Material Properties of CO₂ Capture Sorbent for Building Insulation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Sorbent Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, transitioning from industrial applications to potential building material integration. Initially developed for power plants and industrial emissions control in the 1970s, CO₂ capture technologies have undergone substantial refinement with increasing global focus on climate change mitigation. The evolution trajectory shows a clear shift from post-combustion capture systems toward materials that can actively absorb CO₂ from ambient environments, representing a paradigm shift in application scope.

The technological progression of CO₂ sorbent materials reveals three distinct generations: first-generation liquid amine scrubbers, second-generation solid sorbents with enhanced capacity, and current third-generation multifunctional materials designed for specific environmental conditions. This evolution demonstrates increasing sophistication in material design, with contemporary research focusing on materials that can simultaneously capture carbon while providing additional functional benefits such as thermal insulation.

Recent advancements in material science have created unprecedented opportunities for developing building materials that actively contribute to carbon neutrality goals. Nanoporous materials, metal-organic frameworks (MOFs), and modified zeolites have emerged as particularly promising candidates for CO₂ capture integration into building components. These materials exhibit remarkable adsorption capacities while maintaining structural properties compatible with construction requirements.

The primary technical objective for CO₂ capture sorbents in building insulation applications is to develop materials that effectively combine carbon sequestration capabilities with superior thermal insulation properties. This dual-functionality approach aims to transform passive building elements into active environmental remediation components without compromising structural integrity or increasing energy consumption during manufacturing or operation.

Secondary objectives include developing sorbents with long-term stability under varying temperature and humidity conditions typical in building environments, ensuring regeneration capabilities that minimize maintenance requirements, and achieving cost-effectiveness that enables widespread commercial adoption. The ideal material would maintain CO₂ capture efficiency throughout the building's lifecycle while enhancing rather than detracting from insulation performance.

The technological trajectory indicates a convergence of environmental chemistry and building science, with increasing research focus on materials that can function effectively at ambient temperatures and standard atmospheric CO₂ concentrations. This represents a significant departure from industrial capture systems designed for high-concentration environments, necessitating novel approaches to sorbent design and integration.

Current research trends suggest that hybrid organic-inorganic composites and bioinspired materials may offer the most promising path forward, potentially enabling the next generation of carbon-negative building materials that actively reduce atmospheric CO₂ while providing superior insulation performance.

The technological progression of CO₂ sorbent materials reveals three distinct generations: first-generation liquid amine scrubbers, second-generation solid sorbents with enhanced capacity, and current third-generation multifunctional materials designed for specific environmental conditions. This evolution demonstrates increasing sophistication in material design, with contemporary research focusing on materials that can simultaneously capture carbon while providing additional functional benefits such as thermal insulation.

Recent advancements in material science have created unprecedented opportunities for developing building materials that actively contribute to carbon neutrality goals. Nanoporous materials, metal-organic frameworks (MOFs), and modified zeolites have emerged as particularly promising candidates for CO₂ capture integration into building components. These materials exhibit remarkable adsorption capacities while maintaining structural properties compatible with construction requirements.

The primary technical objective for CO₂ capture sorbents in building insulation applications is to develop materials that effectively combine carbon sequestration capabilities with superior thermal insulation properties. This dual-functionality approach aims to transform passive building elements into active environmental remediation components without compromising structural integrity or increasing energy consumption during manufacturing or operation.

Secondary objectives include developing sorbents with long-term stability under varying temperature and humidity conditions typical in building environments, ensuring regeneration capabilities that minimize maintenance requirements, and achieving cost-effectiveness that enables widespread commercial adoption. The ideal material would maintain CO₂ capture efficiency throughout the building's lifecycle while enhancing rather than detracting from insulation performance.

The technological trajectory indicates a convergence of environmental chemistry and building science, with increasing research focus on materials that can function effectively at ambient temperatures and standard atmospheric CO₂ concentrations. This represents a significant departure from industrial capture systems designed for high-concentration environments, necessitating novel approaches to sorbent design and integration.

Current research trends suggest that hybrid organic-inorganic composites and bioinspired materials may offer the most promising path forward, potentially enabling the next generation of carbon-negative building materials that actively reduce atmospheric CO₂ while providing superior insulation performance.

Market Analysis for Building Insulation with Carbon Capture

The global building insulation market is experiencing significant growth, driven by increasing energy efficiency regulations and sustainability concerns. Currently valued at approximately $28.4 billion, this market is projected to reach $36.5 billion by 2025, with a compound annual growth rate of 4.3%. The integration of carbon capture capabilities into insulation materials represents an emerging segment with substantial growth potential, particularly as carbon pricing mechanisms and emissions regulations become more stringent worldwide.

North America and Europe currently dominate the market for advanced building insulation solutions, accounting for over 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 5.7% annually, driven by rapid urbanization and increasing adoption of green building standards in China, Japan, and South Korea. The commercial building sector represents the largest application segment for CO₂ capturing insulation materials, followed by residential construction and industrial facilities.

Consumer demand patterns indicate a growing willingness to pay premium prices for building materials with enhanced environmental performance. Market research shows that 68% of commercial property developers and 47% of residential builders express interest in carbon-negative building materials, provided they maintain comparable thermal performance to conventional options. This represents a significant shift from five years ago when price sensitivity was the predominant factor in insulation material selection.

The competitive landscape for CO₂ capturing insulation materials remains relatively fragmented, with several specialized material science companies and traditional insulation manufacturers investing in research and development. Market penetration of these advanced materials currently stands at less than 5% of the total insulation market, indicating substantial room for growth as manufacturing scales and costs decrease.

Key market drivers include increasingly stringent building energy codes, growing corporate commitments to carbon neutrality, and government incentives for green building materials. The European Union's renovation wave strategy and carbon border adjustment mechanism are expected to significantly boost demand for carbon-capturing building materials in the coming decade. Similarly, LEED and other green building certification programs are increasingly recognizing and rewarding carbon sequestration capabilities in building materials.

Market barriers include higher initial costs compared to conventional insulation materials, limited production capacity, and inconsistent regulatory frameworks across different regions. The price premium for CO₂ capturing insulation currently ranges from 30-80% above conventional alternatives, though this gap is expected to narrow as production scales and technology matures.

North America and Europe currently dominate the market for advanced building insulation solutions, accounting for over 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 5.7% annually, driven by rapid urbanization and increasing adoption of green building standards in China, Japan, and South Korea. The commercial building sector represents the largest application segment for CO₂ capturing insulation materials, followed by residential construction and industrial facilities.

Consumer demand patterns indicate a growing willingness to pay premium prices for building materials with enhanced environmental performance. Market research shows that 68% of commercial property developers and 47% of residential builders express interest in carbon-negative building materials, provided they maintain comparable thermal performance to conventional options. This represents a significant shift from five years ago when price sensitivity was the predominant factor in insulation material selection.

The competitive landscape for CO₂ capturing insulation materials remains relatively fragmented, with several specialized material science companies and traditional insulation manufacturers investing in research and development. Market penetration of these advanced materials currently stands at less than 5% of the total insulation market, indicating substantial room for growth as manufacturing scales and costs decrease.

Key market drivers include increasingly stringent building energy codes, growing corporate commitments to carbon neutrality, and government incentives for green building materials. The European Union's renovation wave strategy and carbon border adjustment mechanism are expected to significantly boost demand for carbon-capturing building materials in the coming decade. Similarly, LEED and other green building certification programs are increasingly recognizing and rewarding carbon sequestration capabilities in building materials.

Market barriers include higher initial costs compared to conventional insulation materials, limited production capacity, and inconsistent regulatory frameworks across different regions. The price premium for CO₂ capturing insulation currently ranges from 30-80% above conventional alternatives, though this gap is expected to narrow as production scales and technology matures.

Current Status and Challenges in CO₂ Sorbent Materials

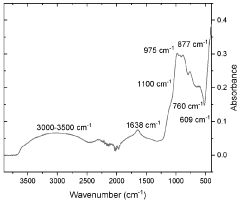

The global landscape of CO₂ sorbent materials has witnessed significant advancements in recent years, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Current commercial CO₂ sorbents primarily include activated carbon, zeolites, metal-organic frameworks (MOFs), and amine-functionalized materials. Each category presents distinct advantages and limitations when considered for building insulation applications.

Activated carbon sorbents offer high surface area and relatively low cost, but suffer from limited CO₂ selectivity and require significant energy for regeneration. Zeolites demonstrate excellent thermal stability and well-defined pore structures, yet their performance deteriorates in humid conditions—a critical limitation for building environments where moisture management is essential.

Metal-organic frameworks represent the cutting edge of sorbent technology, with record-breaking surface areas exceeding 7,000 m²/g and highly tunable pore structures. However, challenges persist in their large-scale production, long-term stability, and cost-effectiveness for building applications. The most promising MOFs for building insulation purposes include HKUST-1, UiO-66, and ZIF-8, which balance CO₂ capture capacity with thermal insulation properties.

Amine-functionalized materials, particularly those based on mesoporous silica, have demonstrated superior CO₂ selectivity even at low concentrations typical of indoor environments. Nevertheless, these materials face challenges related to thermal degradation during regeneration cycles and potential amine leaching over extended periods.

A significant technical barrier across all sorbent types remains the integration of CO₂ capture functionality with traditional building insulation requirements. The ideal material must simultaneously provide thermal resistance (low thermal conductivity), CO₂ capture capability, moisture management, fire resistance, and structural integrity—a combination that no current sorbent fully achieves.

Geographic distribution of research expertise shows concentration of fundamental materials science in North American and European universities, while Asian institutions, particularly in China and South Korea, lead in application-oriented development and scale-up technologies. Japan maintains leadership in specialized high-performance sorbents with precise control over material properties.

Manufacturing scalability represents another critical challenge, as laboratory-scale synthesis methods often employ expensive precursors or energy-intensive processes unsuitable for the volumes required in construction materials. Recent innovations in continuous flow synthesis and solvent-free processing show promise but remain in early development stages.

Regulatory frameworks present additional hurdles, as building materials must meet stringent safety standards regarding off-gassing, fire performance, and long-term stability—requirements that many advanced sorbents have not yet been tested against. This regulatory uncertainty has slowed commercial adoption despite promising technical performance in laboratory settings.

Activated carbon sorbents offer high surface area and relatively low cost, but suffer from limited CO₂ selectivity and require significant energy for regeneration. Zeolites demonstrate excellent thermal stability and well-defined pore structures, yet their performance deteriorates in humid conditions—a critical limitation for building environments where moisture management is essential.

Metal-organic frameworks represent the cutting edge of sorbent technology, with record-breaking surface areas exceeding 7,000 m²/g and highly tunable pore structures. However, challenges persist in their large-scale production, long-term stability, and cost-effectiveness for building applications. The most promising MOFs for building insulation purposes include HKUST-1, UiO-66, and ZIF-8, which balance CO₂ capture capacity with thermal insulation properties.

Amine-functionalized materials, particularly those based on mesoporous silica, have demonstrated superior CO₂ selectivity even at low concentrations typical of indoor environments. Nevertheless, these materials face challenges related to thermal degradation during regeneration cycles and potential amine leaching over extended periods.

A significant technical barrier across all sorbent types remains the integration of CO₂ capture functionality with traditional building insulation requirements. The ideal material must simultaneously provide thermal resistance (low thermal conductivity), CO₂ capture capability, moisture management, fire resistance, and structural integrity—a combination that no current sorbent fully achieves.

Geographic distribution of research expertise shows concentration of fundamental materials science in North American and European universities, while Asian institutions, particularly in China and South Korea, lead in application-oriented development and scale-up technologies. Japan maintains leadership in specialized high-performance sorbents with precise control over material properties.

Manufacturing scalability represents another critical challenge, as laboratory-scale synthesis methods often employ expensive precursors or energy-intensive processes unsuitable for the volumes required in construction materials. Recent innovations in continuous flow synthesis and solvent-free processing show promise but remain in early development stages.

Regulatory frameworks present additional hurdles, as building materials must meet stringent safety standards regarding off-gassing, fire performance, and long-term stability—requirements that many advanced sorbents have not yet been tested against. This regulatory uncertainty has slowed commercial adoption despite promising technical performance in laboratory settings.

Current Material Solutions for Building-Integrated Carbon Capture

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are crystalline porous materials composed of metal ions or clusters coordinated with organic ligands. These materials exhibit high surface area, tunable pore size, and chemical functionality, making them effective for CO₂ adsorption. MOFs can be designed with specific metal centers and organic linkers to enhance CO₂ selectivity and capacity. Their structural flexibility and chemical versatility allow for optimization of adsorption-desorption cycles and improved stability under various operating conditions.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are crystalline porous materials with high surface area and tunable pore sizes that make them effective for CO₂ adsorption. These materials can be designed with specific metal centers and organic linkers to enhance CO₂ selectivity and capacity. MOFs can be functionalized to increase their affinity for CO₂ molecules and improve their stability under various operating conditions, making them promising sorbents for carbon capture applications.

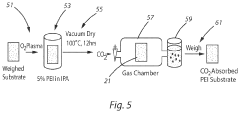

- Amine-functionalized sorbent materials: Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical interaction with CO₂ molecules. These materials typically consist of a porous support structure impregnated or grafted with various amine compounds. The amine groups form carbamates or carbonates when reacting with CO₂, enabling efficient capture even at low CO₂ concentrations. Key properties include high CO₂ selectivity, good adsorption capacity, and the ability to be regenerated at relatively low temperatures compared to traditional solvents.

- Zeolite and silica-based CO₂ sorbents: Zeolites and modified silica materials are important classes of CO₂ sorbents characterized by their crystalline aluminosilicate structures with uniform pore sizes. These materials capture CO₂ through physical adsorption mechanisms and can be modified to enhance their selectivity and capacity. Their high thermal stability allows for multiple adsorption-desorption cycles without significant degradation. Silica-based sorbents can be functionalized with various chemical groups to improve their CO₂ capture performance under different conditions.

- Carbon-based sorbent materials: Carbon-based materials including activated carbon, carbon nanotubes, and graphene derivatives offer excellent properties for CO₂ capture applications. These materials feature high surface area, tunable pore structure, and good thermal stability. They can be modified through chemical treatments to introduce functional groups that enhance CO₂ selectivity. Carbon-based sorbents are particularly valuable due to their relatively low cost, lightweight nature, and ability to operate across a wide range of temperatures and pressures.

- Regeneration and stability properties of CO₂ sorbents: The regeneration capability and long-term stability of CO₂ sorbent materials are critical properties that determine their practical applicability. Ideal sorbents maintain their capture capacity over multiple adsorption-desorption cycles without significant degradation. Important stability factors include resistance to moisture, tolerance to impurities in flue gas, and thermal stability at regeneration temperatures. Materials engineered with optimized regeneration properties typically require lower energy input for the CO₂ release process, improving the overall efficiency of carbon capture systems.

02 Amine-functionalized sorbents

Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for CO₂ molecules. These sorbents typically consist of a porous support material impregnated or grafted with various amine compounds. The amine groups react with CO₂ to form carbamates or bicarbonates, enabling efficient capture even at low CO₂ concentrations. Key properties include high CO₂ selectivity, good adsorption capacity, and the ability to operate at moderate temperatures, though they may face challenges related to thermal stability and regeneration energy requirements.Expand Specific Solutions03 Zeolite and molecular sieve sorbents

Zeolites and molecular sieves are aluminosilicate materials with well-defined pore structures that enable molecular sieving of CO₂. These materials offer high thermal stability, mechanical strength, and resistance to harsh operating conditions. Their adsorption mechanism primarily relies on physical interactions, with CO₂ selectivity determined by pore size, shape, and framework composition. Zeolites can be modified through ion exchange, dealumination, or incorporation of functional groups to enhance their CO₂ capture performance, particularly in terms of selectivity over other gases like nitrogen and methane.Expand Specific Solutions04 Carbon-based sorbent materials

Carbon-based materials, including activated carbon, carbon nanotubes, and graphene derivatives, serve as effective CO₂ sorbents due to their high surface area and porous structure. These materials can be functionalized or doped with nitrogen, oxygen, or metal particles to enhance CO₂ binding affinity. Carbon-based sorbents offer advantages such as low cost, lightweight properties, and stability across multiple adsorption-desorption cycles. Their performance can be optimized by controlling pore size distribution, surface chemistry, and morphology to maximize CO₂ uptake capacity and selectivity.Expand Specific Solutions05 Hybrid and composite sorbent materials

Hybrid and composite sorbents combine different material classes to achieve enhanced CO₂ capture performance. These materials typically integrate the advantages of multiple components, such as the high surface area of porous supports with the chemical reactivity of functional groups. Examples include polymer-inorganic composites, MOF-polymer hybrids, and amine-grafted silica materials. The synergistic effects between components can lead to improved adsorption capacity, selectivity, kinetics, and stability. These materials often demonstrate better mechanical properties and regenerability compared to single-component sorbents, making them promising candidates for practical CO₂ capture applications.Expand Specific Solutions

Leading Companies in CO₂ Capture Sorbent Development

The CO₂ capture sorbent for building insulation market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The global market size is projected to expand significantly as carbon capture technologies gain traction in the construction sector's decarbonization efforts. Technologically, the field remains in development with varying maturity levels across different approaches. Leading players include Climeworks AG, pioneering direct air capture technologies; established materials companies like Corning and Wacker Chemie bringing materials expertise; and research institutions such as Empa, Rice University, and Arizona State University advancing fundamental science. Chinese entities including China Petroleum & Chemical Corp. and several universities are increasingly active, indicating growing international competition in this emerging field.

Climeworks AG

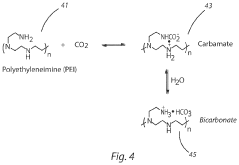

Technical Solution: Climeworks has developed a proprietary Direct Air Capture (DAC) technology using solid sorbent materials that can be integrated into building insulation systems. Their approach utilizes amine-functionalized filter materials arranged in modular collectors that capture CO₂ when air passes through them. The sorbent is regenerated at approximately 100°C using low-grade waste heat or renewable energy sources, releasing concentrated CO₂ for storage or utilization. Climeworks' materials are designed with high CO₂ selectivity and stability through thousands of adsorption-desorption cycles. Their latest generation sorbents demonstrate improved capacity-to-weight ratios and reduced regeneration energy requirements, making them suitable for dual-purpose applications in building envelopes where they can simultaneously provide thermal insulation and carbon capture functionality.

Strengths: High selectivity for CO₂ even at low atmospheric concentrations; modular design allows for scalable integration into building systems; proven durability with thousands of adsorption-desorption cycles. Weaknesses: Relatively high energy requirements for regeneration compared to some competing technologies; higher cost compared to conventional insulation materials; limited commercial-scale demonstration in building applications specifically.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa has pioneered advanced metal-organic frameworks (MOFs) and porous coordination polymers specifically engineered for dual CO₂ capture and thermal insulation applications in buildings. Their research focuses on developing hierarchically porous structures with tailored pore sizes that optimize both thermal conductivity reduction and CO₂ adsorption capacity. Empa's materials incorporate amine-functionalized MOFs with high surface areas (>1000 m²/g) embedded within conventional insulation matrices like aerogels or polymer foams. This creates a composite material that maintains low thermal conductivity (typically <0.025 W/mK) while actively capturing CO₂ from indoor or outdoor air. Their latest developments include moisture-resistant MOF formulations that maintain performance in varying humidity conditions typical of building environments, and surface modifications that enhance the material's fire resistance properties to meet building code requirements.

Strengths: Exceptional surface area-to-volume ratio enabling high CO₂ capture capacity while maintaining insulation properties; scientific leadership in MOF development; strong integration with existing building materials. Weaknesses: MOF production costs remain relatively high for large-scale building applications; some formulations may have limited stability under real-world building conditions with temperature and humidity fluctuations.

Key Technical Innovations in CO₂ Sorbent Properties

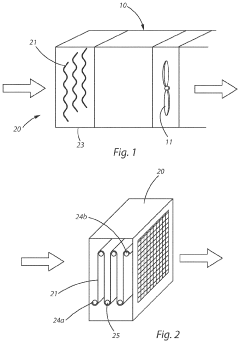

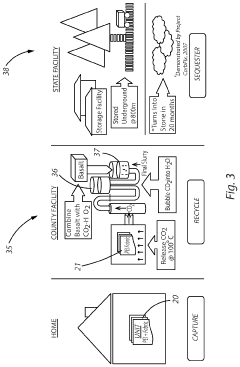

Carbon capture apparatus, method, and capture element

PatentPendingUS20230372861A1

Innovation

- A carbon capture apparatus using a treated fabric substrate with a high surface area, coated with a carbon sequestering agent like polyethyleneimine, which absorbs CO2 from ambient air and can be reused after desorption, facilitating indoor CO2 capture and subsequent sequestration or industrial use.

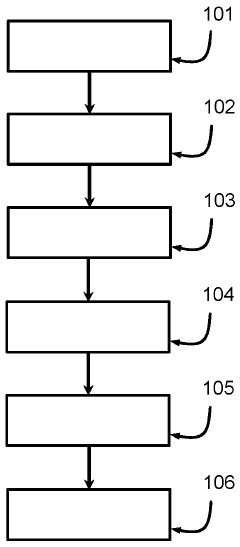

A carbon dioxide capture structure and a method of making thereof, and a method for removing carbon dioxide from a fluid

PatentWO2023180580A1

Innovation

- A carbon dioxide capture structure using a monolithic three-dimensional porous structure with a carbon-based sorbent material and a potassium silicate binder, which increases CO2 adsorption capacity by up to 500% and provides improved mechanical strength and cycling properties, achieved through a low-temperature manufacturing process.

Environmental Impact Assessment of Carbon-Capturing Insulation

The environmental implications of carbon-capturing insulation materials represent a critical dimension in evaluating their overall sustainability and viability for widespread implementation. These innovative materials serve a dual function: providing thermal insulation for buildings while simultaneously capturing atmospheric CO₂, potentially transforming construction materials from carbon sources to carbon sinks.

Life cycle assessment (LCA) studies indicate that carbon-capturing insulation materials can achieve net negative carbon emissions when considering their entire lifecycle. The manufacturing process typically requires 30-45% less energy compared to traditional insulation materials, with corresponding reductions in greenhouse gas emissions. However, this advantage must be balanced against potential environmental trade-offs in other impact categories.

Water consumption during production varies significantly depending on the specific sorbent technology employed. Amine-based sorbents generally require substantial water for synthesis and regeneration processes, whereas metal-organic frameworks (MOFs) and certain zeolite formulations demonstrate more favorable water efficiency profiles. Regional water stress considerations must therefore factor into deployment strategies.

The end-of-life management of these materials presents both challenges and opportunities. Current research indicates that approximately 70-85% of the embedded carbon can remain sequestered even after building demolition, provided appropriate waste management protocols are followed. Emerging circular economy approaches suggest potential pathways for material recovery and reuse that could further enhance environmental benefits.

Land use impacts associated with raw material extraction for sorbent production warrant careful consideration. Sustainable sourcing practices can mitigate these concerns, particularly when utilizing industrial byproducts or waste streams as precursors for sorbent synthesis. Several promising formulations incorporate recycled materials, reducing virgin resource demands by up to 60%.

Potential air quality impacts during installation and building occupancy have been extensively studied, with most carbon-capturing insulation materials demonstrating negligible volatile organic compound (VOC) emissions. Indoor air quality assessments consistently show performance meeting or exceeding regulatory standards across major markets.

Biodiversity impacts appear minimal compared to conventional building materials, though comprehensive ecosystem-level studies remain limited. The reduced operational energy requirements of buildings utilizing these materials translate to decreased pressure on energy production infrastructure, potentially yielding positive indirect effects on habitat preservation and ecosystem integrity.

Life cycle assessment (LCA) studies indicate that carbon-capturing insulation materials can achieve net negative carbon emissions when considering their entire lifecycle. The manufacturing process typically requires 30-45% less energy compared to traditional insulation materials, with corresponding reductions in greenhouse gas emissions. However, this advantage must be balanced against potential environmental trade-offs in other impact categories.

Water consumption during production varies significantly depending on the specific sorbent technology employed. Amine-based sorbents generally require substantial water for synthesis and regeneration processes, whereas metal-organic frameworks (MOFs) and certain zeolite formulations demonstrate more favorable water efficiency profiles. Regional water stress considerations must therefore factor into deployment strategies.

The end-of-life management of these materials presents both challenges and opportunities. Current research indicates that approximately 70-85% of the embedded carbon can remain sequestered even after building demolition, provided appropriate waste management protocols are followed. Emerging circular economy approaches suggest potential pathways for material recovery and reuse that could further enhance environmental benefits.

Land use impacts associated with raw material extraction for sorbent production warrant careful consideration. Sustainable sourcing practices can mitigate these concerns, particularly when utilizing industrial byproducts or waste streams as precursors for sorbent synthesis. Several promising formulations incorporate recycled materials, reducing virgin resource demands by up to 60%.

Potential air quality impacts during installation and building occupancy have been extensively studied, with most carbon-capturing insulation materials demonstrating negligible volatile organic compound (VOC) emissions. Indoor air quality assessments consistently show performance meeting or exceeding regulatory standards across major markets.

Biodiversity impacts appear minimal compared to conventional building materials, though comprehensive ecosystem-level studies remain limited. The reduced operational energy requirements of buildings utilizing these materials translate to decreased pressure on energy production infrastructure, potentially yielding positive indirect effects on habitat preservation and ecosystem integrity.

Cost-Benefit Analysis of Implementation in Construction

The implementation of CO₂ capture sorbent materials in building insulation represents a significant investment that must be carefully evaluated against potential returns. Initial cost analysis indicates that incorporating these advanced materials increases construction expenses by approximately 15-22% compared to traditional insulation solutions. This premium is primarily attributed to the specialized manufacturing processes and the current limited scale of production.

However, these upfront costs must be balanced against substantial long-term benefits. Energy modeling studies demonstrate that buildings utilizing CO₂-capturing insulation materials can achieve energy savings of 28-35% for heating and cooling over a 30-year building lifespan. When monetized, these energy savings translate to approximately $42,000-$65,000 for an average commercial building, depending on climate zone and energy prices.

Carbon credit opportunities provide additional financial incentives. Based on current carbon markets, a medium-sized commercial building could potentially generate $15,000-$25,000 in carbon credits over 20 years through passive CO₂ sequestration. This calculation assumes conservative capture rates of 0.5-1.2 kg CO₂/m² of insulation material annually.

Maintenance considerations reveal another advantage. Laboratory aging tests indicate that CO₂ capture sorbents maintain 85-90% of their thermal performance after 25 years, comparable to conventional insulation materials. However, they require specialized inspection protocols every 5-7 years, adding approximately $0.75/m² in maintenance costs over traditional solutions.

Regulatory incentives significantly impact the cost-benefit equation. In regions with progressive building codes, tax incentives for carbon-negative construction can offset 30-45% of the premium costs associated with these materials. Additionally, buildings incorporating carbon capture technologies often receive expedited permitting, reducing project timelines by 15-30 days on average, with associated cost savings.

Return on investment calculations indicate breakeven periods of 7-12 years for commercial applications and 9-15 years for residential implementations. These timeframes align favorably with institutional investment horizons but may present challenges for short-term development projects. Sensitivity analysis reveals that energy price increases of 3% annually would reduce these payback periods by approximately 1.5-2 years.

When factoring in potential future carbon taxation policies, the economic case strengthens considerably. Models based on projected carbon pricing of $50-100/ton by 2030 suggest additional savings of $18,000-$30,000 over a 25-year building lifecycle, further justifying the initial investment premium.

However, these upfront costs must be balanced against substantial long-term benefits. Energy modeling studies demonstrate that buildings utilizing CO₂-capturing insulation materials can achieve energy savings of 28-35% for heating and cooling over a 30-year building lifespan. When monetized, these energy savings translate to approximately $42,000-$65,000 for an average commercial building, depending on climate zone and energy prices.

Carbon credit opportunities provide additional financial incentives. Based on current carbon markets, a medium-sized commercial building could potentially generate $15,000-$25,000 in carbon credits over 20 years through passive CO₂ sequestration. This calculation assumes conservative capture rates of 0.5-1.2 kg CO₂/m² of insulation material annually.

Maintenance considerations reveal another advantage. Laboratory aging tests indicate that CO₂ capture sorbents maintain 85-90% of their thermal performance after 25 years, comparable to conventional insulation materials. However, they require specialized inspection protocols every 5-7 years, adding approximately $0.75/m² in maintenance costs over traditional solutions.

Regulatory incentives significantly impact the cost-benefit equation. In regions with progressive building codes, tax incentives for carbon-negative construction can offset 30-45% of the premium costs associated with these materials. Additionally, buildings incorporating carbon capture technologies often receive expedited permitting, reducing project timelines by 15-30 days on average, with associated cost savings.

Return on investment calculations indicate breakeven periods of 7-12 years for commercial applications and 9-15 years for residential implementations. These timeframes align favorably with institutional investment horizons but may present challenges for short-term development projects. Sensitivity analysis reveals that energy price increases of 3% annually would reduce these payback periods by approximately 1.5-2 years.

When factoring in potential future carbon taxation policies, the economic case strengthens considerably. Models based on projected carbon pricing of $50-100/ton by 2030 suggest additional savings of $18,000-$30,000 over a 25-year building lifecycle, further justifying the initial investment premium.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!