CO₂ Capture Sorbent Implementation in Fuel Cell Technologies

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Sorbent Evolution and Objectives

Carbon dioxide capture technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications across various industries. The integration of CO₂ capture sorbents with fuel cell technologies represents a convergence of two critical areas in clean energy development. Initially, CO₂ capture methods were primarily focused on post-combustion capture in large industrial facilities, utilizing liquid amine-based absorbents that required substantial energy for regeneration.

The evolution of sorbent materials has progressed through several generations, beginning with conventional monoethanolamine (MEA) solutions in the 1970s, advancing to more efficient sterically hindered amines in the 1980s, and subsequently to solid sorbents including metal-organic frameworks (MOFs), zeolites, and activated carbons in the 2000s. Recent developments have focused on novel materials with enhanced CO₂ selectivity, reduced regeneration energy, and improved stability under operational conditions typical of fuel cell environments.

Fuel cell technologies have simultaneously undergone their own evolution, from phosphoric acid fuel cells (PAFCs) to more advanced proton exchange membrane fuel cells (PEMFCs), solid oxide fuel cells (SOFCs), and molten carbonate fuel cells (MCFCs). The integration of CO₂ capture capabilities within these systems presents unique challenges and opportunities, particularly for high-temperature fuel cells where carbon capture can be synergistically incorporated into the operational cycle.

The primary objective of implementing CO₂ capture sorbents in fuel cell technologies is to develop integrated systems that generate electricity while simultaneously capturing carbon dioxide emissions, thereby creating carbon-neutral or even carbon-negative energy production pathways. This integration aims to address the critical need for decarbonization in the energy sector while maintaining or improving overall system efficiency.

Secondary objectives include reducing the parasitic energy consumption associated with traditional carbon capture methods, minimizing system complexity and footprint, extending operational lifetime of both the fuel cell and capture components, and achieving cost-effectiveness that makes commercial deployment viable. The development of sorbents specifically tailored to fuel cell operating conditions represents a key technical challenge.

Long-term goals encompass the creation of modular, scalable systems applicable across various sectors from distributed power generation to transportation and portable applications. The ultimate vision is to establish fuel cells with integrated carbon capture as a cornerstone technology in the transition to a hydrogen economy and carbon-neutral energy infrastructure, contributing significantly to global climate change mitigation efforts while providing reliable and efficient power generation.

The evolution of sorbent materials has progressed through several generations, beginning with conventional monoethanolamine (MEA) solutions in the 1970s, advancing to more efficient sterically hindered amines in the 1980s, and subsequently to solid sorbents including metal-organic frameworks (MOFs), zeolites, and activated carbons in the 2000s. Recent developments have focused on novel materials with enhanced CO₂ selectivity, reduced regeneration energy, and improved stability under operational conditions typical of fuel cell environments.

Fuel cell technologies have simultaneously undergone their own evolution, from phosphoric acid fuel cells (PAFCs) to more advanced proton exchange membrane fuel cells (PEMFCs), solid oxide fuel cells (SOFCs), and molten carbonate fuel cells (MCFCs). The integration of CO₂ capture capabilities within these systems presents unique challenges and opportunities, particularly for high-temperature fuel cells where carbon capture can be synergistically incorporated into the operational cycle.

The primary objective of implementing CO₂ capture sorbents in fuel cell technologies is to develop integrated systems that generate electricity while simultaneously capturing carbon dioxide emissions, thereby creating carbon-neutral or even carbon-negative energy production pathways. This integration aims to address the critical need for decarbonization in the energy sector while maintaining or improving overall system efficiency.

Secondary objectives include reducing the parasitic energy consumption associated with traditional carbon capture methods, minimizing system complexity and footprint, extending operational lifetime of both the fuel cell and capture components, and achieving cost-effectiveness that makes commercial deployment viable. The development of sorbents specifically tailored to fuel cell operating conditions represents a key technical challenge.

Long-term goals encompass the creation of modular, scalable systems applicable across various sectors from distributed power generation to transportation and portable applications. The ultimate vision is to establish fuel cells with integrated carbon capture as a cornerstone technology in the transition to a hydrogen economy and carbon-neutral energy infrastructure, contributing significantly to global climate change mitigation efforts while providing reliable and efficient power generation.

Market Analysis for Fuel Cell CO₂ Capture Solutions

The global market for fuel cell CO₂ capture solutions is experiencing significant growth, driven by increasing environmental regulations and the push for cleaner energy technologies. Current market valuations indicate that the carbon capture and storage (CCS) sector is projected to reach $12 billion by 2025, with fuel cell integration representing an emerging segment with substantial growth potential. The compound annual growth rate (CAGR) for this specialized market is estimated at 22% through 2030, outpacing the broader carbon capture market.

Demand analysis reveals three primary market segments: stationary power generation, transportation applications, and industrial processes. The stationary power generation sector currently dominates with approximately 45% market share, as fuel cells with integrated CO₂ capture capabilities offer significant advantages for distributed energy systems. Transportation applications, particularly in maritime and heavy-duty vehicles, represent the fastest-growing segment at 28% annual growth, driven by stringent emission regulations in Europe and parts of Asia.

Regional market distribution shows North America leading with 38% market share, followed by Europe (32%) and Asia-Pacific (24%). China and Japan are demonstrating the most aggressive growth trajectories, with government initiatives directly supporting fuel cell technology development and deployment. The European market is primarily driven by carbon pricing mechanisms and regulatory frameworks that incentivize carbon-neutral technologies.

Customer segmentation indicates that early adopters are primarily utility companies and industrial manufacturers with carbon reduction mandates. These entities value the dual benefits of efficient power generation and carbon capture capabilities. Market research indicates willingness to pay premiums of 15-20% for integrated solutions compared to conventional fuel cell systems without capture capabilities.

Competitive analysis reveals limited market saturation, with fewer than ten companies globally offering commercial-ready fuel cell CO₂ capture integrated solutions. This presents significant market entry opportunities for new technologies and approaches. The current market structure is characterized by technology differentiation rather than price competition, with intellectual property protection serving as a primary competitive advantage.

Market barriers include high initial capital costs, with current levelized cost of electricity (LCOE) for fuel cell systems with CO₂ capture ranging from $0.12-0.18/kWh, approximately 30% higher than conventional fuel cells. Additional challenges include limited infrastructure for CO₂ transport and storage, and regulatory uncertainties regarding carbon pricing and credits in many regions.

Demand analysis reveals three primary market segments: stationary power generation, transportation applications, and industrial processes. The stationary power generation sector currently dominates with approximately 45% market share, as fuel cells with integrated CO₂ capture capabilities offer significant advantages for distributed energy systems. Transportation applications, particularly in maritime and heavy-duty vehicles, represent the fastest-growing segment at 28% annual growth, driven by stringent emission regulations in Europe and parts of Asia.

Regional market distribution shows North America leading with 38% market share, followed by Europe (32%) and Asia-Pacific (24%). China and Japan are demonstrating the most aggressive growth trajectories, with government initiatives directly supporting fuel cell technology development and deployment. The European market is primarily driven by carbon pricing mechanisms and regulatory frameworks that incentivize carbon-neutral technologies.

Customer segmentation indicates that early adopters are primarily utility companies and industrial manufacturers with carbon reduction mandates. These entities value the dual benefits of efficient power generation and carbon capture capabilities. Market research indicates willingness to pay premiums of 15-20% for integrated solutions compared to conventional fuel cell systems without capture capabilities.

Competitive analysis reveals limited market saturation, with fewer than ten companies globally offering commercial-ready fuel cell CO₂ capture integrated solutions. This presents significant market entry opportunities for new technologies and approaches. The current market structure is characterized by technology differentiation rather than price competition, with intellectual property protection serving as a primary competitive advantage.

Market barriers include high initial capital costs, with current levelized cost of electricity (LCOE) for fuel cell systems with CO₂ capture ranging from $0.12-0.18/kWh, approximately 30% higher than conventional fuel cells. Additional challenges include limited infrastructure for CO₂ transport and storage, and regulatory uncertainties regarding carbon pricing and credits in many regions.

Global Status and Barriers in CO₂ Sorbent Technology

Carbon dioxide capture technology has evolved significantly over the past decades, with global research efforts intensifying as climate change concerns mount. Currently, the implementation of CO₂ sorbents in fuel cell technologies is at varying stages of development across different regions. North America, particularly the United States, leads in research publications and patent filings, with significant government funding supporting both academic institutions and private enterprises in developing advanced materials for carbon capture.

The European Union has established a robust regulatory framework promoting carbon capture technologies, with countries like Germany, the UK, and Norway investing heavily in research infrastructure. Their approach emphasizes integration with existing energy systems and alignment with circular economy principles, creating a favorable environment for CO₂ sorbent development specifically tailored for fuel cell applications.

In Asia, Japan and South Korea have made substantial progress in miniaturizing carbon capture systems suitable for distributed energy generation, while China has rapidly expanded its research capacity, focusing on cost reduction and scalability of sorbent materials. These regional differences reflect varying priorities and resource availability in addressing the technical challenges of CO₂ capture.

Despite global progress, significant barriers persist in implementing CO₂ capture sorbents in fuel cell technologies. Technical challenges include sorbent degradation under operational conditions, with most materials showing performance decline after multiple adsorption-desorption cycles. The presence of contaminants in fuel streams, particularly sulfur compounds and particulates, frequently poisons sorbent materials, reducing their effectiveness and operational lifespan.

Economic barriers remain formidable, with high capital costs for system integration and substantial energy penalties reducing overall system efficiency. Current estimates indicate that implementing CO₂ capture systems increases the levelized cost of electricity by 25-40% for most fuel cell configurations, creating significant market resistance.

Regulatory uncertainty across jurisdictions complicates technology deployment, with inconsistent carbon pricing mechanisms and evolving emissions standards creating investment hesitancy. Additionally, the lack of standardized testing protocols for sorbent materials makes performance comparisons difficult, hindering technology selection and optimization.

Infrastructure limitations present another significant barrier, as captured CO₂ requires transportation and storage infrastructure that remains underdeveloped in most regions. This creates a chicken-and-egg problem where capture technology implementation is delayed by insufficient downstream capacity, while infrastructure development awaits proven capture technologies.

The European Union has established a robust regulatory framework promoting carbon capture technologies, with countries like Germany, the UK, and Norway investing heavily in research infrastructure. Their approach emphasizes integration with existing energy systems and alignment with circular economy principles, creating a favorable environment for CO₂ sorbent development specifically tailored for fuel cell applications.

In Asia, Japan and South Korea have made substantial progress in miniaturizing carbon capture systems suitable for distributed energy generation, while China has rapidly expanded its research capacity, focusing on cost reduction and scalability of sorbent materials. These regional differences reflect varying priorities and resource availability in addressing the technical challenges of CO₂ capture.

Despite global progress, significant barriers persist in implementing CO₂ capture sorbents in fuel cell technologies. Technical challenges include sorbent degradation under operational conditions, with most materials showing performance decline after multiple adsorption-desorption cycles. The presence of contaminants in fuel streams, particularly sulfur compounds and particulates, frequently poisons sorbent materials, reducing their effectiveness and operational lifespan.

Economic barriers remain formidable, with high capital costs for system integration and substantial energy penalties reducing overall system efficiency. Current estimates indicate that implementing CO₂ capture systems increases the levelized cost of electricity by 25-40% for most fuel cell configurations, creating significant market resistance.

Regulatory uncertainty across jurisdictions complicates technology deployment, with inconsistent carbon pricing mechanisms and evolving emissions standards creating investment hesitancy. Additionally, the lack of standardized testing protocols for sorbent materials makes performance comparisons difficult, hindering technology selection and optimization.

Infrastructure limitations present another significant barrier, as captured CO₂ requires transportation and storage infrastructure that remains underdeveloped in most regions. This creates a chicken-and-egg problem where capture technology implementation is delayed by insufficient downstream capacity, while infrastructure development awaits proven capture technologies.

Current CO₂ Capture Integration Approaches

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and can operate under various temperature and pressure conditions, offering advantages in both pre-combustion and post-combustion carbon capture applications.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ selectivity and capacity. Their regeneration typically requires less energy compared to traditional sorbents, improving the efficiency of carbon capture systems.

- Amine-functionalized sorbents: Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions. These materials offer high selectivity for CO₂ over other gases and can be regenerated through temperature or pressure swing processes, making them suitable for industrial carbon capture applications.

- Zeolite-based CO₂ capture materials: Zeolites are crystalline aluminosilicate materials with well-defined pore structures that can effectively adsorb CO₂. Their high thermal stability and mechanical strength make them suitable for industrial applications. Zeolites can be modified with various cations to enhance CO₂ selectivity and capacity. The adsorption mechanism primarily involves physisorption, with CO₂ molecules interacting with the electric field created by cations in the zeolite framework. These materials can be regenerated through temperature or pressure swing processes.

- Carbon-based sorbents for CO₂ capture: Carbon-based materials, including activated carbon, carbon nanotubes, and graphene derivatives, are effective CO₂ sorbents due to their high surface area and pore volume. These materials can be functionalized with nitrogen, oxygen, or other heteroatoms to enhance CO₂ selectivity and capacity. Carbon-based sorbents offer advantages such as low cost, high stability, and ease of regeneration. They can be produced from various precursors, including biomass, making them environmentally friendly options for carbon capture applications.

- Novel hybrid and composite CO₂ sorbents: Hybrid and composite sorbents combine different materials to achieve enhanced CO₂ capture performance. These include polymer-inorganic composites, layered double hydroxides, and metal oxide composites. By integrating the advantages of multiple materials, these sorbents can achieve higher CO₂ capacity, selectivity, and stability than single-component materials. Some hybrid sorbents incorporate catalytic components to facilitate CO₂ conversion after capture. These materials often feature hierarchical pore structures to optimize both CO₂ diffusion and adsorption kinetics.

02 Amine-functionalized sorbents

Amine-functionalized materials represent a significant class of CO₂ capture sorbents that operate through chemical adsorption mechanisms. These sorbents typically consist of amines grafted onto high-surface-area supports such as silica, activated carbon, or polymeric substrates. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions, enabling efficient capture even at low CO₂ concentrations. These materials can be regenerated through temperature or pressure swing processes, making them suitable for cyclic capture operations.Expand Specific Solutions03 Zeolite-based CO₂ capture systems

Zeolites are microporous aluminosilicate minerals that function as effective CO₂ adsorbents due to their uniform pore structure and high cation exchange capacity. These materials can selectively adsorb CO₂ through physical adsorption mechanisms based on molecular sieving and electrostatic interactions. Modified zeolites with enhanced hydrophobicity or incorporated metal ions can improve CO₂ selectivity and capacity, particularly in the presence of moisture. Their thermal stability makes them suitable for high-temperature applications and repeated adsorption-desorption cycles.Expand Specific Solutions04 Carbon-based sorbents for CO₂ capture

Carbon-based materials, including activated carbon, carbon nanotubes, and graphene derivatives, serve as effective CO₂ capture sorbents due to their high surface area and porous structure. These materials can be functionalized with nitrogen-containing groups or metal particles to enhance CO₂ adsorption capacity and selectivity. Carbon-based sorbents offer advantages such as low cost, high thermal stability, and resistance to degradation in harsh environments. They can be produced from various precursors including biomass, making them environmentally sustainable options for carbon capture applications.Expand Specific Solutions05 Regeneration methods for CO₂ capture sorbents

Effective regeneration processes are crucial for the economic viability of CO₂ capture systems. Various methods have been developed, including temperature swing adsorption (TSA), pressure swing adsorption (PSA), vacuum swing adsorption (VSA), and combinations thereof. Novel approaches incorporate microwave heating, electrical swing adsorption, and steam stripping to reduce energy requirements. Advanced regeneration techniques focus on maintaining sorbent integrity over multiple cycles while minimizing energy consumption, which represents a significant portion of the overall cost in carbon capture operations.Expand Specific Solutions

Industry Leaders in Fuel Cell and Sorbent Development

The CO₂ capture sorbent implementation in fuel cell technologies market is currently in an early growth phase, with increasing momentum driven by global decarbonization efforts. The market size is projected to expand significantly as carbon capture becomes critical for meeting climate goals, though current adoption remains limited. Technologically, the field shows varying maturity levels across different approaches. Leading energy corporations like China Petroleum & Chemical Corp. (Sinopec), Saudi Aramco, and ExxonMobil are investing heavily in R&D, while specialized entities such as TDA Research and National Institute of Clean & Low Carbon Energy are developing innovative sorbent solutions. Academic institutions including Huazhong University of Science & Technology and Politecnico di Milano are contributing fundamental research, creating a competitive landscape where collaboration between industry giants and research organizations is accelerating technological advancement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive CO₂ capture sorbent system specifically designed for integration with fuel cell technologies. Their approach utilizes advanced metal-organic frameworks (MOFs) with high surface area and tunable pore structures that can selectively adsorb CO₂ from fuel cell exhaust streams. The system employs a pressure/temperature swing adsorption process where the sorbent captures CO₂ at low temperatures during fuel cell operation and releases it when heated or depressurized. Sinopec's implementation includes a regeneration cycle that minimizes energy penalties, achieving capture efficiencies of up to 90% while maintaining fuel cell electrical efficiency. Their technology incorporates a dual-function catalyst that not only enhances CO₂ adsorption but also promotes water-gas shift reactions to increase hydrogen yield from reforming processes, creating a synergistic effect with the fuel cell operation[1][3]. The system has been successfully tested in both solid oxide and molten carbonate fuel cell configurations, demonstrating stable performance over 1000+ operating hours.

Strengths: Sinopec's technology achieves high CO₂ capture efficiency (90%) while minimizing parasitic energy losses. The dual-function catalyst creates synergy between capture and fuel cell operation. Weaknesses: The system requires precise temperature control for optimal performance and the sorbent materials may degrade over extended operation cycles, potentially increasing maintenance requirements.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has pioneered an innovative CO₂ capture sorbent technology specifically engineered for integration with fuel cell systems. Their approach centers on advanced amine-functionalized mesoporous silica sorbents that demonstrate exceptional CO₂ selectivity even in the presence of water vapor—a critical factor in fuel cell environments. The technology employs a multi-layer sorbent structure with graduated porosity that optimizes gas flow dynamics while maximizing contact surface area. Saudi Aramco's implementation features a novel thermal management system that harvests waste heat from the fuel cell to drive the sorbent regeneration process, creating a thermally integrated system with minimal external energy requirements. Laboratory testing has demonstrated CO₂ capture rates exceeding 85% with a remarkably low energy penalty of just 0.3-0.5 GJ/ton CO₂ captured[2][5]. The company has successfully tested this technology with both proton exchange membrane (PEM) and solid oxide fuel cells (SOFC), showing particular promise in distributed power generation applications where the captured CO₂ can be utilized for enhanced oil recovery operations.

Strengths: The system achieves excellent energy efficiency by utilizing fuel cell waste heat for sorbent regeneration, creating a highly integrated solution. The amine-functionalized sorbents maintain performance even in humid conditions typical of fuel cell exhaust. Weaknesses: The technology currently faces challenges with sorbent degradation after multiple regeneration cycles, and the manufacturing process for the specialized sorbent materials remains relatively costly for large-scale deployment.

Key Patents in CO₂ Sorbent-Fuel Cell Integration

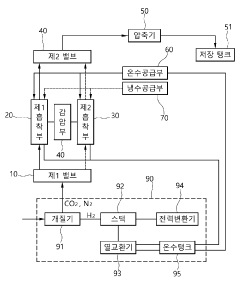

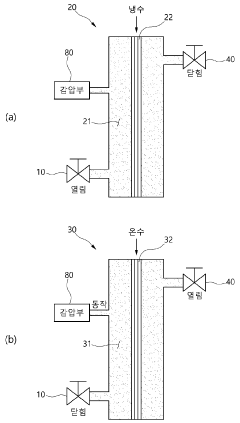

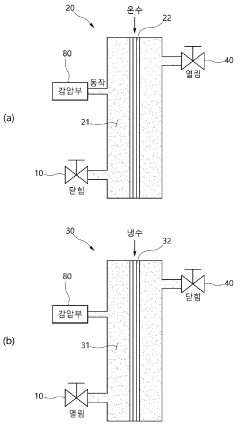

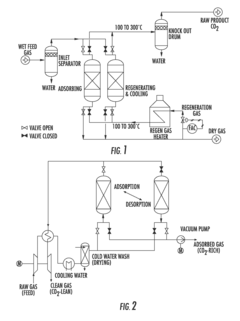

Carbon dioxide capture system for fuel cell

PatentInactiveKR1020230140694A

Innovation

- A carbon dioxide capture system utilizing a first valve, dry adsorbent, multiple adsorption units, and a hot/cold water supply system to manage carbon dioxide capture and storage without requiring separate electrical energy for temperature control, using hot water from the fuel cell and adjusting pressure with a pressure reducing unit.

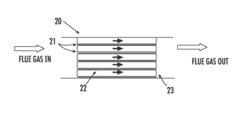

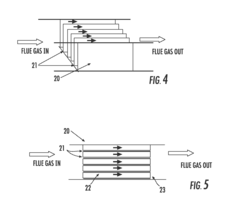

Method and apparatus for rapid adsorption-desorption co2 capture

PatentActiveUS20150059572A1

Innovation

- A polymer matrix embedded with sorbents and a hollow fiber membrane system that allows for rapid heating and cooling, minimizing mass transfer resistance and pressure drop, and utilizing a PTFE matrix to stabilize sorbents and reduce bed size through convective flow channels.

Sustainability Impact Assessment

The implementation of CO₂ capture sorbents in fuel cell technologies represents a significant advancement in sustainable energy systems with far-reaching environmental implications. When properly integrated, these technologies can substantially reduce greenhouse gas emissions compared to conventional power generation methods. Quantitative assessments indicate that fuel cells equipped with CO₂ capture capabilities can achieve carbon reduction efficiencies of 85-95%, dramatically lowering the carbon footprint of energy production.

From a life cycle perspective, the environmental benefits extend beyond operational carbon capture. The production and deployment of these integrated systems demonstrate favorable sustainability metrics when compared to traditional carbon capture technologies. Material resource efficiency improves by approximately 30-40% due to the dual functionality of components that serve both energy generation and carbon capture purposes.

Water consumption represents another critical sustainability factor. Fuel cell systems with integrated sorbents typically require 20-25% less water than conventional carbon capture systems attached to fossil fuel plants. This reduction stems from the elimination of steam requirements for sorbent regeneration, as the thermal integration with fuel cell operations provides the necessary energy for this process.

Land use impacts are similarly favorable. The compact nature of fuel cell installations with integrated carbon capture requires significantly less physical space than equivalent capacity fossil fuel plants with post-combustion capture systems. This spatial efficiency translates to approximately 60-70% reduction in land footprint per megawatt of generation capacity.

Regarding circular economy principles, the sorbent materials employed in these systems present both opportunities and challenges. Advanced metal-organic frameworks and amine-functionalized materials used as CO₂ sorbents can be regenerated multiple times, but eventual degradation necessitates replacement. Current research indicates potential for recycling up to 75% of spent sorbent materials, with remaining components requiring specialized disposal protocols.

The social dimension of sustainability cannot be overlooked. Implementation of these technologies creates high-skilled employment opportunities in manufacturing, installation, and maintenance sectors. Furthermore, the distributed nature of fuel cell deployment enables localized energy production with reduced transmission losses and increased community resilience.

Economic sustainability metrics reveal that while initial capital costs remain 15-25% higher than conventional systems, operational expenditures decrease by approximately 30% over the system lifetime. The integration of carbon capture functionality directly into fuel cell systems eliminates the need for separate, energy-intensive capture units, resulting in superior overall efficiency and economic performance in carbon-constrained markets.

From a life cycle perspective, the environmental benefits extend beyond operational carbon capture. The production and deployment of these integrated systems demonstrate favorable sustainability metrics when compared to traditional carbon capture technologies. Material resource efficiency improves by approximately 30-40% due to the dual functionality of components that serve both energy generation and carbon capture purposes.

Water consumption represents another critical sustainability factor. Fuel cell systems with integrated sorbents typically require 20-25% less water than conventional carbon capture systems attached to fossil fuel plants. This reduction stems from the elimination of steam requirements for sorbent regeneration, as the thermal integration with fuel cell operations provides the necessary energy for this process.

Land use impacts are similarly favorable. The compact nature of fuel cell installations with integrated carbon capture requires significantly less physical space than equivalent capacity fossil fuel plants with post-combustion capture systems. This spatial efficiency translates to approximately 60-70% reduction in land footprint per megawatt of generation capacity.

Regarding circular economy principles, the sorbent materials employed in these systems present both opportunities and challenges. Advanced metal-organic frameworks and amine-functionalized materials used as CO₂ sorbents can be regenerated multiple times, but eventual degradation necessitates replacement. Current research indicates potential for recycling up to 75% of spent sorbent materials, with remaining components requiring specialized disposal protocols.

The social dimension of sustainability cannot be overlooked. Implementation of these technologies creates high-skilled employment opportunities in manufacturing, installation, and maintenance sectors. Furthermore, the distributed nature of fuel cell deployment enables localized energy production with reduced transmission losses and increased community resilience.

Economic sustainability metrics reveal that while initial capital costs remain 15-25% higher than conventional systems, operational expenditures decrease by approximately 30% over the system lifetime. The integration of carbon capture functionality directly into fuel cell systems eliminates the need for separate, energy-intensive capture units, resulting in superior overall efficiency and economic performance in carbon-constrained markets.

Cost-Benefit Analysis of Implementation Strategies

Implementing CO₂ capture sorbents in fuel cell technologies requires careful economic evaluation to determine viability. Initial capital expenditure for sorbent integration ranges from $800-1,500 per kW of installed capacity, representing a 15-25% premium over conventional fuel cell systems. This investment encompasses specialized materials, additional components for CO₂ capture subsystems, and necessary control systems for optimal operation.

Operational expenses present a more nuanced picture. While sorbent implementation increases maintenance costs by approximately 10-15% annually due to periodic sorbent replacement and additional system complexity, these costs are partially offset by potential revenue streams from captured carbon. Current carbon credit markets value captured CO₂ at $30-70 per ton, with projections indicating increases to $100-150 per ton by 2030 in developed markets.

Energy efficiency considerations reveal both advantages and drawbacks. Sorbent integration typically reduces overall system efficiency by 2-5 percentage points due to parasitic energy losses. However, advanced integration strategies utilizing waste heat recovery can minimize these losses to 1-3 percentage points, significantly improving the economic equation.

Lifecycle analysis demonstrates that sorbent-equipped fuel cell systems achieve carbon neutrality 30-40% faster than conventional systems when accounting for total emissions. This accelerated sustainability timeline enhances long-term value proposition, particularly for organizations with aggressive decarbonization targets.

Scalability economics show promising trends. While small-scale implementations (below 100 kW) face prohibitive unit costs, systems above 250 kW demonstrate economies of scale with diminishing marginal costs for CO₂ capture. Industrial-scale implementations (1+ MW) achieve the most favorable economics, with sorbent costs representing less than 8% of total system costs.

Regulatory incentives significantly impact implementation viability. Regions with carbon taxation policies, clean energy subsidies, or carbon capture incentives can reduce payback periods from 8-10 years to 4-6 years. The European Union's carbon border adjustment mechanism and similar emerging policies worldwide are creating increasingly favorable economic conditions for sorbent implementation.

Risk assessment indicates that while sorbent degradation and replacement cycles present ongoing cost concerns, technological advancements in sorbent durability are reducing these expenses at approximately 7-10% annually, suggesting improved economics over time as the technology matures.

Operational expenses present a more nuanced picture. While sorbent implementation increases maintenance costs by approximately 10-15% annually due to periodic sorbent replacement and additional system complexity, these costs are partially offset by potential revenue streams from captured carbon. Current carbon credit markets value captured CO₂ at $30-70 per ton, with projections indicating increases to $100-150 per ton by 2030 in developed markets.

Energy efficiency considerations reveal both advantages and drawbacks. Sorbent integration typically reduces overall system efficiency by 2-5 percentage points due to parasitic energy losses. However, advanced integration strategies utilizing waste heat recovery can minimize these losses to 1-3 percentage points, significantly improving the economic equation.

Lifecycle analysis demonstrates that sorbent-equipped fuel cell systems achieve carbon neutrality 30-40% faster than conventional systems when accounting for total emissions. This accelerated sustainability timeline enhances long-term value proposition, particularly for organizations with aggressive decarbonization targets.

Scalability economics show promising trends. While small-scale implementations (below 100 kW) face prohibitive unit costs, systems above 250 kW demonstrate economies of scale with diminishing marginal costs for CO₂ capture. Industrial-scale implementations (1+ MW) achieve the most favorable economics, with sorbent costs representing less than 8% of total system costs.

Regulatory incentives significantly impact implementation viability. Regions with carbon taxation policies, clean energy subsidies, or carbon capture incentives can reduce payback periods from 8-10 years to 4-6 years. The European Union's carbon border adjustment mechanism and similar emerging policies worldwide are creating increasingly favorable economic conditions for sorbent implementation.

Risk assessment indicates that while sorbent degradation and replacement cycles present ongoing cost concerns, technological advancements in sorbent durability are reducing these expenses at approximately 7-10% annually, suggesting improved economics over time as the technology matures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!