media. Alloys such as Inconel 625, Hastelloy C-276, and Alloy 59 have demonstrated excellent performance in environments containing chlorides, sulfuric acid, and other corrosive substances. These materials have enabled the use of plate heat exchangers in applications previously considered too challenging for conventional materials.

Surface modification techniques have further enhanced the corrosion resistance of plate heat exchangers. Advanced coating technologies, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), have been employed to apply thin, protective layers of corrosion-resistant materials onto the plate surfaces. These coatings can significantly extend the service life of heat exchangers in corrosive environments while maintaining optimal heat transfer efficiency.

Nanotechnology has also contributed to corrosion resistance advancements in plate heat exchanger manufacturing. Nanostructured materials and nanocomposite coatings have shown promise in providing enhanced protection against various forms of corrosion. These innovations offer the potential for improved performance and longevity in challenging operating conditions.

The integration of computational modeling and simulation tools has greatly accelerated the development of corrosion-resistant alloys and coatings for plate heat exchangers. Advanced software packages allow engineers to predict corrosion behavior under different operating conditions, optimize material selection, and design more effective corrosion protection strategies. This approach has led to more targeted and efficient research and development efforts in the field of corrosion-resistant materials for heat exchanger applications.

Environmental Impact Assessment

The use of advanced alloys in plate heat exchanger manufacturing has significant environmental implications that warrant careful consideration. These alloys, while offering superior performance and durability, also present unique challenges and opportunities from an environmental perspective.

The production of advanced alloys often requires energy-intensive processes and rare earth elements, which can lead to increased carbon emissions and resource depletion. However, the improved efficiency and longevity of plate heat exchangers made with these alloys can offset these initial environmental costs over the product lifecycle. The enhanced heat transfer capabilities and corrosion resistance of advanced alloys allow for more compact and efficient heat exchanger designs, potentially reducing material usage and energy consumption in various industrial applications.

Recycling and end-of-life management of advanced alloy components pose both challenges and opportunities. While these alloys are often more difficult to recycle due to their complex compositions, their high value incentivizes the development of more sophisticated recycling technologies. This could lead to advancements in material recovery processes, potentially benefiting the broader metals recycling industry.

The use of advanced alloys can also contribute to reduced environmental impact during the operational phase of plate heat exchangers. Their superior corrosion resistance minimizes the need for chemical treatments and reduces the frequency of maintenance and replacement, thereby lowering the overall environmental footprint associated with ongoing operations and maintenance activities.

In terms of water conservation, plate heat exchangers made with advanced alloys can operate more efficiently in challenging environments, such as those involving seawater or aggressive process fluids. This capability can lead to reduced freshwater consumption in industrial processes and potentially enable more widespread use of alternative water sources.

The manufacturing processes for advanced alloy plate heat exchangers may require stricter environmental controls due to the potential release of hazardous substances. However, these more stringent manufacturing practices could drive innovations in cleaner production technologies, benefiting the broader manufacturing sector.

Lastly, the improved performance of advanced alloy plate heat exchangers in high-temperature and high-pressure applications can contribute to overall system efficiency improvements in various industries. This can lead to significant energy savings and reduced greenhouse gas emissions on a larger scale, particularly in energy-intensive sectors such as power generation, chemical processing, and oil refining.

The production of advanced alloys often requires energy-intensive processes and rare earth elements, which can lead to increased carbon emissions and resource depletion. However, the improved efficiency and longevity of plate heat exchangers made with these alloys can offset these initial environmental costs over the product lifecycle. The enhanced heat transfer capabilities and corrosion resistance of advanced alloys allow for more compact and efficient heat exchanger designs, potentially reducing material usage and energy consumption in various industrial applications.

Recycling and end-of-life management of advanced alloy components pose both challenges and opportunities. While these alloys are often more difficult to recycle due to their complex compositions, their high value incentivizes the development of more sophisticated recycling technologies. This could lead to advancements in material recovery processes, potentially benefiting the broader metals recycling industry.

The use of advanced alloys can also contribute to reduced environmental impact during the operational phase of plate heat exchangers. Their superior corrosion resistance minimizes the need for chemical treatments and reduces the frequency of maintenance and replacement, thereby lowering the overall environmental footprint associated with ongoing operations and maintenance activities.

In terms of water conservation, plate heat exchangers made with advanced alloys can operate more efficiently in challenging environments, such as those involving seawater or aggressive process fluids. This capability can lead to reduced freshwater consumption in industrial processes and potentially enable more widespread use of alternative water sources.

The manufacturing processes for advanced alloy plate heat exchangers may require stricter environmental controls due to the potential release of hazardous substances. However, these more stringent manufacturing practices could drive innovations in cleaner production technologies, benefiting the broader manufacturing sector.

Lastly, the improved performance of advanced alloy plate heat exchangers in high-temperature and high-pressure applications can contribute to overall system efficiency improvements in various industries. This can lead to significant energy savings and reduced greenhouse gas emissions on a larger scale, particularly in energy-intensive sectors such as power generation, chemical processing, and oil refining.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!