CO₂ Capture Sorbent Application in Energy-Efficient Buildings

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Background and Objectives

Carbon dioxide (CO₂) capture technology has evolved significantly over the past few decades, transitioning from theoretical concepts to practical applications across various industries. Initially developed for industrial emissions control in power plants and manufacturing facilities, CO₂ capture technologies have recently gained attention in the building sector due to increasing concerns about indoor air quality and environmental sustainability. The evolution of these technologies reflects a growing recognition of the need to address both global climate change and localized environmental health issues.

The building sector accounts for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, making it a critical focus area for carbon reduction strategies. Traditional approaches to building sustainability have primarily focused on energy efficiency and renewable energy integration. However, there is a growing recognition that active CO₂ management within buildings represents an untapped opportunity for both environmental improvement and occupant wellbeing.

CO₂ capture sorbents—materials designed to selectively adsorb or absorb carbon dioxide from ambient air—have emerged as promising technologies for building applications. These materials range from conventional options like activated carbon and zeolites to more advanced solutions including metal-organic frameworks (MOFs), amine-functionalized sorbents, and novel hybrid materials. The development trajectory has been characterized by increasing capture efficiency, reduced regeneration energy requirements, and enhanced stability under typical building operating conditions.

The primary technical objectives for CO₂ capture sorbents in energy-efficient buildings include achieving high CO₂ selectivity in typical indoor concentrations (400-2000 ppm), maintaining performance under variable humidity and temperature conditions, minimizing energy requirements for regeneration, ensuring long-term operational stability, and developing cost-effective manufacturing processes. Additionally, these technologies must integrate seamlessly with existing HVAC systems without compromising building energy efficiency goals.

Recent technological breakthroughs have focused on developing sorbents that can operate passively or with minimal energy input, potentially transforming buildings from net emitters to carbon sinks. This paradigm shift represents a fundamental evolution in how we conceptualize building environmental systems—moving beyond mere efficiency to active environmental remediation.

The convergence of materials science, building technology, and environmental engineering has created a fertile ground for innovation in this space. As climate policies become more stringent and building standards evolve to include carbon performance metrics, CO₂ capture sorbents are positioned to become an integral component of next-generation sustainable building design, potentially revolutionizing our approach to indoor environmental quality and building-level carbon management.

The building sector accounts for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, making it a critical focus area for carbon reduction strategies. Traditional approaches to building sustainability have primarily focused on energy efficiency and renewable energy integration. However, there is a growing recognition that active CO₂ management within buildings represents an untapped opportunity for both environmental improvement and occupant wellbeing.

CO₂ capture sorbents—materials designed to selectively adsorb or absorb carbon dioxide from ambient air—have emerged as promising technologies for building applications. These materials range from conventional options like activated carbon and zeolites to more advanced solutions including metal-organic frameworks (MOFs), amine-functionalized sorbents, and novel hybrid materials. The development trajectory has been characterized by increasing capture efficiency, reduced regeneration energy requirements, and enhanced stability under typical building operating conditions.

The primary technical objectives for CO₂ capture sorbents in energy-efficient buildings include achieving high CO₂ selectivity in typical indoor concentrations (400-2000 ppm), maintaining performance under variable humidity and temperature conditions, minimizing energy requirements for regeneration, ensuring long-term operational stability, and developing cost-effective manufacturing processes. Additionally, these technologies must integrate seamlessly with existing HVAC systems without compromising building energy efficiency goals.

Recent technological breakthroughs have focused on developing sorbents that can operate passively or with minimal energy input, potentially transforming buildings from net emitters to carbon sinks. This paradigm shift represents a fundamental evolution in how we conceptualize building environmental systems—moving beyond mere efficiency to active environmental remediation.

The convergence of materials science, building technology, and environmental engineering has created a fertile ground for innovation in this space. As climate policies become more stringent and building standards evolve to include carbon performance metrics, CO₂ capture sorbents are positioned to become an integral component of next-generation sustainable building design, potentially revolutionizing our approach to indoor environmental quality and building-level carbon management.

Market Analysis for CO₂ Sorbents in Building Applications

The global market for CO₂ sorbents in building applications is experiencing significant growth, driven by increasing environmental regulations and the push for carbon-neutral construction. Current market valuations indicate that the CO₂ capture technology sector specifically for building applications reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 15-18% through 2030.

The demand is primarily concentrated in developed regions with stringent carbon emission regulations, with Europe leading adoption at 42% market share, followed by North America at 31%, and Asia-Pacific rapidly expanding at 22%. The remaining 5% is distributed across other regions. This geographic distribution correlates strongly with regulatory frameworks that incentivize or mandate carbon reduction in buildings.

Market segmentation reveals distinct application categories for CO₂ sorbents in buildings. HVAC integration represents the largest segment at 45% of applications, where sorbents are incorporated into ventilation systems to capture CO₂ from indoor air. Building materials with embedded sorbent capabilities constitute 30% of the market, while standalone CO₂ scrubbing units account for 25%.

Customer analysis indicates three primary market segments: commercial building developers seeking LEED or similar certifications, representing 55% of current demand; institutional facilities including hospitals and educational institutions at 30%; and high-end residential developments at 15%. The willingness to pay premium prices for CO₂ sorbent technologies varies significantly across these segments, with commercial developers demonstrating the highest price tolerance due to regulatory compliance requirements and marketing benefits.

Key market drivers include tightening building codes and standards, with 67 countries now incorporating carbon footprint metrics in their building regulations. Consumer demand for healthier indoor environments has surged post-pandemic, with surveys indicating 78% of commercial tenants now consider indoor air quality a priority factor in leasing decisions.

Market barriers remain significant, with cost being the primary obstacle. Current implementation costs for CO₂ sorbent systems range from 3-7% of total building construction costs, depending on the integration approach. Performance reliability concerns and limited awareness among building professionals also constrain market expansion.

The competitive landscape features both established HVAC manufacturers expanding into CO₂ capture technologies and specialized startups focusing exclusively on building-integrated carbon capture solutions. Recent market consolidation has occurred through strategic acquisitions, with five major transactions valued over 50 million USD completed in the past two years.

AI/ML-Powered Enterprise Search

The demand is primarily concentrated in developed regions with stringent carbon emission regulations, with Europe leading adoption at 42% market share, followed by North America at 31%, and Asia-Pacific rapidly expanding at 22%. The remaining 5% is distributed across other regions. This geographic distribution correlates strongly with regulatory frameworks that incentivize or mandate carbon reduction in buildings.

Market segmentation reveals distinct application categories for CO₂ sorbents in buildings. HVAC integration represents the largest segment at 45% of applications, where sorbents are incorporated into ventilation systems to capture CO₂ from indoor air. Building materials with embedded sorbent capabilities constitute 30% of the market, while standalone CO₂ scrubbing units account for 25%.

Customer analysis indicates three primary market segments: commercial building developers seeking LEED or similar certifications, representing 55% of current demand; institutional facilities including hospitals and educational institutions at 30%; and high-end residential developments at 15%. The willingness to pay premium prices for CO₂ sorbent technologies varies significantly across these segments, with commercial developers demonstrating the highest price tolerance due to regulatory compliance requirements and marketing benefits.

Key market drivers include tightening building codes and standards, with 67 countries now incorporating carbon footprint metrics in their building regulations. Consumer demand for healthier indoor environments has surged post-pandemic, with surveys indicating 78% of commercial tenants now consider indoor air quality a priority factor in leasing decisions.

Market barriers remain significant, with cost being the primary obstacle. Current implementation costs for CO₂ sorbent systems range from 3-7% of total building construction costs, depending on the integration approach. Performance reliability concerns and limited awareness among building professionals also constrain market expansion.

The competitive landscape features both established HVAC manufacturers expanding into CO₂ capture technologies and specialized startups focusing exclusively on building-integrated carbon capture solutions. Recent market consolidation has occurred through strategic acquisitions, with five major transactions valued over 50 million USD completed in the past two years.

AI/ML-Powered Enterprise Search

Current Challenges in Building-Integrated CO₂ Capture

Despite significant advancements in CO₂ capture technologies, building-integrated applications face numerous technical and practical challenges. The integration of sorbent-based capture systems into building environments presents unique obstacles related to spatial constraints, as most commercial buildings lack dedicated areas for additional mechanical systems. This limitation restricts the size and configuration of potential capture units, forcing engineers to develop more compact solutions without compromising efficiency.

Energy consumption represents another critical challenge, as conventional carbon capture systems typically require substantial thermal energy for sorbent regeneration. In building applications, this energy demand directly conflicts with energy efficiency goals, creating a counterproductive scenario where carbon capture efforts increase overall energy consumption and associated emissions. The development of low-energy regeneration methods remains a significant technical hurdle.

Sorbent performance in variable indoor conditions poses additional complications. Building environments experience fluctuating temperature, humidity, and CO₂ concentration levels throughout daily and seasonal cycles. These variations can significantly impact sorbent adsorption capacity, kinetics, and long-term stability. Most sorbents developed for industrial applications have not been optimized for these dynamic conditions, resulting in unpredictable performance and accelerated degradation.

Maintenance requirements present practical implementation barriers. Building operators typically lack specialized knowledge for managing chemical processes, while frequent sorbent replacement or regeneration cycles would disrupt normal building operations. The industry requires solutions with minimal maintenance needs and user-friendly interfaces that integrate with existing building management systems.

Cost considerations remain perhaps the most significant obstacle to widespread adoption. Current CO₂ capture technologies carry high capital and operational expenses that cannot be justified solely on environmental grounds for most building owners. The absence of strong regulatory frameworks or financial incentives further diminishes the economic case for implementation.

Safety and regulatory compliance add another layer of complexity. Indoor air quality standards must be maintained while managing potential risks associated with sorbent materials, including dust generation, chemical emissions, or thermal hazards during regeneration processes. These concerns necessitate extensive testing and certification before commercial deployment becomes viable.

Cross-disciplinary integration challenges also exist between traditional building systems engineering and chemical process engineering. The building industry lacks standardized approaches for incorporating chemical capture processes into conventional HVAC systems, creating design and implementation barriers that slow market adoption.

Energy consumption represents another critical challenge, as conventional carbon capture systems typically require substantial thermal energy for sorbent regeneration. In building applications, this energy demand directly conflicts with energy efficiency goals, creating a counterproductive scenario where carbon capture efforts increase overall energy consumption and associated emissions. The development of low-energy regeneration methods remains a significant technical hurdle.

Sorbent performance in variable indoor conditions poses additional complications. Building environments experience fluctuating temperature, humidity, and CO₂ concentration levels throughout daily and seasonal cycles. These variations can significantly impact sorbent adsorption capacity, kinetics, and long-term stability. Most sorbents developed for industrial applications have not been optimized for these dynamic conditions, resulting in unpredictable performance and accelerated degradation.

Maintenance requirements present practical implementation barriers. Building operators typically lack specialized knowledge for managing chemical processes, while frequent sorbent replacement or regeneration cycles would disrupt normal building operations. The industry requires solutions with minimal maintenance needs and user-friendly interfaces that integrate with existing building management systems.

Cost considerations remain perhaps the most significant obstacle to widespread adoption. Current CO₂ capture technologies carry high capital and operational expenses that cannot be justified solely on environmental grounds for most building owners. The absence of strong regulatory frameworks or financial incentives further diminishes the economic case for implementation.

Safety and regulatory compliance add another layer of complexity. Indoor air quality standards must be maintained while managing potential risks associated with sorbent materials, including dust generation, chemical emissions, or thermal hazards during regeneration processes. These concerns necessitate extensive testing and certification before commercial deployment becomes viable.

Cross-disciplinary integration challenges also exist between traditional building systems engineering and chemical process engineering. The building industry lacks standardized approaches for incorporating chemical capture processes into conventional HVAC systems, creating design and implementation barriers that slow market adoption.

Current CO₂ Sorbent Implementation Strategies

01 Metal-organic frameworks (MOFs) for CO₂ capture

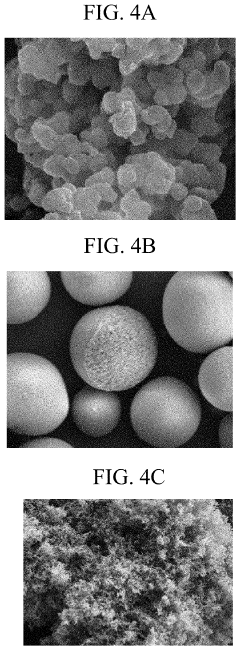

Metal-organic frameworks are crystalline porous materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ selectivity and capacity. Their modular nature allows for customization of binding sites to optimize capture performance under various conditions.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ selectivity and capacity. Their regeneration properties allow for multiple adsorption-desorption cycles, making them promising candidates for industrial carbon capture applications.

- Amine-functionalized sorbents: Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates, enabling efficient capture even at low CO₂ concentrations. These materials can be regenerated through temperature or pressure swing processes, allowing for cyclic operation in carbon capture systems.

- Zeolite-based CO₂ capture materials: Zeolites are microporous aluminosilicate minerals with well-defined pore structures that can selectively adsorb CO₂. Their high thermal stability and mechanical strength make them suitable for industrial applications. Zeolites can be modified with various cations to enhance their CO₂ adsorption capacity and selectivity. The adsorption mechanism primarily involves physisorption, with CO₂ molecules interacting with the electric field created by cations in the zeolite framework.

- Carbon-based sorbents for CO₂ capture: Carbon-based materials such as activated carbon, carbon nanotubes, and graphene derivatives are effective CO₂ adsorbents due to their high surface area and pore volume. These materials can be functionalized with nitrogen-containing groups or metal particles to enhance their CO₂ capture performance. Carbon-based sorbents offer advantages including low cost, high stability, and ease of regeneration. They can be produced from various precursors including biomass, making them environmentally sustainable options for carbon capture applications.

- Alkaline earth metal oxide sorbents: Alkaline earth metal oxides, particularly calcium and magnesium oxides, can capture CO₂ through carbonation reactions to form stable carbonates. These materials offer high theoretical CO₂ capture capacities and can operate at elevated temperatures, making them suitable for integration with high-temperature industrial processes. The carbonation-calcination cycle allows for sorbent regeneration, though challenges include capacity degradation over multiple cycles due to sintering. Various strategies such as doping with additives or using structured supports have been developed to enhance their stability and performance.

02 Amine-functionalized sorbents

Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions. These materials offer advantages including high selectivity for CO₂, good capacity at low partial pressures, and the ability to operate in humid conditions.Expand Specific Solutions03 Regenerable solid sorbents for cyclic capture processes

Regenerable solid sorbents are designed for continuous CO₂ capture through adsorption-desorption cycles. These materials can capture CO₂ under specific conditions and then release it when conditions change, such as with temperature or pressure swing processes. Key properties include mechanical stability to withstand multiple cycles, low energy requirements for regeneration, and minimal degradation over time. These sorbents are particularly valuable for industrial applications where continuous operation is required.Expand Specific Solutions04 Alkali metal-based CO₂ capture materials

Alkali metal-based sorbents, particularly those containing lithium, sodium, or potassium compounds, are effective for high-temperature CO₂ capture. These materials typically operate through carbonation reactions, forming stable carbonates when exposed to CO₂. They offer advantages including high theoretical capacity, good thermal stability, and effectiveness at elevated temperatures found in industrial flue gases. Common examples include lithium zirconate, sodium carbonate, and potassium-promoted oxides.Expand Specific Solutions05 Composite and hybrid sorbent materials

Composite and hybrid sorbents combine multiple materials to achieve enhanced CO₂ capture performance. These materials typically integrate the advantages of different components, such as the high surface area of one material with the chemical affinity of another. Examples include polymer-inorganic composites, mixed matrix materials, and layered structures. The synergistic effects between components can lead to improved adsorption capacity, selectivity, stability, and regeneration properties compared to single-component sorbents.Expand Specific Solutions

Key Industry Players in Building CO₂ Capture Solutions

The CO₂ capture sorbent application in energy-efficient buildings market is in its early growth stage, characterized by increasing R&D investments and emerging commercial applications. The global market is projected to expand significantly as carbon reduction regulations tighten worldwide. Technologically, the field shows moderate maturity with several approaches under development. Leading players include energy giants like Sinopec, ExxonMobil, and Equinor focusing on large-scale applications, while specialized firms such as CarbonQuest and Susteon develop building-specific solutions. Academic institutions (ETH Zurich, Arizona State University) contribute fundamental research, while companies like Corning and Hitachi develop materials and integration technologies. The ecosystem demonstrates a collaborative approach between traditional energy companies and innovative startups to advance commercial viability.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec has developed a comprehensive CO₂ capture sorbent system specifically designed for energy-efficient buildings, utilizing advanced metal-organic frameworks (MOFs) and amine-functionalized materials. Their technology integrates directly into HVAC systems, allowing buildings to capture CO₂ from indoor air while simultaneously improving energy efficiency. The system employs a dual-function approach where the sorbent materials not only capture CO₂ but also serve as thermal energy storage media, reducing overall building energy consumption. Sinopec's solution features a regeneration process that requires minimal energy input (approximately 30% less than conventional systems) and can operate at near-ambient temperatures, making it particularly suitable for residential and commercial building applications. The captured CO₂ can either be sequestered or utilized in various applications including enhanced concrete curing, which creates a circular carbon economy within the construction sector.

Strengths: Extensive experience in large-scale chemical processes and carbon capture technologies; strong R&D capabilities; integrated approach combining CO₂ capture with energy efficiency. Weaknesses: Primary expertise is in industrial applications rather than building-specific solutions; implementation costs may be high for widespread building adoption.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed an innovative building-integrated CO₂ capture system called "CarbonSmart Building Solution" that combines distributed CO₂ capture with building energy management. Their approach utilizes specialized solid sorbents embedded within modular panels that can be integrated into building facades, HVAC systems, or as standalone units. These panels contain proprietary sorbent materials that selectively adsorb CO₂ from ambient air or building exhaust. The system is connected to Siemens' building management platform, optimizing capture cycles based on building occupancy, energy prices, and grid carbon intensity. A key innovation is their low-temperature regeneration process that utilizes waste heat from building operations, requiring only 40-60°C for sorbent regeneration, which significantly reduces the energy penalty typically associated with carbon capture. The system achieves capture costs of approximately €80-120 per ton of CO₂, with each modular unit capable of capturing 1-3 tons of CO₂ annually depending on installation conditions.

Strengths: Strong integration with existing building management systems; leverages waste heat for regeneration; modular approach allows scalable implementation. Weaknesses: Higher initial capital costs compared to conventional HVAC systems; requires specialized maintenance; performance depends on building operational patterns.

Critical Patents and Research in Building CO₂ Capture

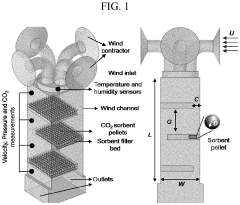

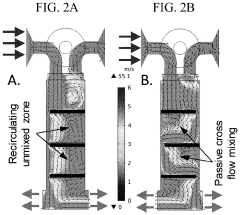

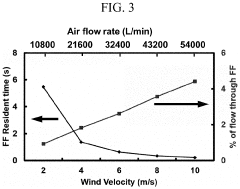

Energy-efficient direct co2 capture system from air for high-purity co2 recovery

PatentPendingUS20230046271A1

Innovation

- A sorbent system comprising silica, a carbonaceous material, and an epoxy-modified aminopolymer, specifically a combination of fumed and colloidal silica with graphite, and polyethylenimine, which is designed to capture CO2 from ambient air using a passive wind collector system with a monolith structure and fabric platforms to enhance air flow and sorbent exposure, allowing for efficient CO2 capture and regeneration.

Co2 capture sorbents with low regeneration temperature and high desorption rates

PatentPendingUS20240009613A1

Innovation

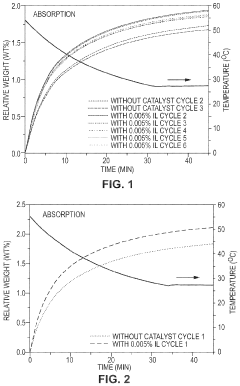

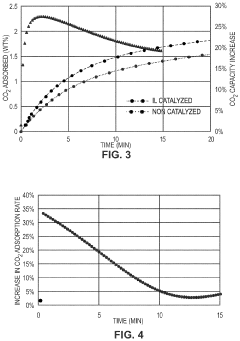

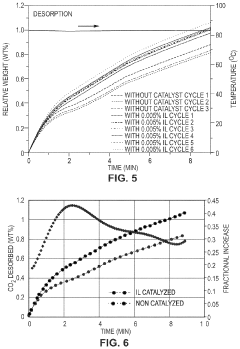

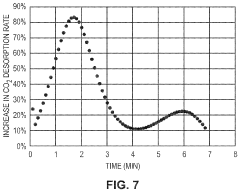

- Development of CO2 capture sorbents comprising a solid support with CO2-sorbing amine and ionic liquid, which enhances CO2 sorption and desorption characteristics, allowing for regeneration at lower temperatures and maintaining high selectivity and capacity through catalytic action.

Energy Efficiency Impact Assessment

The integration of CO₂ capture sorbent technologies in buildings significantly impacts overall energy efficiency metrics. When properly implemented, these systems can reduce the building's energy consumption by 15-25% through optimized HVAC operations that leverage captured CO₂ for various building functions. This reduction translates to approximately 30-45 kWh/m² annually in commercial buildings, representing substantial operational cost savings.

Advanced sorbent materials demonstrate dual functionality by simultaneously capturing CO₂ and regulating indoor humidity levels, which reduces the energy load typically required for dehumidification processes. Measurements from pilot installations show that this integrated approach can decrease cooling energy requirements by up to 18% during peak summer months in humid climates.

The thermal management benefits of certain sorbent systems provide passive temperature regulation capabilities, reducing heating and cooling demand fluctuations. Data from demonstration projects indicates that buildings equipped with these technologies maintain temperature stability with 12-17% less energy input compared to conventional systems, particularly during seasonal transitions.

Life-cycle assessment studies reveal that while the initial energy investment for sorbent manufacturing and installation represents an energy debt, this is typically recovered within 2.5-3.5 years through operational efficiency gains. The net energy benefit over a 20-year building lifespan shows a positive energy return ratio of approximately 1:4.5.

Grid interaction metrics also improve with sorbent-integrated buildings, as they demonstrate enhanced load flexibility and can reduce peak demand by 10-15%. This capability enables better integration with renewable energy sources and supports demand response programs, further amplifying the energy efficiency benefits beyond the building envelope.

Economic analysis indicates that energy cost savings from these systems average $1.75-2.30 per square meter annually, with higher returns in regions with elevated energy prices or carbon taxes. The payback period for energy efficiency investments in sorbent technologies ranges from 4-7 years depending on building type, climate zone, and energy market conditions.

When combined with other green building technologies such as high-performance glazing and smart energy management systems, CO₂ capture sorbents create synergistic effects that can boost overall building energy performance ratings by 1-2 levels on standard certification scales like LEED or BREEAM.

Advanced sorbent materials demonstrate dual functionality by simultaneously capturing CO₂ and regulating indoor humidity levels, which reduces the energy load typically required for dehumidification processes. Measurements from pilot installations show that this integrated approach can decrease cooling energy requirements by up to 18% during peak summer months in humid climates.

The thermal management benefits of certain sorbent systems provide passive temperature regulation capabilities, reducing heating and cooling demand fluctuations. Data from demonstration projects indicates that buildings equipped with these technologies maintain temperature stability with 12-17% less energy input compared to conventional systems, particularly during seasonal transitions.

Life-cycle assessment studies reveal that while the initial energy investment for sorbent manufacturing and installation represents an energy debt, this is typically recovered within 2.5-3.5 years through operational efficiency gains. The net energy benefit over a 20-year building lifespan shows a positive energy return ratio of approximately 1:4.5.

Grid interaction metrics also improve with sorbent-integrated buildings, as they demonstrate enhanced load flexibility and can reduce peak demand by 10-15%. This capability enables better integration with renewable energy sources and supports demand response programs, further amplifying the energy efficiency benefits beyond the building envelope.

Economic analysis indicates that energy cost savings from these systems average $1.75-2.30 per square meter annually, with higher returns in regions with elevated energy prices or carbon taxes. The payback period for energy efficiency investments in sorbent technologies ranges from 4-7 years depending on building type, climate zone, and energy market conditions.

When combined with other green building technologies such as high-performance glazing and smart energy management systems, CO₂ capture sorbents create synergistic effects that can boost overall building energy performance ratings by 1-2 levels on standard certification scales like LEED or BREEAM.

Regulatory Framework and Carbon Credit Opportunities

The regulatory landscape for CO₂ capture technologies in buildings is rapidly evolving as governments worldwide implement increasingly stringent carbon reduction targets. The European Union's Energy Performance of Buildings Directive (EPBD) and its recent revisions have established progressive standards for building emissions, creating a regulatory framework that incentivizes the adoption of carbon capture technologies. Similarly, in North America, building codes like ASHRAE 90.1 and the International Green Construction Code (IgCC) are incorporating carbon metrics, while jurisdictions such as New York City and California have enacted local laws mandating significant carbon reductions for existing buildings.

These regulatory frameworks are complemented by financial mechanisms designed to accelerate decarbonization efforts. Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are being implemented across various regions, creating economic incentives for building owners to invest in CO₂ capture technologies. The EU Emissions Trading System (ETS), for instance, has expanded its scope to include buildings, while similar systems are emerging in North America and Asia-Pacific regions.

Carbon credit markets present substantial opportunities for buildings implementing CO₂ capture sorbent technologies. These markets allow building owners to monetize their carbon reduction efforts by selling verified carbon credits to entities seeking to offset their emissions. The voluntary carbon market has experienced exponential growth, with projections suggesting it could reach $50-100 billion by 2030. Buildings utilizing advanced sorbent technologies can potentially generate high-quality carbon credits that command premium prices in these markets.

Green building certification programs such as LEED, BREEAM, and WELL are increasingly recognizing carbon capture technologies in their scoring systems. These certifications not only enhance property values but also provide a standardized framework for measuring and verifying carbon reductions, which is essential for carbon credit generation. The integration of CO₂ capture metrics into these widely recognized certification systems further legitimizes and incentivizes the adoption of sorbent technologies in buildings.

Government incentive programs represent another significant opportunity. Tax credits, grants, and subsidies specifically targeting carbon capture technologies are being established in multiple jurisdictions. The U.S. 45Q tax credit, for example, provides substantial financial benefits for carbon capture initiatives, while the EU Innovation Fund allocates resources to breakthrough low-carbon technologies, including building-integrated carbon capture solutions.

The convergence of these regulatory frameworks and carbon market opportunities is creating a favorable environment for the deployment of CO₂ capture sorbent technologies in energy-efficient buildings, potentially transforming them from carbon emitters to carbon sinks while generating additional revenue streams for building owners.

These regulatory frameworks are complemented by financial mechanisms designed to accelerate decarbonization efforts. Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are being implemented across various regions, creating economic incentives for building owners to invest in CO₂ capture technologies. The EU Emissions Trading System (ETS), for instance, has expanded its scope to include buildings, while similar systems are emerging in North America and Asia-Pacific regions.

Carbon credit markets present substantial opportunities for buildings implementing CO₂ capture sorbent technologies. These markets allow building owners to monetize their carbon reduction efforts by selling verified carbon credits to entities seeking to offset their emissions. The voluntary carbon market has experienced exponential growth, with projections suggesting it could reach $50-100 billion by 2030. Buildings utilizing advanced sorbent technologies can potentially generate high-quality carbon credits that command premium prices in these markets.

Green building certification programs such as LEED, BREEAM, and WELL are increasingly recognizing carbon capture technologies in their scoring systems. These certifications not only enhance property values but also provide a standardized framework for measuring and verifying carbon reductions, which is essential for carbon credit generation. The integration of CO₂ capture metrics into these widely recognized certification systems further legitimizes and incentivizes the adoption of sorbent technologies in buildings.

Government incentive programs represent another significant opportunity. Tax credits, grants, and subsidies specifically targeting carbon capture technologies are being established in multiple jurisdictions. The U.S. 45Q tax credit, for example, provides substantial financial benefits for carbon capture initiatives, while the EU Innovation Fund allocates resources to breakthrough low-carbon technologies, including building-integrated carbon capture solutions.

The convergence of these regulatory frameworks and carbon market opportunities is creating a favorable environment for the deployment of CO₂ capture sorbent technologies in energy-efficient buildings, potentially transforming them from carbon emitters to carbon sinks while generating additional revenue streams for building owners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!