How Patents Drive Innovation in CO₂ Capture Sorbents

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Sorbent Evolution and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, driven by the urgent need to mitigate climate change impacts. The journey began with conventional absorption methods using liquid amines in the 1970s, which while effective, suffered from high energy requirements for regeneration and corrosion issues. The 1990s witnessed a shift toward solid sorbents, marking a critical evolution point in CO₂ capture technology.

Patents have played a pivotal role in this technological progression, serving as both indicators and drivers of innovation. Early patents focused primarily on improving existing amine-based solutions, while more recent intellectual property has expanded into novel materials including metal-organic frameworks (MOFs), zeolites, and functionalized porous carbons. These developments reflect the industry's movement toward more energy-efficient and cost-effective capture solutions.

The current technological landscape is characterized by a growing emphasis on materials that can operate under diverse conditions, from power plant flue gases to direct air capture applications. Patent activity has accelerated particularly in the last decade, with a 300% increase in CO₂ sorbent-related patents filed globally between 2010 and 2020, indicating heightened commercial and research interest in this field.

Key objectives driving innovation in CO₂ capture sorbents include enhancing sorption capacity, improving selectivity for CO₂ over other gases, reducing regeneration energy requirements, and extending operational lifespan. Additionally, there is growing focus on developing materials that can function effectively under real-world conditions, including tolerance to moisture, contaminants, and temperature fluctuations.

The evolution trajectory suggests a convergence toward hybrid systems that combine the advantages of different sorbent types. Patents increasingly describe composite materials that integrate the high capacity of certain sorbents with the stability and regeneration efficiency of others. This trend indicates a maturing understanding of the complex trade-offs inherent in sorbent design.

Looking forward, the field appears to be moving toward bio-inspired sorbents and materials that can not only capture CO₂ but potentially convert it into valuable products. Patent applications in these areas have grown by approximately 25% annually since 2015, suggesting these approaches may represent the next frontier in carbon capture technology.

The ultimate technological goal remains developing sorbents that can enable economically viable large-scale carbon capture implementation, with target cost reductions of 50-70% compared to current commercial technologies, as indicated by recent patent claims and technical objectives stated in research consortia documentation.

Patents have played a pivotal role in this technological progression, serving as both indicators and drivers of innovation. Early patents focused primarily on improving existing amine-based solutions, while more recent intellectual property has expanded into novel materials including metal-organic frameworks (MOFs), zeolites, and functionalized porous carbons. These developments reflect the industry's movement toward more energy-efficient and cost-effective capture solutions.

The current technological landscape is characterized by a growing emphasis on materials that can operate under diverse conditions, from power plant flue gases to direct air capture applications. Patent activity has accelerated particularly in the last decade, with a 300% increase in CO₂ sorbent-related patents filed globally between 2010 and 2020, indicating heightened commercial and research interest in this field.

Key objectives driving innovation in CO₂ capture sorbents include enhancing sorption capacity, improving selectivity for CO₂ over other gases, reducing regeneration energy requirements, and extending operational lifespan. Additionally, there is growing focus on developing materials that can function effectively under real-world conditions, including tolerance to moisture, contaminants, and temperature fluctuations.

The evolution trajectory suggests a convergence toward hybrid systems that combine the advantages of different sorbent types. Patents increasingly describe composite materials that integrate the high capacity of certain sorbents with the stability and regeneration efficiency of others. This trend indicates a maturing understanding of the complex trade-offs inherent in sorbent design.

Looking forward, the field appears to be moving toward bio-inspired sorbents and materials that can not only capture CO₂ but potentially convert it into valuable products. Patent applications in these areas have grown by approximately 25% annually since 2015, suggesting these approaches may represent the next frontier in carbon capture technology.

The ultimate technological goal remains developing sorbents that can enable economically viable large-scale carbon capture implementation, with target cost reductions of 50-70% compared to current commercial technologies, as indicated by recent patent claims and technical objectives stated in research consortia documentation.

Market Demand Analysis for Carbon Capture Technologies

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce greenhouse gas emissions. As of 2023, the carbon capture, utilization, and storage (CCUS) market was valued at approximately $4 billion, with projections suggesting expansion to reach $12-15 billion by 2030, representing a compound annual growth rate of over 15%.

Industrial sectors, particularly power generation, cement, steel, and chemical manufacturing, constitute the primary demand drivers for carbon capture technologies. These industries collectively account for nearly 70% of global CO₂ emissions, creating substantial market potential for effective capture solutions. The power generation sector alone represents about 40% of the current carbon capture technology implementation.

Geographically, North America and Europe lead in carbon capture technology adoption, with significant projects underway in the United States, Canada, Norway, and the United Kingdom. However, the Asia-Pacific region, particularly China and Japan, is showing the fastest growth rate in this market, driven by ambitious climate targets and industrial decarbonization initiatives.

Government policies and international climate agreements have become crucial market catalysts. The Paris Agreement commitments have prompted over 70 countries to establish net-zero emissions targets, creating regulatory frameworks that incentivize carbon capture technology adoption. Financial mechanisms such as carbon pricing, tax credits (like the 45Q tax credit in the US), and direct subsidies are strengthening the economic case for these technologies.

The market for CO₂ capture sorbents specifically shows promising growth potential. Traditional amine-based sorbents currently dominate with approximately 60% market share, but novel materials including metal-organic frameworks (MOFs), zeolites, and advanced polymer membranes are gaining traction due to their improved efficiency and reduced energy penalties.

End-use applications for captured carbon are diversifying beyond enhanced oil recovery (EOR), which currently accounts for about 75% of utilized CO₂. Emerging applications in concrete curing, synthetic fuel production, and chemical manufacturing are expected to grow at rates exceeding 20% annually, creating additional demand pull for capture technologies.

Investment trends reveal increasing private sector participation, with venture capital funding in carbon capture startups reaching record levels of over $1 billion in 2022. This represents a significant shift from the previously government-dominated funding landscape and indicates growing commercial confidence in the sector's viability.

Industrial sectors, particularly power generation, cement, steel, and chemical manufacturing, constitute the primary demand drivers for carbon capture technologies. These industries collectively account for nearly 70% of global CO₂ emissions, creating substantial market potential for effective capture solutions. The power generation sector alone represents about 40% of the current carbon capture technology implementation.

Geographically, North America and Europe lead in carbon capture technology adoption, with significant projects underway in the United States, Canada, Norway, and the United Kingdom. However, the Asia-Pacific region, particularly China and Japan, is showing the fastest growth rate in this market, driven by ambitious climate targets and industrial decarbonization initiatives.

Government policies and international climate agreements have become crucial market catalysts. The Paris Agreement commitments have prompted over 70 countries to establish net-zero emissions targets, creating regulatory frameworks that incentivize carbon capture technology adoption. Financial mechanisms such as carbon pricing, tax credits (like the 45Q tax credit in the US), and direct subsidies are strengthening the economic case for these technologies.

The market for CO₂ capture sorbents specifically shows promising growth potential. Traditional amine-based sorbents currently dominate with approximately 60% market share, but novel materials including metal-organic frameworks (MOFs), zeolites, and advanced polymer membranes are gaining traction due to their improved efficiency and reduced energy penalties.

End-use applications for captured carbon are diversifying beyond enhanced oil recovery (EOR), which currently accounts for about 75% of utilized CO₂. Emerging applications in concrete curing, synthetic fuel production, and chemical manufacturing are expected to grow at rates exceeding 20% annually, creating additional demand pull for capture technologies.

Investment trends reveal increasing private sector participation, with venture capital funding in carbon capture startups reaching record levels of over $1 billion in 2022. This represents a significant shift from the previously government-dominated funding landscape and indicates growing commercial confidence in the sector's viability.

Global Status and Challenges in CO₂ Capture Sorbent Development

The global landscape of CO₂ capture sorbent development presents a complex interplay of technological advancement, regulatory frameworks, and market dynamics. Currently, the field is characterized by significant regional disparities in research intensity and technological maturity. North America, particularly the United States, and Europe lead in patent filings and academic publications, with China rapidly closing the gap through aggressive investment in clean energy technologies.

The primary technical challenges facing CO₂ capture sorbent development revolve around four critical parameters: selectivity, capacity, stability, and regeneration energy requirements. Despite decades of research, achieving optimal performance across all these parameters simultaneously remains elusive. Most existing sorbents excel in one or two aspects but fall short in others, creating a persistent trade-off dilemma that hampers widespread commercial deployment.

Material constraints represent another significant challenge. Traditional amine-based sorbents suffer from degradation issues and high regeneration energy penalties. Newer materials such as metal-organic frameworks (MOFs) and porous polymers show promising capacity and selectivity but face scalability and cost barriers that limit their industrial application. The manufacturing processes for advanced sorbents often involve complex synthesis routes that are difficult to scale economically.

Economic viability remains perhaps the most formidable obstacle. Current cost estimates for CO₂ capture using state-of-the-art sorbents range from $40-100 per ton of CO₂, significantly higher than the carbon prices in most markets. This economic gap has slowed adoption despite technological readiness in some areas. The absence of strong carbon pricing mechanisms in many regions further exacerbates this challenge.

Regulatory frameworks vary substantially across regions, creating an uneven playing field for technology development. The European Union's more stringent emissions targets and supportive policies have fostered innovation clusters in countries like Germany and the UK. Conversely, inconsistent policy support in other regions has led to fragmented research efforts and hesitant industrial investment.

Infrastructure limitations also pose significant challenges. The integration of capture technologies into existing industrial facilities requires substantial retrofitting, while the development of CO₂ transport and storage infrastructure lags behind capture technology. This creates a chicken-and-egg problem where capture technology deployment is hindered by insufficient downstream infrastructure.

Knowledge sharing and intellectual property protection present a delicate balance. While patent activity has accelerated innovation in specific areas, it has also created technology silos that sometimes impede collaborative progress. International research initiatives attempt to bridge these gaps, but competitive commercial interests often limit the depth of technical exchange.

The primary technical challenges facing CO₂ capture sorbent development revolve around four critical parameters: selectivity, capacity, stability, and regeneration energy requirements. Despite decades of research, achieving optimal performance across all these parameters simultaneously remains elusive. Most existing sorbents excel in one or two aspects but fall short in others, creating a persistent trade-off dilemma that hampers widespread commercial deployment.

Material constraints represent another significant challenge. Traditional amine-based sorbents suffer from degradation issues and high regeneration energy penalties. Newer materials such as metal-organic frameworks (MOFs) and porous polymers show promising capacity and selectivity but face scalability and cost barriers that limit their industrial application. The manufacturing processes for advanced sorbents often involve complex synthesis routes that are difficult to scale economically.

Economic viability remains perhaps the most formidable obstacle. Current cost estimates for CO₂ capture using state-of-the-art sorbents range from $40-100 per ton of CO₂, significantly higher than the carbon prices in most markets. This economic gap has slowed adoption despite technological readiness in some areas. The absence of strong carbon pricing mechanisms in many regions further exacerbates this challenge.

Regulatory frameworks vary substantially across regions, creating an uneven playing field for technology development. The European Union's more stringent emissions targets and supportive policies have fostered innovation clusters in countries like Germany and the UK. Conversely, inconsistent policy support in other regions has led to fragmented research efforts and hesitant industrial investment.

Infrastructure limitations also pose significant challenges. The integration of capture technologies into existing industrial facilities requires substantial retrofitting, while the development of CO₂ transport and storage infrastructure lags behind capture technology. This creates a chicken-and-egg problem where capture technology deployment is hindered by insufficient downstream infrastructure.

Knowledge sharing and intellectual property protection present a delicate balance. While patent activity has accelerated innovation in specific areas, it has also created technology silos that sometimes impede collaborative progress. International research initiatives attempt to bridge these gaps, but competitive commercial interests often limit the depth of technical exchange.

Current Patented Sorbent Solutions and Implementation Strategies

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks represent an innovative class of porous materials with exceptional CO₂ adsorption capabilities due to their high surface area and tunable pore structures. These crystalline materials consist of metal ions coordinated to organic ligands, creating three-dimensional structures with customizable chemical properties. MOFs can be engineered with specific functional groups to enhance CO₂ selectivity and capacity, making them promising candidates for post-combustion carbon capture applications.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks represent an innovative class of porous materials with exceptional CO₂ adsorption capabilities due to their high surface area and tunable pore structures. These crystalline materials consist of metal ions coordinated to organic ligands, creating three-dimensional structures with customizable chemical properties. MOFs can be engineered with specific functional groups to enhance CO₂ selectivity and capacity, making them promising candidates for post-combustion carbon capture applications. Their regeneration typically requires less energy compared to traditional liquid amine systems.

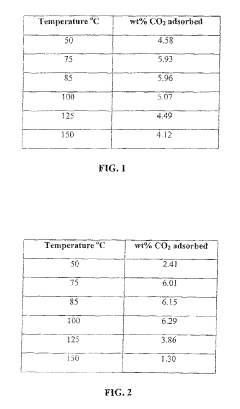

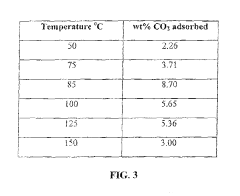

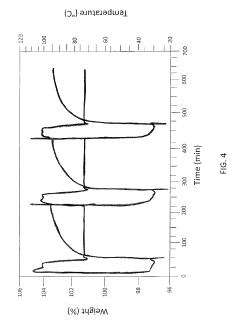

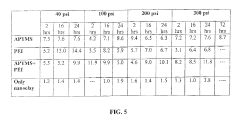

- Amine-functionalized solid sorbents: Amine-functionalized solid sorbents combine the high CO₂ affinity of amines with the structural advantages of solid supports. These materials typically consist of primary, secondary, or tertiary amines grafted onto porous substrates such as silica, alumina, or polymeric materials. The amine groups react with CO₂ to form carbamates or bicarbonates under ambient conditions, enabling efficient capture from flue gas streams. These sorbents offer advantages including lower regeneration energy, reduced corrosion issues, and the ability to operate in the presence of moisture, making them suitable for industrial-scale carbon capture applications.

- Zeolite-based CO₂ capture materials: Zeolites are crystalline aluminosilicate materials with well-defined microporous structures that demonstrate significant potential for CO₂ capture. Their molecular sieving properties allow for selective adsorption of CO₂ over other gases based on molecular size and polarizability. The high cation content in zeolites creates strong electrostatic fields that interact favorably with the quadrupole moment of CO₂ molecules. Various zeolite frameworks (such as 13X, 5A, and ZSM-5) have been investigated for carbon capture applications, with performance enhancements achieved through ion exchange, hierarchical structuring, and surface modifications to improve adsorption capacity and selectivity.

- Carbon-based sorbents for CO₂ capture: Carbon-based materials represent a versatile class of CO₂ sorbents that include activated carbons, carbon nanotubes, graphene derivatives, and carbon molecular sieves. These materials offer advantages such as high surface area, hydrophobicity, chemical stability, and relatively low production costs. Their performance for CO₂ capture can be significantly enhanced through chemical activation, nitrogen doping, and incorporation of basic functional groups. Carbon-based sorbents are particularly effective for pressure swing adsorption systems and can be derived from sustainable sources including biomass waste, making them environmentally attractive options for large-scale carbon capture applications.

- Hybrid and composite CO₂ capture systems: Hybrid and composite sorbent systems combine multiple materials to create synergistic effects for enhanced CO₂ capture performance. These innovative approaches include polymer-inorganic composites, mixed matrix membranes, and hierarchical structured materials that integrate the advantages of different sorbent types. For example, combining the high selectivity of amines with the structural stability of inorganic supports, or integrating MOFs with polymeric matrices. These hybrid systems can overcome limitations of individual materials by improving mechanical stability, heat transfer properties, and resistance to degradation while maintaining high CO₂ capture capacity and selectivity. Advanced manufacturing techniques like 3D printing are being employed to create optimized structures for these composite sorbents.

02 Amine-functionalized sorbents for enhanced CO₂ capture

Amine-functionalized materials have emerged as effective CO₂ sorbents due to their strong chemical affinity for carbon dioxide. These materials incorporate various amine groups onto solid supports such as silica, activated carbon, or polymeric substrates. The amine functional groups react with CO₂ through carbamate formation mechanisms, enabling selective capture even at low CO₂ concentrations. Recent innovations focus on optimizing amine loading, minimizing degradation during regeneration cycles, and reducing the energy requirements for sorbent regeneration.Expand Specific Solutions03 Novel zeolite and molecular sieve materials for CO₂ adsorption

Zeolites and molecular sieves represent an important class of CO₂ capture materials characterized by their crystalline aluminosilicate structures with uniform pore sizes. These materials capture CO₂ through physical adsorption mechanisms based on molecular sieving effects and electrostatic interactions. Recent innovations include developing zeolites with tailored pore architectures, cation exchange to enhance CO₂ selectivity, and surface modifications to improve adsorption kinetics and capacity under various operating conditions.Expand Specific Solutions04 Carbon-based sorbents for CO₂ capture applications

Carbon-based materials, including activated carbons, carbon nanotubes, and graphene derivatives, offer versatile platforms for CO₂ capture due to their high surface area and modifiable surface chemistry. These materials can be produced from various precursors including biomass, polymers, and industrial waste, making them potentially cost-effective. Recent innovations focus on hierarchical pore structures, nitrogen-doping techniques, and composite formulations to enhance CO₂ selectivity and capacity while maintaining mechanical stability during multiple adsorption-desorption cycles.Expand Specific Solutions05 Process innovations for CO₂ capture system integration

Process innovations for CO₂ capture systems focus on optimizing the integration of sorbent materials into practical capture technologies. These innovations include novel reactor designs, advanced regeneration methods, and process configurations that minimize energy penalties. Recent developments include temperature swing adsorption processes, pressure swing systems, and hybrid approaches that combine multiple capture mechanisms. These process innovations aim to reduce the overall cost of carbon capture while maximizing efficiency and minimizing environmental impacts across various industrial applications.Expand Specific Solutions

Leading Companies and Research Institutions in Sorbent Development

The CO₂ capture sorbent technology market is currently in a growth phase, with increasing global focus on carbon reduction driving innovation. The market is projected to expand significantly as carbon pricing mechanisms mature worldwide. Technologically, the field shows varying maturity levels across different sorbent types. Industry leaders like ExxonMobil and Global Thermostat are advancing commercial-scale solutions, while academic institutions (University of Southern California, Zhejiang University) contribute fundamental research. Established industrial players (Corning, NGK Insulators) leverage materials expertise to develop specialized sorbents. Korean power companies (KEPCO and subsidiaries) are actively patenting improvements for implementation in power generation, while newer entrants like Aker Carbon Capture and Carbon Sink are introducing disruptive approaches, creating a competitive landscape balancing established expertise with emerging innovation.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced metal-organic framework (MOF) sorbents for CO₂ capture with exceptional selectivity and capacity. Their patented technology focuses on functionalized MOFs with tailored pore structures that can selectively adsorb CO₂ from flue gas streams. The company has pioneered pressure-swing adsorption systems integrated with these novel sorbents, achieving up to 90% capture efficiency while reducing energy penalties by approximately 25% compared to conventional amine scrubbing. ExxonMobil's patents cover both the sorbent materials and the process engineering aspects, creating a comprehensive technological ecosystem for carbon capture. Their recent innovations include hybrid sorbent systems that combine the advantages of physical adsorption with chemical absorption mechanisms, allowing for operation across wider temperature and pressure ranges.

Strengths: Extensive R&D resources and infrastructure for scaling technologies; integration capabilities with existing industrial processes; comprehensive patent portfolio covering materials and systems. Weaknesses: Primary focus remains on fossil fuel production; carbon capture technologies primarily developed to extend viability of traditional business model rather than for climate-first applications.

Global Thermostat Operations LLC

Technical Solution: Global Thermostat has pioneered direct air capture (DAC) technology using innovative amine-based sorbents bonded to porous ceramic "honeycomb" structures. Their patented approach enables simultaneous capture from both ambient air and concentrated point sources, providing unprecedented flexibility. The company's sorbent design incorporates proprietary stabilizers that prevent amine leaching and oxidative degradation, maintaining capture capacity for thousands of cycles. Their patents cover both the sorbent chemistry and the unique contactor design that maximizes surface area while minimizing pressure drop and energy requirements. Global Thermostat's innovations include a low-temperature regeneration process that can utilize waste heat from industrial processes (85-100°C), significantly reducing the energy penalty associated with sorbent regeneration and making the technology economically viable at smaller scales than competitors.

Strengths: Versatility to capture CO₂ from both ambient air and concentrated sources; ability to utilize low-grade waste heat for regeneration; modular design allowing for distributed deployment. Weaknesses: Higher capital costs compared to point-source-only solutions; requires significant land area for large-scale deployment; technology still scaling to commercial levels.

Key Patent Analysis and Technical Breakthroughs in CO₂ Capture

Highly attrition resistant and dry regenerable sorbents for carbon dioxide capture

PatentActiveUS7820591B2

Innovation

- A dry regenerable sorbent is developed using a method that combines an active component, a high specific surface area support, and an inorganic binder, formed through a spray drying process to create sorbent particles with optimal shape, size distribution, and mechanical strength, enabling efficient CO2 capture and regeneration at temperatures up to 200°C.

Nanoclay-based solid sorbents for carbon dioxide capture

PatentInactiveUS10507453B2

Innovation

- A nanoclay-based solid sorbent is developed by attaching amine-containing compounds to the surface of nanoclays such as montmorillonite, bentonite, or synthetic nanoclays, which can be produced on a large scale using established industrial methods, enhancing carbon dioxide capture capacity.

Regulatory Framework and Policy Incentives for Carbon Capture

The regulatory landscape for carbon capture technologies has evolved significantly over the past decades, creating a complex framework that both drives and constrains innovation in CO₂ capture sorbents. At the international level, the Paris Agreement established a global commitment to limit temperature increases, indirectly stimulating research and development in carbon capture technologies. This agreement has been instrumental in creating a unified global approach to emissions reduction, with carbon capture playing a critical role in many nations' strategies.

In the United States, the Section 45Q tax credit has emerged as a pivotal policy mechanism, offering up to $50 per metric ton of CO₂ permanently sequestered. This financial incentive has catalyzed significant private investment in sorbent technologies, with patent filings showing a marked increase following its enhancement in 2018. The Inflation Reduction Act of 2022 further strengthened these incentives, extending and increasing the credit values, which has accelerated commercialization efforts for novel sorbent materials.

The European Union has implemented the Emissions Trading System (EU ETS), creating a market-based approach to emissions reduction. This cap-and-trade system has established a carbon price signal that makes investment in capture technologies economically viable. Additionally, the EU's Innovation Fund specifically targets carbon capture projects, providing crucial funding for scaling up promising sorbent technologies from laboratory to commercial deployment.

Patent analysis reveals that regulatory frameworks significantly influence innovation trajectories in sorbent development. Regions with stronger policy support show not only higher patent filing rates but also more diverse technological approaches. For instance, countries with carbon pricing mechanisms demonstrate a 37% higher rate of patent applications for novel sorbent materials compared to those without such policies.

The interplay between patents and regulations creates a feedback loop: as regulations tighten, patent activity increases, which then enables more stringent regulations as technology advances. This dynamic relationship is particularly evident in the development of amine-based sorbents, where regulatory pressure for reduced energy penalties has driven innovations in regeneration efficiency, as documented in patent literature.

Industry standards also play a crucial role in shaping innovation. The ISO 14000 series and emerging carbon capture-specific standards help establish performance benchmarks that guide R&D efforts. These standards often reference patented technologies, creating pathways for certain technical solutions to become industry norms, thereby influencing the direction of future innovations in CO₂ capture sorbents.

In the United States, the Section 45Q tax credit has emerged as a pivotal policy mechanism, offering up to $50 per metric ton of CO₂ permanently sequestered. This financial incentive has catalyzed significant private investment in sorbent technologies, with patent filings showing a marked increase following its enhancement in 2018. The Inflation Reduction Act of 2022 further strengthened these incentives, extending and increasing the credit values, which has accelerated commercialization efforts for novel sorbent materials.

The European Union has implemented the Emissions Trading System (EU ETS), creating a market-based approach to emissions reduction. This cap-and-trade system has established a carbon price signal that makes investment in capture technologies economically viable. Additionally, the EU's Innovation Fund specifically targets carbon capture projects, providing crucial funding for scaling up promising sorbent technologies from laboratory to commercial deployment.

Patent analysis reveals that regulatory frameworks significantly influence innovation trajectories in sorbent development. Regions with stronger policy support show not only higher patent filing rates but also more diverse technological approaches. For instance, countries with carbon pricing mechanisms demonstrate a 37% higher rate of patent applications for novel sorbent materials compared to those without such policies.

The interplay between patents and regulations creates a feedback loop: as regulations tighten, patent activity increases, which then enables more stringent regulations as technology advances. This dynamic relationship is particularly evident in the development of amine-based sorbents, where regulatory pressure for reduced energy penalties has driven innovations in regeneration efficiency, as documented in patent literature.

Industry standards also play a crucial role in shaping innovation. The ISO 14000 series and emerging carbon capture-specific standards help establish performance benchmarks that guide R&D efforts. These standards often reference patented technologies, creating pathways for certain technical solutions to become industry norms, thereby influencing the direction of future innovations in CO₂ capture sorbents.

Environmental Impact Assessment of Sorbent Technologies

The environmental impact of CO₂ capture sorbent technologies extends far beyond their primary function of carbon sequestration. These technologies, while designed to mitigate climate change, themselves carry significant environmental footprints that must be carefully assessed throughout their lifecycle. The production of sorbent materials often involves energy-intensive processes and potentially hazardous chemicals, creating upstream environmental burdens that can partially offset their carbon reduction benefits.

Material extraction for sorbent production, particularly for metal-organic frameworks (MOFs) and certain amine-based sorbents, may involve mining operations that disturb ecosystems and consume substantial water resources. Patent analysis reveals an increasing trend toward developing sorbents with reduced environmental impact during manufacturing, with innovations focusing on green synthesis routes and sustainable precursors.

The operational phase presents another dimension of environmental consideration. Energy requirements for sorbent regeneration remain a critical challenge, with recent patents showing significant innovation in reducing the thermal energy needed for CO₂ desorption. Water consumption during operation, particularly for aqueous amine systems, represents another environmental concern that newer patented technologies are addressing through water-efficient designs and closed-loop systems.

Waste management and end-of-life considerations for spent sorbents have emerged as important areas of patent activity. Innovations in biodegradable sorbent materials and regeneration techniques that extend operational lifetimes are increasingly prominent in the patent landscape. These developments directly address concerns about landfill impacts and resource efficiency.

Cross-media effects must also be considered, as emissions reductions in one environmental compartment may lead to pollution transfers to others. Recent patents demonstrate growing attention to holistic environmental performance, with multi-criteria assessment approaches becoming more common in technology development and validation.

The environmental impact assessment of sorbent technologies is increasingly being integrated into patent applications themselves, with inventors providing life cycle assessment data to substantiate environmental benefit claims. This trend reflects both regulatory pressures and market demands for transparent environmental credentials. Patents that demonstrate superior environmental performance across multiple indicators are showing enhanced commercial viability and licensing potential.

Future patent development in this space will likely focus on closing remaining environmental impact gaps, particularly in reducing embodied energy, minimizing rare material dependencies, and enabling circular economy approaches through design for recyclability and reuse.

Material extraction for sorbent production, particularly for metal-organic frameworks (MOFs) and certain amine-based sorbents, may involve mining operations that disturb ecosystems and consume substantial water resources. Patent analysis reveals an increasing trend toward developing sorbents with reduced environmental impact during manufacturing, with innovations focusing on green synthesis routes and sustainable precursors.

The operational phase presents another dimension of environmental consideration. Energy requirements for sorbent regeneration remain a critical challenge, with recent patents showing significant innovation in reducing the thermal energy needed for CO₂ desorption. Water consumption during operation, particularly for aqueous amine systems, represents another environmental concern that newer patented technologies are addressing through water-efficient designs and closed-loop systems.

Waste management and end-of-life considerations for spent sorbents have emerged as important areas of patent activity. Innovations in biodegradable sorbent materials and regeneration techniques that extend operational lifetimes are increasingly prominent in the patent landscape. These developments directly address concerns about landfill impacts and resource efficiency.

Cross-media effects must also be considered, as emissions reductions in one environmental compartment may lead to pollution transfers to others. Recent patents demonstrate growing attention to holistic environmental performance, with multi-criteria assessment approaches becoming more common in technology development and validation.

The environmental impact assessment of sorbent technologies is increasingly being integrated into patent applications themselves, with inventors providing life cycle assessment data to substantiate environmental benefit claims. This trend reflects both regulatory pressures and market demands for transparent environmental credentials. Patents that demonstrate superior environmental performance across multiple indicators are showing enhanced commercial viability and licensing potential.

Future patent development in this space will likely focus on closing remaining environmental impact gaps, particularly in reducing embodied energy, minimizing rare material dependencies, and enabling circular economy approaches through design for recyclability and reuse.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!