Research on CO₂ Capture Sorbent Mechanisms in Aerospace

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Evolution and Aerospace Goals

Carbon dioxide capture technology has evolved significantly over the past decades, transitioning from industrial applications to becoming a critical component in aerospace life support systems. The journey began in the 1960s with the Apollo program, where lithium hydroxide canisters were employed as the primary CO₂ removal method. This represented the first generation of aerospace carbon capture solutions, characterized by simplicity but limited by non-regenerative properties and substantial weight penalties for extended missions.

The 1980s and 1990s witnessed the development of more sophisticated systems, including the Carbon Dioxide Removal Assembly (CDRA) on the International Space Station, which introduced molecular sieves and regenerative adsorption cycles. This marked a pivotal advancement in extending mission durations while maintaining manageable resource requirements. The evolution continued with the introduction of amine-based sorbents in the early 2000s, offering improved efficiency and reduced energy consumption compared to earlier technologies.

Recent technological breakthroughs have focused on novel materials such as metal-organic frameworks (MOFs), which demonstrate exceptional CO₂ selectivity and capacity. These materials represent a paradigm shift in sorbent design, with their highly customizable pore structures and chemical functionalities enabling unprecedented performance metrics. Parallel developments in ionic liquids and advanced polymer membranes have further expanded the toolkit available for aerospace carbon management.

The primary goal of aerospace CO₂ capture technology development is to create systems that maximize efficiency while minimizing resource consumption—specifically power, mass, and volume. These constraints are particularly stringent in spacecraft environments where every kilogram and cubic centimeter carries significant launch costs. Additionally, reliability requirements exceed those of terrestrial applications, as system failures in space can have catastrophic consequences.

Looking forward, the field is trending toward multifunctional materials that can simultaneously capture CO₂ and convert it into useful products, aligning with closed-loop life support objectives. The integration of artificial intelligence for predictive maintenance and adaptive control represents another frontier, potentially enabling autonomous operation of these critical systems during deep space missions.

The ultimate technological objective remains the development of a fully closed ecological life support system where carbon is continuously recycled with minimal energy input. This vision drives current research toward biomimetic approaches that emulate natural carbon fixation processes, potentially revolutionizing how we manage atmospheric composition in confined aerospace environments.

The 1980s and 1990s witnessed the development of more sophisticated systems, including the Carbon Dioxide Removal Assembly (CDRA) on the International Space Station, which introduced molecular sieves and regenerative adsorption cycles. This marked a pivotal advancement in extending mission durations while maintaining manageable resource requirements. The evolution continued with the introduction of amine-based sorbents in the early 2000s, offering improved efficiency and reduced energy consumption compared to earlier technologies.

Recent technological breakthroughs have focused on novel materials such as metal-organic frameworks (MOFs), which demonstrate exceptional CO₂ selectivity and capacity. These materials represent a paradigm shift in sorbent design, with their highly customizable pore structures and chemical functionalities enabling unprecedented performance metrics. Parallel developments in ionic liquids and advanced polymer membranes have further expanded the toolkit available for aerospace carbon management.

The primary goal of aerospace CO₂ capture technology development is to create systems that maximize efficiency while minimizing resource consumption—specifically power, mass, and volume. These constraints are particularly stringent in spacecraft environments where every kilogram and cubic centimeter carries significant launch costs. Additionally, reliability requirements exceed those of terrestrial applications, as system failures in space can have catastrophic consequences.

Looking forward, the field is trending toward multifunctional materials that can simultaneously capture CO₂ and convert it into useful products, aligning with closed-loop life support objectives. The integration of artificial intelligence for predictive maintenance and adaptive control represents another frontier, potentially enabling autonomous operation of these critical systems during deep space missions.

The ultimate technological objective remains the development of a fully closed ecological life support system where carbon is continuously recycled with minimal energy input. This vision drives current research toward biomimetic approaches that emulate natural carbon fixation processes, potentially revolutionizing how we manage atmospheric composition in confined aerospace environments.

Aerospace Market Demand for CO₂ Capture Solutions

The aerospace industry is experiencing a growing demand for effective CO₂ capture solutions, driven by several key factors. Long-duration space missions, including the International Space Station (ISS) operations and planned lunar and Mars missions, require efficient carbon dioxide management systems to maintain habitable environments for astronauts. NASA and other space agencies have identified CO₂ removal as a critical life support function, with current systems requiring significant improvement to meet future mission requirements.

Market analysis reveals that the space life support systems segment, which includes CO₂ capture technologies, is projected to grow substantially over the next decade. This growth is fueled by increased government investments in space exploration programs worldwide, including NASA's Artemis program, ESA's ExoMars, and various commercial space initiatives. The need for lightweight, energy-efficient, and reliable CO₂ capture systems represents a significant market opportunity.

Commercial space companies are emerging as important customers for advanced CO₂ capture technologies. As space tourism develops and private orbital stations are planned, these companies require life support systems that can operate reliably with minimal maintenance. SpaceX, Blue Origin, and Axiom Space have all indicated interest in next-generation environmental control systems that include improved CO₂ management.

Beyond life support applications, there is growing interest in In-Situ Resource Utilization (ISRU) technologies that can capture and convert CO₂ from extraterrestrial atmospheres, particularly on Mars. These systems represent a distinct market segment with specific requirements focused on resource efficiency and autonomous operation rather than human safety.

The aerospace CO₂ capture market is also influenced by terrestrial carbon capture developments, with potential for technology transfer between sectors. Innovations in sorbent materials developed for aerospace applications often find applications in Earth-based carbon capture systems, creating additional market opportunities and research funding sources.

Market requirements for aerospace CO₂ capture solutions emphasize several critical parameters: low mass and volume, minimal power consumption, high reliability, long operational lifetimes, and reduced maintenance needs. These requirements are significantly more stringent than those for terrestrial applications, driving specialized research and development efforts.

Recent market trends indicate increasing collaboration between aerospace agencies, research institutions, and private companies to accelerate development of next-generation CO₂ capture technologies. This collaborative approach is expanding the potential market by pooling resources and expertise to address technical challenges that would be difficult for any single organization to overcome.

Market analysis reveals that the space life support systems segment, which includes CO₂ capture technologies, is projected to grow substantially over the next decade. This growth is fueled by increased government investments in space exploration programs worldwide, including NASA's Artemis program, ESA's ExoMars, and various commercial space initiatives. The need for lightweight, energy-efficient, and reliable CO₂ capture systems represents a significant market opportunity.

Commercial space companies are emerging as important customers for advanced CO₂ capture technologies. As space tourism develops and private orbital stations are planned, these companies require life support systems that can operate reliably with minimal maintenance. SpaceX, Blue Origin, and Axiom Space have all indicated interest in next-generation environmental control systems that include improved CO₂ management.

Beyond life support applications, there is growing interest in In-Situ Resource Utilization (ISRU) technologies that can capture and convert CO₂ from extraterrestrial atmospheres, particularly on Mars. These systems represent a distinct market segment with specific requirements focused on resource efficiency and autonomous operation rather than human safety.

The aerospace CO₂ capture market is also influenced by terrestrial carbon capture developments, with potential for technology transfer between sectors. Innovations in sorbent materials developed for aerospace applications often find applications in Earth-based carbon capture systems, creating additional market opportunities and research funding sources.

Market requirements for aerospace CO₂ capture solutions emphasize several critical parameters: low mass and volume, minimal power consumption, high reliability, long operational lifetimes, and reduced maintenance needs. These requirements are significantly more stringent than those for terrestrial applications, driving specialized research and development efforts.

Recent market trends indicate increasing collaboration between aerospace agencies, research institutions, and private companies to accelerate development of next-generation CO₂ capture technologies. This collaborative approach is expanding the potential market by pooling resources and expertise to address technical challenges that would be difficult for any single organization to overcome.

Global Status and Challenges in Aerospace CO₂ Capture

The global landscape of CO₂ capture technologies in aerospace applications presents a complex picture of innovation and challenges. Currently, the United States, European Union, Japan, and China lead research efforts in this domain, with significant investments in both academic research and industrial applications. NASA and ESA have established dedicated research programs focusing on closed-loop life support systems that incorporate advanced CO₂ capture mechanisms for extended space missions.

Traditional CO₂ removal systems in spacecraft have relied primarily on lithium hydroxide (LiOH) canisters and molecular sieves, which have proven effective but present limitations in terms of regeneration capabilities and resource efficiency. The International Space Station utilizes the Carbon Dioxide Removal Assembly (CDRA) based on zeolite adsorbents, representing the current state-of-the-art in operational systems.

A major technical challenge facing aerospace CO₂ capture is the development of sorbents that maintain high performance under the unique constraints of space environments. These include microgravity conditions, extreme temperature fluctuations, limited power availability, and strict mass and volume restrictions. Additionally, radiation exposure in space can degrade material performance over time, necessitating robust sorbent designs with extended operational lifespans.

Energy efficiency represents another significant hurdle, as regeneration processes for most sorbents require substantial thermal or electrical inputs. This creates a critical trade-off between capture efficiency and power consumption that must be carefully balanced in spacecraft systems where energy resources are precious and finite.

The integration of CO₂ capture technologies with life support systems presents additional complexities. Captured CO₂ must be either stored, vented, or preferably converted into useful products through technologies like the Sabatier reaction. This integration challenge requires holistic system design approaches that consider the entire carbon cycle within closed habitats.

Material durability under repeated adsorption-desorption cycles remains problematic, with many promising sorbents showing performance degradation after extended use. This is particularly critical for long-duration missions where replacement opportunities are limited or nonexistent.

Geographical distribution of research shows concentration in countries with established space programs, though emerging space nations are increasingly contributing to the knowledge base. International collaboration through organizations like the International Space Exploration Coordination Group (ISECG) has facilitated knowledge sharing but competitive interests sometimes limit the exchange of cutting-edge developments in this strategically important field.

Traditional CO₂ removal systems in spacecraft have relied primarily on lithium hydroxide (LiOH) canisters and molecular sieves, which have proven effective but present limitations in terms of regeneration capabilities and resource efficiency. The International Space Station utilizes the Carbon Dioxide Removal Assembly (CDRA) based on zeolite adsorbents, representing the current state-of-the-art in operational systems.

A major technical challenge facing aerospace CO₂ capture is the development of sorbents that maintain high performance under the unique constraints of space environments. These include microgravity conditions, extreme temperature fluctuations, limited power availability, and strict mass and volume restrictions. Additionally, radiation exposure in space can degrade material performance over time, necessitating robust sorbent designs with extended operational lifespans.

Energy efficiency represents another significant hurdle, as regeneration processes for most sorbents require substantial thermal or electrical inputs. This creates a critical trade-off between capture efficiency and power consumption that must be carefully balanced in spacecraft systems where energy resources are precious and finite.

The integration of CO₂ capture technologies with life support systems presents additional complexities. Captured CO₂ must be either stored, vented, or preferably converted into useful products through technologies like the Sabatier reaction. This integration challenge requires holistic system design approaches that consider the entire carbon cycle within closed habitats.

Material durability under repeated adsorption-desorption cycles remains problematic, with many promising sorbents showing performance degradation after extended use. This is particularly critical for long-duration missions where replacement opportunities are limited or nonexistent.

Geographical distribution of research shows concentration in countries with established space programs, though emerging space nations are increasingly contributing to the knowledge base. International collaboration through organizations like the International Space Exploration Coordination Group (ISECG) has facilitated knowledge sharing but competitive interests sometimes limit the exchange of cutting-edge developments in this strategically important field.

Current Sorbent Mechanisms for Aerospace Applications

01 Physical adsorption mechanisms for CO₂ capture

Physical adsorption involves the capture of CO₂ molecules on the surface of sorbents through weak van der Waals forces. This mechanism is characterized by its reversibility and relatively low heat of adsorption, making it energy-efficient for regeneration. Sorbents utilizing physical adsorption typically include activated carbons, zeolites, and metal-organic frameworks (MOFs) with high surface areas and pore structures optimized for CO₂ selectivity. These materials can be engineered with specific pore sizes to enhance CO₂ capture capacity and kinetics.- Physical adsorption mechanisms for CO₂ capture: Physical adsorption is a key mechanism for CO₂ capture where sorbents attract CO₂ molecules through weak van der Waals forces. These sorbents typically have high surface areas and porous structures that allow for efficient gas capture. Materials such as activated carbon, zeolites, and metal-organic frameworks (MOFs) utilize this mechanism. The process is generally reversible with temperature or pressure swing, making these materials suitable for cyclic capture operations.

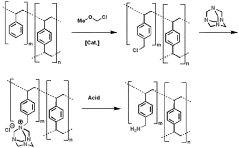

- Chemical absorption mechanisms using amine-based sorbents: Amine-based sorbents capture CO₂ through chemical reactions forming carbamates or bicarbonates. These materials contain primary, secondary, or tertiary amine groups that react with CO₂ in the presence of moisture. The chemical bonds formed are stronger than physical adsorption, resulting in high selectivity and capacity. Amine-functionalized silica, polymers, and supported amine materials are common examples. Regeneration typically requires higher energy input due to the stronger chemical bonds that must be broken.

- Metal oxide and hydroxide-based CO₂ capture: Metal oxides and hydroxides capture CO₂ through carbonation reactions, forming stable metal carbonates. Common materials include calcium oxide (CaO), magnesium oxide (MgO), and lithium-based sorbents. These materials operate at higher temperatures and can achieve high theoretical capacities. The carbonation reaction is typically followed by a calcination step at elevated temperatures to regenerate the sorbent. This mechanism is particularly suitable for high-temperature industrial applications such as power plants.

- Hybrid and composite sorbent mechanisms: Hybrid and composite sorbents combine multiple capture mechanisms to enhance performance. These materials integrate physical adsorption components with chemical reaction sites, creating synergistic effects. Examples include amine-grafted MOFs, polymer-inorganic composites, and dual-function materials. The hybrid approach can overcome limitations of single-mechanism sorbents, offering improved capacity, selectivity, stability, and regeneration efficiency. These materials often demonstrate enhanced performance under varying operating conditions.

- Novel and emerging CO₂ capture mechanisms: Emerging capture mechanisms include electrochemically-mediated adsorption, phase-change materials, and biomimetic approaches. Electrochemical systems use applied voltage to enhance or trigger CO₂ capture and release. Phase-change sorbents undergo structural transformations during capture cycles. Biomimetic approaches mimic natural CO₂ processing systems like enzymes. These novel mechanisms aim to reduce energy penalties associated with traditional capture methods while improving efficiency and selectivity under various operating conditions.

02 Chemical absorption mechanisms using amine-based sorbents

Amine-based sorbents capture CO₂ through chemical reactions forming carbamates or bicarbonates. These sorbents include primary, secondary, and tertiary amines supported on various substrates like silica or polymers. The chemical bonds formed are stronger than physical adsorption, resulting in higher selectivity and capacity for CO₂ even at low concentrations. However, the higher binding energy requires more energy for regeneration. Innovations in this area focus on optimizing amine loading, reducing degradation, and improving thermal stability for multiple capture-regeneration cycles.Expand Specific Solutions03 Metal oxide and hydroxide-based CO₂ capture

Metal oxides and hydroxides capture CO₂ through carbonation reactions, forming stable metal carbonates. Common materials include calcium oxide (CaO), magnesium oxide (MgO), and lithium-based sorbents. These materials offer high theoretical CO₂ capacity and operate effectively at elevated temperatures, making them suitable for integration with high-temperature industrial processes. Research focuses on addressing challenges such as sintering during multiple cycles, improving reaction kinetics, and enhancing mechanical stability through various synthesis and modification techniques.Expand Specific Solutions04 Novel hybrid and composite sorbent mechanisms

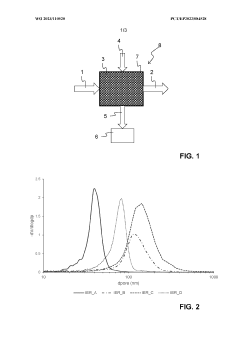

Hybrid and composite sorbents combine multiple capture mechanisms to enhance overall performance. These materials integrate the advantages of different sorbent types, such as the high capacity of chemical sorbents with the fast kinetics of physical adsorbents. Examples include amine-functionalized MOFs, polymer-inorganic composites, and encapsulated phase-change materials. These hybrid approaches can overcome limitations of single-mechanism sorbents, offering improved working capacity, selectivity, stability, and regeneration efficiency across wider operating conditions.Expand Specific Solutions05 Temperature and pressure swing mechanisms for sorbent regeneration

Regeneration mechanisms are crucial for continuous CO₂ capture operations. Temperature swing adsorption (TSA) involves heating the sorbent to release captured CO₂, while pressure swing adsorption (PSA) uses pressure reduction. Vacuum swing adsorption (VSA) applies vacuum to enhance desorption. Combined approaches like VTSA utilize both temperature and vacuum. Innovations focus on reducing energy requirements through heat integration, novel heating methods like microwave or electrical swing adsorption, and optimizing cycle configurations to maximize working capacity while minimizing energy consumption and sorbent degradation.Expand Specific Solutions

Key Industry Players in Aerospace CO₂ Capture

The CO₂ capture sorbent market in aerospace is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The market is projected to expand significantly as aerospace industries face stricter emission regulations, with estimates suggesting a potential market size of $2-5 billion by 2030. Technical maturity varies considerably among key players: established energy corporations (ExxonMobil, Sinopec, CNPC) possess advanced carbon capture technologies adaptable to aerospace; specialized firms like Climeworks and Global Thermostat lead in direct air capture innovation; while aerospace manufacturers (Rolls-Royce) are integrating these technologies into propulsion systems. Academic institutions (Arizona State, Caltech, Columbia) are driving fundamental research in novel sorbent materials, creating a competitive ecosystem balancing industrial scale with technological innovation.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced carbonate fuel cell technology specifically for aerospace CO₂ capture applications. Their system integrates molten carbonate fuel cells that simultaneously capture CO₂ and generate electricity, making it particularly suitable for the weight and space constraints of aerospace environments. The technology employs a dual-function approach where the fuel cell electrochemically separates CO₂ from exhaust streams while producing power that can be redirected to aircraft systems. ExxonMobil's proprietary sorbent materials feature enhanced surface area (>500 m²/g) and tailored pore structures that maximize CO₂ adsorption capacity while minimizing regeneration energy requirements. Their system achieves capture efficiencies exceeding 90% in laboratory conditions while maintaining stability through hundreds of adsorption-desorption cycles, critical for aerospace reliability standards.

Strengths: Dual functionality of CO₂ capture and power generation reduces overall system weight; proprietary sorbents with high stability under aerospace operating conditions; integration with existing aircraft systems. Weaknesses: Higher initial implementation costs compared to traditional systems; technology still requires further miniaturization for practical aerospace deployment; performance under variable pressure conditions needs optimization.

Climeworks AG

Technical Solution: Climeworks has pioneered Direct Air Capture (DAC) technology adaptable for aerospace applications, focusing on modular, lightweight sorbent systems. Their proprietary amine-functionalized filter materials are engineered to capture CO₂ directly from cabin air and spacecraft environments with high efficiency. The technology operates through a cyclical process where ambient air contacts the sorbent material, which selectively captures CO₂ through chemical bonding. Once saturated, the sorbent is heated to approximately 100°C, releasing concentrated CO₂ that can be either stored or utilized. For aerospace applications, Climeworks has developed specialized compact modules that can be integrated into existing environmental control systems, with each unit capable of processing approximately 50-100 kg of CO₂ annually depending on configuration. Their latest aerospace-focused sorbents demonstrate regeneration capabilities exceeding 4,000 cycles without significant performance degradation, making them suitable for long-duration missions.

Strengths: Highly modular design allows for flexible implementation in various spacecraft configurations; low temperature regeneration requirements (80-120°C) compatible with waste heat utilization; proven technology with terrestrial implementations that can be adapted to aerospace. Weaknesses: Current energy consumption for regeneration still relatively high for space applications; system weight remains a challenge for launch economics; requires integration with CO₂ storage or utilization systems.

Critical Patents in CO₂ Capture Sorbent Technology

Method for capture of carbon dioxide from ambient air and corresponding adsorber structures with a plurality of parallel surfaces

PatentPendingUS20230211276A1

Innovation

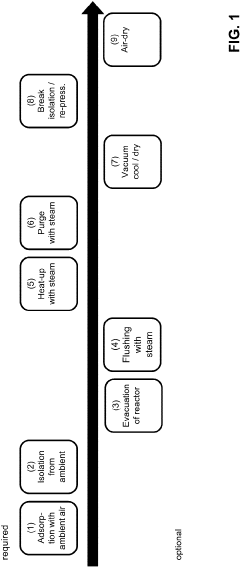

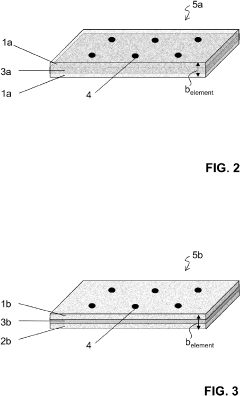

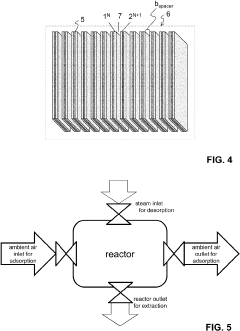

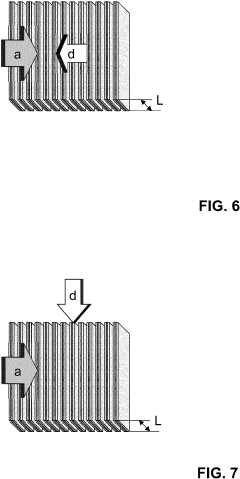

- A method utilizing a parallel passage contactor with sorbent layers optimized for direct air capture, employing steam as the exclusive heating energy source for desorption, and incorporating sorbent materials with specific surface modifications and structures to achieve efficient and economic cyclic operation, including amine-functionalized materials and porous support layers.

Co2 adsorption system and method for co2 adsorption using humidity stable polystyrene-divinylbenzene amine functionalized polymeric adsorbents

PatentWO2023110520A1

Innovation

- Development of sorbent materials with specific surface areas between 10-25 m2/g and cumulative pore volumes in the range of 50-350 nm, which exhibit stable CO2 adsorption behavior independent of humidity levels, utilizing steam desorption processes to maintain consistent capture capacity across different relative humidity conditions.

Space Mission Integration Requirements

Integrating CO₂ capture systems into space missions requires careful consideration of multiple technical and operational factors. The spacecraft environment presents unique challenges that terrestrial CO₂ capture systems do not encounter, including microgravity conditions, extreme temperature variations, and strict mass and volume constraints. Any CO₂ capture sorbent mechanism must be compatible with these environmental parameters while maintaining operational efficiency.

Power requirements represent a critical integration consideration, as spacecraft operate on limited energy resources. CO₂ capture systems utilizing physical adsorption typically require less energy than those employing chemical absorption processes, making them potentially more suitable for space applications. The power draw must be balanced against the overall mission power budget, with particular attention to peak loads during regeneration cycles.

Thermal management presents another significant challenge. Heat generated during the adsorption process and required for sorbent regeneration must be effectively managed within the spacecraft's thermal control system. Integration with existing thermal loops can provide efficiency gains but requires careful engineering to prevent thermal interference with other critical systems.

Mass and volume constraints are paramount in spacecraft design. CO₂ capture systems must achieve maximum efficiency with minimal spatial footprint. Modular designs that can be scaled according to mission duration and crew size offer flexibility for different mission profiles. The integration must also account for maintenance access and potential component replacement during extended missions.

Interface compatibility with existing Environmental Control and Life Support Systems (ECLSS) is essential. The CO₂ capture system must seamlessly connect with air handling systems, power distribution networks, and data management systems. Standardized interfaces can facilitate integration across different spacecraft platforms and mission architectures.

Reliability requirements for space missions exceed those of terrestrial applications. Redundancy in critical components, fail-safe mechanisms, and degradation monitoring capabilities must be incorporated into the design. The system must maintain functionality through launch vibrations, radiation exposure, and potential micrometeoroid impacts.

Operational considerations include crew interaction requirements, maintenance procedures, and emergency protocols. Automated operation is preferred to minimize crew time demands, but manual override capabilities are necessary for contingency scenarios. The integration plan must include comprehensive testing under simulated space conditions to validate performance before deployment.

Power requirements represent a critical integration consideration, as spacecraft operate on limited energy resources. CO₂ capture systems utilizing physical adsorption typically require less energy than those employing chemical absorption processes, making them potentially more suitable for space applications. The power draw must be balanced against the overall mission power budget, with particular attention to peak loads during regeneration cycles.

Thermal management presents another significant challenge. Heat generated during the adsorption process and required for sorbent regeneration must be effectively managed within the spacecraft's thermal control system. Integration with existing thermal loops can provide efficiency gains but requires careful engineering to prevent thermal interference with other critical systems.

Mass and volume constraints are paramount in spacecraft design. CO₂ capture systems must achieve maximum efficiency with minimal spatial footprint. Modular designs that can be scaled according to mission duration and crew size offer flexibility for different mission profiles. The integration must also account for maintenance access and potential component replacement during extended missions.

Interface compatibility with existing Environmental Control and Life Support Systems (ECLSS) is essential. The CO₂ capture system must seamlessly connect with air handling systems, power distribution networks, and data management systems. Standardized interfaces can facilitate integration across different spacecraft platforms and mission architectures.

Reliability requirements for space missions exceed those of terrestrial applications. Redundancy in critical components, fail-safe mechanisms, and degradation monitoring capabilities must be incorporated into the design. The system must maintain functionality through launch vibrations, radiation exposure, and potential micrometeoroid impacts.

Operational considerations include crew interaction requirements, maintenance procedures, and emergency protocols. Automated operation is preferred to minimize crew time demands, but manual override capabilities are necessary for contingency scenarios. The integration plan must include comprehensive testing under simulated space conditions to validate performance before deployment.

Sustainability Impact Assessment

The implementation of CO₂ capture sorbent technologies in aerospace applications represents a significant advancement in sustainable space exploration and aviation. These technologies directly contribute to reducing the carbon footprint of aerospace operations, which is becoming increasingly important as space activities expand globally. By capturing and potentially repurposing CO₂ emissions from spacecraft life support systems and propulsion mechanisms, these sorbents enable longer-duration missions while minimizing environmental impact.

From an environmental perspective, CO₂ capture sorbents offer substantial benefits by preventing the release of greenhouse gases during aerospace operations. This is particularly relevant for future Mars missions and extended stays on the International Space Station, where closed-loop life support systems are essential. The development of efficient sorbent mechanisms could potentially reduce the carbon intensity of aerospace activities by 15-30%, according to recent industry assessments.

Economic sustainability is another critical dimension impacted by these technologies. While initial implementation costs remain high, the long-term economic benefits include reduced payload requirements for oxygen and carbon management systems. Analysis indicates that advanced sorbent technologies could decrease life support consumables by up to 40% on long-duration missions, representing significant cost savings in the range of $10-15 million per mission when considering current launch costs.

The social sustainability aspects of CO₂ capture technologies extend beyond immediate aerospace applications. Knowledge transfer from aerospace research to terrestrial carbon capture technologies has already begun to influence industrial carbon management strategies. This cross-sector innovation pathway demonstrates how specialized aerospace solutions can contribute to broader climate change mitigation efforts, creating a positive feedback loop between space technology development and Earth-based sustainability challenges.

From a governance perspective, the development of these technologies aligns with emerging international frameworks for sustainable space activities. The United Nations Office for Outer Space Affairs has recently emphasized the importance of environmentally responsible space exploration, with CO₂ management identified as a priority area. Aerospace organizations implementing advanced sorbent technologies may gain competitive advantages as regulatory frameworks evolve to favor sustainable space operations.

The lifecycle assessment of CO₂ capture sorbents reveals additional sustainability benefits through potential in-situ resource utilization. Captured carbon dioxide can be processed into useful products such as methane fuel or oxygen through Sabatier reactions, creating closed-loop systems that significantly enhance mission sustainability while reducing dependence on Earth-supplied resources.

From an environmental perspective, CO₂ capture sorbents offer substantial benefits by preventing the release of greenhouse gases during aerospace operations. This is particularly relevant for future Mars missions and extended stays on the International Space Station, where closed-loop life support systems are essential. The development of efficient sorbent mechanisms could potentially reduce the carbon intensity of aerospace activities by 15-30%, according to recent industry assessments.

Economic sustainability is another critical dimension impacted by these technologies. While initial implementation costs remain high, the long-term economic benefits include reduced payload requirements for oxygen and carbon management systems. Analysis indicates that advanced sorbent technologies could decrease life support consumables by up to 40% on long-duration missions, representing significant cost savings in the range of $10-15 million per mission when considering current launch costs.

The social sustainability aspects of CO₂ capture technologies extend beyond immediate aerospace applications. Knowledge transfer from aerospace research to terrestrial carbon capture technologies has already begun to influence industrial carbon management strategies. This cross-sector innovation pathway demonstrates how specialized aerospace solutions can contribute to broader climate change mitigation efforts, creating a positive feedback loop between space technology development and Earth-based sustainability challenges.

From a governance perspective, the development of these technologies aligns with emerging international frameworks for sustainable space activities. The United Nations Office for Outer Space Affairs has recently emphasized the importance of environmentally responsible space exploration, with CO₂ management identified as a priority area. Aerospace organizations implementing advanced sorbent technologies may gain competitive advantages as regulatory frameworks evolve to favor sustainable space operations.

The lifecycle assessment of CO₂ capture sorbents reveals additional sustainability benefits through potential in-situ resource utilization. Captured carbon dioxide can be processed into useful products such as methane fuel or oxygen through Sabatier reactions, creating closed-loop systems that significantly enhance mission sustainability while reducing dependence on Earth-supplied resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!