Advances in Gas Distribution Systems for Welding Efficiency

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Welding Gas Distribution Evolution and Objectives

Gas distribution systems for welding have undergone significant evolution over the past century, driven by the need for improved efficiency, safety, and precision in welding processes. The journey began with simple compressed gas cylinders and basic regulators, which provided limited control over gas flow and pressure. As industrial welding demands grew, so did the sophistication of gas distribution systems.

The mid-20th century saw the introduction of centralized gas supply systems, which allowed for more efficient distribution of welding gases across large manufacturing facilities. This development marked a crucial step in streamlining welding operations and reducing downtime associated with cylinder changes. Concurrently, advancements in gas mixing technologies enabled more precise control over shielding gas compositions, leading to improved weld quality and consistency.

The advent of digital technologies in the late 20th and early 21st centuries ushered in a new era of gas distribution systems. Computerized flow controllers and electronic gas management systems emerged, offering unprecedented levels of accuracy and repeatability in gas delivery. These innovations not only enhanced weld quality but also contributed to significant reductions in gas consumption and overall operational costs.

Recent years have witnessed a focus on intelligent gas distribution systems that integrate with broader manufacturing ecosystems. Internet of Things (IoT) enabled devices now allow for real-time monitoring and adjustment of gas flow parameters, ensuring optimal welding conditions are maintained throughout production cycles. Additionally, data analytics capabilities have been incorporated, providing valuable insights into gas usage patterns and facilitating predictive maintenance of distribution systems.

The overarching objective of these technological advancements has been to maximize welding efficiency while minimizing resource consumption and environmental impact. Current research and development efforts are aimed at further refining gas distribution systems to meet the evolving needs of modern manufacturing. Key areas of focus include the development of more compact and modular distribution units, integration of renewable energy sources for gas production, and the implementation of artificial intelligence for autonomous optimization of gas flow parameters.

As the welding industry continues to evolve, gas distribution systems are expected to play an increasingly critical role in achieving higher levels of productivity and quality. Future objectives include the creation of fully automated gas management systems capable of adapting to varying welding conditions in real-time, as well as the development of more environmentally friendly gas production and distribution methods. These advancements will not only enhance welding efficiency but also contribute to the broader goals of sustainable manufacturing and Industry 4.0 initiatives.

The mid-20th century saw the introduction of centralized gas supply systems, which allowed for more efficient distribution of welding gases across large manufacturing facilities. This development marked a crucial step in streamlining welding operations and reducing downtime associated with cylinder changes. Concurrently, advancements in gas mixing technologies enabled more precise control over shielding gas compositions, leading to improved weld quality and consistency.

The advent of digital technologies in the late 20th and early 21st centuries ushered in a new era of gas distribution systems. Computerized flow controllers and electronic gas management systems emerged, offering unprecedented levels of accuracy and repeatability in gas delivery. These innovations not only enhanced weld quality but also contributed to significant reductions in gas consumption and overall operational costs.

Recent years have witnessed a focus on intelligent gas distribution systems that integrate with broader manufacturing ecosystems. Internet of Things (IoT) enabled devices now allow for real-time monitoring and adjustment of gas flow parameters, ensuring optimal welding conditions are maintained throughout production cycles. Additionally, data analytics capabilities have been incorporated, providing valuable insights into gas usage patterns and facilitating predictive maintenance of distribution systems.

The overarching objective of these technological advancements has been to maximize welding efficiency while minimizing resource consumption and environmental impact. Current research and development efforts are aimed at further refining gas distribution systems to meet the evolving needs of modern manufacturing. Key areas of focus include the development of more compact and modular distribution units, integration of renewable energy sources for gas production, and the implementation of artificial intelligence for autonomous optimization of gas flow parameters.

As the welding industry continues to evolve, gas distribution systems are expected to play an increasingly critical role in achieving higher levels of productivity and quality. Future objectives include the creation of fully automated gas management systems capable of adapting to varying welding conditions in real-time, as well as the development of more environmentally friendly gas production and distribution methods. These advancements will not only enhance welding efficiency but also contribute to the broader goals of sustainable manufacturing and Industry 4.0 initiatives.

Market Demand for Efficient Welding Gas Systems

The global welding industry has witnessed a significant surge in demand for efficient gas distribution systems, driven by the need for improved productivity, cost reduction, and enhanced quality in welding processes. This market demand is particularly pronounced in sectors such as automotive, construction, aerospace, and shipbuilding, where precision welding is critical for product integrity and safety.

The increasing adoption of automated and robotic welding systems has further amplified the need for advanced gas distribution solutions. These systems require precise control over gas flow and composition to maintain consistent weld quality across large production runs. As a result, manufacturers are actively seeking gas distribution systems that can integrate seamlessly with their automated welding setups, offering real-time monitoring and adjustment capabilities.

Environmental concerns and regulatory pressures have also played a crucial role in shaping market demand. Stricter emissions standards and sustainability goals have led industries to seek more efficient gas utilization methods, reducing waste and minimizing environmental impact. This has created a strong market pull for gas distribution systems that offer improved gas management and reduced consumption without compromising weld quality.

The rise of Industry 4.0 and smart manufacturing concepts has introduced new expectations in the welding gas distribution market. Customers now demand systems with IoT connectivity, data analytics capabilities, and predictive maintenance features. These advanced functionalities allow for better process optimization, remote monitoring, and proactive system management, aligning with the broader trend of digital transformation in manufacturing.

Cost considerations remain a significant driver of market demand. As industries face increasing pressure to reduce operational expenses, there is a growing interest in gas distribution systems that can minimize gas waste, optimize usage, and reduce overall welding costs. Systems that can demonstrate tangible cost savings through improved efficiency and reduced gas consumption are highly sought after in the market.

The global nature of manufacturing supply chains has also influenced market demand for welding gas distribution systems. Multinational corporations require standardized welding processes across their global operations, creating a need for gas distribution solutions that can maintain consistent performance in various geographical locations and under different environmental conditions.

In conclusion, the market demand for efficient welding gas distribution systems is characterized by a complex interplay of factors including technological advancement, environmental concerns, cost pressures, and global manufacturing trends. This multifaceted demand landscape presents both challenges and opportunities for innovators in the welding technology sector, driving continuous improvement and innovation in gas distribution systems for welding efficiency.

The increasing adoption of automated and robotic welding systems has further amplified the need for advanced gas distribution solutions. These systems require precise control over gas flow and composition to maintain consistent weld quality across large production runs. As a result, manufacturers are actively seeking gas distribution systems that can integrate seamlessly with their automated welding setups, offering real-time monitoring and adjustment capabilities.

Environmental concerns and regulatory pressures have also played a crucial role in shaping market demand. Stricter emissions standards and sustainability goals have led industries to seek more efficient gas utilization methods, reducing waste and minimizing environmental impact. This has created a strong market pull for gas distribution systems that offer improved gas management and reduced consumption without compromising weld quality.

The rise of Industry 4.0 and smart manufacturing concepts has introduced new expectations in the welding gas distribution market. Customers now demand systems with IoT connectivity, data analytics capabilities, and predictive maintenance features. These advanced functionalities allow for better process optimization, remote monitoring, and proactive system management, aligning with the broader trend of digital transformation in manufacturing.

Cost considerations remain a significant driver of market demand. As industries face increasing pressure to reduce operational expenses, there is a growing interest in gas distribution systems that can minimize gas waste, optimize usage, and reduce overall welding costs. Systems that can demonstrate tangible cost savings through improved efficiency and reduced gas consumption are highly sought after in the market.

The global nature of manufacturing supply chains has also influenced market demand for welding gas distribution systems. Multinational corporations require standardized welding processes across their global operations, creating a need for gas distribution solutions that can maintain consistent performance in various geographical locations and under different environmental conditions.

In conclusion, the market demand for efficient welding gas distribution systems is characterized by a complex interplay of factors including technological advancement, environmental concerns, cost pressures, and global manufacturing trends. This multifaceted demand landscape presents both challenges and opportunities for innovators in the welding technology sector, driving continuous improvement and innovation in gas distribution systems for welding efficiency.

Current Challenges in Gas Distribution for Welding

Gas distribution systems play a crucial role in welding processes, directly impacting efficiency, quality, and safety. However, several challenges persist in this domain, hindering optimal performance and productivity in welding operations.

One of the primary challenges is maintaining consistent gas flow rates throughout the welding process. Fluctuations in gas pressure can lead to inconsistent shielding, resulting in porosity, oxidation, and overall reduced weld quality. This issue is particularly pronounced in large-scale operations or when working with long gas lines, where pressure drops become more significant.

Another significant challenge is the accurate control and monitoring of gas consumption. Many welding operations lack precise measurement systems, leading to inefficient use of shielding gases and increased operational costs. This problem is exacerbated by potential leaks in the distribution system, which can go undetected for extended periods.

The selection and optimization of gas mixtures for specific welding applications also present ongoing challenges. Different materials and welding processes require tailored gas compositions to achieve optimal results. However, the complexity of gas interactions and their effects on weld characteristics make it difficult to determine the ideal mixture for each application.

Environmental factors pose additional challenges to gas distribution systems. Temperature fluctuations can affect gas flow rates and composition, particularly in outdoor welding environments. Moreover, humidity and contaminants in the surrounding air can compromise the integrity of the shielding gas, leading to weld defects.

The integration of gas distribution systems with automated welding processes presents another set of challenges. Coordinating gas flow with robotic movements and welding parameters requires sophisticated control systems and real-time monitoring capabilities, which are not always readily available or easily implemented.

Safety concerns related to gas storage and distribution continue to be a critical challenge. High-pressure gas cylinders and distribution lines pose potential risks, necessitating robust safety protocols and regular maintenance. Ensuring proper ventilation and preventing gas accumulation in confined spaces remain ongoing concerns in many welding environments.

Lastly, the industry faces challenges in adapting gas distribution systems to emerging welding technologies, such as additive manufacturing and hybrid welding processes. These new applications often require more precise gas control and novel distribution methods, pushing the boundaries of traditional gas management systems.

Addressing these challenges requires a multifaceted approach, combining technological innovations, improved monitoring systems, and enhanced training for welding personnel. As the welding industry continues to evolve, overcoming these obstacles in gas distribution will be crucial for achieving higher efficiency, quality, and safety standards.

One of the primary challenges is maintaining consistent gas flow rates throughout the welding process. Fluctuations in gas pressure can lead to inconsistent shielding, resulting in porosity, oxidation, and overall reduced weld quality. This issue is particularly pronounced in large-scale operations or when working with long gas lines, where pressure drops become more significant.

Another significant challenge is the accurate control and monitoring of gas consumption. Many welding operations lack precise measurement systems, leading to inefficient use of shielding gases and increased operational costs. This problem is exacerbated by potential leaks in the distribution system, which can go undetected for extended periods.

The selection and optimization of gas mixtures for specific welding applications also present ongoing challenges. Different materials and welding processes require tailored gas compositions to achieve optimal results. However, the complexity of gas interactions and their effects on weld characteristics make it difficult to determine the ideal mixture for each application.

Environmental factors pose additional challenges to gas distribution systems. Temperature fluctuations can affect gas flow rates and composition, particularly in outdoor welding environments. Moreover, humidity and contaminants in the surrounding air can compromise the integrity of the shielding gas, leading to weld defects.

The integration of gas distribution systems with automated welding processes presents another set of challenges. Coordinating gas flow with robotic movements and welding parameters requires sophisticated control systems and real-time monitoring capabilities, which are not always readily available or easily implemented.

Safety concerns related to gas storage and distribution continue to be a critical challenge. High-pressure gas cylinders and distribution lines pose potential risks, necessitating robust safety protocols and regular maintenance. Ensuring proper ventilation and preventing gas accumulation in confined spaces remain ongoing concerns in many welding environments.

Lastly, the industry faces challenges in adapting gas distribution systems to emerging welding technologies, such as additive manufacturing and hybrid welding processes. These new applications often require more precise gas control and novel distribution methods, pushing the boundaries of traditional gas management systems.

Addressing these challenges requires a multifaceted approach, combining technological innovations, improved monitoring systems, and enhanced training for welding personnel. As the welding industry continues to evolve, overcoming these obstacles in gas distribution will be crucial for achieving higher efficiency, quality, and safety standards.

State-of-the-Art Gas Distribution Solutions

01 Optimization of gas flow and pressure control

Improving gas distribution efficiency through advanced flow control systems and pressure regulation techniques. This includes the use of smart valves, pressure sensors, and automated control systems to optimize gas flow rates and maintain consistent pressure throughout the distribution network.- Optimization of gas flow and pressure control: Improving gas distribution efficiency through advanced flow control mechanisms and pressure regulation systems. This includes the use of smart valves, pressure sensors, and automated control systems to optimize gas flow rates and maintain consistent pressure throughout the distribution network.

- Smart metering and monitoring systems: Implementation of intelligent metering and monitoring technologies to enhance gas distribution efficiency. These systems provide real-time data on gas consumption, detect leaks, and enable predictive maintenance, leading to reduced losses and improved overall system performance.

- Energy-efficient compressor and pump technologies: Utilization of advanced compressor and pump designs to reduce energy consumption in gas distribution systems. This includes the use of variable speed drives, high-efficiency motors, and optimized compression cycles to minimize power usage while maintaining required gas flow rates.

- Pipeline network optimization and leak detection: Improving gas distribution efficiency through optimized pipeline network design and advanced leak detection technologies. This involves the use of computational fluid dynamics, network modeling tools, and sensor-based leak detection systems to minimize losses and enhance overall system reliability.

- Integration of renewable gas sources: Enhancing gas distribution system efficiency by incorporating renewable gas sources such as biogas and hydrogen. This includes the development of technologies for gas blending, purification, and storage to enable seamless integration of renewable gases into existing distribution networks.

02 Leak detection and prevention systems

Implementing advanced leak detection technologies and preventive maintenance strategies to minimize gas losses in distribution systems. This involves the use of sensors, monitoring software, and predictive analytics to identify and address potential leaks before they become significant issues.Expand Specific Solutions03 Smart metering and data analytics

Utilizing smart meters and data analytics to improve gas distribution efficiency. This includes real-time monitoring of consumption patterns, demand forecasting, and load balancing to optimize gas distribution and reduce waste.Expand Specific Solutions04 Energy-efficient compression and storage technologies

Developing and implementing energy-efficient gas compression and storage technologies to reduce energy consumption in the distribution process. This includes advanced compressor designs, thermal energy recovery systems, and innovative storage solutions to minimize losses and improve overall system efficiency.Expand Specific Solutions05 Integration of renewable gas sources

Incorporating renewable gas sources, such as biogas and hydrogen, into existing gas distribution systems to improve overall efficiency and reduce environmental impact. This involves developing technologies for gas blending, purification, and compatible infrastructure to seamlessly integrate these alternative gas sources.Expand Specific Solutions

Key Players in Welding Gas Distribution Industry

The gas distribution systems for welding efficiency market is in a growth phase, driven by increasing demand for automation and precision in manufacturing. The global market size is estimated to be in the billions, with steady growth projected. Technologically, the field is advancing rapidly, with key players like Illinois Tool Works, Lincoln Electric, and Fronius International leading innovation. These companies are developing smart, connected systems that integrate with robotics and IoT. Emerging players such as Suxin IoT Technology and Delta Electronics are also contributing to technological advancements, particularly in digital control and power management. The market is characterized by a mix of established industrial giants and specialized welding technology firms, indicating a mature yet dynamic competitive landscape.

Alexander Binzel Schweisstechnik GmbH & Co. KG

Technical Solution: Binzel has developed the iSYSTEM gas distribution technology for improved welding efficiency. This system incorporates a digital gas flow meter and controller, allowing for precise regulation of gas flow rates. Binzel's technology includes a pulsed gas delivery feature that synchronizes gas flow with the welding cycle, reducing overall gas consumption. The iSYSTEM also features a gas mixing capability, enabling the creation of custom gas blends for specific welding applications[9]. Binzel has integrated their gas distribution system with their welding torch designs, optimizing gas coverage and reducing turbulence at the weld pool. The company has also implemented a data logging function that tracks gas usage and flow rates, providing valuable insights for process optimization[10].

Strengths: Precise gas control, pulsed delivery, and integration with welding torch designs. Weaknesses: May require additional training for operators to fully utilize advanced features.

Fronius International GmbH

Technical Solution: Fronius has introduced their innovative TPS/i (Trans Process Solution/intelligent) welding platform, which incorporates advanced gas distribution systems. Their technology includes the Dynamic Gas Control (DGC) feature, which automatically adjusts gas flow rates based on welding parameters and arc conditions. Fronius has also developed the PMC (Pulse Multi Control) process, which optimizes gas usage during pulsed welding[2]. The company's gas distribution systems are integrated with their WeldCube data management platform, allowing for comprehensive analysis of gas consumption and welding efficiency[4]. Additionally, Fronius has implemented a gas-saving function in their systems that can reduce gas consumption by up to 50% compared to conventional methods[6].

Strengths: Automatic gas flow adjustment, significant gas savings, and integration with data management platforms. Weaknesses: Higher initial investment cost compared to traditional systems.

Innovative Gas Flow Control Technologies

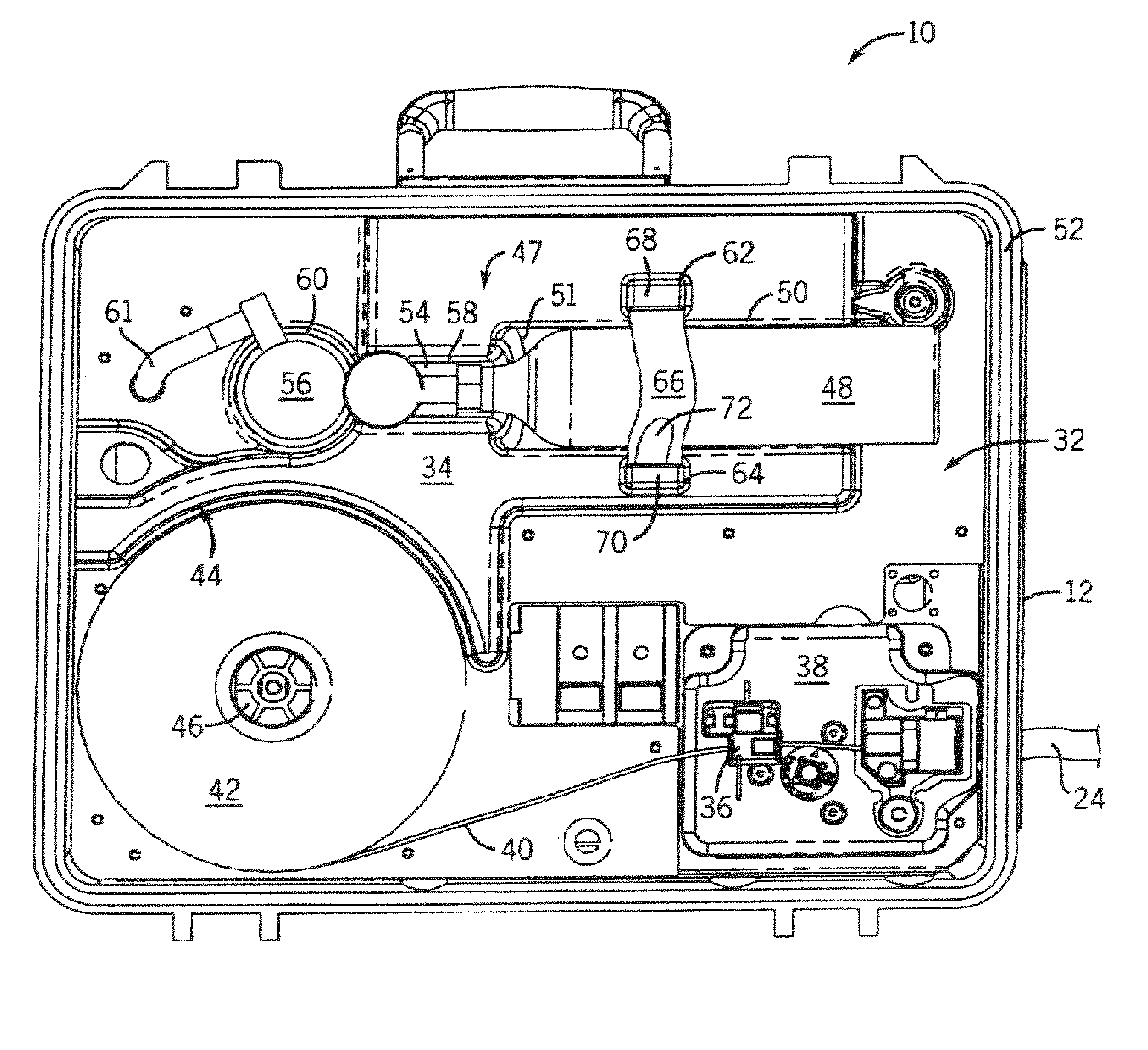

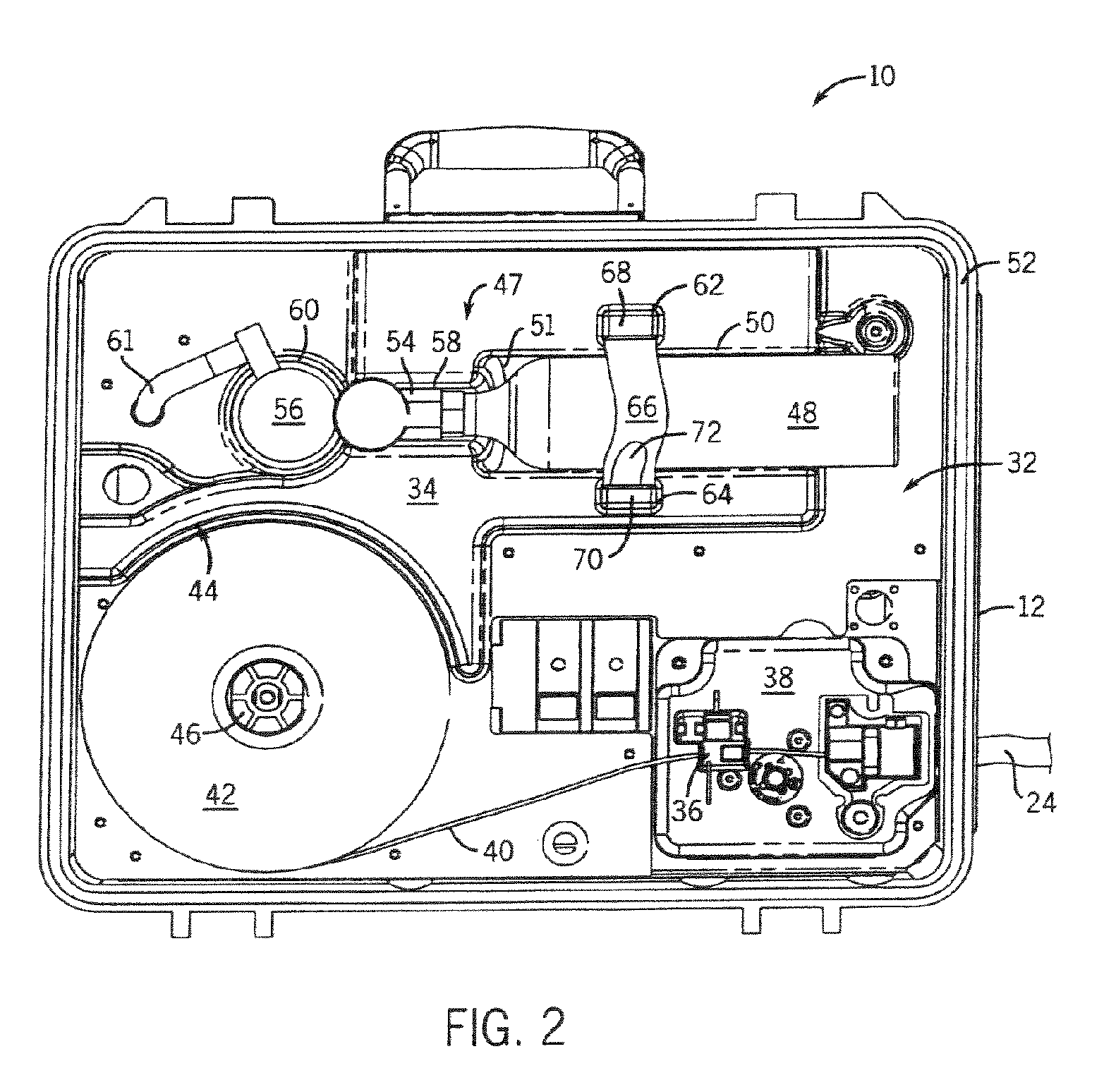

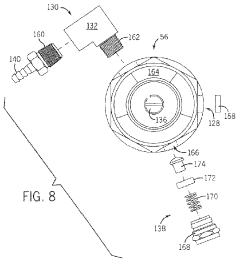

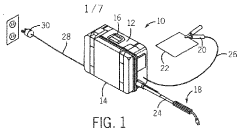

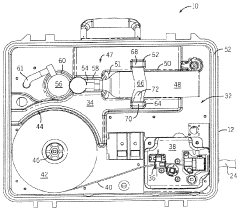

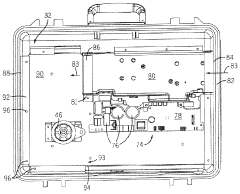

Gas system for wire feeding devices

PatentInactiveUS20050252899A1

Innovation

- A portable wire feeder system with a removable pressure vessel that securely supports a shielding gas source, allowing for efficient transport and use of shielding gas independently of the welding power source, featuring a housing with a cavity for weld wire and a feed drive mechanism in fluid communication with the gas system.

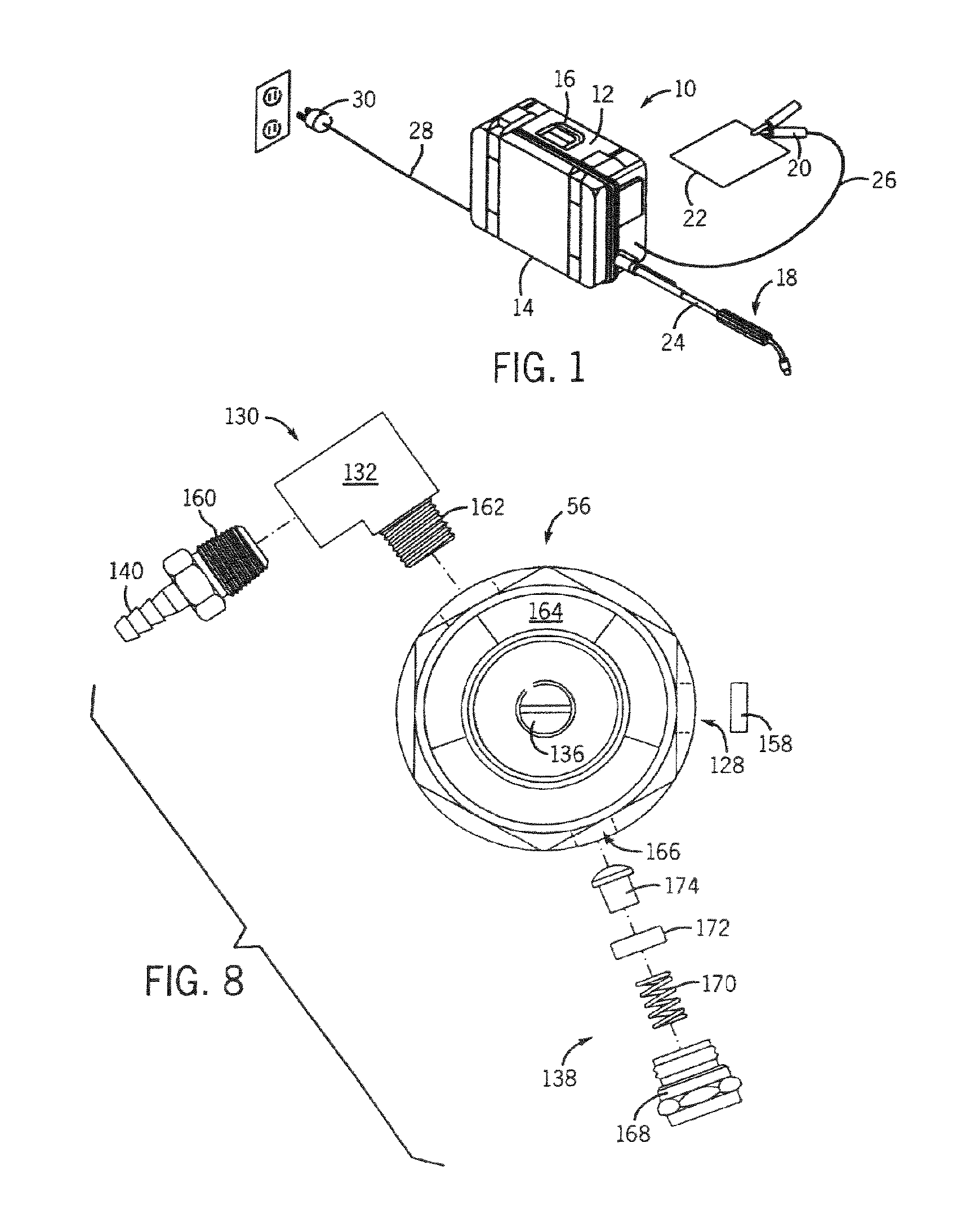

Gas system for welding-type devices

PatentWO2006085229A1

Innovation

- A lightweight shielding gas system where a pressure vessel is integrated into the welding device's housing, with a retainer to securely attach a gas canister externally, allowing for direct mounting and easy transport, and a regulator connected to a gas container for controlled gas flow.

Environmental Impact of Advanced Gas Systems

The environmental impact of advanced gas distribution systems for welding efficiency is a critical consideration in the ongoing development of this technology. These systems have the potential to significantly reduce the carbon footprint of welding operations while improving overall efficiency. By optimizing gas flow and minimizing waste, advanced distribution systems can lead to a substantial decrease in greenhouse gas emissions associated with welding processes.

One of the primary environmental benefits of these systems is the reduction in gas consumption. Traditional welding setups often result in excessive gas usage due to inefficient distribution and control mechanisms. Advanced systems, however, employ precise flow control and monitoring technologies that ensure only the necessary amount of gas is delivered to the welding point. This optimization can lead to gas savings of up to 50% in some applications, directly translating to a lower environmental impact.

Furthermore, the improved accuracy and consistency of gas delivery in advanced systems contribute to higher quality welds. This reduction in defects and rework not only enhances productivity but also minimizes material waste. Less material waste means fewer resources consumed and less energy expended in the production and transportation of raw materials, further reducing the overall environmental footprint of welding operations.

Advanced gas distribution systems also often incorporate smart technologies that enable real-time monitoring and data analytics. These features allow for continuous optimization of gas usage based on specific welding parameters and conditions. By adapting to changing requirements in real-time, these systems can maintain optimal efficiency throughout the welding process, preventing unnecessary gas consumption and emissions.

The integration of these systems with renewable energy sources presents another avenue for environmental improvement. As industrial operations increasingly shift towards clean energy, the combination of advanced gas distribution systems with solar or wind power can create a more sustainable welding ecosystem. This synergy not only reduces direct emissions from gas consumption but also minimizes the indirect carbon footprint associated with the energy used to power welding equipment.

Moreover, the longevity and durability of advanced gas distribution systems contribute to their positive environmental impact. These systems are typically designed with high-quality components that have longer operational lifespans compared to traditional setups. This durability reduces the frequency of replacements and repairs, thereby decreasing the environmental costs associated with manufacturing and disposing of equipment components.

One of the primary environmental benefits of these systems is the reduction in gas consumption. Traditional welding setups often result in excessive gas usage due to inefficient distribution and control mechanisms. Advanced systems, however, employ precise flow control and monitoring technologies that ensure only the necessary amount of gas is delivered to the welding point. This optimization can lead to gas savings of up to 50% in some applications, directly translating to a lower environmental impact.

Furthermore, the improved accuracy and consistency of gas delivery in advanced systems contribute to higher quality welds. This reduction in defects and rework not only enhances productivity but also minimizes material waste. Less material waste means fewer resources consumed and less energy expended in the production and transportation of raw materials, further reducing the overall environmental footprint of welding operations.

Advanced gas distribution systems also often incorporate smart technologies that enable real-time monitoring and data analytics. These features allow for continuous optimization of gas usage based on specific welding parameters and conditions. By adapting to changing requirements in real-time, these systems can maintain optimal efficiency throughout the welding process, preventing unnecessary gas consumption and emissions.

The integration of these systems with renewable energy sources presents another avenue for environmental improvement. As industrial operations increasingly shift towards clean energy, the combination of advanced gas distribution systems with solar or wind power can create a more sustainable welding ecosystem. This synergy not only reduces direct emissions from gas consumption but also minimizes the indirect carbon footprint associated with the energy used to power welding equipment.

Moreover, the longevity and durability of advanced gas distribution systems contribute to their positive environmental impact. These systems are typically designed with high-quality components that have longer operational lifespans compared to traditional setups. This durability reduces the frequency of replacements and repairs, thereby decreasing the environmental costs associated with manufacturing and disposing of equipment components.

Safety Standards in Modern Welding Gas Distribution

Safety standards in modern welding gas distribution systems have evolved significantly to address the inherent risks associated with handling and distributing flammable gases. These standards are crucial for ensuring the safety of welding operations and protecting workers from potential hazards.

One of the primary focuses of safety standards is the proper storage and handling of welding gases. Regulations typically require that gas cylinders be stored in well-ventilated areas, away from heat sources and potential ignition points. Cylinders must be secured to prevent tipping or falling, and they should be clearly labeled with their contents and associated hazards.

Gas distribution systems are required to incorporate various safety features to prevent leaks and minimize the risk of accidents. These include pressure regulators, flow meters, and shut-off valves that allow for precise control of gas flow and quick isolation in case of emergencies. Regular inspection and maintenance of these components are mandated to ensure their proper functioning.

Safety standards also address the design and installation of gas distribution pipelines. Materials used must be compatible with the specific gases being transported and capable of withstanding the pressures involved. Proper installation techniques, including leak testing and pressure testing, are essential to verify the integrity of the system.

Personal protective equipment (PPE) requirements are another critical aspect of safety standards. Welders and other personnel working with gas distribution systems must use appropriate PPE, including safety glasses, gloves, and flame-resistant clothing. Training programs on the proper use of equipment and emergency procedures are typically mandated to ensure that workers can respond effectively to potential incidents.

Emergency response planning is a key component of modern safety standards. Facilities must have clearly defined procedures for dealing with gas leaks, fires, or other emergencies related to the gas distribution system. This includes the installation of gas detection systems, emergency shut-off mechanisms, and evacuation plans.

Environmental considerations are increasingly being incorporated into safety standards for welding gas distribution. This includes measures to prevent the release of harmful gases into the atmosphere and proper disposal procedures for empty cylinders and other waste materials.

Compliance with these safety standards is typically enforced through regular inspections and audits by regulatory bodies. Companies are required to maintain detailed records of their gas distribution systems, including maintenance logs, safety checks, and incident reports.

One of the primary focuses of safety standards is the proper storage and handling of welding gases. Regulations typically require that gas cylinders be stored in well-ventilated areas, away from heat sources and potential ignition points. Cylinders must be secured to prevent tipping or falling, and they should be clearly labeled with their contents and associated hazards.

Gas distribution systems are required to incorporate various safety features to prevent leaks and minimize the risk of accidents. These include pressure regulators, flow meters, and shut-off valves that allow for precise control of gas flow and quick isolation in case of emergencies. Regular inspection and maintenance of these components are mandated to ensure their proper functioning.

Safety standards also address the design and installation of gas distribution pipelines. Materials used must be compatible with the specific gases being transported and capable of withstanding the pressures involved. Proper installation techniques, including leak testing and pressure testing, are essential to verify the integrity of the system.

Personal protective equipment (PPE) requirements are another critical aspect of safety standards. Welders and other personnel working with gas distribution systems must use appropriate PPE, including safety glasses, gloves, and flame-resistant clothing. Training programs on the proper use of equipment and emergency procedures are typically mandated to ensure that workers can respond effectively to potential incidents.

Emergency response planning is a key component of modern safety standards. Facilities must have clearly defined procedures for dealing with gas leaks, fires, or other emergencies related to the gas distribution system. This includes the installation of gas detection systems, emergency shut-off mechanisms, and evacuation plans.

Environmental considerations are increasingly being incorporated into safety standards for welding gas distribution. This includes measures to prevent the release of harmful gases into the atmosphere and proper disposal procedures for empty cylinders and other waste materials.

Compliance with these safety standards is typically enforced through regular inspections and audits by regulatory bodies. Companies are required to maintain detailed records of their gas distribution systems, including maintenance logs, safety checks, and incident reports.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!