CO₂ Capture Sorbent Patent Landscape in Renewable Energy

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. The journey began in the 1970s with basic absorption techniques primarily used in natural gas processing. By the 1990s, growing environmental concerns catalyzed research into more efficient capture methods, leading to the development of diverse sorbent materials and capture processes.

The renewable energy sector has increasingly recognized CO₂ capture as a critical component in achieving carbon neutrality goals. This intersection has created a unique technological landscape where sorbent materials play a pivotal role in enhancing the environmental credentials of renewable energy systems. The evolution of these materials has been marked by continuous improvements in selectivity, capacity, and regeneration efficiency.

Current technological trajectories indicate a shift from conventional amine-based sorbents toward more innovative materials including metal-organic frameworks (MOFs), zeolites, activated carbons, and novel polymer-based sorbents. These advanced materials offer promising characteristics such as higher CO₂ selectivity, lower regeneration energy requirements, and enhanced stability under various operating conditions.

The patent landscape in this domain reflects an accelerating innovation pace, with significant growth in patent filings over the past decade. This trend underscores the strategic importance of CO₂ capture technology in the renewable energy sector's future development. Geographic distribution of patent activities shows concentration in North America, Europe, and East Asia, with emerging contributions from other regions.

The primary objective of CO₂ capture technology development in renewable energy applications is to create economically viable systems that can effectively reduce carbon emissions while maintaining or enhancing energy production efficiency. This includes developing sorbents with improved performance metrics, reducing energy penalties associated with capture processes, and designing systems that integrate seamlessly with existing renewable energy infrastructure.

Secondary objectives include enhancing the durability and lifespan of sorbent materials, reducing manufacturing costs, minimizing environmental impacts of the sorbents themselves, and developing scalable solutions applicable across different renewable energy platforms. The ultimate goal is to establish CO₂ capture as a standard component in renewable energy systems, contributing to global decarbonization efforts.

The technological evolution in this field is expected to continue accelerating, driven by increasingly stringent environmental regulations, growing market demand for carbon-neutral energy solutions, and continued investment in research and development. Future breakthroughs will likely focus on bio-inspired sorbents, hybrid materials combining multiple capture mechanisms, and intelligent systems that optimize capture performance based on operating conditions.

The renewable energy sector has increasingly recognized CO₂ capture as a critical component in achieving carbon neutrality goals. This intersection has created a unique technological landscape where sorbent materials play a pivotal role in enhancing the environmental credentials of renewable energy systems. The evolution of these materials has been marked by continuous improvements in selectivity, capacity, and regeneration efficiency.

Current technological trajectories indicate a shift from conventional amine-based sorbents toward more innovative materials including metal-organic frameworks (MOFs), zeolites, activated carbons, and novel polymer-based sorbents. These advanced materials offer promising characteristics such as higher CO₂ selectivity, lower regeneration energy requirements, and enhanced stability under various operating conditions.

The patent landscape in this domain reflects an accelerating innovation pace, with significant growth in patent filings over the past decade. This trend underscores the strategic importance of CO₂ capture technology in the renewable energy sector's future development. Geographic distribution of patent activities shows concentration in North America, Europe, and East Asia, with emerging contributions from other regions.

The primary objective of CO₂ capture technology development in renewable energy applications is to create economically viable systems that can effectively reduce carbon emissions while maintaining or enhancing energy production efficiency. This includes developing sorbents with improved performance metrics, reducing energy penalties associated with capture processes, and designing systems that integrate seamlessly with existing renewable energy infrastructure.

Secondary objectives include enhancing the durability and lifespan of sorbent materials, reducing manufacturing costs, minimizing environmental impacts of the sorbents themselves, and developing scalable solutions applicable across different renewable energy platforms. The ultimate goal is to establish CO₂ capture as a standard component in renewable energy systems, contributing to global decarbonization efforts.

The technological evolution in this field is expected to continue accelerating, driven by increasingly stringent environmental regulations, growing market demand for carbon-neutral energy solutions, and continued investment in research and development. Future breakthroughs will likely focus on bio-inspired sorbents, hybrid materials combining multiple capture mechanisms, and intelligent systems that optimize capture performance based on operating conditions.

Market Analysis for CO₂ Capture Solutions

The global CO₂ capture solutions market is experiencing significant growth, driven by increasing environmental concerns and stringent regulations aimed at reducing carbon emissions. Current market valuations indicate that the carbon capture and storage (CCS) market reached approximately 3 billion USD in 2022, with projections suggesting growth to reach 9 billion USD by 2030, representing a compound annual growth rate of over 15%.

The market segmentation reveals distinct categories based on technology types, with post-combustion capture currently dominating the market share at roughly 45%, followed by pre-combustion and oxy-fuel combustion technologies. Among sorbent technologies, amine-based solutions lead with approximately 40% market share, while emerging technologies like metal-organic frameworks (MOFs) and solid sorbents are gaining traction due to their improved efficiency and reduced energy penalties.

Geographically, North America and Europe represent the largest markets for CO₂ capture solutions, collectively accounting for over 60% of global market value. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming decade due to rapid industrialization coupled with increasing environmental commitments.

Industry-wise adoption shows power generation and industrial processes (cement, steel, and chemical manufacturing) as primary end-users, together representing approximately 70% of the total market. The renewable energy sector's integration with carbon capture technologies is creating a new market segment with potential for significant expansion, especially in biomass energy with carbon capture and storage (BECCS) applications.

Market drivers include increasingly stringent carbon emission regulations, growing corporate commitments to carbon neutrality, and the emergence of carbon pricing mechanisms across various jurisdictions. The European Union's Emissions Trading System (ETS) and similar initiatives worldwide are creating economic incentives for CO₂ capture implementation.

Key market restraints include high capital expenditure requirements, with typical large-scale installations costing between 400-900 million USD, and operational challenges related to energy penalties that can reduce overall plant efficiency by 10-30%. Additionally, limited infrastructure for CO₂ transportation and storage presents a significant barrier to widespread adoption.

Consumer trends indicate growing preference for products and services from companies with demonstrated commitment to carbon reduction, creating additional market pull for CO₂ capture technologies across various industries. This shift in consumer behavior is particularly evident in sectors with direct consumer interfaces, such as energy utilities and consumer goods manufacturing.

The market segmentation reveals distinct categories based on technology types, with post-combustion capture currently dominating the market share at roughly 45%, followed by pre-combustion and oxy-fuel combustion technologies. Among sorbent technologies, amine-based solutions lead with approximately 40% market share, while emerging technologies like metal-organic frameworks (MOFs) and solid sorbents are gaining traction due to their improved efficiency and reduced energy penalties.

Geographically, North America and Europe represent the largest markets for CO₂ capture solutions, collectively accounting for over 60% of global market value. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate in the coming decade due to rapid industrialization coupled with increasing environmental commitments.

Industry-wise adoption shows power generation and industrial processes (cement, steel, and chemical manufacturing) as primary end-users, together representing approximately 70% of the total market. The renewable energy sector's integration with carbon capture technologies is creating a new market segment with potential for significant expansion, especially in biomass energy with carbon capture and storage (BECCS) applications.

Market drivers include increasingly stringent carbon emission regulations, growing corporate commitments to carbon neutrality, and the emergence of carbon pricing mechanisms across various jurisdictions. The European Union's Emissions Trading System (ETS) and similar initiatives worldwide are creating economic incentives for CO₂ capture implementation.

Key market restraints include high capital expenditure requirements, with typical large-scale installations costing between 400-900 million USD, and operational challenges related to energy penalties that can reduce overall plant efficiency by 10-30%. Additionally, limited infrastructure for CO₂ transportation and storage presents a significant barrier to widespread adoption.

Consumer trends indicate growing preference for products and services from companies with demonstrated commitment to carbon reduction, creating additional market pull for CO₂ capture technologies across various industries. This shift in consumer behavior is particularly evident in sectors with direct consumer interfaces, such as energy utilities and consumer goods manufacturing.

Global Sorbent Technology Status and Barriers

Carbon dioxide capture technology has evolved significantly over the past decades, with sorbent-based approaches emerging as a promising solution for mitigating greenhouse gas emissions. Currently, the global landscape of CO₂ capture sorbent technologies encompasses several categories including physical sorbents (activated carbon, zeolites), chemical sorbents (amines, metal oxides), and hybrid materials. Each category demonstrates varying degrees of technological maturity and commercial readiness across different regions.

In North America and Europe, advanced amine-based sorbents have reached commercial deployment stage, with several large-scale demonstration projects operational. Asian markets, particularly China and Japan, have made substantial progress in metal-organic frameworks (MOFs) and novel porous materials research, filing numerous patents in these areas. However, the Middle East and Africa remain relatively underrepresented in sorbent technology development despite their significant carbon emissions from energy production.

The primary technical barriers limiting widespread adoption of CO₂ capture sorbents include insufficient adsorption capacity under practical conditions, degradation issues during multiple adsorption-desorption cycles, and high energy requirements for regeneration. Most current sorbents exhibit a trade-off between selectivity and capacity, making optimization challenging. Additionally, many promising materials demonstrate excellent performance in laboratory settings but fail to maintain effectiveness at industrial scales due to mechanical stability issues and sensitivity to contaminants in real flue gas streams.

Economic barriers further complicate technology deployment, with high manufacturing costs for advanced sorbents like MOFs and functionalized materials. The energy penalty associated with sorbent regeneration significantly impacts operational expenses, making the overall cost of captured CO₂ prohibitively high for many applications without substantial policy support or carbon pricing mechanisms.

Regulatory frameworks vary considerably across regions, creating an uneven playing field for technology development. While the EU's emissions trading system and recent U.S. tax incentives have accelerated investment in carbon capture technologies, many developing economies lack similar mechanisms to drive innovation and deployment.

Infrastructure limitations present additional challenges, as existing industrial facilities often require significant modifications to accommodate sorbent-based capture systems. The absence of comprehensive CO₂ transport and storage networks in many regions further complicates the value proposition for capture technologies, creating a chicken-and-egg problem for infrastructure development.

Despite these barriers, recent technological breakthroughs in materials science and process engineering suggest pathways toward more efficient and cost-effective sorbent technologies. Collaborative international research initiatives and public-private partnerships are gradually addressing these challenges, though significant hurdles remain before widespread commercial adoption becomes feasible.

In North America and Europe, advanced amine-based sorbents have reached commercial deployment stage, with several large-scale demonstration projects operational. Asian markets, particularly China and Japan, have made substantial progress in metal-organic frameworks (MOFs) and novel porous materials research, filing numerous patents in these areas. However, the Middle East and Africa remain relatively underrepresented in sorbent technology development despite their significant carbon emissions from energy production.

The primary technical barriers limiting widespread adoption of CO₂ capture sorbents include insufficient adsorption capacity under practical conditions, degradation issues during multiple adsorption-desorption cycles, and high energy requirements for regeneration. Most current sorbents exhibit a trade-off between selectivity and capacity, making optimization challenging. Additionally, many promising materials demonstrate excellent performance in laboratory settings but fail to maintain effectiveness at industrial scales due to mechanical stability issues and sensitivity to contaminants in real flue gas streams.

Economic barriers further complicate technology deployment, with high manufacturing costs for advanced sorbents like MOFs and functionalized materials. The energy penalty associated with sorbent regeneration significantly impacts operational expenses, making the overall cost of captured CO₂ prohibitively high for many applications without substantial policy support or carbon pricing mechanisms.

Regulatory frameworks vary considerably across regions, creating an uneven playing field for technology development. While the EU's emissions trading system and recent U.S. tax incentives have accelerated investment in carbon capture technologies, many developing economies lack similar mechanisms to drive innovation and deployment.

Infrastructure limitations present additional challenges, as existing industrial facilities often require significant modifications to accommodate sorbent-based capture systems. The absence of comprehensive CO₂ transport and storage networks in many regions further complicates the value proposition for capture technologies, creating a chicken-and-egg problem for infrastructure development.

Despite these barriers, recent technological breakthroughs in materials science and process engineering suggest pathways toward more efficient and cost-effective sorbent technologies. Collaborative international research initiatives and public-private partnerships are gradually addressing these challenges, though significant hurdles remain before widespread commercial adoption becomes feasible.

Current Sorbent Solutions Assessment

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and can operate under various temperature and pressure conditions, offering promising solutions for carbon capture applications.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks are porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. These materials have high surface areas and tunable pore sizes, making them effective for selective CO₂ adsorption. MOFs can be designed with specific functional groups to enhance CO₂ binding affinity and can operate under various temperature and pressure conditions, offering advantages in both pre-combustion and post-combustion carbon capture applications.

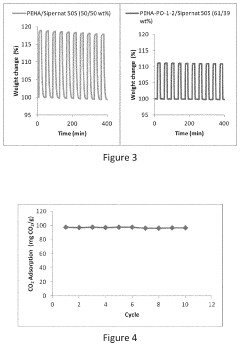

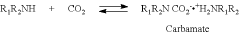

- Amine-functionalized sorbents: Amine-functionalized materials represent a significant class of CO₂ capture sorbents that operate through chemical adsorption mechanisms. These sorbents contain primary, secondary, or tertiary amine groups that react with CO₂ to form carbamates or bicarbonates. Common supports include silica, activated carbon, and polymeric materials that are impregnated or grafted with amines. These materials offer high selectivity for CO₂ even at low concentrations and can be regenerated through temperature or pressure swing processes.

- Zeolite-based CO₂ capture systems: Zeolites are aluminosilicate minerals with highly ordered microporous structures that make them effective for CO₂ adsorption. Their molecular sieving properties allow for selective capture of CO₂ from gas mixtures. The adsorption capacity of zeolites can be enhanced through ion exchange, introducing cations that increase the affinity for CO₂. These materials are particularly effective at moderate temperatures and can be regenerated multiple times without significant loss of performance.

- Regenerable solid oxide sorbents: Regenerable solid oxide sorbents, including calcium oxide, magnesium oxide, and lithium-based materials, capture CO₂ through carbonation reactions at elevated temperatures. These materials form stable carbonates when exposed to CO₂ and can be regenerated through calcination at higher temperatures. The cyclic capacity and mechanical stability of these sorbents can be improved through the addition of support materials or dopants. These systems are particularly suitable for integration with high-temperature industrial processes where waste heat can be utilized for sorbent regeneration.

- Novel composite and hybrid sorbent materials: Composite and hybrid sorbent materials combine different capture mechanisms to enhance CO₂ adsorption performance. These materials integrate physical and chemical adsorption properties by combining components such as activated carbon with amine-functionalized polymers or metal oxides with zeolites. The synergistic effects between components can improve capacity, selectivity, and regeneration efficiency. Additionally, these materials often feature engineered structures like core-shell configurations or hierarchical pore networks that optimize mass transfer and minimize pressure drop in practical applications.

02 Amine-functionalized sorbents

Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents typically consist of amines grafted onto porous supports such as silica, activated carbon, or polymers. The amine groups react with CO₂ to form carbamates or bicarbonates, enabling efficient capture even at low CO₂ concentrations. These materials can be regenerated through temperature or pressure swing processes, making them suitable for cyclic capture operations.Expand Specific Solutions03 Zeolite and molecular sieve-based CO₂ adsorbents

Zeolites and molecular sieves are aluminosilicate materials with well-defined pore structures that can selectively adsorb CO₂ based on molecular size and polarity. These materials offer high thermal stability and can be modified with cations to enhance CO₂ selectivity. Their rigid framework provides consistent performance over multiple adsorption-desorption cycles, making them suitable for pressure swing adsorption systems in industrial carbon capture applications.Expand Specific Solutions04 Carbon-based sorbents for CO₂ capture

Carbon-based materials such as activated carbon, carbon nanotubes, and graphene derivatives serve as effective CO₂ adsorbents due to their high surface area and pore volume. These materials can be functionalized with nitrogen-containing groups or metal particles to enhance CO₂ selectivity and capacity. Carbon-based sorbents offer advantages including low cost, high thermal stability, and resistance to moisture, making them practical for large-scale carbon capture applications.Expand Specific Solutions05 Regeneration methods for CO₂ capture sorbents

Effective regeneration processes are crucial for the economic viability of CO₂ capture systems. Various methods include temperature swing adsorption (TSA), pressure swing adsorption (PSA), vacuum swing adsorption (VSA), and combinations thereof. Novel approaches incorporate microwave heating, electrical swing adsorption, and steam stripping to reduce energy requirements. Advanced regeneration techniques focus on maintaining sorbent integrity over multiple cycles while minimizing energy consumption and operational costs.Expand Specific Solutions

Key Industry Players in CO₂ Capture Market

The CO₂ capture sorbent market in renewable energy is in a growth phase, with increasing market size driven by global decarbonization efforts. The technology maturity varies across different approaches, with major players demonstrating diverse capabilities. Chinese entities like Xi'an Thermal Power Research Institute, Sinopec, and Huaneng Clean Energy Research Institute are advancing indigenous technologies, while ExxonMobil and Global Thermostat lead in North America. Korean power companies (KEPCO and subsidiaries) show strong collaborative development patterns. Academic institutions (ETH Zurich, Columbia, Caltech) contribute fundamental research, while specialized firms like Climeworks and TDA Research focus on commercialization pathways. The competitive landscape reflects regional innovation clusters with varying degrees of commercial readiness and intellectual property protection.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed proprietary direct air capture (DAC) technology using metal-organic frameworks (MOFs) as CO₂ sorbents. Their approach focuses on highly selective, porous materials with exceptional CO₂ adsorption capacity even at low atmospheric concentrations. The company's patented technology incorporates functionalized MOFs with open metal sites that enhance CO₂ binding affinity while maintaining regeneration efficiency. ExxonMobil's system employs a temperature-swing adsorption process where ambient air passes through sorbent-filled contactors, followed by controlled heating to release concentrated CO₂ for subsequent utilization or storage. Their modular design allows for scalable implementation across various deployment scenarios, from industrial point sources to distributed renewable energy installations. The company has demonstrated continuous operation with minimal performance degradation over thousands of adsorption-desorption cycles.

Strengths: Superior CO₂ selectivity in the presence of moisture; industrial-scale manufacturing capabilities; extensive experience in process integration. Weaknesses: Higher energy requirements for sorbent regeneration compared to some emerging technologies; relatively high capital costs for initial deployment; dependence on fossil fuel infrastructure for implementation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced solid amine-based CO₂ capture sorbents specifically designed for integration with renewable energy systems. Their patented technology utilizes polyethyleneimine (PEI) impregnated onto mesoporous silica supports, creating materials with high CO₂ adsorption capacity and excellent selectivity. Sinopec's approach incorporates a unique surface modification technique that enhances the stability of the amine groups, preventing leaching and degradation during repeated cycling. Their system operates through a temperature-vacuum swing adsorption process, where CO₂ is captured at ambient conditions and released under moderate heating (70-90°C) and reduced pressure. This significantly reduces the energy penalty compared to conventional amine scrubbing technologies. Sinopec has demonstrated the integration of their sorbent technology with solar thermal systems, utilizing renewable heat for the regeneration process. Their pilot installations have shown consistent performance with CO₂ capture efficiencies exceeding 90% from flue gas streams and maintaining capacity over hundreds of cycles. The company has also developed specialized sorbent formulations for different operating conditions, including high humidity environments typical in renewable energy applications.

Strengths: Lower regeneration energy requirements compared to liquid amine systems; excellent integration potential with renewable heat sources; strong resistance to degradation from moisture and contaminants; extensive industrial scaling capabilities. Weaknesses: Relatively lower CO₂ capacity under atmospheric concentrations compared to some specialized DAC sorbents; potential for mechanical attrition in large-scale operations; higher manufacturing complexity for advanced sorbent materials.

Patent Analysis of Leading CO₂ Capture Technologies

Highly attrition resistant and dry regenerable sorbents for carbon dioxide capture

PatentInactiveUS8110523B2

Innovation

- A dry regenerable sorbent is developed using a method that mixes active components, supports, and inorganic binders to create a slurry, which is then spray-dried to produce sorbent particles with optimized shape, size, and mechanical strength, allowing for efficient CO2 capture and regeneration at lower temperatures.

Regenerative adsorbents of modified amines on solid supports

PatentInactiveUS20210197172A1

Innovation

- A modified polyamine is reacted with an epoxide to form a cross-linked amine, which is then deposited on a nano-structured support, enhancing CO2 adsorption and desorption characteristics by increasing molecular weight and stability, while maintaining low volatility, thereby improving the sorbent's ability to capture CO2 from gas mixtures at various temperatures and humidity levels.

Regulatory Framework for Carbon Capture Technologies

The regulatory landscape for carbon capture technologies has evolved significantly over the past decade, reflecting growing global concern about climate change. International frameworks such as the Paris Agreement have established targets for emissions reduction, indirectly driving the development and implementation of carbon capture technologies. These agreements create a foundation for national policies that specifically address carbon capture, utilization, and storage (CCUS) technologies.

In the United States, the 45Q tax credit has emerged as a pivotal policy mechanism, offering financial incentives for carbon sequestration activities. Recent amendments have increased credit values to $50 per metric ton for geological sequestration and $35 per ton for enhanced oil recovery or beneficial use, significantly improving the economic viability of carbon capture projects. The Infrastructure Investment and Jobs Act of 2021 further allocated $3.5 billion specifically for direct air capture hubs.

The European Union has implemented the EU Emissions Trading System (ETS), which creates a market-based approach to emissions reduction. By placing a price on carbon emissions, the ETS incentivizes the adoption of carbon capture technologies. The EU Innovation Fund additionally provides targeted support for innovative low-carbon technologies, including advanced sorbent development for CO₂ capture.

In Asia, China has incorporated carbon capture into its Five-Year Plans and established regional carbon trading markets, while Japan's Green Innovation Fund allocates substantial resources toward decarbonization technologies. These regulatory frameworks have directly influenced patent activity in CO₂ capture sorbent technologies, with clear correlations between policy implementation and patent filing trends.

Regulatory requirements for technology performance have also shaped innovation directions. Standards for capture efficiency, energy penalties, and environmental impact assessments have driven research toward specific sorbent characteristics. For instance, regulations requiring 90%+ capture efficiency have spurred development of advanced materials with higher CO₂ selectivity and capacity.

Looking forward, emerging regulatory trends indicate increasing stringency in emissions standards and greater harmonization of international carbon markets. The development of standardized methodologies for measuring and verifying carbon removal will likely influence future sorbent technologies, particularly those aimed at direct air capture applications. These evolving regulatory frameworks will continue to shape the competitive landscape for CO₂ capture sorbent patents in renewable energy applications.

In the United States, the 45Q tax credit has emerged as a pivotal policy mechanism, offering financial incentives for carbon sequestration activities. Recent amendments have increased credit values to $50 per metric ton for geological sequestration and $35 per ton for enhanced oil recovery or beneficial use, significantly improving the economic viability of carbon capture projects. The Infrastructure Investment and Jobs Act of 2021 further allocated $3.5 billion specifically for direct air capture hubs.

The European Union has implemented the EU Emissions Trading System (ETS), which creates a market-based approach to emissions reduction. By placing a price on carbon emissions, the ETS incentivizes the adoption of carbon capture technologies. The EU Innovation Fund additionally provides targeted support for innovative low-carbon technologies, including advanced sorbent development for CO₂ capture.

In Asia, China has incorporated carbon capture into its Five-Year Plans and established regional carbon trading markets, while Japan's Green Innovation Fund allocates substantial resources toward decarbonization technologies. These regulatory frameworks have directly influenced patent activity in CO₂ capture sorbent technologies, with clear correlations between policy implementation and patent filing trends.

Regulatory requirements for technology performance have also shaped innovation directions. Standards for capture efficiency, energy penalties, and environmental impact assessments have driven research toward specific sorbent characteristics. For instance, regulations requiring 90%+ capture efficiency have spurred development of advanced materials with higher CO₂ selectivity and capacity.

Looking forward, emerging regulatory trends indicate increasing stringency in emissions standards and greater harmonization of international carbon markets. The development of standardized methodologies for measuring and verifying carbon removal will likely influence future sorbent technologies, particularly those aimed at direct air capture applications. These evolving regulatory frameworks will continue to shape the competitive landscape for CO₂ capture sorbent patents in renewable energy applications.

Environmental Impact Assessment of Sorbent Materials

The environmental impact of CO₂ capture sorbent materials extends far beyond their primary function of carbon sequestration. A comprehensive assessment reveals that while these materials contribute significantly to greenhouse gas reduction, their production, deployment, and disposal present complex environmental trade-offs that must be carefully evaluated.

Production processes for advanced sorbents, particularly metal-organic frameworks (MOFs) and amine-functionalized materials, often require energy-intensive synthesis methods and potentially toxic precursors. Life cycle assessments indicate that the embodied carbon in manufacturing high-performance sorbents can temporarily offset their carbon capture benefits, with an environmental payback period ranging from 3-18 months depending on material composition and synthesis route.

Water consumption represents another critical environmental consideration. Hydrophilic sorbents, while effective for CO₂ capture, may compete with water resources in water-stressed regions. Recent studies demonstrate that next-generation sorbents with hydrophobic properties can reduce water requirements by up to 40% compared to conventional materials, though often at the cost of reduced capture efficiency.

Land use impacts vary significantly across sorbent technologies. Direct air capture installations utilizing solid sorbents require approximately 0.5-2 hectares per kiloton of annual CO₂ capture capacity, substantially less than biomass-based approaches but still representing meaningful land commitments when scaled to gigaton levels.

Waste management challenges emerge at end-of-life stages. Chemical degradation of amine-based sorbents can produce potentially harmful byproducts requiring specialized disposal protocols. Encouragingly, recent patent filings indicate progress in developing regenerable sorbent systems with extended operational lifespans exceeding 5,000 capture-release cycles, significantly reducing waste generation rates.

Ecosystem impacts must also be considered, particularly for large-scale deployment scenarios. Airflow modifications around direct air capture arrays may alter local microclimate conditions, while chemical leaching from improperly contained sorbent materials poses potential risks to soil and groundwater systems that remain inadequately characterized in current literature.

The renewable energy sector presents unique environmental considerations for sorbent deployment. Integration with intermittent renewable energy sources can optimize environmental performance by utilizing excess renewable capacity for energy-intensive regeneration processes, creating valuable synergies that enhance the overall sustainability profile of both technologies.

Production processes for advanced sorbents, particularly metal-organic frameworks (MOFs) and amine-functionalized materials, often require energy-intensive synthesis methods and potentially toxic precursors. Life cycle assessments indicate that the embodied carbon in manufacturing high-performance sorbents can temporarily offset their carbon capture benefits, with an environmental payback period ranging from 3-18 months depending on material composition and synthesis route.

Water consumption represents another critical environmental consideration. Hydrophilic sorbents, while effective for CO₂ capture, may compete with water resources in water-stressed regions. Recent studies demonstrate that next-generation sorbents with hydrophobic properties can reduce water requirements by up to 40% compared to conventional materials, though often at the cost of reduced capture efficiency.

Land use impacts vary significantly across sorbent technologies. Direct air capture installations utilizing solid sorbents require approximately 0.5-2 hectares per kiloton of annual CO₂ capture capacity, substantially less than biomass-based approaches but still representing meaningful land commitments when scaled to gigaton levels.

Waste management challenges emerge at end-of-life stages. Chemical degradation of amine-based sorbents can produce potentially harmful byproducts requiring specialized disposal protocols. Encouragingly, recent patent filings indicate progress in developing regenerable sorbent systems with extended operational lifespans exceeding 5,000 capture-release cycles, significantly reducing waste generation rates.

Ecosystem impacts must also be considered, particularly for large-scale deployment scenarios. Airflow modifications around direct air capture arrays may alter local microclimate conditions, while chemical leaching from improperly contained sorbent materials poses potential risks to soil and groundwater systems that remain inadequately characterized in current literature.

The renewable energy sector presents unique environmental considerations for sorbent deployment. Integration with intermittent renewable energy sources can optimize environmental performance by utilizing excess renewable capacity for energy-intensive regeneration processes, creating valuable synergies that enhance the overall sustainability profile of both technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!