CO₂ Capture Sorbent and Its Impact on Energy Efficiency Metrics

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, driven by growing concerns about climate change and the need to reduce greenhouse gas emissions. Initially developed in the 1930s for natural gas purification, CO₂ capture technologies have since expanded into various industrial applications, particularly in response to the 1997 Kyoto Protocol and subsequent international climate agreements that established frameworks for emissions reduction.

The evolution of CO₂ capture sorbents represents a critical technological trajectory in this field. First-generation technologies primarily utilized liquid amine-based solvents such as monoethanolamine (MEA), which while effective, suffered from high energy penalties during regeneration. This led to the development of second-generation sorbents including advanced amines, ionic liquids, and metal-organic frameworks (MOFs) with improved capacity and selectivity characteristics.

Current technological trends are focused on developing sorbent materials that can significantly reduce the energy penalty associated with carbon capture processes. This is particularly important as the energy required for sorbent regeneration often constitutes 70-80% of the total operational costs in carbon capture systems. Research is increasingly directed toward novel materials that combine high CO₂ selectivity with low regeneration energy requirements.

The primary objective of contemporary CO₂ capture sorbent development is to achieve the "30-30-30" target: 30% energy efficiency improvement, $30/ton CO₂ capture cost, and commercial deployment by 2030. This ambitious goal requires sorbents that not only demonstrate excellent technical performance but also economic viability at industrial scales.

Emerging approaches include temperature-swing adsorption (TSA), pressure-swing adsorption (PSA), and vacuum-swing adsorption (VSA) processes utilizing advanced solid sorbents. These technologies aim to reduce the parasitic energy load that has historically plagued carbon capture systems, particularly in power generation applications where efficiency losses can reach 8-12 percentage points.

The technological landscape is further complicated by the diverse requirements across different carbon sources. Post-combustion capture from power plants demands sorbents that can handle low CO₂ concentrations (12-15%) in flue gas, while pre-combustion and industrial applications may involve higher concentrations but different impurity profiles and operating conditions.

As research progresses, the integration of sorbent performance with overall system efficiency metrics has become increasingly important. This holistic approach considers not only the intrinsic properties of the sorbent materials but also their behavior within engineered systems, their lifecycle environmental impact, and their economic performance across different deployment scenarios.

The evolution of CO₂ capture sorbents represents a critical technological trajectory in this field. First-generation technologies primarily utilized liquid amine-based solvents such as monoethanolamine (MEA), which while effective, suffered from high energy penalties during regeneration. This led to the development of second-generation sorbents including advanced amines, ionic liquids, and metal-organic frameworks (MOFs) with improved capacity and selectivity characteristics.

Current technological trends are focused on developing sorbent materials that can significantly reduce the energy penalty associated with carbon capture processes. This is particularly important as the energy required for sorbent regeneration often constitutes 70-80% of the total operational costs in carbon capture systems. Research is increasingly directed toward novel materials that combine high CO₂ selectivity with low regeneration energy requirements.

The primary objective of contemporary CO₂ capture sorbent development is to achieve the "30-30-30" target: 30% energy efficiency improvement, $30/ton CO₂ capture cost, and commercial deployment by 2030. This ambitious goal requires sorbents that not only demonstrate excellent technical performance but also economic viability at industrial scales.

Emerging approaches include temperature-swing adsorption (TSA), pressure-swing adsorption (PSA), and vacuum-swing adsorption (VSA) processes utilizing advanced solid sorbents. These technologies aim to reduce the parasitic energy load that has historically plagued carbon capture systems, particularly in power generation applications where efficiency losses can reach 8-12 percentage points.

The technological landscape is further complicated by the diverse requirements across different carbon sources. Post-combustion capture from power plants demands sorbents that can handle low CO₂ concentrations (12-15%) in flue gas, while pre-combustion and industrial applications may involve higher concentrations but different impurity profiles and operating conditions.

As research progresses, the integration of sorbent performance with overall system efficiency metrics has become increasingly important. This holistic approach considers not only the intrinsic properties of the sorbent materials but also their behavior within engineered systems, their lifecycle environmental impact, and their economic performance across different deployment scenarios.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. As of 2023, the market size has reached approximately $7 billion, with projections indicating expansion to $30 billion by 2030, representing a compound annual growth rate of over 20%. This growth trajectory is supported by substantial government investments, with the United States allocating $12 billion for carbon capture development through the Infrastructure Investment and Jobs Act, and the European Union committing €10 billion through various climate initiatives.

The market segmentation reveals distinct categories based on technology types, with post-combustion capture currently dominating at 65% market share due to its retrofit compatibility with existing infrastructure. Pre-combustion and oxy-fuel combustion technologies hold smaller but growing segments at 20% and 15% respectively. Geographically, North America leads with 40% of the global market, followed by Europe at 30% and Asia-Pacific at 25%, with the remaining 5% distributed across other regions.

Customer demand is primarily driven by three sectors: power generation (45%), oil and gas (30%), and industrial manufacturing (20%). The cement, steel, and chemical industries collectively represent the fastest-growing segment with annual adoption rates exceeding 25%. This acceleration is largely attributed to stringent emission regulations and carbon pricing mechanisms implemented across major economies.

Price sensitivity analysis indicates that the current cost of carbon capture ranges from $40-$80 per ton of CO₂, with sorbent materials representing 15-25% of operational expenses. Market research suggests that achieving a price point below $30 per ton would trigger mass adoption across multiple industries. The economic viability threshold varies significantly by region, with higher tolerance in Europe due to elevated carbon taxes compared to developing markets.

Competitive landscape assessment identifies three tiers of market participants: established industrial gas companies with comprehensive solutions, specialized carbon capture technology providers focusing on proprietary sorbent formulations, and emerging startups developing disruptive approaches. Recent market consolidation has been evident, with 12 significant mergers and acquisitions recorded in the past 24 months, indicating industry maturation and strategic positioning for anticipated regulatory developments.

Customer feedback analysis reveals that energy efficiency metrics are the primary consideration for 78% of potential adopters, followed by operational reliability (65%) and integration complexity (52%). The market demonstrates strong correlation between sorbent performance characteristics and customer willingness to invest, with regeneration energy requirements being the most critical specification influencing purchasing decisions.

The market segmentation reveals distinct categories based on technology types, with post-combustion capture currently dominating at 65% market share due to its retrofit compatibility with existing infrastructure. Pre-combustion and oxy-fuel combustion technologies hold smaller but growing segments at 20% and 15% respectively. Geographically, North America leads with 40% of the global market, followed by Europe at 30% and Asia-Pacific at 25%, with the remaining 5% distributed across other regions.

Customer demand is primarily driven by three sectors: power generation (45%), oil and gas (30%), and industrial manufacturing (20%). The cement, steel, and chemical industries collectively represent the fastest-growing segment with annual adoption rates exceeding 25%. This acceleration is largely attributed to stringent emission regulations and carbon pricing mechanisms implemented across major economies.

Price sensitivity analysis indicates that the current cost of carbon capture ranges from $40-$80 per ton of CO₂, with sorbent materials representing 15-25% of operational expenses. Market research suggests that achieving a price point below $30 per ton would trigger mass adoption across multiple industries. The economic viability threshold varies significantly by region, with higher tolerance in Europe due to elevated carbon taxes compared to developing markets.

Competitive landscape assessment identifies three tiers of market participants: established industrial gas companies with comprehensive solutions, specialized carbon capture technology providers focusing on proprietary sorbent formulations, and emerging startups developing disruptive approaches. Recent market consolidation has been evident, with 12 significant mergers and acquisitions recorded in the past 24 months, indicating industry maturation and strategic positioning for anticipated regulatory developments.

Customer feedback analysis reveals that energy efficiency metrics are the primary consideration for 78% of potential adopters, followed by operational reliability (65%) and integration complexity (52%). The market demonstrates strong correlation between sorbent performance characteristics and customer willingness to invest, with regeneration energy requirements being the most critical specification influencing purchasing decisions.

Current Sorbent Technologies and Challenges

Carbon dioxide capture technologies have evolved significantly over the past decades, with various sorbent materials being developed to address the growing concern of greenhouse gas emissions. Currently, the market is dominated by several key sorbent technologies, each with distinct advantages and limitations that impact their energy efficiency metrics.

Amine-based sorbents remain the most commercially mature technology, with monoethanolamine (MEA) solutions being widely deployed in industrial settings. These liquid absorbents typically achieve 85-95% CO₂ capture efficiency but suffer from high regeneration energy requirements (3.5-4.2 GJ/tonne CO₂), leading to significant parasitic energy loads on power plants. The thermal degradation of amines at temperatures above 120°C and corrosion issues further complicate their long-term application.

Solid sorbents have emerged as promising alternatives, with activated carbons, zeolites, and metal-organic frameworks (MOFs) showing considerable potential. These materials offer lower regeneration energy penalties (1.8-2.5 GJ/tonne CO₂) and greater stability across multiple capture-release cycles. However, they face challenges related to moisture sensitivity, which can reduce CO₂ selectivity by up to 40% in humid conditions typical of flue gas environments.

Calcium looping technology, utilizing limestone as a CO₂ sorbent, has demonstrated effectiveness in pilot-scale operations. While offering low material costs, this approach requires high operating temperatures (>850°C) for sorbent regeneration, creating significant energy demands. Additionally, the rapid deactivation of calcium-based sorbents after multiple carbonation-calcination cycles remains a persistent challenge, with capacity typically decreasing by 30-50% after just 20 cycles.

Novel hybrid materials combining the advantages of different sorbent types have shown promising results in laboratory settings. Amine-functionalized silica and polymer-supported amine sorbents demonstrate improved CO₂ selectivity and reduced regeneration energy requirements (2.0-2.8 GJ/tonne CO₂). However, these materials face scalability challenges and higher production costs compared to conventional options.

A significant technical barrier across all sorbent technologies is the trade-off between CO₂ capture capacity and regeneration energy requirements. Materials with high binding affinity for CO₂ typically demand more energy for regeneration, creating an inherent efficiency dilemma. This relationship directly impacts the energy penalty associated with carbon capture, which currently ranges from 20-40% for power generation applications.

Geographically, sorbent technology development shows distinct patterns, with North American and European research focusing on advanced materials like MOFs and functionalized sorbents, while Asian development emphasizes cost-effective, scalable solutions for industrial implementation. This regional specialization has created complementary innovation pathways but also challenges in technology standardization.

Amine-based sorbents remain the most commercially mature technology, with monoethanolamine (MEA) solutions being widely deployed in industrial settings. These liquid absorbents typically achieve 85-95% CO₂ capture efficiency but suffer from high regeneration energy requirements (3.5-4.2 GJ/tonne CO₂), leading to significant parasitic energy loads on power plants. The thermal degradation of amines at temperatures above 120°C and corrosion issues further complicate their long-term application.

Solid sorbents have emerged as promising alternatives, with activated carbons, zeolites, and metal-organic frameworks (MOFs) showing considerable potential. These materials offer lower regeneration energy penalties (1.8-2.5 GJ/tonne CO₂) and greater stability across multiple capture-release cycles. However, they face challenges related to moisture sensitivity, which can reduce CO₂ selectivity by up to 40% in humid conditions typical of flue gas environments.

Calcium looping technology, utilizing limestone as a CO₂ sorbent, has demonstrated effectiveness in pilot-scale operations. While offering low material costs, this approach requires high operating temperatures (>850°C) for sorbent regeneration, creating significant energy demands. Additionally, the rapid deactivation of calcium-based sorbents after multiple carbonation-calcination cycles remains a persistent challenge, with capacity typically decreasing by 30-50% after just 20 cycles.

Novel hybrid materials combining the advantages of different sorbent types have shown promising results in laboratory settings. Amine-functionalized silica and polymer-supported amine sorbents demonstrate improved CO₂ selectivity and reduced regeneration energy requirements (2.0-2.8 GJ/tonne CO₂). However, these materials face scalability challenges and higher production costs compared to conventional options.

A significant technical barrier across all sorbent technologies is the trade-off between CO₂ capture capacity and regeneration energy requirements. Materials with high binding affinity for CO₂ typically demand more energy for regeneration, creating an inherent efficiency dilemma. This relationship directly impacts the energy penalty associated with carbon capture, which currently ranges from 20-40% for power generation applications.

Geographically, sorbent technology development shows distinct patterns, with North American and European research focusing on advanced materials like MOFs and functionalized sorbents, while Asian development emphasizes cost-effective, scalable solutions for industrial implementation. This regional specialization has created complementary innovation pathways but also challenges in technology standardization.

Existing CO₂ Sorbent Solutions and Energy Efficiency Impacts

01 Regeneration energy efficiency metrics for CO₂ sorbents

Energy efficiency metrics for CO₂ capture sorbents focus on the regeneration process, which is often the most energy-intensive part of carbon capture systems. These metrics evaluate the energy required to release captured CO₂ from the sorbent material and regenerate it for reuse. Key parameters include regeneration temperature, heat capacity, and energy consumption per unit of CO₂ captured. Lower regeneration energy requirements directly translate to more efficient and economically viable carbon capture systems.- Regeneration energy efficiency metrics for CO₂ sorbents: Energy efficiency metrics for CO₂ capture sorbents focus on the regeneration process, which is often the most energy-intensive part of carbon capture. These metrics evaluate the energy required to release captured CO₂ from the sorbent material. Lower regeneration energy requirements indicate more efficient sorbents. Various parameters such as temperature, pressure, and heat transfer efficiency during the regeneration phase are measured to determine overall energy performance of the capture system.

- Adsorption capacity and kinetics metrics: Metrics for evaluating CO₂ capture sorbents include adsorption capacity (how much CO₂ can be captured per unit of sorbent) and adsorption kinetics (how quickly the capture occurs). Higher capacity and faster kinetics generally lead to more energy-efficient systems as they reduce the amount of sorbent needed and the time required for capture. These parameters are typically measured under various temperature and pressure conditions to determine optimal operating parameters for energy efficiency.

- Cyclic stability and working capacity metrics: The long-term performance of CO₂ capture sorbents is evaluated through cyclic stability metrics, which measure how well the sorbent maintains its capture efficiency over multiple adsorption-desorption cycles. Working capacity, which is the difference between the amount of CO₂ captured under adsorption conditions and the amount remaining after desorption, is a critical energy efficiency metric. Sorbents with high working capacity and minimal degradation over many cycles offer better energy efficiency in practical applications.

- System-level energy efficiency metrics: Beyond the properties of the sorbent itself, system-level metrics evaluate the overall energy efficiency of the entire carbon capture process. These include metrics such as energy penalty (additional energy required per unit of power generated), equivalent work (the work required for capture, compression, and storage), and SPECCA (Specific Primary Energy Consumption for CO₂ Avoided). These comprehensive metrics account for heat integration, pressure drops, auxiliary power requirements, and other factors that affect the total energy consumption of carbon capture systems.

- Novel sorbent materials and structures for improved energy efficiency: Research on novel sorbent materials and structures focuses on improving energy efficiency metrics through innovative approaches. These include developing hierarchical porous structures, metal-organic frameworks (MOFs), functionalized amine sorbents, and composite materials. The energy efficiency metrics for these novel sorbents evaluate their performance based on reduced heat of adsorption, faster mass transfer, improved heat transfer properties, and enhanced selectivity for CO₂ over other gases, all of which contribute to lower overall energy requirements for the capture process.

02 Adsorption capacity and kinetics performance metrics

Metrics for evaluating CO₂ capture sorbents include adsorption capacity (how much CO₂ can be captured per unit of sorbent) and adsorption kinetics (how quickly the sorbent can capture CO₂). These parameters directly impact energy efficiency as higher capacity sorbents require less material and energy for operation, while faster kinetics reduce the time and energy needed for the capture cycle. Performance is typically measured under various temperature and pressure conditions to determine optimal operating parameters that minimize energy consumption.Expand Specific Solutions03 Cyclic stability and working capacity metrics

The long-term performance of CO₂ capture sorbents is evaluated through cyclic stability metrics, which measure how well the sorbent maintains its capture efficiency over multiple adsorption-desorption cycles. Working capacity, which is the difference between the amount of CO₂ captured under adsorption conditions and the amount remaining after desorption, is a critical energy efficiency metric. Sorbents with high working capacity and minimal degradation over many cycles offer better energy efficiency as they reduce the frequency of replacement and maintain consistent performance.Expand Specific Solutions04 Heat management and thermal integration metrics

Energy efficiency metrics for CO₂ capture systems include heat management parameters such as heat integration efficiency, heat recovery rates, and thermal energy utilization. These metrics evaluate how effectively the system recovers and reuses thermal energy throughout the capture process. Advanced sorbent systems incorporate heat exchangers and thermal integration strategies to minimize external energy inputs. The effectiveness of these heat management approaches is quantified through metrics like the ratio of recovered heat to total energy input and the net energy penalty of the capture system.Expand Specific Solutions05 Techno-economic and life cycle assessment metrics

Comprehensive evaluation of CO₂ capture sorbent energy efficiency includes techno-economic and life cycle assessment metrics. These metrics consider the total energy consumption across the sorbent's entire life cycle, from manufacturing to disposal, as well as economic factors like cost per ton of CO₂ captured. Parameters such as energy return on investment (EROI), net energy analysis, and carbon capture cost efficiency provide a holistic view of sorbent performance. These metrics help identify the most energy-efficient and economically viable sorbent technologies for different applications and scales.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon Capture

The CO₂ capture sorbent market is in a growth phase, with increasing global focus on carbon reduction technologies driving market expansion estimated to reach $2.9 billion by 2030. Technical maturity varies significantly across different sorbent technologies, with major players demonstrating diverse approaches. Leading companies like ExxonMobil, Sinopec, and CHN Energy are advancing industrial-scale solutions, while specialized firms such as Carboncapture and Global Thermostat focus on direct air capture innovations. Academic institutions including MIT, Arizona State University, and Caltech are developing next-generation materials with enhanced energy efficiency metrics. The competitive landscape features collaboration between energy conglomerates (Equinor, GE Technology), research institutes (Huaneng Clean Energy Research Institute, SINTEF), and technology startups, indicating a dynamic ecosystem balancing commercial deployment with continued innovation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive CO₂ capture technology portfolio with particular focus on amine-based absorption systems optimized for refinery and petrochemical applications. Their proprietary solvent formulations achieve capture rates of 90%+ while reducing regeneration energy by approximately 25% compared to conventional MEA systems[1]. Sinopec has implemented large-scale demonstration projects utilizing structured packing columns with advanced liquid distribution systems that minimize pressure drop and enhance mass transfer efficiency. Their integrated approach combines pre-treatment systems to remove impurities that could degrade sorbents with heat integration networks that recover waste heat from various process streams, significantly improving overall energy efficiency metrics[2]. Recent innovations include hybrid sorbent systems combining chemical and physical absorption mechanisms to optimize performance across varying CO₂ partial pressures and operating conditions.

Strengths: Extensive industrial implementation experience with proven scalability; proprietary solvent formulations with reduced regeneration energy requirements; comprehensive system integration expertise. Weaknesses: Higher capital costs compared to some emerging technologies; still requires significant thermal energy for solvent regeneration; potential for solvent degradation in presence of oxygen and other contaminants.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has pioneered advanced amine-based CO₂ capture technology specifically tailored for coal-fired power plants. Their proprietary sorbent system employs a multi-component amine formulation that achieves capture efficiencies exceeding 90% while reducing regeneration energy requirements to approximately 2.8-3.2 GJ/ton CO₂, representing a 20-30% improvement over conventional MEA systems[1]. The institute has developed innovative process configurations featuring split-flow arrangements and advanced heat integration that minimize parasitic energy losses. Their technology incorporates specialized anti-corrosion and anti-oxidation additives that extend sorbent lifetime by up to 50% compared to standard formulations[2]. Huaneng has successfully demonstrated this technology at commercial scale with their 120,000 ton/year Shanghai Shidongkou power plant installation and larger 1 million ton/year facility at the GreenGen IGCC plant in Tianjin, proving the technology's viability for large-scale deployment with minimal impact on plant efficiency.

Strengths: Demonstrated commercial-scale implementation in actual power plant environments; significantly reduced regeneration energy requirements; enhanced sorbent stability and lifetime. Weaknesses: Technology primarily optimized for coal power applications; still faces challenges with flue gas contaminants; requires substantial capital investment for retrofit applications.

Key Innovations in High-Efficiency Sorbent Materials

Co2 capture sorbents with low regeneration temperature and high desorption rates

PatentPendingUS20240009613A1

Innovation

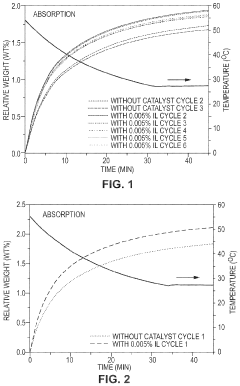

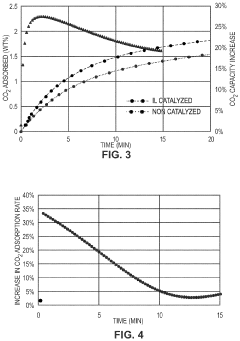

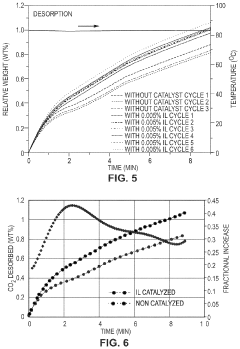

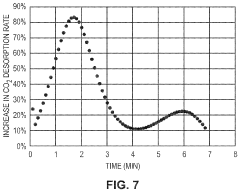

- Development of CO2 capture sorbents comprising a solid support with CO2-sorbing amine and ionic liquid, which enhances CO2 sorption and desorption characteristics, allowing for regeneration at lower temperatures and maintaining high selectivity and capacity through catalytic action.

Improvements to energy performance in co2 capture

PatentWO2024184064A1

Innovation

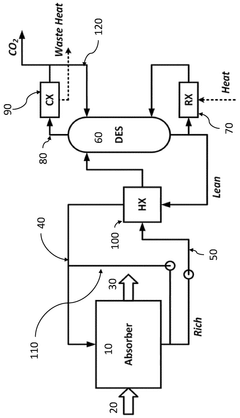

- A system and method that incorporate a sorbent capable of capturing and releasing CO2 across specific temperature ranges, utilizing a flash vessel and compressor to control the temperature of the hot flash vapor stream, and a controller to manage its injection into the desorber, preventing sorbent degradation and optimizing heat transfer through mixing or heat exchanger configurations.

Regulatory Framework and Carbon Pricing Mechanisms

The global regulatory landscape for carbon dioxide emissions has evolved significantly in recent decades, establishing a complex framework that directly impacts CO₂ capture technologies and their economic viability. At the international level, the Paris Agreement represents the cornerstone of climate action, with 196 countries committing to limit global warming to well below 2°C above pre-industrial levels. This agreement has catalyzed the development of national and regional regulatory frameworks that increasingly recognize carbon capture as a critical mitigation technology.

Carbon pricing mechanisms have emerged as primary policy instruments to incentivize CO₂ capture implementation. These mechanisms broadly fall into two categories: carbon taxes and emissions trading systems (ETS). Carbon taxes directly set a price on greenhouse gas emissions, providing a clear cost signal to emitters. Currently, over 40 countries and 25 subnational jurisdictions have implemented some form of carbon pricing, with prices ranging from less than $1 to over $130 per ton of CO₂.

Emissions trading systems, alternatively, establish marketplaces where emission allowances can be bought and sold. The European Union Emissions Trading System (EU ETS), the largest carbon market globally, has seen carbon prices rise to approximately €80-90 per ton in recent years, significantly improving the economic case for carbon capture technologies. Similar systems operate in regions including California, Quebec, and increasingly in Asian markets such as China and South Korea.

Tax incentives specifically targeting carbon capture technologies have gained prominence, with the United States' 45Q tax credit program standing as a notable example. Recent enhancements to this program through the Inflation Reduction Act have increased credits to $85 per metric ton for CO₂ captured and sequestered, and $60 per ton for CO₂ utilized in enhanced oil recovery or other applications.

Regulatory standards for CO₂ capture sorbent performance and energy efficiency are increasingly being incorporated into environmental permitting processes. These standards often establish minimum capture rates, energy penalties, and lifecycle assessment requirements that directly influence sorbent selection and system design. The EU's Industrial Emissions Directive and its evolving Best Available Techniques Reference Documents (BREFs) exemplify this approach.

Looking forward, regulatory frameworks are trending toward more stringent emissions reduction targets and higher carbon prices, which will likely accelerate CO₂ capture technology deployment. The International Energy Agency projects that carbon prices in advanced economies may need to reach $130-140 per ton by 2030 to align with Paris Agreement goals, potentially transforming the economics of sorbent-based capture systems and driving innovation toward more energy-efficient solutions.

Carbon pricing mechanisms have emerged as primary policy instruments to incentivize CO₂ capture implementation. These mechanisms broadly fall into two categories: carbon taxes and emissions trading systems (ETS). Carbon taxes directly set a price on greenhouse gas emissions, providing a clear cost signal to emitters. Currently, over 40 countries and 25 subnational jurisdictions have implemented some form of carbon pricing, with prices ranging from less than $1 to over $130 per ton of CO₂.

Emissions trading systems, alternatively, establish marketplaces where emission allowances can be bought and sold. The European Union Emissions Trading System (EU ETS), the largest carbon market globally, has seen carbon prices rise to approximately €80-90 per ton in recent years, significantly improving the economic case for carbon capture technologies. Similar systems operate in regions including California, Quebec, and increasingly in Asian markets such as China and South Korea.

Tax incentives specifically targeting carbon capture technologies have gained prominence, with the United States' 45Q tax credit program standing as a notable example. Recent enhancements to this program through the Inflation Reduction Act have increased credits to $85 per metric ton for CO₂ captured and sequestered, and $60 per ton for CO₂ utilized in enhanced oil recovery or other applications.

Regulatory standards for CO₂ capture sorbent performance and energy efficiency are increasingly being incorporated into environmental permitting processes. These standards often establish minimum capture rates, energy penalties, and lifecycle assessment requirements that directly influence sorbent selection and system design. The EU's Industrial Emissions Directive and its evolving Best Available Techniques Reference Documents (BREFs) exemplify this approach.

Looking forward, regulatory frameworks are trending toward more stringent emissions reduction targets and higher carbon prices, which will likely accelerate CO₂ capture technology deployment. The International Energy Agency projects that carbon prices in advanced economies may need to reach $130-140 per ton by 2030 to align with Paris Agreement goals, potentially transforming the economics of sorbent-based capture systems and driving innovation toward more energy-efficient solutions.

Life Cycle Assessment of CO₂ Capture Technologies

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of CO₂ capture technologies throughout their entire life cycle. When examining sorbent-based capture systems, LCA considers raw material extraction, sorbent manufacturing, operational phase, and end-of-life disposal or recycling. This holistic approach reveals that while CO₂ capture technologies reduce direct emissions, they may introduce environmental burdens elsewhere in their life cycle.

For sorbent-based capture technologies, material production often represents a significant environmental hotspot. The synthesis of advanced materials like metal-organic frameworks (MOFs), amine-functionalized silica, or activated carbon derivatives requires energy-intensive processes and potentially hazardous chemicals. These upstream impacts must be balanced against the operational benefits of CO₂ reduction.

Energy efficiency metrics derived from LCA studies indicate that sorbent regeneration energy requirements remain a critical factor affecting overall system performance. Current solid sorbents typically require 2.0-3.5 GJ/tonne CO₂ for regeneration, compared to 3.5-4.5 GJ/tonne CO₂ for conventional amine scrubbing. However, when accounting for embodied energy in sorbent manufacturing and replacement frequency, the life cycle energy advantage may diminish.

Water consumption represents another important impact category in LCA studies of capture technologies. Sorbent-based systems generally demonstrate lower direct water requirements than solvent-based approaches, but indirect water consumption through material production and electricity generation must be considered for accurate comparison. Recent studies indicate potential water savings of 30-45% for advanced sorbent systems compared to conventional amine scrubbing.

LCA research has identified sorbent lifetime as a critical parameter affecting environmental performance. Materials with higher durability that maintain capture capacity over numerous cycles significantly improve life cycle metrics. Current commercial sorbents typically achieve 500-2000 cycles before requiring replacement, though laboratory-scale materials have demonstrated potential for 5000+ cycles under ideal conditions.

The geographical context of electricity generation substantially influences LCA outcomes for capture technologies. Sorbent systems powered by renewable energy sources show dramatically improved life cycle performance compared to those relying on fossil fuel electricity. This highlights the importance of considering regional energy mixes when evaluating capture technology deployment scenarios and emphasizes the synergistic relationship between decarbonization of electricity and carbon capture implementation.

For sorbent-based capture technologies, material production often represents a significant environmental hotspot. The synthesis of advanced materials like metal-organic frameworks (MOFs), amine-functionalized silica, or activated carbon derivatives requires energy-intensive processes and potentially hazardous chemicals. These upstream impacts must be balanced against the operational benefits of CO₂ reduction.

Energy efficiency metrics derived from LCA studies indicate that sorbent regeneration energy requirements remain a critical factor affecting overall system performance. Current solid sorbents typically require 2.0-3.5 GJ/tonne CO₂ for regeneration, compared to 3.5-4.5 GJ/tonne CO₂ for conventional amine scrubbing. However, when accounting for embodied energy in sorbent manufacturing and replacement frequency, the life cycle energy advantage may diminish.

Water consumption represents another important impact category in LCA studies of capture technologies. Sorbent-based systems generally demonstrate lower direct water requirements than solvent-based approaches, but indirect water consumption through material production and electricity generation must be considered for accurate comparison. Recent studies indicate potential water savings of 30-45% for advanced sorbent systems compared to conventional amine scrubbing.

LCA research has identified sorbent lifetime as a critical parameter affecting environmental performance. Materials with higher durability that maintain capture capacity over numerous cycles significantly improve life cycle metrics. Current commercial sorbents typically achieve 500-2000 cycles before requiring replacement, though laboratory-scale materials have demonstrated potential for 5000+ cycles under ideal conditions.

The geographical context of electricity generation substantially influences LCA outcomes for capture technologies. Sorbent systems powered by renewable energy sources show dramatically improved life cycle performance compared to those relying on fossil fuel electricity. This highlights the importance of considering regional energy mixes when evaluating capture technology deployment scenarios and emphasizes the synergistic relationship between decarbonization of electricity and carbon capture implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!