CO₂ Capture Sorbents and Their Role in HVAC Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Technology Background and Objectives

Carbon dioxide (CO₂) capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications across various industries. Initially developed for industrial emissions control in power plants and manufacturing facilities, CO₂ capture technologies have gradually expanded into new domains, including building systems. The evolution of these technologies reflects growing global concerns about climate change and the imperative to reduce greenhouse gas emissions.

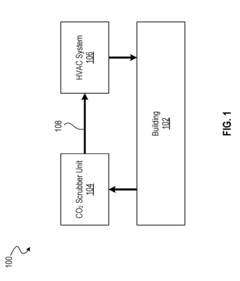

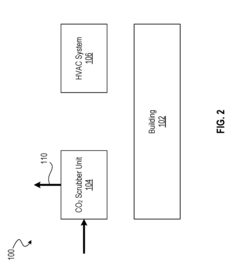

The HVAC (Heating, Ventilation, and Air Conditioning) sector represents a significant but often overlooked contributor to global carbon emissions. Buildings account for approximately 40% of global energy consumption and 30% of energy-related CO₂ emissions, with HVAC systems responsible for a substantial portion of this environmental impact. This realization has driven increased interest in integrating carbon capture capabilities directly into building ventilation systems.

Sorbent-based CO₂ capture represents one of the most promising approaches for HVAC integration due to its relatively low energy requirements, scalability, and adaptability to varying operational conditions. These materials, which can physically or chemically bind with CO₂ molecules, offer potential advantages over traditional liquid absorption systems, particularly in the moderate concentration environments typical of indoor spaces.

The technological trajectory indicates a shift from first-generation sorbents with limited capacity and high regeneration energy requirements toward advanced materials engineered at the nanoscale with precisely tailored properties. Metal-organic frameworks (MOFs), amine-functionalized silicas, and novel polymer-based sorbents represent the cutting edge of this technological evolution, offering unprecedented combinations of selectivity, capacity, and regeneration efficiency.

The primary objectives of CO₂ capture technology in HVAC applications include reducing building carbon footprints, improving indoor air quality, and potentially creating closed-loop systems where captured carbon can be repurposed. Short-term goals focus on developing sorbents that can operate effectively at the temperature, humidity, and concentration conditions typical of indoor environments, while minimizing energy penalties and system complexity.

Long-term technological objectives extend to creating fully integrated building systems that not only capture CO₂ but utilize it productively—either through conversion to useful products or by enabling carbon-negative building operations. This vision aligns with broader sustainability goals and the concept of buildings as active participants in carbon management rather than passive emitters.

The convergence of materials science, chemical engineering, and building systems technology creates a fertile ground for innovation in this domain, with significant potential for transformative impact on both building performance and global carbon management strategies.

The HVAC (Heating, Ventilation, and Air Conditioning) sector represents a significant but often overlooked contributor to global carbon emissions. Buildings account for approximately 40% of global energy consumption and 30% of energy-related CO₂ emissions, with HVAC systems responsible for a substantial portion of this environmental impact. This realization has driven increased interest in integrating carbon capture capabilities directly into building ventilation systems.

Sorbent-based CO₂ capture represents one of the most promising approaches for HVAC integration due to its relatively low energy requirements, scalability, and adaptability to varying operational conditions. These materials, which can physically or chemically bind with CO₂ molecules, offer potential advantages over traditional liquid absorption systems, particularly in the moderate concentration environments typical of indoor spaces.

The technological trajectory indicates a shift from first-generation sorbents with limited capacity and high regeneration energy requirements toward advanced materials engineered at the nanoscale with precisely tailored properties. Metal-organic frameworks (MOFs), amine-functionalized silicas, and novel polymer-based sorbents represent the cutting edge of this technological evolution, offering unprecedented combinations of selectivity, capacity, and regeneration efficiency.

The primary objectives of CO₂ capture technology in HVAC applications include reducing building carbon footprints, improving indoor air quality, and potentially creating closed-loop systems where captured carbon can be repurposed. Short-term goals focus on developing sorbents that can operate effectively at the temperature, humidity, and concentration conditions typical of indoor environments, while minimizing energy penalties and system complexity.

Long-term technological objectives extend to creating fully integrated building systems that not only capture CO₂ but utilize it productively—either through conversion to useful products or by enabling carbon-negative building operations. This vision aligns with broader sustainability goals and the concept of buildings as active participants in carbon management rather than passive emitters.

The convergence of materials science, chemical engineering, and building systems technology creates a fertile ground for innovation in this domain, with significant potential for transformative impact on both building performance and global carbon management strategies.

Market Analysis for CO2 Capture in HVAC Applications

The global market for CO2 capture technologies in HVAC applications is experiencing significant growth, driven by increasing awareness of indoor air quality and stringent environmental regulations. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2030, representing a compound annual growth rate of 14.3%. This growth trajectory is particularly pronounced in commercial buildings, healthcare facilities, and educational institutions where indoor air quality directly impacts occupant health and productivity.

Regional analysis reveals that North America currently holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. The European market is experiencing the fastest growth due to aggressive carbon reduction policies and building efficiency standards. Countries like Germany, France, and the UK are leading adopters, implementing carbon capture technologies in new construction and retrofitting existing HVAC systems.

Demand drivers for CO2 capture in HVAC systems include heightened awareness of sick building syndrome, post-pandemic focus on ventilation, and corporate sustainability commitments. The commercial building sector represents the largest application segment, accounting for 45% of the market, followed by healthcare facilities at 20% and educational institutions at 15%. Residential applications remain limited but are expected to grow as costs decrease and consumer awareness increases.

Market segmentation by technology type shows that solid sorbent-based systems dominate with 55% market share, followed by membrane-based technologies at 25% and liquid absorbent systems at 20%. Zeolite-based sorbents are gaining traction due to their high CO2 selectivity and relatively low regeneration energy requirements.

Customer willingness to pay varies significantly by sector. Commercial property developers report 15-20% premium acceptance for buildings with advanced air quality systems, while healthcare facilities prioritize these technologies regardless of cost premium due to patient health considerations. Educational institutions typically require demonstrable energy savings to offset the initial investment.

Market barriers include high initial capital costs, with integrated CO2 capture systems adding 20-30% to HVAC installation costs. Limited awareness among building owners and facility managers about the benefits of CO2 capture technologies also hinders adoption. Additionally, the lack of standardized performance metrics makes comparison between competing technologies challenging for potential buyers.

The competitive landscape features established HVAC manufacturers expanding their portfolios alongside specialized startups focusing exclusively on carbon capture innovations. Strategic partnerships between technology providers and building management companies are emerging as a key market entry strategy, offering bundled solutions that combine equipment, installation, and ongoing maintenance services.

Regional analysis reveals that North America currently holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. The European market is experiencing the fastest growth due to aggressive carbon reduction policies and building efficiency standards. Countries like Germany, France, and the UK are leading adopters, implementing carbon capture technologies in new construction and retrofitting existing HVAC systems.

Demand drivers for CO2 capture in HVAC systems include heightened awareness of sick building syndrome, post-pandemic focus on ventilation, and corporate sustainability commitments. The commercial building sector represents the largest application segment, accounting for 45% of the market, followed by healthcare facilities at 20% and educational institutions at 15%. Residential applications remain limited but are expected to grow as costs decrease and consumer awareness increases.

Market segmentation by technology type shows that solid sorbent-based systems dominate with 55% market share, followed by membrane-based technologies at 25% and liquid absorbent systems at 20%. Zeolite-based sorbents are gaining traction due to their high CO2 selectivity and relatively low regeneration energy requirements.

Customer willingness to pay varies significantly by sector. Commercial property developers report 15-20% premium acceptance for buildings with advanced air quality systems, while healthcare facilities prioritize these technologies regardless of cost premium due to patient health considerations. Educational institutions typically require demonstrable energy savings to offset the initial investment.

Market barriers include high initial capital costs, with integrated CO2 capture systems adding 20-30% to HVAC installation costs. Limited awareness among building owners and facility managers about the benefits of CO2 capture technologies also hinders adoption. Additionally, the lack of standardized performance metrics makes comparison between competing technologies challenging for potential buyers.

The competitive landscape features established HVAC manufacturers expanding their portfolios alongside specialized startups focusing exclusively on carbon capture innovations. Strategic partnerships between technology providers and building management companies are emerging as a key market entry strategy, offering bundled solutions that combine equipment, installation, and ongoing maintenance services.

Current Sorbent Technologies and Implementation Challenges

The current landscape of CO₂ capture sorbent technologies presents a diverse array of materials with varying degrees of commercial readiness and implementation potential in HVAC systems. Physical sorbents, including activated carbon, zeolites, and metal-organic frameworks (MOFs), have demonstrated promising CO₂ capture capabilities through physical adsorption mechanisms. Activated carbon offers advantages in cost-effectiveness and availability, while zeolites provide high selectivity for CO₂ under specific conditions. MOFs represent a newer class of materials with exceptional surface areas and tunable pore structures, though their commercial-scale production remains limited.

Chemical sorbents, particularly amine-based materials, have gained significant traction due to their strong chemical affinity for CO₂. Solid amine sorbents immobilized on porous supports offer improved handling characteristics compared to liquid amine solutions traditionally used in industrial settings. These materials can achieve high CO₂ capture efficiencies even at the low concentrations typical of indoor environments (400-1000 ppm), making them particularly relevant for HVAC applications.

Despite these technological advances, several implementation challenges persist. Energy requirements for sorbent regeneration represent a significant hurdle, as most materials require substantial thermal energy input to release captured CO₂ and restore their adsorption capacity. This regeneration energy penalty can undermine the overall energy efficiency of HVAC systems, potentially offsetting the environmental benefits of CO₂ capture.

Durability and cycling stability present another critical challenge. Many promising sorbents exhibit performance degradation after multiple adsorption-desorption cycles, necessitating frequent replacement and increasing operational costs. This degradation is often accelerated by exposure to moisture, which is unavoidable in typical HVAC operating conditions.

Integration complexity with existing HVAC infrastructure poses significant engineering challenges. Most commercial HVAC systems are not designed to accommodate additional components for CO₂ capture, requiring substantial modifications or complete system redesigns. The additional pressure drop introduced by sorbent beds can increase fan energy consumption, while the physical space requirements may be prohibitive in many building applications.

Cost considerations remain perhaps the most significant barrier to widespread implementation. Current high-performance sorbents often involve expensive materials or complex synthesis procedures, resulting in prohibitive costs for large-scale HVAC applications. The economic viability of CO₂ capture in buildings is further challenged by the absence of strong regulatory drivers or carbon pricing mechanisms in most markets.

Scalability issues also persist, as many promising materials developed in laboratory settings face significant challenges in scaling to commercial production volumes while maintaining performance characteristics and cost-effectiveness. This scale-up gap has limited the commercial availability of advanced sorbent technologies for building applications.

Chemical sorbents, particularly amine-based materials, have gained significant traction due to their strong chemical affinity for CO₂. Solid amine sorbents immobilized on porous supports offer improved handling characteristics compared to liquid amine solutions traditionally used in industrial settings. These materials can achieve high CO₂ capture efficiencies even at the low concentrations typical of indoor environments (400-1000 ppm), making them particularly relevant for HVAC applications.

Despite these technological advances, several implementation challenges persist. Energy requirements for sorbent regeneration represent a significant hurdle, as most materials require substantial thermal energy input to release captured CO₂ and restore their adsorption capacity. This regeneration energy penalty can undermine the overall energy efficiency of HVAC systems, potentially offsetting the environmental benefits of CO₂ capture.

Durability and cycling stability present another critical challenge. Many promising sorbents exhibit performance degradation after multiple adsorption-desorption cycles, necessitating frequent replacement and increasing operational costs. This degradation is often accelerated by exposure to moisture, which is unavoidable in typical HVAC operating conditions.

Integration complexity with existing HVAC infrastructure poses significant engineering challenges. Most commercial HVAC systems are not designed to accommodate additional components for CO₂ capture, requiring substantial modifications or complete system redesigns. The additional pressure drop introduced by sorbent beds can increase fan energy consumption, while the physical space requirements may be prohibitive in many building applications.

Cost considerations remain perhaps the most significant barrier to widespread implementation. Current high-performance sorbents often involve expensive materials or complex synthesis procedures, resulting in prohibitive costs for large-scale HVAC applications. The economic viability of CO₂ capture in buildings is further challenged by the absence of strong regulatory drivers or carbon pricing mechanisms in most markets.

Scalability issues also persist, as many promising materials developed in laboratory settings face significant challenges in scaling to commercial production volumes while maintaining performance characteristics and cost-effectiveness. This scale-up gap has limited the commercial availability of advanced sorbent technologies for building applications.

Existing CO2 Sorbent Integration Solutions for HVAC Systems

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and can operate under various temperature and pressure conditions, offering promising solutions for carbon capture applications.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and selectivity over other gases, offering promising solutions for carbon capture applications.

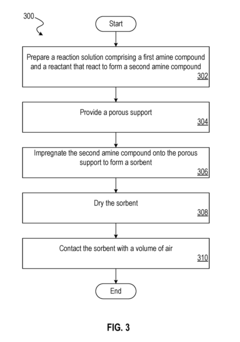

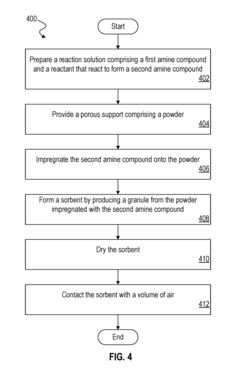

- Amine-functionalized sorbents: Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions, allowing for efficient capture. These materials can be regenerated through temperature or pressure swing processes, making them suitable for cyclic adsorption-desorption operations.

- Zeolite-based CO₂ capture materials: Zeolites are microporous aluminosilicate minerals with well-defined crystalline structures that make them effective for gas separation and CO₂ capture. Their uniform pore sizes and high thermal stability allow for selective adsorption of carbon dioxide from gas mixtures. Modified zeolites with enhanced CO₂ affinity can be created through ion exchange or impregnation with specific metals or functional groups, improving their capture performance and regeneration characteristics.

- Solid oxide-based CO₂ sorbents: Solid oxide materials, particularly calcium, magnesium, and lithium-based oxides, can capture CO₂ through carbonation reactions at elevated temperatures. These materials form stable carbonates when exposed to carbon dioxide and can be regenerated through calcination at higher temperatures. The cyclic carbonation-calcination process makes these materials suitable for high-temperature CO₂ capture applications, such as pre-combustion capture or direct air capture systems. Research focuses on improving their stability over multiple cycles and reducing regeneration energy requirements.

- Novel composite and hybrid CO₂ capture materials: Composite and hybrid materials combine different types of sorbents to leverage their complementary properties for enhanced CO₂ capture performance. These materials may integrate organic and inorganic components, such as polymer-inorganic hybrids, or combine different capture mechanisms within a single material. Advanced manufacturing techniques like 3D printing and microencapsulation are being used to create structured sorbents with optimized mass transfer properties and mechanical stability. These innovative materials aim to address challenges related to capacity, selectivity, stability, and regeneration energy requirements.

02 Amine-functionalized sorbents

Amine-functionalized materials represent a significant class of CO₂ capture sorbents that operate through chemical adsorption mechanisms. These materials contain primary, secondary, or tertiary amine groups that react with CO₂ to form carbamates or bicarbonates. Common supports include silica, polymers, and porous carbon materials. The amine functionality can be incorporated through impregnation, grafting, or polymerization methods, offering high selectivity for CO₂ even in humid conditions.Expand Specific Solutions03 Regenerable solid sorbents for cyclic capture processes

Regenerable solid sorbents are designed for continuous CO₂ capture through adsorption-desorption cycles. These materials can withstand multiple cycles without significant degradation in performance. The regeneration can be triggered by temperature swing, pressure swing, or vacuum swing processes. Key considerations include working capacity, regeneration energy requirements, and long-term stability. These sorbents are particularly valuable for industrial applications where continuous operation is necessary.Expand Specific Solutions04 Novel composite and hybrid materials

Composite and hybrid materials combine different components to achieve enhanced CO₂ capture performance. These materials often integrate the advantages of multiple sorbent types, such as the high surface area of porous supports with the chemical reactivity of functional groups. Examples include polymer-inorganic composites, layered double hydroxides, and functionalized carbon-based materials. The synergistic effects between components can lead to improved adsorption capacity, selectivity, and stability compared to single-component sorbents.Expand Specific Solutions05 Temperature-responsive and stimuli-activated sorbents

Temperature-responsive and stimuli-activated sorbents change their CO₂ capture properties in response to external stimuli such as temperature, light, or electrical current. These smart materials can facilitate more energy-efficient capture and release cycles by requiring smaller energy inputs for regeneration. Some designs incorporate phase-change materials or responsive polymers that undergo conformational changes to modulate CO₂ binding affinity. This approach offers potential for reducing the energy penalty associated with traditional carbon capture processes.Expand Specific Solutions

Leading Companies and Research Institutions in CO2 Capture

The CO₂ capture sorbents market for HVAC systems is in an early growth phase, characterized by increasing adoption as climate regulations tighten globally. The market is projected to expand significantly as building decarbonization efforts accelerate, with current estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field shows varying maturity levels, with companies at different development stages. Industry leaders like Mitsubishi Heavy Industries and GE Technology have established commercial-scale solutions, while specialized players such as enVerid Systems and Global Thermostat Operations are advancing innovative sorbent technologies. Research institutions including MIT and Georgia Tech are driving fundamental breakthroughs, while energy giants Shell, Aramco, and Sinopec are leveraging their infrastructure to scale implementation. BASF and Corning contribute materials expertise, creating a competitive landscape balanced between established corporations and emerging technology providers.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed the KM CDR Process™ (Kansai Mitsubishi Carbon Dioxide Recovery) specifically for CO₂ capture applications, which has been adapted for HVAC integration. Their technology utilizes proprietary KS-1™ amine-based solvent that offers high CO₂ absorption capacity with lower regeneration energy requirements compared to conventional amines. The system captures CO₂ from air streams by passing them through an absorption column where the solvent selectively binds with CO₂. The CO₂-rich solvent is then regenerated in a stripper column using steam heat, releasing concentrated CO₂ while recycling the solvent. For HVAC applications, MHI has miniaturized this technology to create compact modules that can be integrated with building ventilation systems. Their latest developments include heat integration systems that recover waste heat from the regeneration process to improve overall energy efficiency, and advanced solvent formulations that resist degradation and reduce corrosion issues.

Strengths: High CO₂ removal efficiency (90%+); proven technology with commercial-scale implementations; lower energy penalty compared to first-generation amine systems. Weaknesses: Still requires significant energy for solvent regeneration; potential for solvent degradation over time; system complexity requires specialized maintenance.

BASF SE

Technical Solution: BASF has developed advanced metal-organic frameworks (MOFs) and specialized amine-functionalized sorbents for CO₂ capture in HVAC applications. Their proprietary OASE® blue technology utilizes novel aqueous amine solutions with significantly reduced regeneration energy requirements. For direct air capture applications relevant to HVAC, BASF has engineered hierarchical porous materials that combine high CO₂ selectivity with rapid adsorption kinetics. Their sorbent materials feature tailored pore structures that maximize surface area (>1000 m²/g) while maintaining mechanical stability through multiple adsorption-desorption cycles. BASF's latest innovation includes temperature-swing adsorption systems that can operate using low-grade waste heat (60-80°C) for regeneration, making them particularly suitable for integration with existing building thermal management systems. The company has also developed specialized coating technologies that allow their sorbents to be directly applied to heat exchanger surfaces, creating dual-function components that simultaneously manage temperature and CO₂ levels.

Strengths: Industry-leading sorbent durability with minimal performance degradation over thousands of cycles; highly scalable manufacturing capabilities; extensive chemical engineering expertise for system optimization. Weaknesses: Higher production costs for advanced MOF materials compared to conventional sorbents; some formulations may be sensitive to humidity variations in HVAC environments.

Key Advancements in CO2 Capture Material Science

Carbon dioxide sorbents for air quality control

PatentActiveUS20190039047A1

Innovation

- A method of preparing a sorbent by reacting a first amine compound with a carbonate ester or ketone compound to produce a second amine compound, which is then impregnated onto a porous support, resulting in a sorbent with high CO2 adsorption capacity and stability, while being free of formaldehyde contaminants.

Co2 capture sorbents with low regeneration temperature and high desorption rates

PatentPendingUS20240009613A1

Innovation

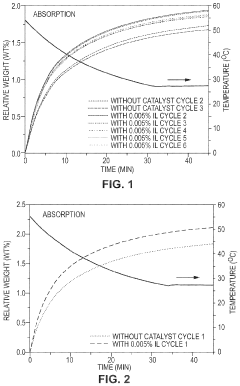

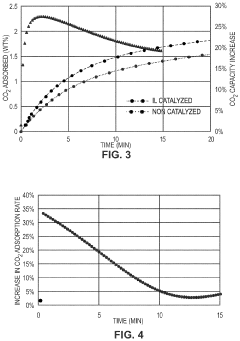

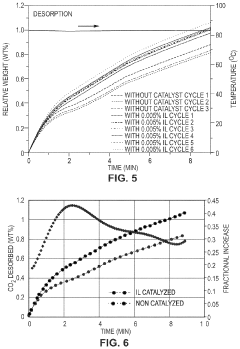

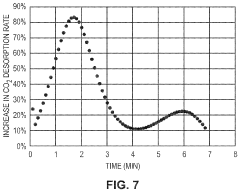

- Development of CO2 capture sorbents comprising a solid support with CO2-sorbing amine and ionic liquid, which enhances CO2 sorption and desorption characteristics, allowing for regeneration at lower temperatures and maintaining high selectivity and capacity through catalytic action.

Energy Efficiency Impact Assessment of CO2 Capture Systems

The integration of CO₂ capture systems into HVAC infrastructure presents significant implications for overall energy efficiency that must be carefully evaluated. Initial assessments indicate that traditional carbon capture technologies can impose energy penalties ranging from 20-30% when implemented in building systems, primarily due to the regeneration requirements of sorbent materials and additional fan power needed to overcome pressure drops.

When examining direct energy consumption, CO₂ capture sorbents in HVAC systems typically require thermal energy for regeneration processes, with temperature requirements varying from 60-120°C depending on the sorbent chemistry. Solid sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials generally demonstrate lower regeneration energy demands compared to liquid amine solutions, potentially reducing the overall energy penalty by 5-15%.

Pressure drop considerations across sorbent beds represent another critical efficiency factor. Recent advancements in structured sorbent configurations, including monoliths and 3D-printed architectures, have demonstrated potential to reduce pressure drops by up to 40% compared to conventional packed beds, directly translating to lower fan energy consumption and improved system coefficient of performance (COP).

The integration of waste heat recovery systems presents a promising approach to offset energy penalties. Studies indicate that utilizing waste heat from building operations or nearby industrial processes can reduce the net energy impact of CO₂ capture by 30-50%, particularly in commercial and industrial settings where waste heat streams are readily available.

System-level optimization strategies have emerged as essential for minimizing efficiency losses. Dynamic operation protocols that adjust capture rates based on building occupancy patterns and outdoor air quality conditions have demonstrated energy savings of 15-25% compared to static operation. Additionally, hybrid ventilation strategies that combine natural ventilation with selective CO₂ capture during peak demand periods can further reduce energy consumption.

Long-term operational considerations reveal that sorbent degradation over time can gradually increase energy requirements by 1-3% annually if not properly managed. Advanced monitoring systems utilizing machine learning algorithms have shown promise in optimizing regeneration cycles and predicting maintenance needs, potentially extending sorbent lifetimes by 20-30% and maintaining energy efficiency over longer operational periods.

When examining direct energy consumption, CO₂ capture sorbents in HVAC systems typically require thermal energy for regeneration processes, with temperature requirements varying from 60-120°C depending on the sorbent chemistry. Solid sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials generally demonstrate lower regeneration energy demands compared to liquid amine solutions, potentially reducing the overall energy penalty by 5-15%.

Pressure drop considerations across sorbent beds represent another critical efficiency factor. Recent advancements in structured sorbent configurations, including monoliths and 3D-printed architectures, have demonstrated potential to reduce pressure drops by up to 40% compared to conventional packed beds, directly translating to lower fan energy consumption and improved system coefficient of performance (COP).

The integration of waste heat recovery systems presents a promising approach to offset energy penalties. Studies indicate that utilizing waste heat from building operations or nearby industrial processes can reduce the net energy impact of CO₂ capture by 30-50%, particularly in commercial and industrial settings where waste heat streams are readily available.

System-level optimization strategies have emerged as essential for minimizing efficiency losses. Dynamic operation protocols that adjust capture rates based on building occupancy patterns and outdoor air quality conditions have demonstrated energy savings of 15-25% compared to static operation. Additionally, hybrid ventilation strategies that combine natural ventilation with selective CO₂ capture during peak demand periods can further reduce energy consumption.

Long-term operational considerations reveal that sorbent degradation over time can gradually increase energy requirements by 1-3% annually if not properly managed. Advanced monitoring systems utilizing machine learning algorithms have shown promise in optimizing regeneration cycles and predicting maintenance needs, potentially extending sorbent lifetimes by 20-30% and maintaining energy efficiency over longer operational periods.

Environmental Regulations and Carbon Reduction Incentives

The global regulatory landscape for carbon emissions has evolved significantly in recent years, creating a complex framework that directly impacts the development and adoption of CO₂ capture technologies in HVAC systems. The Paris Agreement of 2015 established a landmark international consensus on climate action, with 196 countries committing to limit global warming to well below 2°C above pre-industrial levels. This agreement has catalyzed the implementation of carbon reduction policies worldwide, creating both compliance requirements and market opportunities for CO₂ capture technologies.

In the United States, regulations vary significantly by region. California's ambitious carbon reduction targets under AB 32 and subsequent legislation have created a robust market for carbon capture technologies, including applications in commercial HVAC systems. The federal government has also introduced incentives through the 45Q tax credit, which provides up to $50 per metric ton of CO₂ captured and sequestered, significantly improving the economic viability of carbon capture technologies in building systems.

The European Union has established the EU Emissions Trading System (EU ETS), the world's largest carbon market, which places a price on carbon emissions and creates financial incentives for carbon reduction technologies. The EU's Green Deal further strengthens these incentives, aiming for carbon neutrality by 2050. This regulatory framework has spurred innovation in CO₂ capture sorbents specifically designed for integration with HVAC systems in commercial and residential buildings.

In Asia, China has incorporated carbon reduction targets into its Five-Year Plans and launched the world's largest carbon trading market in 2021. Japan's carbon tax and South Korea's Emissions Trading Scheme similarly create economic drivers for carbon capture technologies. These policies have accelerated research and development of cost-effective sorbent materials suitable for HVAC applications in diverse climatic conditions.

Financial incentives beyond direct carbon pricing are also emerging globally. Green building certification programs like LEED, BREEAM, and WELL increasingly recognize and reward carbon capture technologies in their scoring systems. Government grants, subsidies, and low-interest financing for green building technologies provide additional economic support for implementing CO₂ capture in HVAC systems.

The regulatory landscape continues to evolve, with increasing emphasis on embodied carbon and lifecycle emissions. This trend is driving interest in HVAC systems that not only reduce operational emissions but actively remove carbon from indoor environments. As regulations tighten and carbon prices rise, the economic case for integrating CO₂ capture sorbents into HVAC systems strengthens, creating a positive feedback loop of innovation and adoption.

In the United States, regulations vary significantly by region. California's ambitious carbon reduction targets under AB 32 and subsequent legislation have created a robust market for carbon capture technologies, including applications in commercial HVAC systems. The federal government has also introduced incentives through the 45Q tax credit, which provides up to $50 per metric ton of CO₂ captured and sequestered, significantly improving the economic viability of carbon capture technologies in building systems.

The European Union has established the EU Emissions Trading System (EU ETS), the world's largest carbon market, which places a price on carbon emissions and creates financial incentives for carbon reduction technologies. The EU's Green Deal further strengthens these incentives, aiming for carbon neutrality by 2050. This regulatory framework has spurred innovation in CO₂ capture sorbents specifically designed for integration with HVAC systems in commercial and residential buildings.

In Asia, China has incorporated carbon reduction targets into its Five-Year Plans and launched the world's largest carbon trading market in 2021. Japan's carbon tax and South Korea's Emissions Trading Scheme similarly create economic drivers for carbon capture technologies. These policies have accelerated research and development of cost-effective sorbent materials suitable for HVAC applications in diverse climatic conditions.

Financial incentives beyond direct carbon pricing are also emerging globally. Green building certification programs like LEED, BREEAM, and WELL increasingly recognize and reward carbon capture technologies in their scoring systems. Government grants, subsidies, and low-interest financing for green building technologies provide additional economic support for implementing CO₂ capture in HVAC systems.

The regulatory landscape continues to evolve, with increasing emphasis on embodied carbon and lifecycle emissions. This trend is driving interest in HVAC systems that not only reduce operational emissions but actively remove carbon from indoor environments. As regulations tighten and carbon prices rise, the economic case for integrating CO₂ capture sorbents into HVAC systems strengthens, creating a positive feedback loop of innovation and adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!