Aerospace Industry Applications of CO₂ Capture Sorbents

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Evolution in Aerospace

Carbon dioxide capture technology in the aerospace industry has evolved significantly over the past decades, driven by the need for sustainable space exploration and air travel. The initial development began in the 1960s with NASA's Apollo program, where primitive lithium hydroxide canisters were used to absorb CO₂ from spacecraft cabins. This represented the first generation of aerospace CO₂ capture systems, focusing primarily on crew survival rather than environmental considerations.

The 1980s marked a transition toward more sophisticated molecular sieve technologies, particularly zeolite-based systems that offered improved efficiency and regenerative capabilities. These systems became standard in the Space Shuttle program and later in the International Space Station (ISS), where the Carbon Dioxide Removal Assembly (CDRA) utilized zeolite 5A and 13X materials to maintain safe atmospheric conditions for astronauts during extended missions.

By the early 2000s, the focus shifted toward developing more compact and energy-efficient systems. Metal-organic frameworks (MOFs) emerged as promising materials due to their exceptional surface area and customizable pore structures. NASA's Advanced Exploration Systems program began investigating MOFs for next-generation life support systems, achieving significant reductions in system mass and power requirements compared to traditional zeolite-based technologies.

The 2010s witnessed the integration of amine-functionalized sorbents, which demonstrated superior CO₂ selectivity under the unique conditions of spacecraft environments. These materials, including amine-grafted silicas and polymeric amine sorbents, offered advantages in terms of humidity tolerance and operational stability during the thermal cycling required for regeneration processes.

Most recently, the aerospace industry has begun exploring hybrid systems that combine multiple sorbent technologies to optimize performance across varying mission profiles. These systems incorporate smart materials that can adapt to changing environmental conditions, such as variable CO₂ concentrations and temperature fluctuations experienced during different flight phases or mission stages.

Commercial aviation has followed a parallel but distinct evolutionary path, with initial focus on improving cabin air quality gradually expanding to address broader environmental concerns. Modern aircraft designs now incorporate advanced sorbent technologies in environmental control systems, with emerging research focused on capturing CO₂ from engine exhaust—a significantly more challenging application due to high temperatures and flow rates.

The technological progression has consistently moved toward more efficient, lightweight, and multifunctional materials that can simultaneously address CO₂ capture, oxygen generation, and trace contaminant control. This evolution reflects the aerospace industry's unique constraints, where mass, volume, and power efficiency are paramount considerations that have driven innovation in ways distinct from terrestrial carbon capture applications.

The 1980s marked a transition toward more sophisticated molecular sieve technologies, particularly zeolite-based systems that offered improved efficiency and regenerative capabilities. These systems became standard in the Space Shuttle program and later in the International Space Station (ISS), where the Carbon Dioxide Removal Assembly (CDRA) utilized zeolite 5A and 13X materials to maintain safe atmospheric conditions for astronauts during extended missions.

By the early 2000s, the focus shifted toward developing more compact and energy-efficient systems. Metal-organic frameworks (MOFs) emerged as promising materials due to their exceptional surface area and customizable pore structures. NASA's Advanced Exploration Systems program began investigating MOFs for next-generation life support systems, achieving significant reductions in system mass and power requirements compared to traditional zeolite-based technologies.

The 2010s witnessed the integration of amine-functionalized sorbents, which demonstrated superior CO₂ selectivity under the unique conditions of spacecraft environments. These materials, including amine-grafted silicas and polymeric amine sorbents, offered advantages in terms of humidity tolerance and operational stability during the thermal cycling required for regeneration processes.

Most recently, the aerospace industry has begun exploring hybrid systems that combine multiple sorbent technologies to optimize performance across varying mission profiles. These systems incorporate smart materials that can adapt to changing environmental conditions, such as variable CO₂ concentrations and temperature fluctuations experienced during different flight phases or mission stages.

Commercial aviation has followed a parallel but distinct evolutionary path, with initial focus on improving cabin air quality gradually expanding to address broader environmental concerns. Modern aircraft designs now incorporate advanced sorbent technologies in environmental control systems, with emerging research focused on capturing CO₂ from engine exhaust—a significantly more challenging application due to high temperatures and flow rates.

The technological progression has consistently moved toward more efficient, lightweight, and multifunctional materials that can simultaneously address CO₂ capture, oxygen generation, and trace contaminant control. This evolution reflects the aerospace industry's unique constraints, where mass, volume, and power efficiency are paramount considerations that have driven innovation in ways distinct from terrestrial carbon capture applications.

Aerospace Market Demand for CO₂ Capture Solutions

The aerospace industry is experiencing a growing demand for effective CO₂ capture solutions, driven by several key factors. Environmental regulations are becoming increasingly stringent worldwide, with aviation accounting for approximately 2.5% of global carbon emissions. The European Union's Emissions Trading System (ETS) and the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) have created regulatory pressures that directly impact aerospace operations and economics.

Market analysis reveals that aerospace companies are actively seeking carbon capture technologies to achieve sustainability goals while maintaining operational efficiency. The global market for aerospace carbon management solutions reached $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2030, according to industry reports from Aerospace Technology Institute.

Commercial airlines represent the largest segment of potential adopters, with major carriers like United Airlines, Delta, and Lufthansa publicly committing to carbon neutrality targets between 2030 and 2050. These commitments translate to tangible market demand for onboard and ground-based carbon capture systems.

Space agencies and private space companies form another significant market segment. The need for efficient life support systems in spacecraft and potential future space habitats requires advanced CO₂ capture technologies. NASA's budget allocation for environmental control and life support systems research has increased by 15% in recent years, indicating growing investment in this area.

Military aerospace applications constitute a third major market segment. Defense departments worldwide are incorporating sustainability requirements into procurement specifications, creating demand for carbon capture technologies that can function in extreme operational environments without compromising mission capabilities.

Market research indicates specific performance requirements driving demand: systems must be lightweight (under 5kg per capture unit), energy-efficient (consuming less than 2% of aircraft power), compact (occupying minimal space in confined aerospace environments), and capable of operating under variable pressure and temperature conditions.

The economic value proposition for aerospace CO₂ capture solutions extends beyond regulatory compliance. Airlines can potentially monetize captured carbon through emerging carbon credit markets, creating additional revenue streams. Furthermore, passenger surveys indicate that 68% of travelers consider environmental impact when choosing airlines, suggesting market advantages for early adopters of carbon capture technology.

Regional analysis shows Europe leading in demand due to stringent regulations, followed by North America where corporate sustainability commitments drive adoption. The Asia-Pacific region represents the fastest-growing market as countries like China and Japan implement their own aviation emissions regulations.

Market analysis reveals that aerospace companies are actively seeking carbon capture technologies to achieve sustainability goals while maintaining operational efficiency. The global market for aerospace carbon management solutions reached $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2030, according to industry reports from Aerospace Technology Institute.

Commercial airlines represent the largest segment of potential adopters, with major carriers like United Airlines, Delta, and Lufthansa publicly committing to carbon neutrality targets between 2030 and 2050. These commitments translate to tangible market demand for onboard and ground-based carbon capture systems.

Space agencies and private space companies form another significant market segment. The need for efficient life support systems in spacecraft and potential future space habitats requires advanced CO₂ capture technologies. NASA's budget allocation for environmental control and life support systems research has increased by 15% in recent years, indicating growing investment in this area.

Military aerospace applications constitute a third major market segment. Defense departments worldwide are incorporating sustainability requirements into procurement specifications, creating demand for carbon capture technologies that can function in extreme operational environments without compromising mission capabilities.

Market research indicates specific performance requirements driving demand: systems must be lightweight (under 5kg per capture unit), energy-efficient (consuming less than 2% of aircraft power), compact (occupying minimal space in confined aerospace environments), and capable of operating under variable pressure and temperature conditions.

The economic value proposition for aerospace CO₂ capture solutions extends beyond regulatory compliance. Airlines can potentially monetize captured carbon through emerging carbon credit markets, creating additional revenue streams. Furthermore, passenger surveys indicate that 68% of travelers consider environmental impact when choosing airlines, suggesting market advantages for early adopters of carbon capture technology.

Regional analysis shows Europe leading in demand due to stringent regulations, followed by North America where corporate sustainability commitments drive adoption. The Asia-Pacific region represents the fastest-growing market as countries like China and Japan implement their own aviation emissions regulations.

Current Sorbent Technologies and Aerospace Limitations

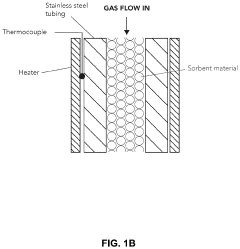

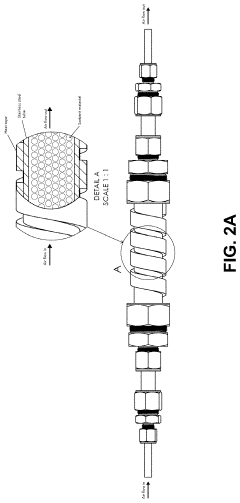

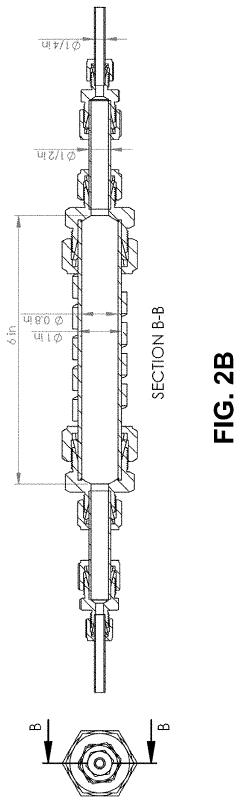

Current CO₂ capture technologies in the aerospace sector face unique challenges due to the extreme operating conditions and stringent weight requirements. Traditional sorbent materials such as zeolites, activated carbons, and metal-organic frameworks (MOFs) have been extensively studied for terrestrial applications but require significant adaptation for aerospace use.

Zeolites demonstrate excellent CO₂ selectivity and thermal stability, making them potentially suitable for cabin air purification systems. However, their performance degrades significantly in humid conditions—a critical limitation for human-occupied spacecraft environments where relative humidity typically ranges between 40-60%. Additionally, zeolites require high regeneration temperatures (150-200°C), imposing substantial energy demands on spacecraft power systems.

Activated carbons offer advantages in terms of low regeneration energy and lightweight properties. Their porous structure provides high surface area for adsorption, but their CO₂ selectivity over other gases remains suboptimal for aerospace applications. Current research focuses on surface functionalization to enhance selectivity, though this often comes at the cost of increased weight and reduced mechanical stability under launch vibration conditions.

Metal-organic frameworks represent the newest class of sorbents with promising characteristics for aerospace applications. Their tunable pore structures and high surface areas (up to 7000 m²/g) enable exceptional CO₂ capture capacity. MOFs such as Mg-MOF-74 and HKUST-1 have demonstrated CO₂ uptake exceeding 25 wt% under ideal conditions. However, their structural integrity under microgravity and radiation exposure remains insufficiently characterized.

Amine-functionalized silica materials offer another approach, with strong chemical affinity for CO₂. These materials operate effectively at ambient temperatures but suffer from performance degradation over multiple adsorption-desorption cycles—a critical concern for long-duration space missions where maintenance opportunities are limited.

The aerospace environment imposes several unique limitations on sorbent deployment. Mass constraints are paramount, with launch costs currently averaging $10,000-20,000 per kilogram to low Earth orbit. Volume restrictions similarly affect system design, necessitating high volumetric efficiency. Power limitations restrict regeneration options, while reliability requirements demand materials that maintain performance over thousands of cycles without degradation.

Microgravity conditions fundamentally alter fluid dynamics and heat transfer processes, complicating sorbent bed design and regeneration procedures. Radiation exposure in space can degrade organic components in functionalized sorbents, potentially reducing operational lifetimes. Additionally, the need for fail-safe operation and minimal maintenance drives requirements for simple, robust systems with minimal moving parts.

Zeolites demonstrate excellent CO₂ selectivity and thermal stability, making them potentially suitable for cabin air purification systems. However, their performance degrades significantly in humid conditions—a critical limitation for human-occupied spacecraft environments where relative humidity typically ranges between 40-60%. Additionally, zeolites require high regeneration temperatures (150-200°C), imposing substantial energy demands on spacecraft power systems.

Activated carbons offer advantages in terms of low regeneration energy and lightweight properties. Their porous structure provides high surface area for adsorption, but their CO₂ selectivity over other gases remains suboptimal for aerospace applications. Current research focuses on surface functionalization to enhance selectivity, though this often comes at the cost of increased weight and reduced mechanical stability under launch vibration conditions.

Metal-organic frameworks represent the newest class of sorbents with promising characteristics for aerospace applications. Their tunable pore structures and high surface areas (up to 7000 m²/g) enable exceptional CO₂ capture capacity. MOFs such as Mg-MOF-74 and HKUST-1 have demonstrated CO₂ uptake exceeding 25 wt% under ideal conditions. However, their structural integrity under microgravity and radiation exposure remains insufficiently characterized.

Amine-functionalized silica materials offer another approach, with strong chemical affinity for CO₂. These materials operate effectively at ambient temperatures but suffer from performance degradation over multiple adsorption-desorption cycles—a critical concern for long-duration space missions where maintenance opportunities are limited.

The aerospace environment imposes several unique limitations on sorbent deployment. Mass constraints are paramount, with launch costs currently averaging $10,000-20,000 per kilogram to low Earth orbit. Volume restrictions similarly affect system design, necessitating high volumetric efficiency. Power limitations restrict regeneration options, while reliability requirements demand materials that maintain performance over thousands of cycles without degradation.

Microgravity conditions fundamentally alter fluid dynamics and heat transfer processes, complicating sorbent bed design and regeneration procedures. Radiation exposure in space can degrade organic components in functionalized sorbents, potentially reducing operational lifetimes. Additionally, the need for fail-safe operation and minimal maintenance drives requirements for simple, robust systems with minimal moving parts.

Current CO₂ Sorbent Integration Methods for Spacecraft

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and selectivity over other gases. Their modular nature allows for customization of properties such as stability, regenerability, and adsorption capacity under various operating conditions.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and can operate under various temperature and pressure conditions, offering promising solutions for carbon capture applications.

- Amine-functionalized sorbents: Amine-functionalized materials represent a significant class of CO₂ capture sorbents that operate through chemical adsorption mechanisms. These sorbents contain primary, secondary, or tertiary amine groups that react with CO₂ to form carbamates or bicarbonates. Common supports include silica, polymers, and porous carbon materials. The amine functionality provides high selectivity for CO₂ over other gases and can be regenerated through temperature or pressure swing processes.

- Zeolite-based CO₂ capture materials: Zeolites are microporous aluminosilicate minerals that serve as effective CO₂ adsorbents due to their uniform pore structure and high thermal stability. These materials capture CO₂ through physical adsorption mechanisms based on molecular sieving and electrostatic interactions. Zeolites can be modified with various cations to enhance their CO₂ selectivity and capacity. Their regenerability and resistance to contaminants make them suitable for industrial carbon capture applications.

- Novel composite and hybrid sorbent materials: Composite and hybrid sorbent materials combine different components to achieve enhanced CO₂ capture performance. These materials often integrate the advantages of multiple sorbent types, such as the high capacity of chemical sorbents with the fast kinetics of physical adsorbents. Examples include polymer-inorganic composites, layered double hydroxides, and hybrid membranes. These materials are designed to overcome limitations of single-component sorbents by improving stability, selectivity, and regeneration efficiency.

- Regeneration and process integration technologies: Advanced regeneration methods and process integration technologies are crucial for practical CO₂ capture systems. These include temperature swing adsorption, pressure swing adsorption, vacuum swing adsorption, and combinations thereof. Innovations in this area focus on reducing energy requirements for sorbent regeneration, improving cycle stability, and integrating capture systems with existing industrial processes. Novel heating methods, such as microwave and electrical swing regeneration, are being developed to enhance energy efficiency.

02 Amine-functionalized sorbents

Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for CO₂ molecules. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions. These materials offer advantages including high CO₂ selectivity, good capacity at low partial pressures, and relatively low regeneration energy requirements compared to traditional liquid amine scrubbing processes.Expand Specific Solutions03 Alkali metal-based CO₂ sorbents

Alkali metal-based sorbents, particularly those containing lithium, sodium, or potassium compounds, are effective for high-temperature CO₂ capture. These materials typically operate through carbonation reactions, where the metal oxide reacts with CO₂ to form stable carbonates. The process is reversible at higher temperatures, allowing for sorbent regeneration. These materials are particularly suitable for pre-combustion capture or integration with industrial processes that generate high-temperature flue gases, offering good stability and cyclic performance in harsh conditions.Expand Specific Solutions04 Zeolite and molecular sieve adsorbents

Zeolites and molecular sieves are aluminosilicate materials with well-defined pore structures that can selectively adsorb CO₂ based on molecular size and polarity. These materials function primarily through physical adsorption mechanisms and can be tailored by adjusting the silicon-to-aluminum ratio or incorporating specific cations to enhance CO₂ selectivity. They offer advantages including high thermal stability, resistance to contaminants, and relatively low cost. Their performance can be optimized for specific operating conditions such as temperature, pressure, and gas composition.Expand Specific Solutions05 Regeneration and process integration technologies

Advanced regeneration methods and process integration technologies are crucial for practical implementation of CO₂ capture sorbents. These include temperature swing adsorption (TSA), pressure swing adsorption (PSA), vacuum swing adsorption (VSA), and hybrid approaches. Novel heating methods such as microwave, electrical, or steam regeneration can reduce energy requirements. Process intensification techniques integrate capture with other operations like water recovery or heat exchange. These technologies focus on minimizing energy penalties, reducing capital costs, and improving overall system efficiency for industrial-scale carbon capture applications.Expand Specific Solutions

Leading Aerospace and Sorbent Technology Companies

The aerospace industry's adoption of CO₂ capture sorbents is in an early growth phase, with market size expanding as environmental regulations tighten globally. The technology is approaching commercial maturity, with key players demonstrating varied levels of advancement. Research institutions like Tianjin University, California Institute of Technology, and Georgia Tech are developing fundamental technologies, while commercial entities are pursuing different implementation strategies. Climeworks AG and Global Thermostat have deployed operational direct air capture systems, while industrial giants like Sinopec, CNPC, and Cabot Corp. are leveraging their manufacturing capabilities to scale sorbent production. Aerospace-specific applications remain specialized, with companies like GE Infrastructure Technology and Munters Corp. adapting these technologies for cabin air purification and sustainable aviation fuel production pathways.

Climeworks AG

Technical Solution: Climeworks has developed a Direct Air Capture (DAC) technology specifically adaptable for aerospace applications. Their solution uses modular air collectors with a proprietary sorbent filter material that selectively captures CO₂ from ambient air. When saturated, the filters are heated to approximately 100°C, releasing concentrated CO₂ that can be collected for utilization or storage. The company has demonstrated the technology's viability in various environments, including their Orca plant in Iceland which captures 4,000 tons of CO₂ annually. For aerospace applications, Climeworks has miniaturized their technology to create compact, lightweight units that can be integrated into aircraft environmental control systems or space habitats. These units operate with minimal energy requirements and can function in low-pressure environments, making them suitable for both aviation and space applications. The technology has been tested in collaboration with aerospace agencies to evaluate performance in simulated space conditions and high-altitude environments.

Strengths: Highly modular and scalable design allows for flexible implementation in various aerospace platforms. The technology operates effectively in low-pressure environments, making it suitable for high-altitude and space applications. Weaknesses: Energy requirements for the thermal swing process may limit application in power-constrained aerospace systems. The current weight-to-capture ratio may need further optimization for flight applications where weight is critical.

Global Thermostat Operations LLC

Technical Solution: Global Thermostat has pioneered an advanced amine-based CO₂ capture technology specifically engineered for potential aerospace applications. Their proprietary system utilizes a honeycomb ceramic monolith structure coated with amine-based sorbents that can operate across a wide temperature range (-20°C to 100°C). This flexibility makes it particularly suitable for the variable conditions encountered in aerospace environments. The technology employs a low-temperature steam regeneration process (85-95°C) that requires minimal energy input, addressing the critical energy constraints in aerospace systems. Global Thermostat's sorbents demonstrate exceptional CO₂ selectivity even at low concentrations (400 ppm) and maintain performance in humid conditions without significant degradation. For aerospace applications, they've developed lightweight, compact modules that can be integrated into existing environmental control systems on aircraft or spacecraft. The technology has demonstrated the ability to capture CO₂ directly from cabin air, potentially eliminating the need for traditional LiOH canisters in spacecraft life support systems while providing a regenerable solution.

Strengths: The system's ability to operate efficiently at low CO₂ concentrations makes it ideal for maintaining spacecraft cabin air quality. The low regeneration temperature significantly reduces energy requirements compared to traditional systems. Weaknesses: The ceramic monolith structure, while efficient, may be susceptible to damage from vibration during launch or turbulence, requiring additional protective measures. The technology's performance in microgravity environments requires further validation for long-duration space missions.

Key Patents in Aerospace-Grade CO₂ Capture Materials

System, sorbents, and processes for capture and release of co2

PatentInactiveUS20130287663A1

Innovation

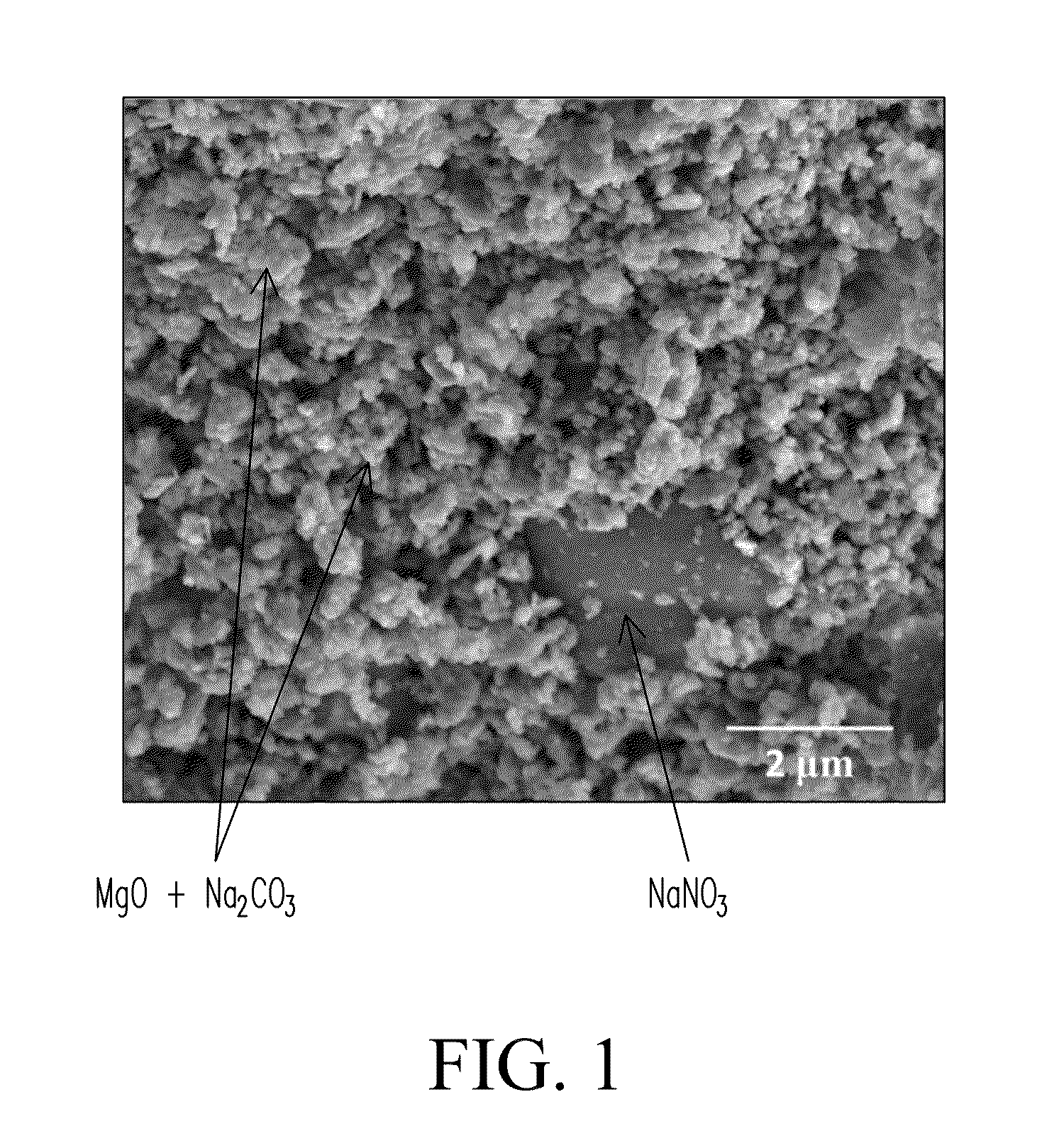

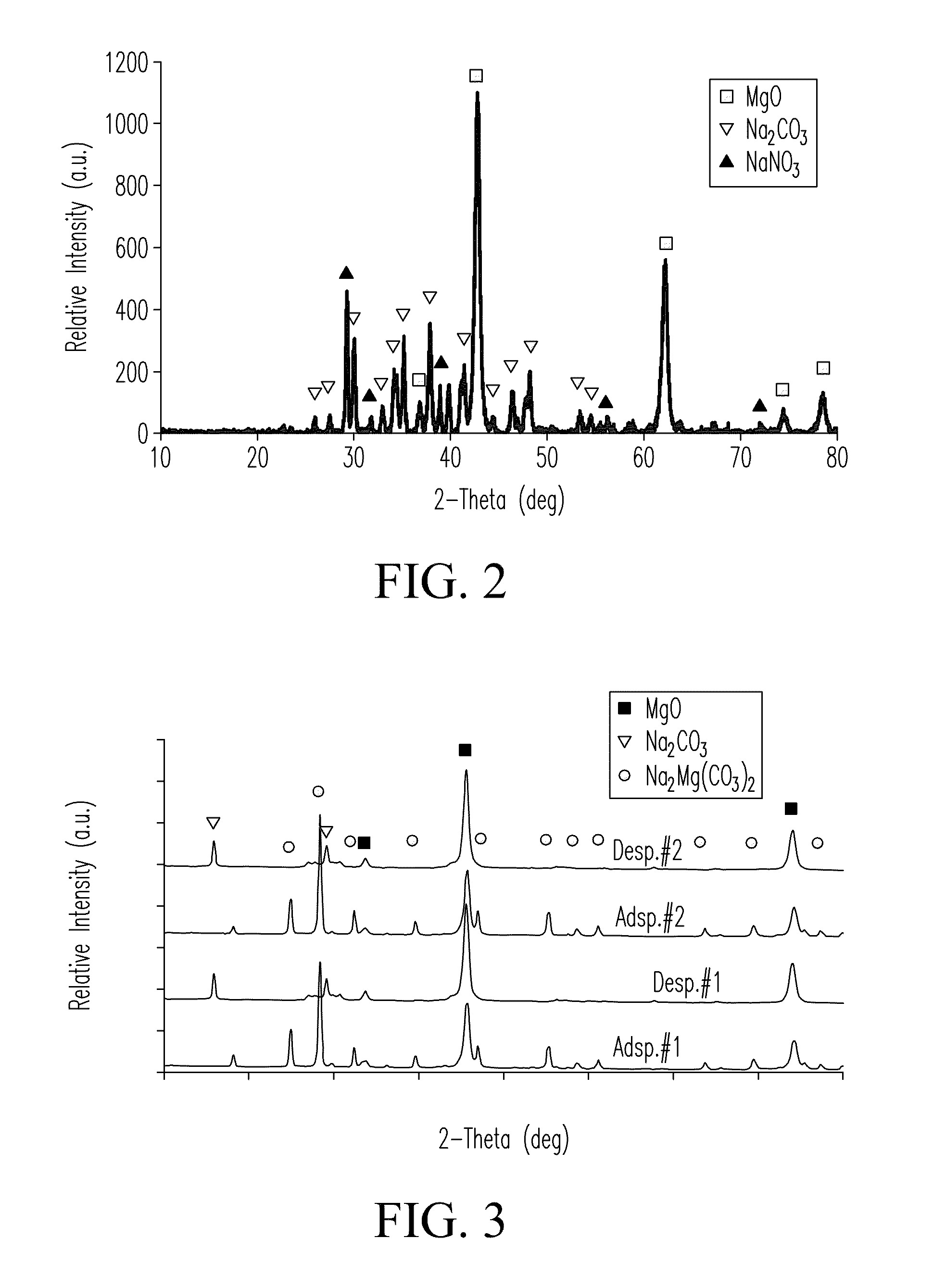

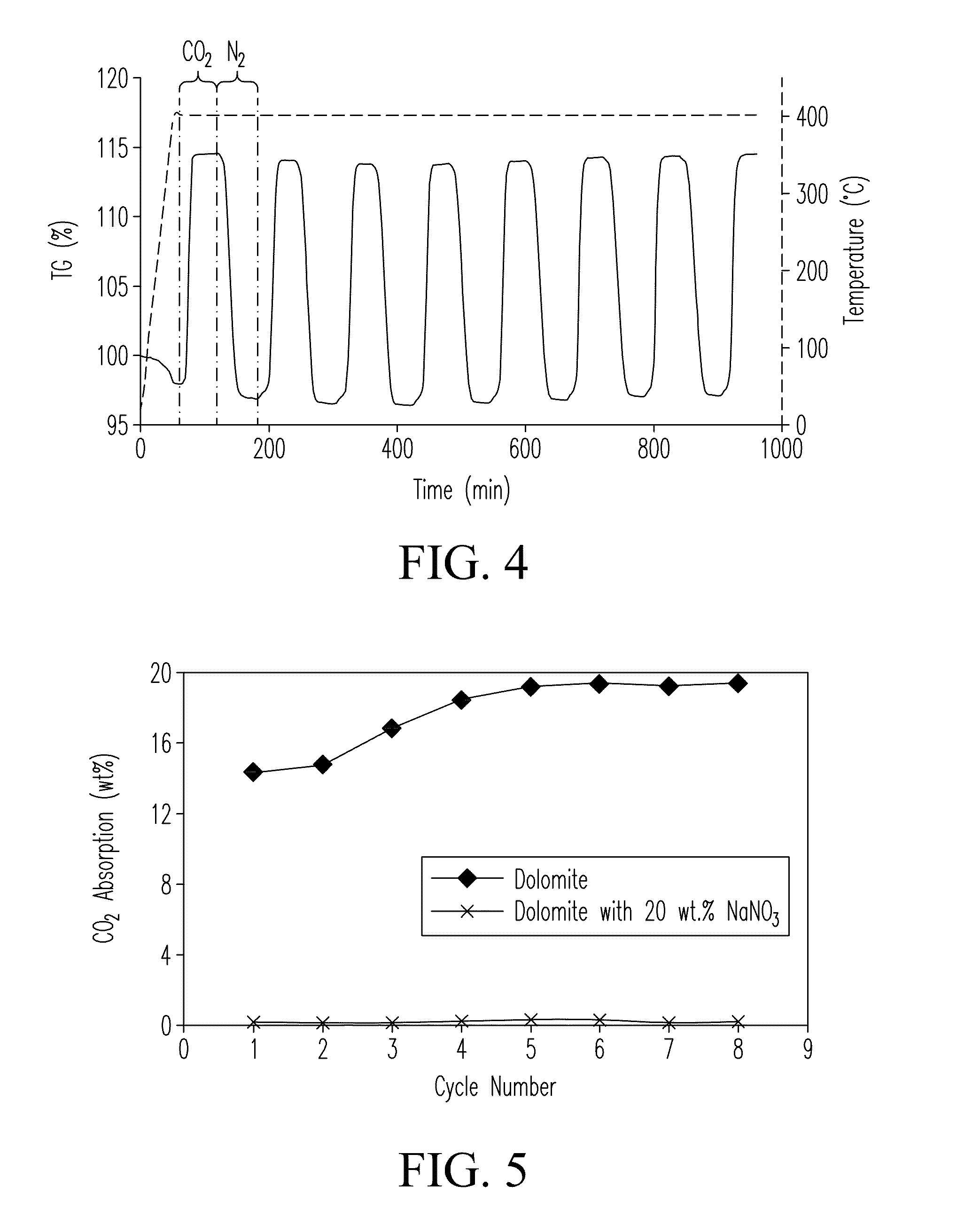

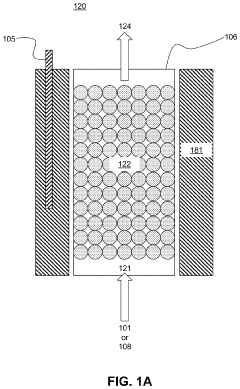

- A sorbent composition comprising magnesium oxide (MgO) and alkali-metal nitrates, with optional alkali-metal carbonates, that operates at warm temperatures to capture and release CO2, forming reversible solid metal carbonate salts, enhancing CO2 sorption capacity and efficiency.

Co2 capture using carbonate sorbents

PatentPendingUS20230182073A1

Innovation

- The use of non-deliquescent metal carbonates like calcium carbonate as sorbents in CO2 capture systems, which reduce waste and energy consumption by minimizing water condensation and sorbent loss, and the regeneration and recycling of spent sorbents through decomposition and granulation, allowing for efficient CO2 capture from both point sources and air.

Space Mission Requirements for CO₂ Management Systems

Space missions present unique challenges for CO₂ management systems due to the closed-loop environment and critical life support requirements. In spacecraft, CO₂ levels must be maintained below 0.5% (compared to Earth's 0.04%) to ensure crew health and cognitive function. Extended missions to the Moon or Mars require systems that can operate reliably for years without maintenance or replacement, significantly exceeding current capabilities of most terrestrial solutions.

Weight and volume constraints are paramount in aerospace applications, with every kilogram adding approximately $20,000 to launch costs. This necessitates CO₂ capture sorbents with high capacity-to-weight ratios and compact form factors. Power consumption represents another critical limitation, as spacecraft energy budgets are strictly controlled, favoring passive or low-energy sorbent technologies over energy-intensive alternatives.

Regenerability requirements differ substantially from Earth-based applications. While terrestrial systems may focus on permanent sequestration, space-based sorbents must be regenerable through vacuum exposure, moderate heating, or other low-resource methods. The captured CO₂ must also be recoverable at sufficient purity for potential utilization in life support systems, such as oxygen recovery through Sabatier reactions or plant growth systems.

Operational reliability under microgravity conditions presents unique challenges for sorbent materials. Flow dynamics, heat transfer, and mass transport phenomena behave differently in space, requiring specialized designs to ensure consistent performance. Additionally, sorbents must maintain stability when exposed to radiation levels significantly higher than Earth's surface, preventing degradation over multi-year missions.

Safety standards for aerospace applications exceed typical industrial requirements. Materials must be non-toxic, non-flammable, and generate minimal particulates or off-gassing. They must also withstand launch vibrations and potential rapid pressure changes without structural failure or performance degradation.

Future deep space missions will require increasingly closed-loop systems where captured CO₂ becomes a resource rather than waste. This drives development of sorbents compatible with in-situ resource utilization (ISRU) systems that can integrate with technologies for converting CO₂ to oxygen, fuel, or other useful products, creating sustainable life support ecosystems for long-duration exploration missions.

Weight and volume constraints are paramount in aerospace applications, with every kilogram adding approximately $20,000 to launch costs. This necessitates CO₂ capture sorbents with high capacity-to-weight ratios and compact form factors. Power consumption represents another critical limitation, as spacecraft energy budgets are strictly controlled, favoring passive or low-energy sorbent technologies over energy-intensive alternatives.

Regenerability requirements differ substantially from Earth-based applications. While terrestrial systems may focus on permanent sequestration, space-based sorbents must be regenerable through vacuum exposure, moderate heating, or other low-resource methods. The captured CO₂ must also be recoverable at sufficient purity for potential utilization in life support systems, such as oxygen recovery through Sabatier reactions or plant growth systems.

Operational reliability under microgravity conditions presents unique challenges for sorbent materials. Flow dynamics, heat transfer, and mass transport phenomena behave differently in space, requiring specialized designs to ensure consistent performance. Additionally, sorbents must maintain stability when exposed to radiation levels significantly higher than Earth's surface, preventing degradation over multi-year missions.

Safety standards for aerospace applications exceed typical industrial requirements. Materials must be non-toxic, non-flammable, and generate minimal particulates or off-gassing. They must also withstand launch vibrations and potential rapid pressure changes without structural failure or performance degradation.

Future deep space missions will require increasingly closed-loop systems where captured CO₂ becomes a resource rather than waste. This drives development of sorbents compatible with in-situ resource utilization (ISRU) systems that can integrate with technologies for converting CO₂ to oxygen, fuel, or other useful products, creating sustainable life support ecosystems for long-duration exploration missions.

Environmental Impact Assessment of Aerospace Sorbents

The environmental impact of CO₂ capture sorbents in aerospace applications requires comprehensive assessment across multiple dimensions. These specialized materials, while crucial for carbon management in spacecraft and aircraft systems, present both benefits and challenges from an environmental perspective.

The primary environmental benefit of aerospace sorbents is their contribution to reducing the carbon footprint of space missions and aviation operations. By capturing CO₂ emissions directly at the source, these materials help mitigate the greenhouse gas impact of aerospace activities, which is particularly significant given the industry's growing operational scale and environmental scrutiny.

Life cycle assessment (LCA) studies indicate that the production phase of advanced sorbents carries considerable environmental burdens. Manufacturing processes for zeolites, metal-organic frameworks (MOFs), and amine-functionalized materials typically involve energy-intensive synthesis routes and potentially hazardous chemical precursors. The ecological footprint extends to resource extraction, with rare earth elements in some formulations raising sustainability concerns regarding mining practices.

Disposal and end-of-life management present additional environmental considerations. Many high-performance aerospace sorbents contain components that resist natural degradation, potentially creating waste management challenges. Research indicates that regeneration capabilities significantly influence the overall environmental profile, with highly regenerable sorbents demonstrating superior sustainability metrics despite higher initial production impacts.

Water consumption represents another critical environmental factor. Certain hydrophilic sorbents require substantial water resources during manufacturing and regeneration cycles. This aspect becomes particularly relevant in water-stressed regions hosting aerospace manufacturing facilities or launch sites.

Energy efficiency during operational use emerges as a key environmental performance indicator. Advanced sorbents requiring lower regeneration temperatures or pressures demonstrate improved environmental profiles through reduced energy consumption during multiple capture-release cycles. This operational efficiency translates directly to lower lifetime emissions when integrated into aerospace environmental control systems.

Toxicity assessments reveal varying profiles among sorbent classes. While most physical sorbents present minimal toxicological concerns, chemical sorbents incorporating reactive amines or metal compounds may pose ecological risks if released into sensitive environments. Emerging research on biodegradable sorbent matrices offers promising pathways to address these concerns while maintaining performance specifications.

The geographical context significantly influences environmental impact, with regional energy mixes and manufacturing standards creating substantial variations in the carbon intensity of identical sorbent technologies produced in different locations. This underscores the importance of supply chain considerations in environmental impact optimization strategies.

The primary environmental benefit of aerospace sorbents is their contribution to reducing the carbon footprint of space missions and aviation operations. By capturing CO₂ emissions directly at the source, these materials help mitigate the greenhouse gas impact of aerospace activities, which is particularly significant given the industry's growing operational scale and environmental scrutiny.

Life cycle assessment (LCA) studies indicate that the production phase of advanced sorbents carries considerable environmental burdens. Manufacturing processes for zeolites, metal-organic frameworks (MOFs), and amine-functionalized materials typically involve energy-intensive synthesis routes and potentially hazardous chemical precursors. The ecological footprint extends to resource extraction, with rare earth elements in some formulations raising sustainability concerns regarding mining practices.

Disposal and end-of-life management present additional environmental considerations. Many high-performance aerospace sorbents contain components that resist natural degradation, potentially creating waste management challenges. Research indicates that regeneration capabilities significantly influence the overall environmental profile, with highly regenerable sorbents demonstrating superior sustainability metrics despite higher initial production impacts.

Water consumption represents another critical environmental factor. Certain hydrophilic sorbents require substantial water resources during manufacturing and regeneration cycles. This aspect becomes particularly relevant in water-stressed regions hosting aerospace manufacturing facilities or launch sites.

Energy efficiency during operational use emerges as a key environmental performance indicator. Advanced sorbents requiring lower regeneration temperatures or pressures demonstrate improved environmental profiles through reduced energy consumption during multiple capture-release cycles. This operational efficiency translates directly to lower lifetime emissions when integrated into aerospace environmental control systems.

Toxicity assessments reveal varying profiles among sorbent classes. While most physical sorbents present minimal toxicological concerns, chemical sorbents incorporating reactive amines or metal compounds may pose ecological risks if released into sensitive environments. Emerging research on biodegradable sorbent matrices offers promising pathways to address these concerns while maintaining performance specifications.

The geographical context significantly influences environmental impact, with regional energy mixes and manufacturing standards creating substantial variations in the carbon intensity of identical sorbent technologies produced in different locations. This underscores the importance of supply chain considerations in environmental impact optimization strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!