Advanced Cooling Techniques For GaN HEMT Power Modules

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Cooling Technology Background and Objectives

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have emerged as revolutionary components in power electronics over the past two decades, offering superior performance characteristics compared to traditional silicon-based devices. The evolution of GaN technology has been marked by significant breakthroughs in material science and semiconductor fabrication, beginning with fundamental research in the 1990s and accelerating rapidly in the 2000s with the development of commercial-grade GaN-on-Si substrates.

The inherent properties of GaN, including wide bandgap (3.4 eV), high electron mobility, and excellent thermal conductivity, enable power devices that operate at higher frequencies, voltages, and temperatures than silicon counterparts. This translates to smaller, more efficient power conversion systems with reduced switching losses and improved power density – critical advantages for applications ranging from electric vehicles to renewable energy systems and data centers.

Despite these advantages, thermal management remains a fundamental challenge limiting the full potential of GaN HEMT power modules. As power densities continue to increase, conventional cooling techniques become insufficient to dissipate the concentrated heat generated during operation. The junction temperature of GaN devices must typically be maintained below 150-175°C to ensure reliability and performance, creating a significant thermal engineering challenge.

The evolution of cooling technologies for GaN HEMTs has progressed from traditional air cooling to more advanced solutions including liquid cooling, phase change materials, and integrated thermal management designs. Recent developments have focused on novel approaches such as microfluidic cooling channels, diamond heat spreaders, and advanced thermal interface materials specifically optimized for wide bandgap semiconductor applications.

The primary technical objective in GaN HEMT cooling is to develop thermal management solutions that can effectively dissipate heat while maintaining the compact form factor and cost advantages that make GaN technology attractive. This requires a multidisciplinary approach combining materials science, thermal engineering, and electronic packaging innovations.

Industry trends indicate a growing focus on holistic thermal design approaches that consider the entire power module as an integrated thermal system rather than addressing individual components in isolation. This includes co-design of semiconductor devices, packaging materials, and cooling structures to optimize overall thermal performance.

The trajectory of GaN HEMT cooling technology is increasingly aligned with sustainability goals, with emphasis on solutions that not only improve performance but also reduce energy consumption and environmental impact. This includes exploration of passive cooling techniques and waste heat recovery systems that complement active cooling methods.

The inherent properties of GaN, including wide bandgap (3.4 eV), high electron mobility, and excellent thermal conductivity, enable power devices that operate at higher frequencies, voltages, and temperatures than silicon counterparts. This translates to smaller, more efficient power conversion systems with reduced switching losses and improved power density – critical advantages for applications ranging from electric vehicles to renewable energy systems and data centers.

Despite these advantages, thermal management remains a fundamental challenge limiting the full potential of GaN HEMT power modules. As power densities continue to increase, conventional cooling techniques become insufficient to dissipate the concentrated heat generated during operation. The junction temperature of GaN devices must typically be maintained below 150-175°C to ensure reliability and performance, creating a significant thermal engineering challenge.

The evolution of cooling technologies for GaN HEMTs has progressed from traditional air cooling to more advanced solutions including liquid cooling, phase change materials, and integrated thermal management designs. Recent developments have focused on novel approaches such as microfluidic cooling channels, diamond heat spreaders, and advanced thermal interface materials specifically optimized for wide bandgap semiconductor applications.

The primary technical objective in GaN HEMT cooling is to develop thermal management solutions that can effectively dissipate heat while maintaining the compact form factor and cost advantages that make GaN technology attractive. This requires a multidisciplinary approach combining materials science, thermal engineering, and electronic packaging innovations.

Industry trends indicate a growing focus on holistic thermal design approaches that consider the entire power module as an integrated thermal system rather than addressing individual components in isolation. This includes co-design of semiconductor devices, packaging materials, and cooling structures to optimize overall thermal performance.

The trajectory of GaN HEMT cooling technology is increasingly aligned with sustainability goals, with emphasis on solutions that not only improve performance but also reduce energy consumption and environmental impact. This includes exploration of passive cooling techniques and waste heat recovery systems that complement active cooling methods.

Market Demand Analysis for High-Performance Thermal Management

The global market for high-performance thermal management solutions in GaN HEMT power modules is experiencing robust growth, driven primarily by the increasing adoption of GaN technology across multiple industries. Current market valuations indicate that the thermal management segment specific to wide bandgap semiconductors reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 18% through 2028.

This accelerated market expansion stems from several converging factors. The automotive sector represents the largest demand driver, with electric vehicle manufacturers seeking more efficient power conversion solutions that can operate reliably under demanding thermal conditions. The transition to 800V and even 1200V architectures in next-generation EVs has intensified the need for advanced cooling techniques that can handle higher power densities while maintaining compact form factors.

Telecommunications infrastructure, particularly with the ongoing global 5G deployment, constitutes another significant market segment. Base station power amplifiers utilizing GaN technology require sophisticated thermal management to ensure optimal performance and longevity in outdoor environments with variable ambient conditions. Industry analysts report that telecom applications account for approximately 24% of the current market demand for advanced cooling solutions.

Industrial power conversion systems represent a rapidly growing application area, with factory automation and renewable energy installations increasingly adopting GaN-based power modules. These applications typically demand cooling solutions that can maintain junction temperatures below critical thresholds while operating continuously in harsh industrial environments. Market research indicates that industrial applications will see the fastest growth rate at 22% annually through 2027.

Consumer electronics manufacturers are also driving demand, albeit at a smaller scale, as they explore GaN technology for fast-charging applications and compact power supplies. This segment values cooling solutions that enable miniaturization while maintaining thermal performance, with particular emphasis on passive cooling techniques that eliminate the need for fans or liquid cooling.

Geographic distribution of market demand shows Asia-Pacific leading with 42% market share, followed by North America (28%) and Europe (23%). China specifically represents the single largest national market, driven by its dominant position in electronics manufacturing and aggressive electrification initiatives.

Customer requirements across these segments consistently emphasize several key performance metrics: thermal resistance below 0.1°C/W, reliability for 100,000+ hours of operation, compatibility with automated manufacturing processes, and cost-effectiveness at scale. The market increasingly values integrated cooling solutions that combine multiple thermal management techniques rather than standalone approaches.

This accelerated market expansion stems from several converging factors. The automotive sector represents the largest demand driver, with electric vehicle manufacturers seeking more efficient power conversion solutions that can operate reliably under demanding thermal conditions. The transition to 800V and even 1200V architectures in next-generation EVs has intensified the need for advanced cooling techniques that can handle higher power densities while maintaining compact form factors.

Telecommunications infrastructure, particularly with the ongoing global 5G deployment, constitutes another significant market segment. Base station power amplifiers utilizing GaN technology require sophisticated thermal management to ensure optimal performance and longevity in outdoor environments with variable ambient conditions. Industry analysts report that telecom applications account for approximately 24% of the current market demand for advanced cooling solutions.

Industrial power conversion systems represent a rapidly growing application area, with factory automation and renewable energy installations increasingly adopting GaN-based power modules. These applications typically demand cooling solutions that can maintain junction temperatures below critical thresholds while operating continuously in harsh industrial environments. Market research indicates that industrial applications will see the fastest growth rate at 22% annually through 2027.

Consumer electronics manufacturers are also driving demand, albeit at a smaller scale, as they explore GaN technology for fast-charging applications and compact power supplies. This segment values cooling solutions that enable miniaturization while maintaining thermal performance, with particular emphasis on passive cooling techniques that eliminate the need for fans or liquid cooling.

Geographic distribution of market demand shows Asia-Pacific leading with 42% market share, followed by North America (28%) and Europe (23%). China specifically represents the single largest national market, driven by its dominant position in electronics manufacturing and aggressive electrification initiatives.

Customer requirements across these segments consistently emphasize several key performance metrics: thermal resistance below 0.1°C/W, reliability for 100,000+ hours of operation, compatibility with automated manufacturing processes, and cost-effectiveness at scale. The market increasingly values integrated cooling solutions that combine multiple thermal management techniques rather than standalone approaches.

Current Cooling Solutions and Technical Barriers

Current cooling solutions for GaN HEMT power modules primarily rely on conventional thermal management techniques that have been adapted to address the unique challenges posed by these high-power density devices. Traditional air cooling methods, while cost-effective, have proven increasingly inadequate for GaN HEMTs due to their limited heat dissipation capacity, typically achieving thermal resistances no lower than 0.5°C/W, which is insufficient for devices operating at power densities exceeding 5 W/mm².

Liquid cooling solutions have gained significant traction, with direct liquid cooling demonstrating thermal resistances as low as 0.1°C/W. Microchannel cooling, a subset of liquid cooling techniques, has shown promising results by integrating small channels directly beneath the device, allowing coolant to flow in close proximity to the heat source. However, these systems face challenges related to pressure drop, flow distribution, and long-term reliability concerns due to potential clogging and corrosion.

Two-phase cooling techniques, including phase change materials (PCMs) and vapor chambers, leverage latent heat of vaporization to achieve high heat transfer coefficients. Recent studies have demonstrated thermal resistances below 0.05°C/W using optimized two-phase cooling designs. Despite their effectiveness, these solutions often require complex integration strategies and face challenges with thermal cycling reliability.

Jet impingement cooling has emerged as another promising approach, directing high-velocity fluid jets onto hotspots to achieve localized cooling with thermal resistances approaching 0.08°C/W. This technique, however, requires precise control of fluid dynamics and presents integration challenges in compact module designs.

The primary technical barriers limiting current cooling solutions include thermal interface material (TIM) limitations, with even advanced TIMs introducing thermal resistances of 0.1-0.2°C/W. Additionally, the thermal boundary resistance between GaN and substrate materials creates a significant bottleneck, particularly at high power densities where localized hotspots can form despite adequate bulk cooling.

Package-level thermal management presents another significant challenge, as traditional packaging materials and designs were not optimized for the extreme thermal conditions of GaN HEMTs. The mismatch in coefficients of thermal expansion (CTE) between GaN, substrate materials, and cooling solutions leads to mechanical stress during thermal cycling, potentially compromising long-term reliability.

System-level integration barriers also exist, as many advanced cooling techniques require additional components such as pumps, heat exchangers, and control systems that increase system complexity, cost, and potential points of failure. The trade-off between cooling performance and system reliability remains a critical consideration for practical implementations.

Liquid cooling solutions have gained significant traction, with direct liquid cooling demonstrating thermal resistances as low as 0.1°C/W. Microchannel cooling, a subset of liquid cooling techniques, has shown promising results by integrating small channels directly beneath the device, allowing coolant to flow in close proximity to the heat source. However, these systems face challenges related to pressure drop, flow distribution, and long-term reliability concerns due to potential clogging and corrosion.

Two-phase cooling techniques, including phase change materials (PCMs) and vapor chambers, leverage latent heat of vaporization to achieve high heat transfer coefficients. Recent studies have demonstrated thermal resistances below 0.05°C/W using optimized two-phase cooling designs. Despite their effectiveness, these solutions often require complex integration strategies and face challenges with thermal cycling reliability.

Jet impingement cooling has emerged as another promising approach, directing high-velocity fluid jets onto hotspots to achieve localized cooling with thermal resistances approaching 0.08°C/W. This technique, however, requires precise control of fluid dynamics and presents integration challenges in compact module designs.

The primary technical barriers limiting current cooling solutions include thermal interface material (TIM) limitations, with even advanced TIMs introducing thermal resistances of 0.1-0.2°C/W. Additionally, the thermal boundary resistance between GaN and substrate materials creates a significant bottleneck, particularly at high power densities where localized hotspots can form despite adequate bulk cooling.

Package-level thermal management presents another significant challenge, as traditional packaging materials and designs were not optimized for the extreme thermal conditions of GaN HEMTs. The mismatch in coefficients of thermal expansion (CTE) between GaN, substrate materials, and cooling solutions leads to mechanical stress during thermal cycling, potentially compromising long-term reliability.

System-level integration barriers also exist, as many advanced cooling techniques require additional components such as pumps, heat exchangers, and control systems that increase system complexity, cost, and potential points of failure. The trade-off between cooling performance and system reliability remains a critical consideration for practical implementations.

State-of-the-Art Cooling Architectures for GaN HEMTs

01 Liquid cooling systems for GaN HEMT power modules

Liquid cooling systems are effective for managing heat in GaN HEMT power modules. These systems typically involve circulating coolants through channels or microchannels directly beneath or adjacent to the GaN HEMT devices. The liquid coolants, which may include water, dielectric fluids, or specialized coolants, efficiently absorb and transfer heat away from the power modules. This approach enables higher power densities and improved thermal management compared to traditional air cooling methods.- Direct liquid cooling systems for GaN HEMT modules: Direct liquid cooling systems provide efficient heat dissipation for GaN HEMT power modules by bringing coolant into direct contact with the heat-generating components. These systems typically use microchannels, jet impingement, or spray cooling techniques to maximize the heat transfer coefficient. The coolant can be water, dielectric fluids, or phase-change materials that efficiently remove heat from the GaN devices, allowing for higher power densities and improved reliability in high-frequency applications.

- Advanced thermal interface materials for GaN HEMT cooling: Specialized thermal interface materials (TIMs) are used between GaN HEMT devices and heat sinks to reduce thermal resistance. These materials include metal-based composites, phase-change materials, and graphene or carbon nanotube-enhanced compounds that offer superior thermal conductivity compared to conventional TIMs. The advanced interface materials minimize the thermal boundary resistance, enabling more efficient heat transfer from the GaN device to the cooling system and maintaining lower junction temperatures during high-power operation.

- Integrated cooling structures in GaN HEMT package design: Novel package designs incorporate cooling structures directly into the GaN HEMT module architecture. These include embedded heat pipes, vapor chambers, and integrated microfluidic channels that are built into the device substrate or package. The integrated approach minimizes thermal resistance by reducing the heat path length from junction to coolant. These designs often feature multi-layer structures with dedicated thermal management layers that efficiently spread and remove heat while maintaining electrical isolation where needed.

- Two-phase cooling solutions for high-power GaN modules: Two-phase cooling technologies utilize the phase change of the coolant (typically from liquid to vapor) to achieve high heat transfer rates in GaN HEMT power modules. These systems leverage the latent heat of vaporization to remove large amounts of heat while maintaining relatively uniform temperatures across the device. Implementations include flow boiling in microchannels, pool boiling systems, and vapor chambers that can handle the high heat fluxes generated by GaN devices operating at maximum power levels.

- Advanced heat sink designs for air-cooled GaN systems: Specialized heat sink designs for air-cooled GaN HEMT modules feature optimized fin geometries, surface treatments, and materials to maximize heat dissipation. These designs often incorporate high thermal conductivity materials like copper, aluminum nitride, or diamond-based composites. Advanced manufacturing techniques enable complex fin structures with increased surface area and reduced air flow resistance. Some designs also integrate heat pipes or vapor chambers to spread heat more effectively across the entire heat sink surface, improving cooling efficiency without liquid cooling complexity.

02 Advanced packaging techniques for thermal management

Innovative packaging designs significantly enhance thermal performance of GaN HEMT power modules. These include direct bonded copper (DBC) substrates, advanced die-attach materials with high thermal conductivity, and flip-chip configurations that minimize thermal resistance. Some designs incorporate thermal vias, embedded heat spreaders, or multi-layer structures specifically engineered to facilitate heat dissipation from the active device layer. These packaging solutions enable more efficient heat transfer paths from the GaN HEMT junction to the cooling system.Expand Specific Solutions03 Integration of novel heat sink designs and materials

Advanced heat sink designs and materials are being developed specifically for GaN HEMT power modules. These include micro-structured heat sinks with optimized fin geometries, vapor chambers, and heat pipes integrated directly into the module package. Novel materials such as diamond-based composites, graphene, and metal matrix composites with enhanced thermal conductivity are being utilized to improve heat spreading. Some designs feature phase-change materials that absorb heat during power pulses, providing additional thermal buffering capacity.Expand Specific Solutions04 Double-sided cooling architectures

Double-sided cooling approaches provide enhanced thermal management for GaN HEMT power modules by removing heat from both the top and bottom surfaces of the device. These configurations typically involve specialized packaging that allows coolant flow or heat sink attachment on both sides of the power module. This approach nearly doubles the available surface area for heat extraction, significantly reducing thermal resistance and junction temperatures. Implementation may include sandwich structures with thermal interfaces on both sides or embedded cooling channels that surround the device.Expand Specific Solutions05 Active cooling control systems for GaN power modules

Intelligent thermal management systems that dynamically adjust cooling parameters based on operating conditions are being developed for GaN HEMT power modules. These systems incorporate temperature sensors, microcontrollers, and variable cooling mechanisms that respond to changing thermal loads. Some implementations feature predictive algorithms that anticipate thermal requirements based on power profiles. Advanced control systems may include multiple cooling zones with independent regulation, allowing for optimized cooling across different parts of the module based on localized heat generation patterns.Expand Specific Solutions

Leading Companies in GaN Cooling Technology

The GaN HEMT power module cooling technology market is in a growth phase, driven by increasing demand for high-performance power electronics in automotive, telecommunications, and renewable energy sectors. The market is projected to expand significantly as GaN technology adoption accelerates, with an estimated compound annual growth rate of 25-30%. Technical maturity varies across competitors, with established players like Wolfspeed, GaN Systems, and Huawei demonstrating advanced cooling solutions, while academic institutions (Xidian University, UESTC) focus on fundamental research. Chinese companies including China Resources Microelectronics, CorEnergy Semiconductor, and Innoscience are rapidly advancing their capabilities, while international players like Imec and Nichia contribute specialized expertise in thermal management for GaN devices.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed advanced cooling solutions for GaN HEMT power modules utilizing direct liquid cooling with dielectric fluids. Their technology implements microchannels directly beneath the GaN die, allowing for junction-to-fluid thermal resistance as low as 0.15°C/W. The company's patented double-sided cooling architecture enables heat extraction from both sides of the device, significantly improving thermal management. Wolfspeed's solution incorporates silver sintering die-attach materials with thermal conductivity exceeding 200 W/mK, compared to traditional solder's 50-60 W/mK. Their latest modules feature integrated temperature sensors and thermal runaway protection circuits that can respond within microseconds to prevent device failure. The cooling system is designed to maintain junction temperatures below 150°C even under high-power density operations of 1000 W/cm².

Strengths: Industry-leading thermal resistance values; double-sided cooling capability maximizes heat extraction; silver sintering technology provides superior thermal interface. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized cooling infrastructure; potential reliability concerns with liquid cooling systems in harsh environments.

CorEnergy Semiconductor Technology Co., Ltd.

Technical Solution: CorEnergy has developed an innovative cooling solution for GaN HEMT power modules that combines advanced packaging technology with novel thermal management approaches. Their system utilizes a proprietary "thermal pillar" architecture that creates direct thermal pathways from the GaN die to the cooling medium, reducing thermal resistance by approximately 40% compared to conventional designs. The company has implemented a composite metal matrix material with thermal conductivity exceeding 500 W/mK for critical heat-spreading components. CorEnergy's solution incorporates a micro-channel cold plate design with optimized fluid dynamics, achieving heat transfer coefficients up to 50,000 W/m²K. Their modules feature a specialized thermal interface material with phase-change properties that ensures consistent thermal performance across varying operating conditions. The company has also developed a patented pressure-contact technology that eliminates the need for solder or sintering at critical thermal interfaces, reducing thermal resistance while improving reliability. This comprehensive approach enables their GaN power modules to maintain junction temperatures below 125°C even at power densities exceeding 800 W/cm².

Strengths: Exceptional thermal performance through innovative thermal pillar design; advanced composite materials provide superior heat spreading; elimination of solder interfaces improves reliability. Weaknesses: Complex manufacturing process increases production costs; requires specialized assembly equipment; thermal performance dependent on proper installation and interface pressure maintenance.

Critical Patents and Research in GaN Thermal Management

High voltage GaN transistors

PatentInactiveEP1965433A3

Innovation

- The implementation of multiple field plate transistors with a specific configuration, including insulating and conducting field plates, reduces peak electric fields and enhances breakdown voltage while maintaining low on resistances, suitable for high-frequency applications.

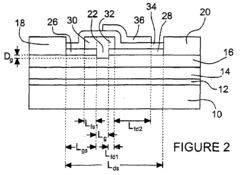

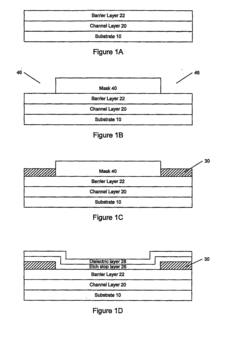

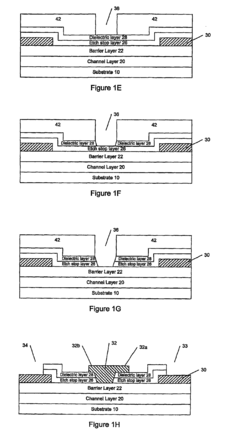

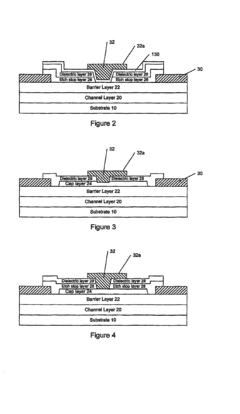

Nitride-based transistors and fabrication methods with an etch stop layer

PatentActiveEP2479790A2

Innovation

- Incorporating an etch stop layer to protect the underlying layers during recess formation, which is subsequently removed to expose the surface layer for the gate contact, thereby reducing damage and enhancing device operation.

Reliability and Lifetime Assessment Methods

Reliability assessment of GaN HEMT power modules with advanced cooling techniques requires systematic methodologies to evaluate performance degradation over time. Traditional reliability testing frameworks must be adapted to account for the unique thermal characteristics and failure mechanisms of GaN technology when integrated with novel cooling solutions.

Accelerated life testing (ALT) represents a cornerstone methodology, where devices are subjected to elevated stress conditions—particularly thermal cycling and power cycling—to induce failure mechanisms that would typically occur over years of normal operation. For GaN HEMTs with advanced cooling, these tests must be modified to accurately reflect the thermal gradients and mechanical stresses unique to these cooling interfaces.

Physics of Failure (PoF) approaches have gained prominence for GaN reliability assessment, focusing on understanding fundamental degradation mechanisms rather than merely statistical failure data. This methodology involves identifying critical failure modes such as gate sinking, electron trapping, and thermomechanical stress at cooling interfaces, then developing mathematical models to predict lifetime under various operating conditions.

Thermal impedance monitoring serves as a crucial in-situ reliability indicator for cooled GaN modules. Progressive increases in thermal resistance often signal degradation at the die-attach or cooling interface before catastrophic failure occurs. Advanced measurement techniques including transient thermal testing and infrared microscopy enable precise tracking of thermal pathway deterioration.

Mission-profile based lifetime prediction has emerged as an industry standard, incorporating actual application conditions into reliability models. This approach simulates real-world power and temperature profiles, accounting for the dynamic thermal management capabilities of advanced cooling solutions to provide more accurate lifetime estimates than constant-stress models.

Non-destructive evaluation techniques including acoustic microscopy, X-ray tomography, and lock-in thermography allow for periodic assessment of cooling interface integrity without compromising the device. These methods can detect delamination, void formation, or crack propagation at early stages, enabling preventive maintenance strategies.

Reliability metrics specific to cooled GaN systems must include Mean Time To Failure (MTTF), Failures In Time (FIT), and activation energy values calibrated for GaN's unique degradation mechanisms. Additionally, thermal cycling capability, defined as the number of temperature excursions before significant performance degradation, serves as a critical benchmark for cooling solution durability.

Industry standards for reliability qualification are still evolving for GaN with advanced cooling, with organizations like JEDEC and AEC developing specialized test protocols. Current frameworks often combine elements from silicon carbide qualification standards with additional thermal performance requirements specific to GaN's higher power density.

Accelerated life testing (ALT) represents a cornerstone methodology, where devices are subjected to elevated stress conditions—particularly thermal cycling and power cycling—to induce failure mechanisms that would typically occur over years of normal operation. For GaN HEMTs with advanced cooling, these tests must be modified to accurately reflect the thermal gradients and mechanical stresses unique to these cooling interfaces.

Physics of Failure (PoF) approaches have gained prominence for GaN reliability assessment, focusing on understanding fundamental degradation mechanisms rather than merely statistical failure data. This methodology involves identifying critical failure modes such as gate sinking, electron trapping, and thermomechanical stress at cooling interfaces, then developing mathematical models to predict lifetime under various operating conditions.

Thermal impedance monitoring serves as a crucial in-situ reliability indicator for cooled GaN modules. Progressive increases in thermal resistance often signal degradation at the die-attach or cooling interface before catastrophic failure occurs. Advanced measurement techniques including transient thermal testing and infrared microscopy enable precise tracking of thermal pathway deterioration.

Mission-profile based lifetime prediction has emerged as an industry standard, incorporating actual application conditions into reliability models. This approach simulates real-world power and temperature profiles, accounting for the dynamic thermal management capabilities of advanced cooling solutions to provide more accurate lifetime estimates than constant-stress models.

Non-destructive evaluation techniques including acoustic microscopy, X-ray tomography, and lock-in thermography allow for periodic assessment of cooling interface integrity without compromising the device. These methods can detect delamination, void formation, or crack propagation at early stages, enabling preventive maintenance strategies.

Reliability metrics specific to cooled GaN systems must include Mean Time To Failure (MTTF), Failures In Time (FIT), and activation energy values calibrated for GaN's unique degradation mechanisms. Additionally, thermal cycling capability, defined as the number of temperature excursions before significant performance degradation, serves as a critical benchmark for cooling solution durability.

Industry standards for reliability qualification are still evolving for GaN with advanced cooling, with organizations like JEDEC and AEC developing specialized test protocols. Current frameworks often combine elements from silicon carbide qualification standards with additional thermal performance requirements specific to GaN's higher power density.

Integration Challenges with Power Electronics Systems

The integration of advanced cooling techniques for GaN HEMT power modules into existing power electronics systems presents significant challenges that must be addressed for successful implementation. These challenges stem from the unique thermal characteristics of GaN technology and the complex requirements of modern power systems.

Thermal interface management represents a primary concern when integrating cooling solutions with GaN HEMT modules. The thermal boundary resistance between GaN devices and cooling structures often creates bottlenecks that limit heat dissipation efficiency. This interface must be carefully engineered to minimize thermal resistance while maintaining electrical isolation where required.

System-level thermal design considerations become increasingly complex as power densities rise. The compact nature of GaN-based systems means that cooling solutions must be effective without compromising the size advantages that GaN technology offers. This creates a delicate balance between thermal performance and form factor constraints that system designers must navigate.

Electromagnetic compatibility (EMC) issues frequently arise when implementing advanced cooling techniques. Metallic cooling structures can act as antennas or create parasitic capacitances that interfere with the high-frequency operation of GaN devices. Careful shielding and grounding strategies must be developed to maintain signal integrity while providing adequate cooling.

Manufacturing processes for integrated cooling solutions present another significant challenge. Techniques such as direct substrate cooling or embedded microchannel cooling require specialized fabrication methods that may not align with standard power electronics manufacturing flows. This misalignment can increase production complexity and costs.

Reliability testing becomes more complex with integrated cooling systems. The interaction between cooling structures and GaN devices under thermal cycling, mechanical stress, and long-term operation must be thoroughly characterized. Traditional reliability models may not adequately capture these interactions, necessitating new qualification methodologies.

Cost considerations often present barriers to adoption of advanced cooling techniques. While GaN technology offers performance benefits, the addition of sophisticated cooling solutions can significantly impact overall system economics. Finding the optimal balance between thermal performance and cost-effectiveness remains a persistent challenge for system integrators.

Standardization efforts are currently limited in this emerging field. The lack of established design guidelines and interface standards for GaN cooling systems complicates integration efforts and slows industry-wide adoption. Development of common practices and standards would facilitate more widespread implementation of advanced cooling techniques.

Thermal interface management represents a primary concern when integrating cooling solutions with GaN HEMT modules. The thermal boundary resistance between GaN devices and cooling structures often creates bottlenecks that limit heat dissipation efficiency. This interface must be carefully engineered to minimize thermal resistance while maintaining electrical isolation where required.

System-level thermal design considerations become increasingly complex as power densities rise. The compact nature of GaN-based systems means that cooling solutions must be effective without compromising the size advantages that GaN technology offers. This creates a delicate balance between thermal performance and form factor constraints that system designers must navigate.

Electromagnetic compatibility (EMC) issues frequently arise when implementing advanced cooling techniques. Metallic cooling structures can act as antennas or create parasitic capacitances that interfere with the high-frequency operation of GaN devices. Careful shielding and grounding strategies must be developed to maintain signal integrity while providing adequate cooling.

Manufacturing processes for integrated cooling solutions present another significant challenge. Techniques such as direct substrate cooling or embedded microchannel cooling require specialized fabrication methods that may not align with standard power electronics manufacturing flows. This misalignment can increase production complexity and costs.

Reliability testing becomes more complex with integrated cooling systems. The interaction between cooling structures and GaN devices under thermal cycling, mechanical stress, and long-term operation must be thoroughly characterized. Traditional reliability models may not adequately capture these interactions, necessitating new qualification methodologies.

Cost considerations often present barriers to adoption of advanced cooling techniques. While GaN technology offers performance benefits, the addition of sophisticated cooling solutions can significantly impact overall system economics. Finding the optimal balance between thermal performance and cost-effectiveness remains a persistent challenge for system integrators.

Standardization efforts are currently limited in this emerging field. The lack of established design guidelines and interface standards for GaN cooling systems complicates integration efforts and slows industry-wide adoption. Development of common practices and standards would facilitate more widespread implementation of advanced cooling techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!