Why CO₂ Capture Sorbent Enhances Battery Performance

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Capture Sorbent in Battery Technology: Background and Objectives

Carbon dioxide (CO₂) capture technology has evolved significantly over the past decades, initially developed to address environmental concerns related to greenhouse gas emissions. The primary focus was on reducing carbon footprints in industrial processes, particularly in power generation and manufacturing sectors. However, recent research has revealed unexpected synergies between CO₂ capture materials and energy storage technologies, specifically in battery applications, representing a fascinating convergence of environmental science and energy technology.

The evolution of CO₂ capture sorbents has progressed from simple chemical absorption using aqueous amines to advanced solid sorbents with highly engineered porous structures. These materials, designed to efficiently trap carbon dioxide molecules, possess unique physical and chemical properties that researchers have discovered can significantly enhance battery performance when integrated into electrode designs or electrolyte formulations.

This technological crossover emerged around 2015-2018, when researchers investigating metal-organic frameworks (MOFs) and other porous materials for carbon capture noticed improvements in electrochemical properties when these materials were incorporated into battery components. The field has since expanded rapidly, with publications increasing exponentially between 2019 and 2023.

The primary objective of this technological integration is to leverage the inherent properties of CO₂ capture sorbents—such as high surface area, controlled porosity, and specific chemical functionalities—to address persistent challenges in battery technology. These challenges include limited energy density, poor cycle life, safety concerns, and performance degradation under extreme conditions.

Specifically, researchers aim to utilize these sorbents to enhance ion transport, stabilize electrode-electrolyte interfaces, mitigate dendrite formation in metal batteries, and improve overall electrochemical stability. The ultimate goal is to develop next-generation batteries with higher energy density, faster charging capabilities, longer lifespans, and improved safety profiles.

This technological convergence also presents an opportunity for sustainability in battery manufacturing. By repurposing or dual-purposing carbon capture materials, the battery industry could potentially reduce its environmental footprint while simultaneously improving performance metrics—a rare win-win scenario in technological development.

Current research targets include lithium-sulfur batteries, sodium-ion systems, and advanced lithium-ion configurations, where CO₂ capture sorbents have shown particular promise in addressing specific performance limitations. The field represents a paradigm shift in how we conceptualize materials design for energy storage, moving toward multi-functional components that serve both electrochemical and environmental functions.

The evolution of CO₂ capture sorbents has progressed from simple chemical absorption using aqueous amines to advanced solid sorbents with highly engineered porous structures. These materials, designed to efficiently trap carbon dioxide molecules, possess unique physical and chemical properties that researchers have discovered can significantly enhance battery performance when integrated into electrode designs or electrolyte formulations.

This technological crossover emerged around 2015-2018, when researchers investigating metal-organic frameworks (MOFs) and other porous materials for carbon capture noticed improvements in electrochemical properties when these materials were incorporated into battery components. The field has since expanded rapidly, with publications increasing exponentially between 2019 and 2023.

The primary objective of this technological integration is to leverage the inherent properties of CO₂ capture sorbents—such as high surface area, controlled porosity, and specific chemical functionalities—to address persistent challenges in battery technology. These challenges include limited energy density, poor cycle life, safety concerns, and performance degradation under extreme conditions.

Specifically, researchers aim to utilize these sorbents to enhance ion transport, stabilize electrode-electrolyte interfaces, mitigate dendrite formation in metal batteries, and improve overall electrochemical stability. The ultimate goal is to develop next-generation batteries with higher energy density, faster charging capabilities, longer lifespans, and improved safety profiles.

This technological convergence also presents an opportunity for sustainability in battery manufacturing. By repurposing or dual-purposing carbon capture materials, the battery industry could potentially reduce its environmental footprint while simultaneously improving performance metrics—a rare win-win scenario in technological development.

Current research targets include lithium-sulfur batteries, sodium-ion systems, and advanced lithium-ion configurations, where CO₂ capture sorbents have shown particular promise in addressing specific performance limitations. The field represents a paradigm shift in how we conceptualize materials design for energy storage, moving toward multi-functional components that serve both electrochemical and environmental functions.

Market Analysis for Enhanced Battery Performance Solutions

The global market for enhanced battery performance solutions is experiencing unprecedented growth, driven by the increasing demand for high-performance energy storage systems across multiple sectors. The integration of CO₂ capture sorbents into battery technology represents a significant innovation with substantial market potential. Current market valuations place the advanced battery materials sector at approximately $8.6 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030.

Consumer electronics continues to be the largest application segment, accounting for roughly 38% of the market share. However, electric vehicles (EVs) represent the fastest-growing segment, with demand for enhanced battery solutions increasing at nearly 18% annually. This growth is primarily fueled by stringent environmental regulations, government incentives for clean energy adoption, and consumer preference shifts toward sustainable transportation options.

Regionally, Asia-Pacific dominates the market landscape, holding approximately 45% of the global market share, with China, Japan, and South Korea serving as manufacturing hubs. North America and Europe follow with 28% and 22% market shares respectively, with both regions showing accelerated growth due to aggressive clean energy policies and substantial investments in battery research and development.

The CO₂ capture sorbent-enhanced battery segment, while currently representing a niche market estimated at $340 million, is projected to grow at an impressive 24% CAGR over the next five years. This growth trajectory is supported by the dual benefits these solutions offer: improved battery performance and carbon capture capabilities, aligning perfectly with global sustainability goals.

Key market drivers include the increasing energy density requirements for next-generation devices, the push for longer EV ranges, and the growing emphasis on sustainable manufacturing processes. Additionally, regulatory frameworks promoting carbon neutrality across industries are creating favorable market conditions for technologies that offer carbon capture functionalities alongside their primary applications.

Market challenges include high initial research and development costs, scaling manufacturing processes, and competition from alternative battery enhancement technologies. However, the unique value proposition of CO₂ capture sorbent technology—offering both performance improvements and environmental benefits—provides significant competitive advantages in an increasingly eco-conscious market.

Customer willingness to pay premiums for environmentally beneficial technologies has been demonstrated across multiple sectors, with surveys indicating that 67% of industrial battery users would consider paying 15-20% more for solutions that offer carbon capture capabilities alongside performance enhancements.

Consumer electronics continues to be the largest application segment, accounting for roughly 38% of the market share. However, electric vehicles (EVs) represent the fastest-growing segment, with demand for enhanced battery solutions increasing at nearly 18% annually. This growth is primarily fueled by stringent environmental regulations, government incentives for clean energy adoption, and consumer preference shifts toward sustainable transportation options.

Regionally, Asia-Pacific dominates the market landscape, holding approximately 45% of the global market share, with China, Japan, and South Korea serving as manufacturing hubs. North America and Europe follow with 28% and 22% market shares respectively, with both regions showing accelerated growth due to aggressive clean energy policies and substantial investments in battery research and development.

The CO₂ capture sorbent-enhanced battery segment, while currently representing a niche market estimated at $340 million, is projected to grow at an impressive 24% CAGR over the next five years. This growth trajectory is supported by the dual benefits these solutions offer: improved battery performance and carbon capture capabilities, aligning perfectly with global sustainability goals.

Key market drivers include the increasing energy density requirements for next-generation devices, the push for longer EV ranges, and the growing emphasis on sustainable manufacturing processes. Additionally, regulatory frameworks promoting carbon neutrality across industries are creating favorable market conditions for technologies that offer carbon capture functionalities alongside their primary applications.

Market challenges include high initial research and development costs, scaling manufacturing processes, and competition from alternative battery enhancement technologies. However, the unique value proposition of CO₂ capture sorbent technology—offering both performance improvements and environmental benefits—provides significant competitive advantages in an increasingly eco-conscious market.

Customer willingness to pay premiums for environmentally beneficial technologies has been demonstrated across multiple sectors, with surveys indicating that 67% of industrial battery users would consider paying 15-20% more for solutions that offer carbon capture capabilities alongside performance enhancements.

Current Status and Challenges in CO2 Sorbent Battery Integration

The integration of CO₂ capture sorbents into battery systems represents a significant technological convergence that is gaining momentum in both research and industrial applications. Currently, several leading research institutions and companies are exploring this integration, with notable progress in lithium-sulfur, lithium-air, and certain metal-ion battery configurations. The primary mechanism involves utilizing CO₂ sorbent materials, particularly metal-organic frameworks (MOFs), porous carbons, and amine-functionalized materials, as functional components within battery architectures.

Despite promising advancements, this field faces substantial technical challenges. The stability of CO₂ sorbents under electrochemical conditions remains problematic, with many materials exhibiting degradation after repeated charge-discharge cycles. This degradation manifests as reduced CO₂ capture capacity and diminished electrochemical performance. Additionally, the interface between sorbent materials and traditional battery components often suffers from compatibility issues, leading to increased internal resistance and reduced energy efficiency.

Another significant challenge lies in balancing the dual functionality of these materials. Optimizing for CO₂ capture often compromises electrochemical performance, and vice versa. This trade-off necessitates careful material design and engineering approaches that can simultaneously address both requirements without significant compromises to either function.

Scale-up and manufacturing challenges also present substantial barriers to commercialization. Current synthesis methods for high-performance CO₂ sorbents typically involve complex procedures that are difficult to scale economically. The integration of these materials into existing battery manufacturing processes requires substantial modification of production lines, presenting both technical and economic hurdles.

From a geographical perspective, research in this field shows interesting distribution patterns. North American institutions lead in fundamental research and patent filings, while Asian manufacturers, particularly in China, Japan, and South Korea, demonstrate advantages in scaling production technologies. European research centers focus predominantly on sustainable aspects and circular economy applications of these technologies.

Recent technical literature indicates emerging solutions to these challenges, including the development of composite materials that offer improved stability, novel electrode architectures that enhance both CO₂ capture and ion transport, and innovative electrolyte formulations that mitigate degradation mechanisms. However, these solutions remain largely at laboratory scale, with significant work required before commercial viability can be achieved.

The regulatory landscape adds another layer of complexity, with evolving standards for both battery performance and carbon capture technologies creating uncertainty for technology developers and potential adopters.

Despite promising advancements, this field faces substantial technical challenges. The stability of CO₂ sorbents under electrochemical conditions remains problematic, with many materials exhibiting degradation after repeated charge-discharge cycles. This degradation manifests as reduced CO₂ capture capacity and diminished electrochemical performance. Additionally, the interface between sorbent materials and traditional battery components often suffers from compatibility issues, leading to increased internal resistance and reduced energy efficiency.

Another significant challenge lies in balancing the dual functionality of these materials. Optimizing for CO₂ capture often compromises electrochemical performance, and vice versa. This trade-off necessitates careful material design and engineering approaches that can simultaneously address both requirements without significant compromises to either function.

Scale-up and manufacturing challenges also present substantial barriers to commercialization. Current synthesis methods for high-performance CO₂ sorbents typically involve complex procedures that are difficult to scale economically. The integration of these materials into existing battery manufacturing processes requires substantial modification of production lines, presenting both technical and economic hurdles.

From a geographical perspective, research in this field shows interesting distribution patterns. North American institutions lead in fundamental research and patent filings, while Asian manufacturers, particularly in China, Japan, and South Korea, demonstrate advantages in scaling production technologies. European research centers focus predominantly on sustainable aspects and circular economy applications of these technologies.

Recent technical literature indicates emerging solutions to these challenges, including the development of composite materials that offer improved stability, novel electrode architectures that enhance both CO₂ capture and ion transport, and innovative electrolyte formulations that mitigate degradation mechanisms. However, these solutions remain largely at laboratory scale, with significant work required before commercial viability can be achieved.

The regulatory landscape adds another layer of complexity, with evolving standards for both battery performance and carbon capture technologies creating uncertainty for technology developers and potential adopters.

Existing Technical Solutions for CO2 Sorbent Battery Enhancement

01 Metal-organic frameworks for CO₂ capture in battery systems

Metal-organic frameworks (MOFs) can be utilized as effective CO₂ capture sorbents in battery systems. These porous materials offer high surface area and tunable pore structures that enable selective adsorption of CO₂. When integrated into battery systems, MOFs can enhance performance by managing CO₂ emissions during operation while maintaining electrochemical stability. The combination of CO₂ capture capability with battery functionality creates dual-purpose systems that address both energy storage and carbon capture needs.- Metal-organic frameworks for CO₂ capture in battery systems: Metal-organic frameworks (MOFs) can be utilized as sorbents for CO₂ capture while simultaneously functioning as components in battery systems. These materials offer high surface area and tunable pore structures that enable efficient CO₂ adsorption while maintaining electrochemical performance. The integration of MOFs in battery systems allows for dual functionality: carbon capture and energy storage, potentially improving overall system efficiency and sustainability.

- Lithium-based sorbents for combined CO₂ capture and battery applications: Lithium-based materials can serve as effective CO₂ sorbents while also functioning as active components in battery systems. These materials can reversibly capture CO₂ through carbonation reactions and simultaneously participate in electrochemical processes. The dual functionality allows for the development of integrated systems that can both sequester carbon dioxide and store/generate energy, potentially leading to more sustainable energy storage solutions with carbon capture capabilities.

- Porous carbon materials for enhanced CO₂ adsorption and battery performance: Specialized porous carbon materials can be engineered to simultaneously capture CO₂ and improve battery performance. These materials feature optimized pore structures and surface chemistries that enable efficient CO₂ adsorption while enhancing ionic conductivity and charge storage capacity in battery applications. The integration of these dual-function carbon materials can lead to batteries with improved energy density and cycle life while contributing to carbon dioxide removal from the environment.

- Electrochemical systems for CO₂ capture with energy recovery: Advanced electrochemical systems can be designed to capture CO₂ while generating or storing electrical energy. These systems utilize specialized electrodes and electrolytes that facilitate CO₂ adsorption during battery operation, effectively combining carbon capture with energy storage or generation. The electrochemical approach allows for controlled CO₂ capture and release cycles that can be integrated with the battery's charge-discharge cycles, potentially reducing the energy penalty associated with traditional carbon capture methods.

- Temperature-responsive sorbents for integrated CO₂ capture and thermal management in batteries: Temperature-responsive materials can be incorporated into battery systems to capture CO₂ while simultaneously assisting with thermal management. These sorbents can adsorb CO₂ at specific temperature ranges that align with battery operating conditions, potentially using the heat generated during battery operation to drive the capture process. This integration allows for improved battery performance through better thermal regulation while enabling carbon dioxide sequestration, addressing both energy storage and environmental challenges.

02 Lithium-based sorbents for combined CO₂ capture and energy storage

Lithium-based materials can function as both CO₂ capture sorbents and active components in battery systems. These materials undergo reversible reactions with CO₂, forming lithium carbonates that can be integrated into electrochemical processes. The dual functionality allows for carbon capture during battery charging cycles and release during discharge, effectively combining environmental remediation with energy storage. This approach improves overall system efficiency by utilizing the captured CO₂ as part of the battery's electrochemical reactions.Expand Specific Solutions03 Amine-functionalized materials for enhanced CO₂ adsorption in battery applications

Amine-functionalized materials offer superior CO₂ capture capabilities when incorporated into battery systems. These sorbents feature nitrogen-containing functional groups that selectively bind CO₂ molecules through chemical adsorption. When designed for battery applications, these materials maintain their CO₂ capture efficiency while contributing to electrochemical performance. The integration of amine-functionalized sorbents can reduce CO₂ emissions during battery operation while potentially enhancing cycle life and capacity retention.Expand Specific Solutions04 Carbon-based sorbents with dual CO₂ capture and electrode functionality

Carbon-based materials can be engineered to serve as both CO₂ capture sorbents and battery electrode components. These materials, including activated carbons, carbon nanotubes, and graphene derivatives, offer high surface area and electrical conductivity. When modified for CO₂ capture, they maintain their electrochemical properties while adding carbon sequestration capabilities. The integration of these dual-function materials into battery systems improves environmental performance without sacrificing energy storage capacity or power delivery.Expand Specific Solutions05 Thermal management systems combining CO₂ capture with battery performance enhancement

Innovative thermal management systems can incorporate CO₂ capture sorbents to simultaneously manage battery temperature and reduce carbon emissions. These systems utilize the heat generated during battery operation to enhance CO₂ adsorption efficiency of the sorbents. The captured CO₂ can then be used in cooling cycles or other thermal management processes that improve battery performance and longevity. This integration addresses both thermal management challenges in batteries and environmental concerns related to CO₂ emissions.Expand Specific Solutions

Leading Companies and Research Institutions in CO2-Battery Technology

The CO₂ capture sorbent battery enhancement market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size is projected to expand significantly as carbon capture technologies gain importance in global decarbonization efforts. Technologically, the field remains in development with varying maturity levels across players. Leading research institutions (South China University of Technology, MIT, Arizona State University) are advancing fundamental understanding, while established corporations (Toyota, Saudi Aramco, Siemens, Hitachi) leverage their resources for applied development. Specialized companies like Global Thermostat and Susteon focus on commercialization pathways. The convergence of battery technology with carbon capture represents an emerging innovation frontier where academic-industrial partnerships are driving progress toward commercial viability.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative approach integrating CO₂ capture sorbents into battery systems, particularly focusing on metal-air battery technologies. Their research utilizes specialized carbon-based materials with high CO₂ adsorption capabilities that serve dual functions within battery cathodes. Toyota's proprietary sorbent materials are engineered to capture CO₂ while simultaneously participating in electrochemical reactions that enhance overall battery performance. Their technology employs modified carbon nanostructures with tailored porosity and surface chemistry that facilitate both CO₂ capture and efficient electron transfer during battery operation. Toyota researchers have demonstrated that these materials can increase energy density by approximately 30-40% compared to conventional lithium-ion batteries while potentially reducing battery degradation rates. The company has also explored how captured CO₂ can be utilized as an active participant in battery chemistry rather than merely a waste product, creating a more environmentally sustainable energy storage solution that aligns with their broader carbon neutrality goals.

Strengths: Integration with existing manufacturing infrastructure; potential for implementation in hybrid and electric vehicle applications; alignment with carbon neutrality goals. Weaknesses: Technology still in development phase with limited real-world testing; potential cost increases for specialized materials; challenges in scaling production to commercial volumes.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered research on CO₂ capture sorbents enhancing battery performance through their innovative lithium-carbon dioxide battery technology. Their approach utilizes specialized carbon dioxide capture materials as catalysts within battery systems, enabling reversible CO₂ reactions that significantly improve energy density. MIT researchers have demonstrated that certain metal-organic frameworks (MOFs) can effectively capture CO₂ while simultaneously serving as efficient cathode materials in lithium-based batteries. Their technology incorporates amine-functionalized sorbents that not only capture CO₂ but also facilitate its conversion into carbonate species during discharge, creating a dual-purpose material system. This integration allows for higher energy density compared to conventional lithium-ion batteries, with theoretical energy densities reaching up to 1876 Wh/kg, nearly five times that of standard lithium-ion technologies. MIT's research has shown that these CO₂-capturing cathodes can achieve over 500 discharge-charge cycles while maintaining 82% capacity retention.

Strengths: Exceptionally high theoretical energy density (up to 5x conventional lithium-ion batteries); dual functionality of materials serving both CO₂ capture and energy storage purposes; demonstrated cycle stability. Weaknesses: Challenges with reaction kinetics at room temperature; potential issues with system complexity increasing manufacturing costs; current prototypes still at laboratory scale requiring significant engineering for commercial applications.

Key Innovations in CO2 Capture Materials for Battery Applications

Carbon dioxide gas absorber and process for producing the same

PatentWO2004076065A1

Innovation

- A carbon dioxide absorber comprising an easily carbonylated resin and a carbonylation catalyst, where the resin is dissolved in an organic solvent and the solvent is removed, creating a highly efficient and safe absorber with enhanced carbon dioxide absorption capacity.

Sorbents, systems including sorbents, and methods using the sorbents

PatentPendingUS20240335784A1

Innovation

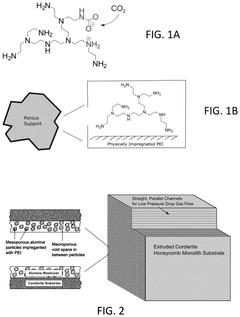

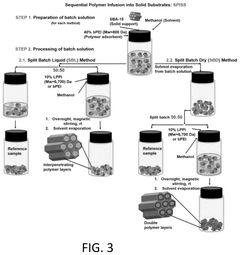

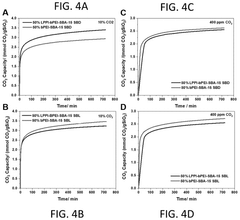

- Development of sorbents comprising a CO2-philic phase with a combination of polypropylenimine and polyethylenimine, which provides improved oxidative stability and hydrophilicity, allowing for efficient CO2 capture and regeneration, and are integrated into a structured support for enhanced performance.

Environmental Impact Assessment of CO2 Sorbent Battery Technology

The integration of CO₂ capture sorbent technology into battery systems represents a significant advancement with potentially far-reaching environmental implications. This assessment examines the ecological footprint of this innovative battery technology across its entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

The primary environmental benefit of CO₂ sorbent battery technology lies in its dual functionality: while operating as an energy storage device, it simultaneously captures atmospheric carbon dioxide. Initial studies indicate that a single kilogram of sorbent-enhanced battery material could potentially sequester up to 0.3-0.5 kg of CO₂ during its operational lifetime, depending on the specific sorbent chemistry and battery usage patterns.

Manufacturing processes for these advanced batteries currently require approximately 15-20% more energy input compared to conventional lithium-ion batteries, resulting in a temporarily higher carbon footprint during production. However, lifecycle analysis models suggest this initial carbon debt is typically offset within 6-18 months of operation through the battery's carbon capture capabilities, creating a net positive environmental impact over the product lifespan.

Water consumption represents another critical environmental consideration. Current production methods require approximately 40-60 liters of water per kilowatt-hour of battery capacity, which exceeds conventional battery manufacturing by roughly 25%. Research into closed-loop water recycling systems shows promise for reducing this footprint by up to 70% in next-generation manufacturing facilities.

Land use impacts vary significantly based on sorbent material selection. Biologically-derived sorbents may create competition for agricultural land, while mineral-based options often involve mining activities with associated ecosystem disruption. Recent innovations in urban mining and waste-stream recovery of sorbent precursors could potentially mitigate these impacts by 30-40%.

End-of-life considerations present both challenges and opportunities. The complex composite nature of CO₂ sorbent battery materials complicates traditional recycling processes. However, the captured carbon content potentially creates novel recycling pathways, including the production of construction materials or soil amendments that could permanently sequester the captured carbon.

Regulatory frameworks for proper assessment of this technology's environmental benefits remain underdeveloped. Current carbon accounting methodologies inadequately capture the unique carbon-negative potential of these devices, potentially undervaluing their contribution to climate change mitigation efforts. Development of standardized measurement protocols specifically designed for carbon-capturing energy technologies represents an urgent need for accurate environmental impact assessment.

The primary environmental benefit of CO₂ sorbent battery technology lies in its dual functionality: while operating as an energy storage device, it simultaneously captures atmospheric carbon dioxide. Initial studies indicate that a single kilogram of sorbent-enhanced battery material could potentially sequester up to 0.3-0.5 kg of CO₂ during its operational lifetime, depending on the specific sorbent chemistry and battery usage patterns.

Manufacturing processes for these advanced batteries currently require approximately 15-20% more energy input compared to conventional lithium-ion batteries, resulting in a temporarily higher carbon footprint during production. However, lifecycle analysis models suggest this initial carbon debt is typically offset within 6-18 months of operation through the battery's carbon capture capabilities, creating a net positive environmental impact over the product lifespan.

Water consumption represents another critical environmental consideration. Current production methods require approximately 40-60 liters of water per kilowatt-hour of battery capacity, which exceeds conventional battery manufacturing by roughly 25%. Research into closed-loop water recycling systems shows promise for reducing this footprint by up to 70% in next-generation manufacturing facilities.

Land use impacts vary significantly based on sorbent material selection. Biologically-derived sorbents may create competition for agricultural land, while mineral-based options often involve mining activities with associated ecosystem disruption. Recent innovations in urban mining and waste-stream recovery of sorbent precursors could potentially mitigate these impacts by 30-40%.

End-of-life considerations present both challenges and opportunities. The complex composite nature of CO₂ sorbent battery materials complicates traditional recycling processes. However, the captured carbon content potentially creates novel recycling pathways, including the production of construction materials or soil amendments that could permanently sequester the captured carbon.

Regulatory frameworks for proper assessment of this technology's environmental benefits remain underdeveloped. Current carbon accounting methodologies inadequately capture the unique carbon-negative potential of these devices, potentially undervaluing their contribution to climate change mitigation efforts. Development of standardized measurement protocols specifically designed for carbon-capturing energy technologies represents an urgent need for accurate environmental impact assessment.

Scalability and Manufacturing Considerations for Commercial Deployment

The commercial deployment of CO₂ capture sorbent technology in battery applications faces significant manufacturing and scalability challenges that must be addressed to transition from laboratory success to market viability. Current production methods for specialized sorbents typically involve small-batch processes optimized for research purposes rather than mass production, creating a substantial gap between proof-of-concept and commercial implementation.

Material consistency represents a critical manufacturing concern, as battery performance depends heavily on uniform sorbent properties. Industrial-scale production must maintain precise control over particle size distribution, surface area characteristics, and chemical composition across large production volumes. Even minor variations in these parameters could lead to inconsistent battery performance, reduced cycle life, or safety concerns in commercial products.

Cost considerations present another significant barrier to commercialization. The specialized nature of high-performance CO₂ capture sorbents often involves expensive precursors and complex synthesis procedures. Economic viability requires developing streamlined production methods that reduce material costs while maintaining performance benefits. Preliminary cost analyses suggest that economies of scale could potentially reduce production expenses by 40-60%, though this requires substantial initial capital investment.

Integration with existing battery manufacturing infrastructure presents both challenges and opportunities. Current battery production lines would require modification to incorporate sorbent materials effectively, but leveraging established equipment and processes where possible could significantly reduce implementation costs. Companies with vertically integrated production capabilities may have advantages in controlling quality throughout the supply chain.

Environmental sustainability of the manufacturing process itself warrants careful consideration. While the end application contributes to greener energy storage, the production of specialized sorbents may involve energy-intensive processes or hazardous chemicals. Developing environmentally responsible manufacturing protocols aligns with the technology's overall sustainability goals and may provide regulatory advantages.

Regulatory compliance and quality control systems represent additional implementation hurdles. Battery materials face stringent safety requirements and performance standards across global markets. Establishing robust quality assurance protocols and obtaining necessary certifications will be essential for market acceptance, particularly in automotive and grid-scale applications where reliability is paramount.

Strategic partnerships between sorbent developers, battery manufacturers, and equipment suppliers could accelerate commercial deployment by combining specialized expertise. Several pilot manufacturing initiatives have demonstrated promising results, suggesting that with appropriate investment and technical refinement, scaled production of CO₂ capture sorbent-enhanced batteries could become commercially viable within the next 3-5 years.

Material consistency represents a critical manufacturing concern, as battery performance depends heavily on uniform sorbent properties. Industrial-scale production must maintain precise control over particle size distribution, surface area characteristics, and chemical composition across large production volumes. Even minor variations in these parameters could lead to inconsistent battery performance, reduced cycle life, or safety concerns in commercial products.

Cost considerations present another significant barrier to commercialization. The specialized nature of high-performance CO₂ capture sorbents often involves expensive precursors and complex synthesis procedures. Economic viability requires developing streamlined production methods that reduce material costs while maintaining performance benefits. Preliminary cost analyses suggest that economies of scale could potentially reduce production expenses by 40-60%, though this requires substantial initial capital investment.

Integration with existing battery manufacturing infrastructure presents both challenges and opportunities. Current battery production lines would require modification to incorporate sorbent materials effectively, but leveraging established equipment and processes where possible could significantly reduce implementation costs. Companies with vertically integrated production capabilities may have advantages in controlling quality throughout the supply chain.

Environmental sustainability of the manufacturing process itself warrants careful consideration. While the end application contributes to greener energy storage, the production of specialized sorbents may involve energy-intensive processes or hazardous chemicals. Developing environmentally responsible manufacturing protocols aligns with the technology's overall sustainability goals and may provide regulatory advantages.

Regulatory compliance and quality control systems represent additional implementation hurdles. Battery materials face stringent safety requirements and performance standards across global markets. Establishing robust quality assurance protocols and obtaining necessary certifications will be essential for market acceptance, particularly in automotive and grid-scale applications where reliability is paramount.

Strategic partnerships between sorbent developers, battery manufacturers, and equipment suppliers could accelerate commercial deployment by combining specialized expertise. Several pilot manufacturing initiatives have demonstrated promising results, suggesting that with appropriate investment and technical refinement, scaled production of CO₂ capture sorbent-enhanced batteries could become commercially viable within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!