Technical Advances in CO₂ Capture Sorbent for Power Plants

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Evolution and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, driven by growing concerns about climate change and the need to reduce greenhouse gas emissions from power generation facilities. The journey began in the 1970s with basic absorption processes using amine solutions, primarily developed for natural gas sweetening rather than climate mitigation. These early technologies were energy-intensive and economically prohibitive for large-scale deployment in power plants.

The 1990s marked a turning point as climate change gained international recognition, catalyzing focused research on CO₂ capture specifically for power plant applications. This period saw the emergence of more efficient amine-based solvents and the initial exploration of solid sorbents as potential alternatives to liquid absorption systems.

By the early 2000s, research expanded dramatically with the introduction of novel materials including metal-organic frameworks (MOFs), zeolites, and activated carbons as potential CO₂ capture media. These materials offered promising theoretical capacities but faced challenges in stability and regeneration under real-world power plant conditions.

The 2010s witnessed significant advancements in sorbent technology, with researchers developing functionalized materials specifically engineered for selective CO₂ capture. This era also saw increased attention to process integration, with innovations in temperature swing adsorption (TSA) and pressure swing adsorption (PSA) systems designed to optimize the performance of these novel sorbents.

Current technological objectives focus on developing sorbents that can achieve several critical performance metrics simultaneously: high CO₂ selectivity in the presence of other flue gas components, rapid adsorption/desorption kinetics, minimal regeneration energy requirements, and long-term stability under repeated cycling. Additionally, there is growing emphasis on materials that can function effectively under the challenging conditions of power plant operations, including tolerance to contaminants like SOx and NOx.

Looking forward, the field aims to develop next-generation sorbents capable of reducing the energy penalty of carbon capture to below 20% while maintaining capture rates above 90%. Research is increasingly focused on biomimetic approaches that draw inspiration from natural carbon fixation processes, as well as composite materials that combine the advantages of different sorbent classes. The ultimate objective remains economically viable carbon capture technology that can be deployed at scale across the global power generation sector, enabling significant reductions in CO₂ emissions while maintaining affordable electricity production.

The 1990s marked a turning point as climate change gained international recognition, catalyzing focused research on CO₂ capture specifically for power plant applications. This period saw the emergence of more efficient amine-based solvents and the initial exploration of solid sorbents as potential alternatives to liquid absorption systems.

By the early 2000s, research expanded dramatically with the introduction of novel materials including metal-organic frameworks (MOFs), zeolites, and activated carbons as potential CO₂ capture media. These materials offered promising theoretical capacities but faced challenges in stability and regeneration under real-world power plant conditions.

The 2010s witnessed significant advancements in sorbent technology, with researchers developing functionalized materials specifically engineered for selective CO₂ capture. This era also saw increased attention to process integration, with innovations in temperature swing adsorption (TSA) and pressure swing adsorption (PSA) systems designed to optimize the performance of these novel sorbents.

Current technological objectives focus on developing sorbents that can achieve several critical performance metrics simultaneously: high CO₂ selectivity in the presence of other flue gas components, rapid adsorption/desorption kinetics, minimal regeneration energy requirements, and long-term stability under repeated cycling. Additionally, there is growing emphasis on materials that can function effectively under the challenging conditions of power plant operations, including tolerance to contaminants like SOx and NOx.

Looking forward, the field aims to develop next-generation sorbents capable of reducing the energy penalty of carbon capture to below 20% while maintaining capture rates above 90%. Research is increasingly focused on biomimetic approaches that draw inspiration from natural carbon fixation processes, as well as composite materials that combine the advantages of different sorbent classes. The ultimate objective remains economically viable carbon capture technology that can be deployed at scale across the global power generation sector, enabling significant reductions in CO₂ emissions while maintaining affordable electricity production.

Market Demand for Carbon Capture Solutions

The global carbon capture market is experiencing unprecedented growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture technology sector at approximately $2 billion, with projections indicating expansion to $7 billion by 2030. This represents a compound annual growth rate of nearly 15%, significantly outpacing many other industrial technology segments.

Power generation remains the largest contributor to stationary CO₂ emissions worldwide, accounting for roughly 40% of global carbon dioxide releases. This positions power plants as the primary target market for advanced carbon capture solutions, particularly sorbent-based technologies. The International Energy Agency estimates that to meet Paris Agreement targets, carbon capture capacity must increase from current levels of about 40 million tonnes annually to over 5.6 gigatonnes by 2050.

Regional market analysis reveals varying demand patterns. North America currently leads adoption, with approximately 65% of operational carbon capture projects, followed by Europe at 25%. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to their heavy reliance on coal-fired power generation and increasing regulatory pressure to reduce emissions.

Industry surveys indicate that power plant operators prioritize three key factors when evaluating carbon capture solutions: operational efficiency impact (minimal energy penalty), implementation costs (capital expenditure and operational costs), and retrofit compatibility with existing infrastructure. Sorbent-based technologies are gaining particular attention as they potentially offer advantages in all three areas compared to traditional amine scrubbing methods.

Economic analyses demonstrate that the cost of carbon capture remains a significant barrier to widespread adoption. Current capture costs range from $40-100 per tonne of CO₂, depending on the technology and implementation context. Market viability requires reduction to below $30 per tonne, creating substantial demand for innovative sorbent materials that can improve efficiency and reduce costs.

Policy mechanisms are increasingly driving market demand, with carbon pricing schemes now covering approximately 22% of global emissions. The European Union's Emissions Trading System prices have reached record levels, exceeding €90 per tonne in 2023, creating economic incentives for capture technology adoption. Similarly, the United States' enhanced 45Q tax credits now offer up to $85 per tonne for permanent CO₂ storage, significantly improving the business case for carbon capture investments.

Power generation remains the largest contributor to stationary CO₂ emissions worldwide, accounting for roughly 40% of global carbon dioxide releases. This positions power plants as the primary target market for advanced carbon capture solutions, particularly sorbent-based technologies. The International Energy Agency estimates that to meet Paris Agreement targets, carbon capture capacity must increase from current levels of about 40 million tonnes annually to over 5.6 gigatonnes by 2050.

Regional market analysis reveals varying demand patterns. North America currently leads adoption, with approximately 65% of operational carbon capture projects, followed by Europe at 25%. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to their heavy reliance on coal-fired power generation and increasing regulatory pressure to reduce emissions.

Industry surveys indicate that power plant operators prioritize three key factors when evaluating carbon capture solutions: operational efficiency impact (minimal energy penalty), implementation costs (capital expenditure and operational costs), and retrofit compatibility with existing infrastructure. Sorbent-based technologies are gaining particular attention as they potentially offer advantages in all three areas compared to traditional amine scrubbing methods.

Economic analyses demonstrate that the cost of carbon capture remains a significant barrier to widespread adoption. Current capture costs range from $40-100 per tonne of CO₂, depending on the technology and implementation context. Market viability requires reduction to below $30 per tonne, creating substantial demand for innovative sorbent materials that can improve efficiency and reduce costs.

Policy mechanisms are increasingly driving market demand, with carbon pricing schemes now covering approximately 22% of global emissions. The European Union's Emissions Trading System prices have reached record levels, exceeding €90 per tonne in 2023, creating economic incentives for capture technology adoption. Similarly, the United States' enhanced 45Q tax credits now offer up to $85 per tonne for permanent CO₂ storage, significantly improving the business case for carbon capture investments.

Current Sorbent Technologies and Limitations

Current CO₂ capture technologies for power plants predominantly rely on various sorbent materials, each with distinct advantages and limitations. Amine-based sorbents, particularly monoethanolamine (MEA), represent the most mature and widely deployed solution. These chemical sorbents offer high CO₂ selectivity and relatively fast absorption kinetics, achieving capture efficiencies of 85-95% in commercial applications. However, they suffer from significant drawbacks including high regeneration energy requirements (3.5-4.2 GJ/ton CO₂), thermal and oxidative degradation issues, equipment corrosion, and substantial solvent losses during operation.

Solid sorbents have emerged as promising alternatives, with materials such as activated carbons, zeolites, and metal-organic frameworks (MOFs) demonstrating considerable potential. These physical adsorbents typically operate through pressure or temperature swing processes and offer lower regeneration energy penalties (1.8-2.5 GJ/ton CO₂). Nevertheless, they face challenges related to moisture sensitivity, limited CO₂ selectivity in flue gas conditions, and mechanical stability issues during multiple adsorption-desorption cycles.

Calcium looping technology, utilizing limestone (CaCO₃) as a sorbent, presents another approach with the advantage of using abundant, low-cost materials. This process can achieve capture rates exceeding 90% and offers potential for heat integration with power plants. However, the rapid deactivation of calcium-based sorbents due to sintering and the high temperatures required for operation (650-900°C) create significant implementation barriers and increase energy consumption.

Ionic liquids represent an innovative class of sorbents with negligible volatility and high thermal stability. These designer solvents can be tailored for specific CO₂ capture applications and demonstrate promising CO₂ solubility characteristics. Their primary limitations include high viscosity, which impedes mass transfer rates, and prohibitive production costs that currently restrict large-scale deployment.

Membrane-based separation technologies, while not strictly sorbents, compete in the same application space and face similar challenges regarding selectivity-permeability trade-offs, membrane fouling in real flue gas conditions, and durability concerns over extended operation periods.

A critical limitation across all current sorbent technologies is the significant energy penalty imposed on power plants, typically reducing net efficiency by 7-12 percentage points. This translates to approximately 20-30% increased fuel consumption per unit of electricity produced. Additionally, most existing sorbents demonstrate suboptimal performance when exposed to real flue gas contaminants such as SOx, NOx, and particulate matter, necessitating expensive pre-treatment processes.

The economic viability of current sorbent technologies remains challenging, with estimated CO₂ capture costs ranging from $40-100 per ton, significantly above carbon pricing in most markets. This economic barrier, combined with the technical limitations outlined above, underscores the urgent need for next-generation sorbent materials that can address these fundamental constraints.

Solid sorbents have emerged as promising alternatives, with materials such as activated carbons, zeolites, and metal-organic frameworks (MOFs) demonstrating considerable potential. These physical adsorbents typically operate through pressure or temperature swing processes and offer lower regeneration energy penalties (1.8-2.5 GJ/ton CO₂). Nevertheless, they face challenges related to moisture sensitivity, limited CO₂ selectivity in flue gas conditions, and mechanical stability issues during multiple adsorption-desorption cycles.

Calcium looping technology, utilizing limestone (CaCO₃) as a sorbent, presents another approach with the advantage of using abundant, low-cost materials. This process can achieve capture rates exceeding 90% and offers potential for heat integration with power plants. However, the rapid deactivation of calcium-based sorbents due to sintering and the high temperatures required for operation (650-900°C) create significant implementation barriers and increase energy consumption.

Ionic liquids represent an innovative class of sorbents with negligible volatility and high thermal stability. These designer solvents can be tailored for specific CO₂ capture applications and demonstrate promising CO₂ solubility characteristics. Their primary limitations include high viscosity, which impedes mass transfer rates, and prohibitive production costs that currently restrict large-scale deployment.

Membrane-based separation technologies, while not strictly sorbents, compete in the same application space and face similar challenges regarding selectivity-permeability trade-offs, membrane fouling in real flue gas conditions, and durability concerns over extended operation periods.

A critical limitation across all current sorbent technologies is the significant energy penalty imposed on power plants, typically reducing net efficiency by 7-12 percentage points. This translates to approximately 20-30% increased fuel consumption per unit of electricity produced. Additionally, most existing sorbents demonstrate suboptimal performance when exposed to real flue gas contaminants such as SOx, NOx, and particulate matter, necessitating expensive pre-treatment processes.

The economic viability of current sorbent technologies remains challenging, with estimated CO₂ capture costs ranging from $40-100 per ton, significantly above carbon pricing in most markets. This economic barrier, combined with the technical limitations outlined above, underscores the urgent need for next-generation sorbent materials that can address these fundamental constraints.

Mainstream Sorbent Solutions for Power Plants

01 Metal-organic frameworks (MOFs) for CO₂ capture

Metal-organic frameworks are porous materials with high surface area that can be engineered for selective CO₂ adsorption. These materials can be modified with functional groups to enhance CO₂ binding affinity and improve capture efficiency. MOFs offer advantages such as tunable pore sizes, high adsorption capacity, and good regeneration properties, making them promising candidates for carbon capture applications.- Metal-organic frameworks (MOFs) for CO₂ capture: Metal-organic frameworks (MOFs) are advanced porous materials that demonstrate high CO₂ capture efficiency due to their large surface area and tunable pore structures. These materials can be modified with specific functional groups to enhance CO₂ selectivity and adsorption capacity. MOFs can operate under various conditions and can be regenerated with minimal energy input, making them promising candidates for industrial-scale carbon capture applications.

- Amine-functionalized sorbents: Amine-functionalized materials represent a significant class of CO₂ capture sorbents with high efficiency. These sorbents work through chemical adsorption mechanisms where amine groups react with CO₂ to form carbamates or bicarbonates. The materials can be designed with various amine types (primary, secondary, tertiary) and loadings to optimize capture performance. Common supports include silica, polymers, and porous carbon, which provide structural stability while maximizing the available amine sites for CO₂ capture.

- Temperature and pressure swing adsorption techniques: Temperature and pressure swing adsorption techniques are critical operational methods that significantly impact CO₂ capture efficiency. These techniques involve cyclical changes in temperature or pressure to facilitate adsorption and desorption processes. By optimizing these parameters, the working capacity and selectivity of sorbents can be enhanced. Advanced process designs incorporate heat integration and pressure recovery systems to minimize energy consumption during the capture and regeneration cycles.

- Novel composite and hybrid sorbent materials: Composite and hybrid sorbent materials combine different components to achieve enhanced CO₂ capture efficiency. These materials often integrate the advantages of multiple capture mechanisms, such as physical adsorption and chemical absorption. Examples include polymer-inorganic composites, layered double hydroxides, and hybrid membranes. The synergistic effects between components can lead to improved selectivity, capacity, and stability under various operating conditions, addressing limitations of single-component sorbents.

- Regeneration efficiency and sorbent durability: Regeneration efficiency and sorbent durability are crucial factors affecting the overall performance of CO₂ capture systems. Developing sorbents that maintain their capture capacity over multiple adsorption-desorption cycles is essential for practical applications. Research focuses on reducing degradation mechanisms such as thermal decomposition, poisoning by impurities, and structural collapse. Innovations in regeneration methods, including microwave, electrical, and vacuum swing approaches, aim to minimize energy requirements while preserving sorbent integrity and extending operational lifetime.

02 Amine-functionalized sorbents

Amine-functionalized materials are widely used for CO₂ capture due to their strong chemical affinity for carbon dioxide. These sorbents can be prepared by incorporating amine groups onto various supports such as silica, polymers, or porous carbon. The capture efficiency can be enhanced by optimizing the amine loading, type of amine (primary, secondary, tertiary), and the support structure to maximize CO₂ adsorption capacity while maintaining good kinetics and stability over multiple cycles.Expand Specific Solutions03 Temperature and pressure swing adsorption techniques

Temperature and pressure swing adsorption are operational techniques that significantly impact CO₂ capture efficiency. By manipulating temperature or pressure conditions, the adsorption and desorption of CO₂ on sorbents can be controlled. These techniques involve cycling between adsorption conditions (typically low temperature or high pressure) and regeneration conditions (high temperature or low pressure) to maximize working capacity and minimize energy requirements for the overall capture process.Expand Specific Solutions04 Composite and hybrid sorbent materials

Composite and hybrid sorbent materials combine different components to achieve enhanced CO₂ capture performance. These materials often integrate the advantages of multiple sorbent types, such as the high capacity of chemical sorbents with the fast kinetics of physical adsorbents. Examples include polymer-inorganic composites, layered double hydroxides, and hybrid membranes. The synergistic effects between components can lead to improved capture efficiency, selectivity, and stability under various operating conditions.Expand Specific Solutions05 Regeneration and cyclic stability enhancement

Improving the regeneration process and cyclic stability of CO₂ capture sorbents is crucial for long-term efficiency. This involves developing materials that maintain their capture capacity over multiple adsorption-desorption cycles while requiring minimal energy for regeneration. Strategies include incorporating stabilizing agents, optimizing the sorbent structure to prevent degradation, and designing regeneration protocols that minimize thermal or chemical stress on the sorbent material.Expand Specific Solutions

Leading Companies in CO₂ Capture Industry

The CO₂ capture sorbent technology for power plants is in a growth phase, with increasing market adoption driven by global decarbonization efforts. The market is projected to expand significantly as carbon pricing mechanisms mature worldwide. Technology maturity varies across different approaches, with major players demonstrating diverse capabilities. Asian entities dominate the landscape, particularly Korean power companies (KEPCO and its subsidiaries) and Chinese research institutions (Huaneng Clean Energy Research Institute). Western organizations like ExxonMobil, CSIRO, and University of Wyoming contribute significant innovations. Academic-industry partnerships are accelerating development, with universities like Tianjin, Zhejiang, and Queensland collaborating with power utilities to bridge the gap between laboratory research and commercial deployment.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed a revolutionary polyethyleneimine (PEI)-based solid sorbent system for post-combustion CO₂ capture. Their technology utilizes a hierarchical porous silica support structure impregnated with branched PEI polymers, creating a high-density array of CO₂ binding sites. The sorbent operates in a temperature swing cycle with adsorption at 60-75°C and regeneration at 120-140°C, achieving CO₂ capacities exceeding 4 mmol/g under typical flue gas conditions[7]. Huaneng has successfully scaled this technology from laboratory to a 30 tonne CO₂/day demonstration unit at the Shidongkou Power Plant, where it has operated continuously for over 10,000 hours. Their process integration approach includes innovative heat recovery systems that reduce the parasitic energy penalty to approximately 20% of plant output - significantly lower than conventional amine scrubbing technologies. The institute's latest generation sorbent incorporates proprietary stabilizers that prevent PEI degradation, maintaining over 85% capacity after 2,000 adsorption-desorption cycles[8].

Strengths: High CO₂ capacity and selectivity; lower regeneration energy requirements than liquid systems; successful large-scale demonstration. Weaknesses: Potential for amine degradation in oxidizing environments; higher material costs than some competing technologies; requires careful moisture management to maintain optimal performance.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed advanced metal-organic frameworks (MOFs) specifically designed for CO₂ capture in power plant applications. Their proprietary MIL-101 and UiO-66 derived sorbents demonstrate exceptional CO₂ selectivity and capacity under typical flue gas conditions. CSIRO's technology utilizes a pressure/temperature swing adsorption process that achieves up to 90% capture efficiency while reducing regeneration energy requirements by approximately 30% compared to conventional amine scrubbing[1]. Their latest generation of sorbents incorporates amine-functionalized surfaces that maintain stability through hundreds of adsorption-desorption cycles, addressing previous durability concerns. CSIRO has successfully scaled this technology from laboratory to pilot demonstrations at actual coal-fired power plants in Australia, proving its viability in real-world conditions with minimal performance degradation over extended operation periods[2].

Strengths: Superior regeneration energy efficiency compared to liquid amine systems; excellent stability over multiple cycles; proven at pilot scale. Weaknesses: Higher initial capital costs than conventional technologies; potential for performance degradation in the presence of SOx and NOx contaminants; requires precise temperature control during regeneration cycles.

Key Patents and Innovations in CO₂ Sorbents

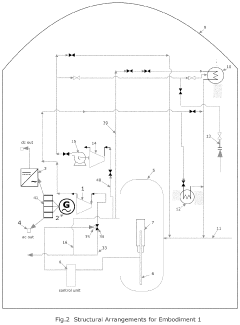

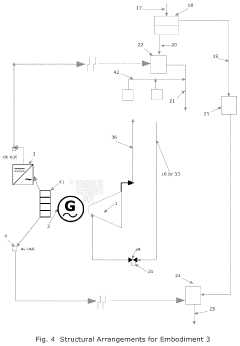

Utilizing Decay Heat via Steam Cycles to Produce Electric Power on Site to Eliminate Accidents Caused by Station Blackout in Nuclear Power Plants

PatentInactiveUS20200143950A1

Innovation

- Harnessing decay heat as a sustainable energy source by employing a cascade arrangement of piping configurations and suitable turbines and generators to produce electricity on-site, ensuring continuous power supply and preventing station blackout scenarios.

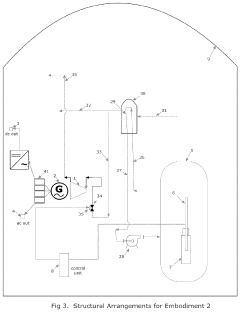

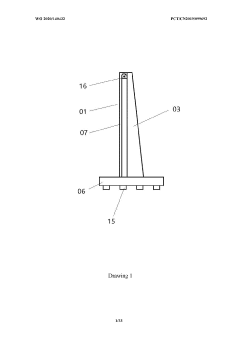

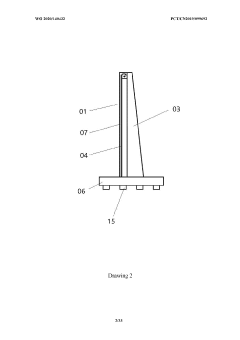

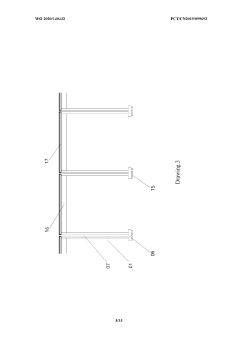

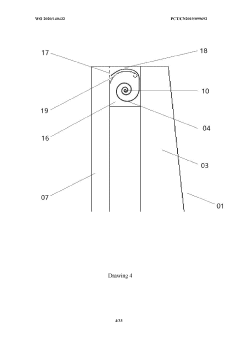

A facility for protecting life in the vicinity of nuclear power plants and other important facilities or areas

PatentWO2020140432A1

Innovation

- A protective installation comprising a main part with pillar assemblies, reinforcement bars, baffles, gear assemblies, winches, and pulley-cables, designed to quickly unfold and block radiation, and a subsidiary part with fire control and transport assemblies to facilitate firefighting and rescue operations, coordinating with fending groynes to manage wind and wave directions.

Economic Viability and Cost Reduction Strategies

The economic viability of CO₂ capture technologies remains a significant barrier to widespread implementation in power plants. Current cost estimates for CO₂ capture using sorbent technologies range from $40-100 per ton of CO₂ captured, making it prohibitively expensive for many facilities without substantial policy incentives or carbon pricing mechanisms. These costs primarily stem from high capital expenditures, energy penalties, and operational expenses associated with sorbent regeneration and replacement.

Several promising cost reduction strategies have emerged in recent years. Process intensification approaches focus on optimizing the integration of capture systems with power plant operations, potentially reducing energy penalties by 15-30%. This includes heat integration techniques that utilize waste heat from power generation for sorbent regeneration, significantly lowering the parasitic energy load.

Material innovations represent another critical pathway to economic viability. Development of next-generation sorbents with higher CO₂ selectivity, capacity, and durability could reduce both capital and operational costs. Advanced solid sorbents with lower regeneration energy requirements and longer operational lifetimes (3-5 years versus current 1-2 years) could decrease costs by 20-35% compared to first-generation materials.

Manufacturing scale-up presents significant opportunities for cost reduction. Current production of specialized sorbents often occurs at laboratory or pilot scales, resulting in high unit costs. Industry analysts project that transitioning to industrial-scale manufacturing could reduce sorbent costs by 40-60% through economies of scale and process optimization. Several companies have begun establishing commercial-scale production facilities, potentially bringing costs below $30 per ton by 2030.

Modular design approaches are gaining traction as a means to reduce capital expenditures and deployment timelines. Standardized, factory-built capture units that can be transported to power plants reduce on-site construction costs and enable incremental capacity additions. This approach has demonstrated potential cost reductions of 15-25% compared to traditional custom-engineered systems.

Policy mechanisms remain crucial for bridging the economic gap in the near term. Carbon pricing, tax incentives, and regulatory frameworks that value carbon reduction create the necessary economic conditions for investment. The 45Q tax credit in the United States, offering up to $85 per ton for captured and sequestered CO₂, has significantly improved project economics. Similar mechanisms in the EU and Asia are creating market conditions where capture technologies can achieve positive returns on investment despite current cost challenges.

Several promising cost reduction strategies have emerged in recent years. Process intensification approaches focus on optimizing the integration of capture systems with power plant operations, potentially reducing energy penalties by 15-30%. This includes heat integration techniques that utilize waste heat from power generation for sorbent regeneration, significantly lowering the parasitic energy load.

Material innovations represent another critical pathway to economic viability. Development of next-generation sorbents with higher CO₂ selectivity, capacity, and durability could reduce both capital and operational costs. Advanced solid sorbents with lower regeneration energy requirements and longer operational lifetimes (3-5 years versus current 1-2 years) could decrease costs by 20-35% compared to first-generation materials.

Manufacturing scale-up presents significant opportunities for cost reduction. Current production of specialized sorbents often occurs at laboratory or pilot scales, resulting in high unit costs. Industry analysts project that transitioning to industrial-scale manufacturing could reduce sorbent costs by 40-60% through economies of scale and process optimization. Several companies have begun establishing commercial-scale production facilities, potentially bringing costs below $30 per ton by 2030.

Modular design approaches are gaining traction as a means to reduce capital expenditures and deployment timelines. Standardized, factory-built capture units that can be transported to power plants reduce on-site construction costs and enable incremental capacity additions. This approach has demonstrated potential cost reductions of 15-25% compared to traditional custom-engineered systems.

Policy mechanisms remain crucial for bridging the economic gap in the near term. Carbon pricing, tax incentives, and regulatory frameworks that value carbon reduction create the necessary economic conditions for investment. The 45Q tax credit in the United States, offering up to $85 per ton for captured and sequestered CO₂, has significantly improved project economics. Similar mechanisms in the EU and Asia are creating market conditions where capture technologies can achieve positive returns on investment despite current cost challenges.

Environmental Impact and Regulatory Framework

The implementation of CO₂ capture technologies in power plants operates within a complex environmental and regulatory landscape that continues to evolve globally. Climate change mitigation policies have increasingly focused on reducing greenhouse gas emissions, with CO₂ capture technologies recognized as critical tools for achieving emission reduction targets while maintaining energy security.

The environmental impact assessment of CO₂ capture sorbents must consider their entire lifecycle. While these technologies significantly reduce CO₂ emissions from power generation, they also introduce new environmental considerations. The production, deployment, and disposal of sorbent materials can generate additional environmental footprints, including potential chemical leaching, resource consumption, and waste management challenges. Advanced sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials require careful evaluation of their long-term environmental stability and degradation pathways.

Energy penalties associated with CO₂ capture systems represent another environmental consideration. Current technologies typically increase a power plant's energy consumption by 20-30%, necessitating additional fuel consumption and potentially offsetting some emission benefits. Next-generation sorbents aim to reduce this penalty to below 10%, which would significantly improve the net environmental benefit of capture technologies.

The regulatory framework governing CO₂ capture has matured considerably in recent years. In the United States, the EPA's Clean Power Plan and New Source Performance Standards have established CO₂ emission limits for power plants, creating regulatory drivers for capture technology adoption. The EU Emissions Trading System has similarly incentivized carbon capture through carbon pricing mechanisms, while countries like Canada have implemented performance standards specifically targeting coal-fired power generation.

Financial incentives have emerged as powerful regulatory tools, with tax credits such as the U.S. 45Q providing up to $50 per ton of CO₂ captured and sequestered. Similar schemes exist in Norway, the UK, and Australia, creating market pull for advanced sorbent technologies. These incentives are particularly important given the significant capital investment required for retrofitting existing power plants with capture systems.

International agreements, most notably the Paris Climate Accord, have established frameworks for national commitments to emissions reduction, indirectly supporting the development and deployment of CO₂ capture technologies. The recent Glasgow Climate Pact further emphasized the role of technological solutions in meeting increasingly ambitious climate targets.

Standardization efforts for CO₂ capture technologies are advancing through organizations like ISO and ASTM International, which are developing protocols for performance evaluation, safety requirements, and environmental impact assessments of various sorbent materials. These standards will be crucial for regulatory compliance and technology comparison as the market for capture technologies continues to expand globally.

The environmental impact assessment of CO₂ capture sorbents must consider their entire lifecycle. While these technologies significantly reduce CO₂ emissions from power generation, they also introduce new environmental considerations. The production, deployment, and disposal of sorbent materials can generate additional environmental footprints, including potential chemical leaching, resource consumption, and waste management challenges. Advanced sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials require careful evaluation of their long-term environmental stability and degradation pathways.

Energy penalties associated with CO₂ capture systems represent another environmental consideration. Current technologies typically increase a power plant's energy consumption by 20-30%, necessitating additional fuel consumption and potentially offsetting some emission benefits. Next-generation sorbents aim to reduce this penalty to below 10%, which would significantly improve the net environmental benefit of capture technologies.

The regulatory framework governing CO₂ capture has matured considerably in recent years. In the United States, the EPA's Clean Power Plan and New Source Performance Standards have established CO₂ emission limits for power plants, creating regulatory drivers for capture technology adoption. The EU Emissions Trading System has similarly incentivized carbon capture through carbon pricing mechanisms, while countries like Canada have implemented performance standards specifically targeting coal-fired power generation.

Financial incentives have emerged as powerful regulatory tools, with tax credits such as the U.S. 45Q providing up to $50 per ton of CO₂ captured and sequestered. Similar schemes exist in Norway, the UK, and Australia, creating market pull for advanced sorbent technologies. These incentives are particularly important given the significant capital investment required for retrofitting existing power plants with capture systems.

International agreements, most notably the Paris Climate Accord, have established frameworks for national commitments to emissions reduction, indirectly supporting the development and deployment of CO₂ capture technologies. The recent Glasgow Climate Pact further emphasized the role of technological solutions in meeting increasingly ambitious climate targets.

Standardization efforts for CO₂ capture technologies are advancing through organizations like ISO and ASTM International, which are developing protocols for performance evaluation, safety requirements, and environmental impact assessments of various sorbent materials. These standards will be crucial for regulatory compliance and technology comparison as the market for capture technologies continues to expand globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!