Advanced Gas Welding Techniques for Aircraft Hull Repairs

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aircraft Hull Welding Evolution and Objectives

Gas welding techniques for aircraft hull repairs have undergone significant evolution since the early days of aviation. Initially, welding was primarily used for simple repairs and minor structural modifications. However, as aircraft design became more complex and safety standards more stringent, the need for advanced welding techniques grew exponentially.

The development of gas welding for aircraft hulls can be traced back to the 1920s and 1930s when aluminum alloys began to replace wood and fabric in aircraft construction. During World War II, the demand for rapid aircraft production and repair led to significant advancements in welding technology. Post-war, the focus shifted towards improving weld quality, consistency, and efficiency to meet the growing demands of commercial aviation.

In the 1960s and 1970s, the introduction of computer-controlled welding systems marked a significant milestone in aircraft hull welding. These systems allowed for more precise control of welding parameters, resulting in higher quality welds and reduced human error. Concurrently, advancements in metallurgy led to the development of new aluminum alloys specifically designed for improved weldability and strength.

The 1980s and 1990s saw the integration of robotics into aircraft welding processes, further enhancing precision and repeatability. This period also witnessed the development of advanced non-destructive testing methods, such as ultrasonic and radiographic inspection, which greatly improved the ability to verify weld integrity without compromising the structure.

In recent years, the focus has shifted towards developing more environmentally friendly and energy-efficient welding processes. Pulse gas metal arc welding (GMAW-P) and friction stir welding have emerged as promising techniques for aircraft hull repairs, offering reduced heat input and minimal distortion.

The primary objectives of advanced gas welding techniques for aircraft hull repairs are multifaceted. Firstly, they aim to ensure the highest level of structural integrity and safety, meeting or exceeding stringent aviation industry standards. Secondly, these techniques seek to minimize repair time and costs, reducing aircraft downtime and improving operational efficiency for airlines and maintenance organizations.

Another crucial objective is to develop welding methods that can effectively join new, advanced materials being introduced in modern aircraft design, such as high-strength aluminum-lithium alloys and composite-metal hybrid structures. Additionally, there is a growing emphasis on creating more sustainable welding processes that reduce energy consumption and minimize environmental impact.

Looking ahead, the field of aircraft hull welding continues to evolve. Research is ongoing to develop intelligent welding systems that can adapt in real-time to varying material properties and environmental conditions. The integration of artificial intelligence and machine learning algorithms promises to further optimize welding parameters and predict potential defects before they occur.

The development of gas welding for aircraft hulls can be traced back to the 1920s and 1930s when aluminum alloys began to replace wood and fabric in aircraft construction. During World War II, the demand for rapid aircraft production and repair led to significant advancements in welding technology. Post-war, the focus shifted towards improving weld quality, consistency, and efficiency to meet the growing demands of commercial aviation.

In the 1960s and 1970s, the introduction of computer-controlled welding systems marked a significant milestone in aircraft hull welding. These systems allowed for more precise control of welding parameters, resulting in higher quality welds and reduced human error. Concurrently, advancements in metallurgy led to the development of new aluminum alloys specifically designed for improved weldability and strength.

The 1980s and 1990s saw the integration of robotics into aircraft welding processes, further enhancing precision and repeatability. This period also witnessed the development of advanced non-destructive testing methods, such as ultrasonic and radiographic inspection, which greatly improved the ability to verify weld integrity without compromising the structure.

In recent years, the focus has shifted towards developing more environmentally friendly and energy-efficient welding processes. Pulse gas metal arc welding (GMAW-P) and friction stir welding have emerged as promising techniques for aircraft hull repairs, offering reduced heat input and minimal distortion.

The primary objectives of advanced gas welding techniques for aircraft hull repairs are multifaceted. Firstly, they aim to ensure the highest level of structural integrity and safety, meeting or exceeding stringent aviation industry standards. Secondly, these techniques seek to minimize repair time and costs, reducing aircraft downtime and improving operational efficiency for airlines and maintenance organizations.

Another crucial objective is to develop welding methods that can effectively join new, advanced materials being introduced in modern aircraft design, such as high-strength aluminum-lithium alloys and composite-metal hybrid structures. Additionally, there is a growing emphasis on creating more sustainable welding processes that reduce energy consumption and minimize environmental impact.

Looking ahead, the field of aircraft hull welding continues to evolve. Research is ongoing to develop intelligent welding systems that can adapt in real-time to varying material properties and environmental conditions. The integration of artificial intelligence and machine learning algorithms promises to further optimize welding parameters and predict potential defects before they occur.

Aerospace Industry Demand for Advanced Welding

The aerospace industry's demand for advanced welding techniques, particularly in aircraft hull repairs, has been steadily increasing over the past decade. This surge in demand is driven by several factors, including the growing global fleet of commercial and military aircraft, the need for more efficient and cost-effective repair methods, and the push for lighter, stronger materials in aircraft construction.

Aircraft manufacturers and maintenance, repair, and overhaul (MRO) companies are constantly seeking innovative welding solutions to address the unique challenges posed by aircraft hull repairs. These challenges include working with thin, high-strength alloys, maintaining structural integrity in critical areas, and minimizing heat-affected zones that could compromise the material properties.

Advanced gas welding techniques have emerged as a promising solution for many of these challenges. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, has become a preferred method for many aerospace applications due to its precision and ability to produce high-quality welds on thin materials. The aerospace industry has been investing heavily in research and development to further improve GTAW techniques, focusing on areas such as automated welding systems, adaptive control algorithms, and advanced shielding gas mixtures.

The demand for these advanced welding techniques is also driven by the increasing use of advanced materials in aircraft construction, such as titanium alloys and high-strength aluminum alloys. These materials offer significant weight savings and improved performance but require specialized welding processes to maintain their properties and ensure structural integrity.

Furthermore, the aerospace industry's push towards more sustainable practices has led to an increased focus on repair and refurbishment rather than replacement of components. This trend has further amplified the demand for advanced welding techniques that can effectively restore damaged aircraft hulls to their original strength and performance characteristics.

The market for advanced welding equipment and services in the aerospace industry is projected to grow significantly in the coming years. This growth is fueled by the increasing number of aircraft in service, the aging of existing fleets, and the continuous development of new aircraft models that incorporate advanced materials and construction techniques.

In response to this growing demand, welding equipment manufacturers and service providers are investing in the development of new technologies and training programs to meet the specific needs of the aerospace industry. This includes the creation of specialized welding systems designed for aircraft hull repairs, as well as the development of advanced training simulators to improve the skills of welding technicians in the aerospace sector.

Aircraft manufacturers and maintenance, repair, and overhaul (MRO) companies are constantly seeking innovative welding solutions to address the unique challenges posed by aircraft hull repairs. These challenges include working with thin, high-strength alloys, maintaining structural integrity in critical areas, and minimizing heat-affected zones that could compromise the material properties.

Advanced gas welding techniques have emerged as a promising solution for many of these challenges. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, has become a preferred method for many aerospace applications due to its precision and ability to produce high-quality welds on thin materials. The aerospace industry has been investing heavily in research and development to further improve GTAW techniques, focusing on areas such as automated welding systems, adaptive control algorithms, and advanced shielding gas mixtures.

The demand for these advanced welding techniques is also driven by the increasing use of advanced materials in aircraft construction, such as titanium alloys and high-strength aluminum alloys. These materials offer significant weight savings and improved performance but require specialized welding processes to maintain their properties and ensure structural integrity.

Furthermore, the aerospace industry's push towards more sustainable practices has led to an increased focus on repair and refurbishment rather than replacement of components. This trend has further amplified the demand for advanced welding techniques that can effectively restore damaged aircraft hulls to their original strength and performance characteristics.

The market for advanced welding equipment and services in the aerospace industry is projected to grow significantly in the coming years. This growth is fueled by the increasing number of aircraft in service, the aging of existing fleets, and the continuous development of new aircraft models that incorporate advanced materials and construction techniques.

In response to this growing demand, welding equipment manufacturers and service providers are investing in the development of new technologies and training programs to meet the specific needs of the aerospace industry. This includes the creation of specialized welding systems designed for aircraft hull repairs, as well as the development of advanced training simulators to improve the skills of welding technicians in the aerospace sector.

Current Challenges in Aircraft Hull Gas Welding

Gas welding techniques for aircraft hull repairs face several significant challenges in the current aerospace industry. One of the primary issues is the complexity of working with advanced aerospace materials. Modern aircraft hulls often incorporate lightweight alloys and composite materials that require specialized welding techniques. These materials can be sensitive to heat and prone to distortion, making precise temperature control during the welding process crucial.

Another challenge lies in the stringent safety and quality standards imposed by aviation regulatory bodies. Aircraft hull repairs must meet exacting specifications to ensure the structural integrity and airworthiness of the aircraft. This necessitates highly skilled welders and advanced quality control measures, which can be difficult to consistently maintain across different repair scenarios.

The need for portability and flexibility in repair operations also presents challenges. Aircraft repairs often need to be conducted in various locations, including remote airfields or maintenance facilities. This requires gas welding equipment that is both portable and capable of delivering consistent results in diverse environmental conditions.

Minimizing downtime is a critical concern for airlines and aircraft operators. The time required for gas welding repairs can be substantial, especially for complex hull structures. Developing techniques that can expedite the repair process without compromising quality is an ongoing challenge in the industry.

Environmental considerations also play a role in the challenges faced by gas welding techniques. The aerospace industry is under increasing pressure to reduce emissions and improve sustainability. This has led to a push for more environmentally friendly welding processes and materials, which can be challenging to implement while maintaining the required performance standards.

The integration of automation and robotics in gas welding for aircraft hull repairs is another area of focus. While automation can potentially improve precision and consistency, it presents challenges in terms of equipment design, programming, and adaptation to the complex geometries of aircraft hulls.

Lastly, the ongoing evolution of aircraft design and materials poses a continuous challenge for gas welding techniques. As manufacturers develop new hull designs and incorporate novel materials, welding processes must adapt quickly to accommodate these changes. This requires ongoing research and development to ensure that gas welding techniques remain effective and relevant for future aircraft repair needs.

Another challenge lies in the stringent safety and quality standards imposed by aviation regulatory bodies. Aircraft hull repairs must meet exacting specifications to ensure the structural integrity and airworthiness of the aircraft. This necessitates highly skilled welders and advanced quality control measures, which can be difficult to consistently maintain across different repair scenarios.

The need for portability and flexibility in repair operations also presents challenges. Aircraft repairs often need to be conducted in various locations, including remote airfields or maintenance facilities. This requires gas welding equipment that is both portable and capable of delivering consistent results in diverse environmental conditions.

Minimizing downtime is a critical concern for airlines and aircraft operators. The time required for gas welding repairs can be substantial, especially for complex hull structures. Developing techniques that can expedite the repair process without compromising quality is an ongoing challenge in the industry.

Environmental considerations also play a role in the challenges faced by gas welding techniques. The aerospace industry is under increasing pressure to reduce emissions and improve sustainability. This has led to a push for more environmentally friendly welding processes and materials, which can be challenging to implement while maintaining the required performance standards.

The integration of automation and robotics in gas welding for aircraft hull repairs is another area of focus. While automation can potentially improve precision and consistency, it presents challenges in terms of equipment design, programming, and adaptation to the complex geometries of aircraft hulls.

Lastly, the ongoing evolution of aircraft design and materials poses a continuous challenge for gas welding techniques. As manufacturers develop new hull designs and incorporate novel materials, welding processes must adapt quickly to accommodate these changes. This requires ongoing research and development to ensure that gas welding techniques remain effective and relevant for future aircraft repair needs.

State-of-the-Art Gas Welding Techniques

01 Underwater welding techniques for hull repairs

Specialized underwater welding techniques have been developed for repairing ship hulls below the waterline. These methods involve using waterproof welding equipment and specially trained divers to perform repairs without the need for dry-docking. This approach can significantly reduce repair time and costs for minor hull damage.- Underwater welding techniques for hull repairs: Specialized techniques for performing gas welding underwater to repair ship hulls. This involves using waterproof welding equipment and methods to maintain a dry welding environment beneath the water surface, allowing for effective repairs without dry-docking the vessel.

- Portable welding systems for on-site hull repairs: Development of compact and portable gas welding systems specifically designed for on-site hull repairs. These systems allow for greater flexibility in performing repairs in various locations, including remote areas or directly on the ship while docked.

- Automated welding processes for hull repair: Implementation of automated gas welding systems for hull repairs, incorporating robotic arms and computer-controlled welding parameters. This approach enhances precision, consistency, and efficiency in repairing large hull sections or complex geometries.

- Specialized welding alloys for marine applications: Development of specific welding alloys and filler materials tailored for marine environments. These materials are designed to withstand corrosion, high stress, and other challenges associated with hull repairs in saltwater conditions.

- Non-destructive testing methods for weld quality assurance: Integration of non-destructive testing techniques to assess the quality and integrity of gas welds in hull repairs. This includes methods such as ultrasonic testing, radiographic inspection, and magnetic particle testing to ensure the durability and safety of the repaired sections.

02 Automated welding systems for hull repair

Advanced automated welding systems have been designed specifically for hull repairs. These systems use robotic arms and computer-controlled welding heads to perform precise and consistent welds on large hull surfaces. They can operate in various positions and handle complex geometries, improving efficiency and quality of repairs.Expand Specific Solutions03 Portable gas welding equipment for on-site repairs

Portable gas welding equipment has been developed for on-site hull repairs. These compact systems include gas cylinders, regulators, and specialized torches designed for use in confined spaces and awkward positions often encountered during hull repair work. The portability allows for quick response to emergency repairs in various locations.Expand Specific Solutions04 Welding techniques for thin hull materials

Specialized welding techniques have been developed for repairing thin hull materials, such as those used in lightweight vessels. These methods focus on minimizing heat input to prevent warping or damage to the surrounding structure. Techniques may include pulsed welding or the use of backing materials to control heat distribution.Expand Specific Solutions05 Corrosion-resistant welding for marine environments

Welding techniques and materials have been developed to enhance corrosion resistance in marine environments. These methods focus on using specialized filler materials and post-weld treatments to create welds that can withstand the harsh saltwater environment. This approach helps to extend the life of hull repairs and reduce the need for frequent maintenance.Expand Specific Solutions

Key Players in Aerospace Welding Industry

The advanced gas welding techniques for aircraft hull repairs market is in a mature stage, characterized by established players and well-defined processes. The market size is substantial, driven by the ongoing need for aircraft maintenance and repair across the global aviation industry. Technologically, the field is relatively mature, with incremental improvements rather than disruptive innovations. Key players like United Technologies Corp., Honeywell International Technologies Ltd., and The Boeing Co. dominate the market, leveraging their extensive experience and resources. These companies, along with others such as MTU Aero Engines AG and Lufthansa Technik AG, continue to invest in research and development to enhance welding techniques, improve efficiency, and meet evolving safety standards in the aerospace industry.

General Electric Company

Technical Solution: GE has innovated in the field of gas welding for aircraft hull repairs with their adaptive gas flow control system. This technology dynamically adjusts gas flow rates based on real-time welding conditions, optimizing shielding and improving weld quality[8]. GE's technique also incorporates advanced alloy-specific welding parameters and a pulsed welding current to control heat input precisely. They have developed a unique torch design that improves gas coverage and allows for welding in tight spaces common in aircraft structures[10]. Furthermore, GE has integrated their welding system with digital twin technology, enabling predictive maintenance and quality assurance for repaired hull sections[12].

Strengths: Adaptive technology for various conditions and integration with digital systems. Weaknesses: Potential for system complexity leading to maintenance challenges.

The Boeing Co.

Technical Solution: Boeing has developed advanced gas welding techniques for aircraft hull repairs, focusing on precision and efficiency. Their method utilizes a computer-controlled gas welding system that maintains optimal gas mixture and temperature throughout the welding process[1]. This system incorporates real-time monitoring of weld quality using ultrasonic sensors, ensuring structural integrity. Boeing's technique also employs a proprietary shielding gas blend that minimizes oxidation and improves weld strength[3]. Additionally, they have implemented a robotic arm for consistent welding patterns, reducing human error and increasing repeatability in complex hull geometries[5].

Strengths: High precision, consistent quality, and reduced human error. Weaknesses: High initial equipment cost and potential over-reliance on technology.

Innovative Patents in Aircraft Hull Welding

System and process for manufacturing of welded structures, as well as a welding filler material therefor

PatentInactiveEP1640111A2

Innovation

- A system and method using a welding filler material adapted to the design of components, melted by a heat source like a laser beam to form U- or L-profile welds, eliminating the need for wire feed devices and ensuring uniform distribution for improved mechanical properties and accessibility.

method of rapid repair by welding of thin-walled parts of aviation equipment

PatentActiveRU2015123546A

Innovation

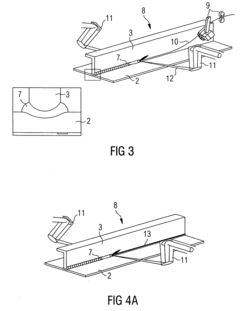

- Use of fiberglass tape secured on a ferromagnetic welding lining to form the weld root, enabling one-sided access for thin-walled aircraft part repairs.

- Application of variable power electromagnets to press and retain the welding lining during the welding process.

- Optional use of a flexible endoscope for monitoring and controlling the welding lining position on the reverse side of welded parts.

Safety Standards for Aircraft Welding

Safety standards for aircraft welding are paramount in ensuring the structural integrity and airworthiness of repaired aircraft hulls. These standards are meticulously developed and enforced by regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe. The primary focus of these standards is to maintain the highest level of safety in aircraft repair and maintenance operations.

The welding process for aircraft hull repairs must adhere to strict quality control measures. This includes the use of certified welding equipment, approved welding materials, and qualified welding personnel. Welders working on aircraft structures are required to undergo specialized training and certification processes, which typically involve both theoretical knowledge and practical skills assessments.

One of the key safety standards for aircraft welding is the proper preparation of the welding area. This involves thorough cleaning and inspection of the repair site to ensure it is free from contaminants that could compromise the weld quality. Additionally, the surrounding areas must be protected from heat damage and potential fire hazards during the welding process.

The selection of appropriate welding techniques and parameters is crucial for maintaining safety standards. Gas welding, while less common in modern aircraft repair, still finds applications in certain scenarios. When used, it requires precise control of gas mixtures, flame temperature, and welding speed to achieve the desired weld quality without compromising the aircraft's structural integrity.

Post-weld inspection and testing are integral components of safety standards in aircraft welding. Non-destructive testing methods such as radiographic, ultrasonic, or dye penetrant testing are employed to detect any flaws or defects in the welded joints. These tests help ensure that the repaired area meets or exceeds the original structural specifications of the aircraft hull.

Environmental controls are also a critical aspect of safety standards for aircraft welding. Proper ventilation systems must be in place to remove harmful fumes and gases generated during the welding process. Additionally, welders must use appropriate personal protective equipment (PPE) to safeguard against potential health hazards associated with welding operations.

Documentation and traceability are essential elements of safety standards in aircraft welding. Detailed records of welding procedures, materials used, and inspection results must be maintained for each repair. This documentation serves as a crucial reference for future maintenance activities and ensures compliance with regulatory requirements.

The welding process for aircraft hull repairs must adhere to strict quality control measures. This includes the use of certified welding equipment, approved welding materials, and qualified welding personnel. Welders working on aircraft structures are required to undergo specialized training and certification processes, which typically involve both theoretical knowledge and practical skills assessments.

One of the key safety standards for aircraft welding is the proper preparation of the welding area. This involves thorough cleaning and inspection of the repair site to ensure it is free from contaminants that could compromise the weld quality. Additionally, the surrounding areas must be protected from heat damage and potential fire hazards during the welding process.

The selection of appropriate welding techniques and parameters is crucial for maintaining safety standards. Gas welding, while less common in modern aircraft repair, still finds applications in certain scenarios. When used, it requires precise control of gas mixtures, flame temperature, and welding speed to achieve the desired weld quality without compromising the aircraft's structural integrity.

Post-weld inspection and testing are integral components of safety standards in aircraft welding. Non-destructive testing methods such as radiographic, ultrasonic, or dye penetrant testing are employed to detect any flaws or defects in the welded joints. These tests help ensure that the repaired area meets or exceeds the original structural specifications of the aircraft hull.

Environmental controls are also a critical aspect of safety standards for aircraft welding. Proper ventilation systems must be in place to remove harmful fumes and gases generated during the welding process. Additionally, welders must use appropriate personal protective equipment (PPE) to safeguard against potential health hazards associated with welding operations.

Documentation and traceability are essential elements of safety standards in aircraft welding. Detailed records of welding procedures, materials used, and inspection results must be maintained for each repair. This documentation serves as a crucial reference for future maintenance activities and ensures compliance with regulatory requirements.

Environmental Impact of Gas Welding Processes

Gas welding techniques used in aircraft hull repairs have significant environmental implications that warrant careful consideration. The process involves the combustion of gases, typically acetylene and oxygen, which produces emissions that can impact air quality. These emissions include carbon dioxide, nitrogen oxides, and particulate matter, all of which contribute to atmospheric pollution and potential health hazards for workers and surrounding communities.

The high temperatures generated during gas welding can also lead to the release of volatile organic compounds (VOCs) from paints, coatings, and other materials present on aircraft surfaces. These VOCs are known to contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on respiratory health and ecosystems.

Furthermore, the use of shielding gases in certain advanced welding techniques may involve the release of inert gases such as argon or helium. While these gases are not directly harmful to the environment, their production and transportation contribute to the overall carbon footprint of the welding process.

Water pollution is another concern associated with gas welding in aircraft repair. Cooling processes and cleaning of welded surfaces often involve the use of water, which can become contaminated with metal particles, oils, and other pollutants. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources.

The production and disposal of welding consumables, such as filler rods and flux materials, also have environmental implications. These materials often contain metals and chemicals that can be harmful if not properly managed throughout their lifecycle.

Energy consumption is a significant factor in the environmental impact of gas welding. The process requires substantial amounts of energy to produce and compress the gases used, as well as to power the welding equipment itself. This energy demand contributes to greenhouse gas emissions and resource depletion, particularly when non-renewable energy sources are utilized.

To mitigate these environmental impacts, the aviation industry is increasingly focusing on developing and implementing more sustainable welding practices. This includes the use of more efficient equipment, improved ventilation systems, and the adoption of alternative welding technologies that produce fewer emissions. Additionally, there is a growing emphasis on proper waste management, recycling of materials, and the use of environmentally friendly cleaning agents.

As regulations surrounding environmental protection become more stringent, aircraft manufacturers and repair facilities are under pressure to adopt cleaner welding technologies and practices. This has led to increased research and development in areas such as low-emission welding techniques, advanced filtration systems, and the use of renewable energy sources to power welding operations.

The high temperatures generated during gas welding can also lead to the release of volatile organic compounds (VOCs) from paints, coatings, and other materials present on aircraft surfaces. These VOCs are known to contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on respiratory health and ecosystems.

Furthermore, the use of shielding gases in certain advanced welding techniques may involve the release of inert gases such as argon or helium. While these gases are not directly harmful to the environment, their production and transportation contribute to the overall carbon footprint of the welding process.

Water pollution is another concern associated with gas welding in aircraft repair. Cooling processes and cleaning of welded surfaces often involve the use of water, which can become contaminated with metal particles, oils, and other pollutants. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources.

The production and disposal of welding consumables, such as filler rods and flux materials, also have environmental implications. These materials often contain metals and chemicals that can be harmful if not properly managed throughout their lifecycle.

Energy consumption is a significant factor in the environmental impact of gas welding. The process requires substantial amounts of energy to produce and compress the gases used, as well as to power the welding equipment itself. This energy demand contributes to greenhouse gas emissions and resource depletion, particularly when non-renewable energy sources are utilized.

To mitigate these environmental impacts, the aviation industry is increasingly focusing on developing and implementing more sustainable welding practices. This includes the use of more efficient equipment, improved ventilation systems, and the adoption of alternative welding technologies that produce fewer emissions. Additionally, there is a growing emphasis on proper waste management, recycling of materials, and the use of environmentally friendly cleaning agents.

As regulations surrounding environmental protection become more stringent, aircraft manufacturers and repair facilities are under pressure to adopt cleaner welding technologies and practices. This has led to increased research and development in areas such as low-emission welding techniques, advanced filtration systems, and the use of renewable energy sources to power welding operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!