The Role of CO₂ Capture Sorbent in Carbon Footprint Reduction

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO₂ Capture Technology Background and Objectives

Carbon dioxide capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. The development trajectory began in the 1970s with basic absorption techniques and has since expanded to include multiple sophisticated approaches including adsorption, membrane separation, cryogenic separation, and chemical looping. This evolution has been driven by the growing recognition of climate change as a global challenge and the need to reduce greenhouse gas emissions across all sectors of the economy.

The current technological landscape for CO₂ capture is characterized by three primary approaches: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. Each methodology presents distinct advantages and challenges in terms of energy requirements, capture efficiency, and implementation costs. Sorbent-based capture systems have emerged as particularly promising due to their potential for lower energy penalties and operational flexibility across diverse industrial applications.

Recent advancements in material science have accelerated the development of novel sorbents with enhanced CO₂ selectivity, capacity, and regeneration characteristics. These include metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials, each offering specific benefits for different capture scenarios. The progression of these materials represents a critical frontier in addressing the technical and economic barriers to widespread carbon capture implementation.

The primary objective of CO₂ capture sorbent technology is to develop cost-effective, energy-efficient, and environmentally sustainable solutions for reducing carbon emissions from both stationary and mobile sources. Specific technical goals include achieving capture rates exceeding 90%, reducing energy penalties below 20% of plant output, and lowering capture costs to under $40 per ton of CO₂ by 2030. These targets are essential for making carbon capture economically viable without significant government subsidies.

Beyond technical performance, the development of CO₂ capture sorbents aims to address broader environmental objectives, including minimizing water usage, reducing waste generation, and avoiding the creation of secondary pollutants. The technology must also demonstrate scalability to handle the massive volumes of emissions from large industrial facilities and power plants, which collectively account for approximately 65% of global CO₂ emissions.

The trajectory of sorbent technology development is increasingly influenced by policy frameworks and market mechanisms designed to incentivize carbon reduction. These include carbon pricing schemes, tax credits for carbon sequestration, and regulatory requirements for emission reductions across various industries. The interplay between technological advancement and policy evolution will significantly shape the future deployment and impact of CO₂ capture sorbents in global carbon footprint reduction efforts.

The current technological landscape for CO₂ capture is characterized by three primary approaches: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. Each methodology presents distinct advantages and challenges in terms of energy requirements, capture efficiency, and implementation costs. Sorbent-based capture systems have emerged as particularly promising due to their potential for lower energy penalties and operational flexibility across diverse industrial applications.

Recent advancements in material science have accelerated the development of novel sorbents with enhanced CO₂ selectivity, capacity, and regeneration characteristics. These include metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials, each offering specific benefits for different capture scenarios. The progression of these materials represents a critical frontier in addressing the technical and economic barriers to widespread carbon capture implementation.

The primary objective of CO₂ capture sorbent technology is to develop cost-effective, energy-efficient, and environmentally sustainable solutions for reducing carbon emissions from both stationary and mobile sources. Specific technical goals include achieving capture rates exceeding 90%, reducing energy penalties below 20% of plant output, and lowering capture costs to under $40 per ton of CO₂ by 2030. These targets are essential for making carbon capture economically viable without significant government subsidies.

Beyond technical performance, the development of CO₂ capture sorbents aims to address broader environmental objectives, including minimizing water usage, reducing waste generation, and avoiding the creation of secondary pollutants. The technology must also demonstrate scalability to handle the massive volumes of emissions from large industrial facilities and power plants, which collectively account for approximately 65% of global CO₂ emissions.

The trajectory of sorbent technology development is increasingly influenced by policy frameworks and market mechanisms designed to incentivize carbon reduction. These include carbon pricing schemes, tax credits for carbon sequestration, and regulatory requirements for emission reductions across various industries. The interplay between technological advancement and policy evolution will significantly shape the future deployment and impact of CO₂ capture sorbents in global carbon footprint reduction efforts.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. As of 2023, the market was valued at approximately $7.3 billion, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030, potentially reaching $35.6 billion by the end of the decade. This growth trajectory is supported by substantial government investments, with the US Inflation Reduction Act allocating $369 billion for climate and energy initiatives, including carbon capture technologies.

The demand for CO₂ capture sorbents is particularly strong in regions with stringent emission regulations, notably Europe, North America, and increasingly in Asia-Pacific countries like China and Japan. The European Union's commitment to carbon neutrality by 2050 has established a robust regulatory framework that incentivizes carbon capture implementation across industries.

Market segmentation reveals that power generation and industrial sectors constitute the largest market segments, accounting for approximately 65% of the total carbon capture market. Within these sectors, cement production, steel manufacturing, and fossil fuel power plants represent the most promising application areas due to their high emission profiles and the technical feasibility of implementing capture solutions.

The economic viability of carbon capture technologies has improved significantly, with the cost per ton of CO₂ captured decreasing from $80-120 in 2010 to $40-80 in recent implementations. This cost reduction trend is expected to continue as technologies mature and economies of scale are realized. However, the market still faces economic challenges, as carbon pricing mechanisms in many regions remain insufficient to fully incentivize widespread adoption.

Customer adoption patterns indicate a preference for integrated solutions that offer both technical efficiency and economic viability. End-users increasingly demand sorbents with high CO₂ selectivity, low regeneration energy requirements, and long operational lifespans. Additionally, there is growing interest in solutions that can be retrofitted to existing infrastructure rather than requiring complete system overhauls.

Market research indicates that the most successful carbon capture products combine technological innovation with clear value propositions related to regulatory compliance, operational cost savings, and corporate social responsibility benefits. The market is also witnessing increased collaboration between technology providers, industrial end-users, and government entities, creating ecosystem partnerships that accelerate commercialization and deployment of advanced sorbent technologies.

The demand for CO₂ capture sorbents is particularly strong in regions with stringent emission regulations, notably Europe, North America, and increasingly in Asia-Pacific countries like China and Japan. The European Union's commitment to carbon neutrality by 2050 has established a robust regulatory framework that incentivizes carbon capture implementation across industries.

Market segmentation reveals that power generation and industrial sectors constitute the largest market segments, accounting for approximately 65% of the total carbon capture market. Within these sectors, cement production, steel manufacturing, and fossil fuel power plants represent the most promising application areas due to their high emission profiles and the technical feasibility of implementing capture solutions.

The economic viability of carbon capture technologies has improved significantly, with the cost per ton of CO₂ captured decreasing from $80-120 in 2010 to $40-80 in recent implementations. This cost reduction trend is expected to continue as technologies mature and economies of scale are realized. However, the market still faces economic challenges, as carbon pricing mechanisms in many regions remain insufficient to fully incentivize widespread adoption.

Customer adoption patterns indicate a preference for integrated solutions that offer both technical efficiency and economic viability. End-users increasingly demand sorbents with high CO₂ selectivity, low regeneration energy requirements, and long operational lifespans. Additionally, there is growing interest in solutions that can be retrofitted to existing infrastructure rather than requiring complete system overhauls.

Market research indicates that the most successful carbon capture products combine technological innovation with clear value propositions related to regulatory compliance, operational cost savings, and corporate social responsibility benefits. The market is also witnessing increased collaboration between technology providers, industrial end-users, and government entities, creating ecosystem partnerships that accelerate commercialization and deployment of advanced sorbent technologies.

Current Sorbent Technologies and Challenges

Carbon dioxide capture technologies have evolved significantly over the past decades, with various sorbent materials being developed to address the growing need for carbon footprint reduction. Currently, the landscape of CO₂ capture sorbents can be categorized into several major types, each with distinct characteristics and applications.

Amine-based sorbents remain the most commercially mature technology, with monoethanolamine (MEA) being widely deployed in industrial settings. These sorbents offer high CO₂ selectivity and relatively fast kinetics, achieving capture efficiencies of 85-95%. However, they face significant challenges including high regeneration energy requirements (3.5-4.0 GJ/ton CO₂), corrosion issues, and degradation over multiple cycles, limiting their long-term economic viability.

Metal-organic frameworks (MOFs) represent a promising class of advanced sorbents with exceptional surface areas (up to 7000 m²/g) and tunable pore structures. MOFs such as Mg-MOF-74 and HKUST-1 have demonstrated CO₂ uptake capacities exceeding 200 mg/g under ambient conditions. Despite these advantages, MOFs struggle with stability issues in humid environments and high manufacturing costs, currently estimated at $100-200/kg, which hinders their large-scale implementation.

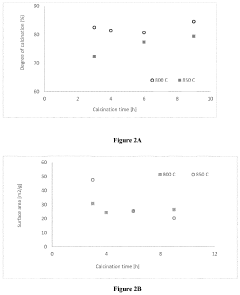

Solid oxide sorbents, particularly calcium-based materials like CaO, offer high theoretical CO₂ uptake (approximately 0.78 g CO₂/g sorbent) and operate effectively at high temperatures. However, these materials suffer from rapid capacity decay, losing up to 70% of their initial capacity after just 10-20 cycles due to sintering and pore closure phenomena.

Zeolites and activated carbons present lower-cost alternatives with moderate CO₂ capacities (50-150 mg/g). Their main limitations include sensitivity to moisture, which can reduce capacity by up to 75%, and relatively low selectivity in flue gas conditions containing multiple components.

Emerging technologies include ionic liquids and porous polymer networks, which show promising CO₂ selectivity but face challenges in scaling production processes and maintaining performance under real-world conditions. Ionic liquids, for instance, demonstrate excellent CO₂ solubility but suffer from high viscosity issues that impede mass transfer rates.

A critical cross-cutting challenge across all sorbent technologies is the energy penalty associated with regeneration, which typically accounts for 70-80% of the total energy consumption in carbon capture processes. This energy requirement significantly impacts the overall carbon footprint reduction potential of these technologies.

Material stability under industrial conditions remains problematic, with most advanced sorbents showing performance degradation when exposed to contaminants like SOx, NOx, and water vapor commonly found in industrial emissions. Additionally, the manufacturing scalability of novel sorbents presents a substantial barrier to commercialization, with production volumes currently orders of magnitude below what would be required for meaningful climate impact.

Amine-based sorbents remain the most commercially mature technology, with monoethanolamine (MEA) being widely deployed in industrial settings. These sorbents offer high CO₂ selectivity and relatively fast kinetics, achieving capture efficiencies of 85-95%. However, they face significant challenges including high regeneration energy requirements (3.5-4.0 GJ/ton CO₂), corrosion issues, and degradation over multiple cycles, limiting their long-term economic viability.

Metal-organic frameworks (MOFs) represent a promising class of advanced sorbents with exceptional surface areas (up to 7000 m²/g) and tunable pore structures. MOFs such as Mg-MOF-74 and HKUST-1 have demonstrated CO₂ uptake capacities exceeding 200 mg/g under ambient conditions. Despite these advantages, MOFs struggle with stability issues in humid environments and high manufacturing costs, currently estimated at $100-200/kg, which hinders their large-scale implementation.

Solid oxide sorbents, particularly calcium-based materials like CaO, offer high theoretical CO₂ uptake (approximately 0.78 g CO₂/g sorbent) and operate effectively at high temperatures. However, these materials suffer from rapid capacity decay, losing up to 70% of their initial capacity after just 10-20 cycles due to sintering and pore closure phenomena.

Zeolites and activated carbons present lower-cost alternatives with moderate CO₂ capacities (50-150 mg/g). Their main limitations include sensitivity to moisture, which can reduce capacity by up to 75%, and relatively low selectivity in flue gas conditions containing multiple components.

Emerging technologies include ionic liquids and porous polymer networks, which show promising CO₂ selectivity but face challenges in scaling production processes and maintaining performance under real-world conditions. Ionic liquids, for instance, demonstrate excellent CO₂ solubility but suffer from high viscosity issues that impede mass transfer rates.

A critical cross-cutting challenge across all sorbent technologies is the energy penalty associated with regeneration, which typically accounts for 70-80% of the total energy consumption in carbon capture processes. This energy requirement significantly impacts the overall carbon footprint reduction potential of these technologies.

Material stability under industrial conditions remains problematic, with most advanced sorbents showing performance degradation when exposed to contaminants like SOx, NOx, and water vapor commonly found in industrial emissions. Additionally, the manufacturing scalability of novel sorbents presents a substantial barrier to commercialization, with production volumes currently orders of magnitude below what would be required for meaningful climate impact.

Existing CO₂ Sorbent Implementation Strategies

01 Low carbon footprint sorbent materials for CO₂ capture

Various materials with inherently low carbon footprints can be used as effective CO₂ capture sorbents. These include naturally occurring minerals, modified biomass-derived materials, and synthetically optimized compounds designed specifically to minimize embodied carbon while maximizing capture efficiency. The environmental impact of these materials is significantly lower compared to conventional sorbents, making them more sustainable options for carbon capture applications.- Low carbon footprint sorbent materials for CO₂ capture: Various materials with low carbon footprints can be used as sorbents for CO₂ capture. These include naturally derived materials, recycled materials, and synthetically optimized compounds designed to minimize environmental impact during their production and use. These sorbents are specifically engineered to maximize CO₂ capture efficiency while maintaining a minimal carbon footprint throughout their lifecycle.

- Life cycle assessment of CO₂ capture sorbents: Life cycle assessment methodologies are applied to evaluate the overall carbon footprint of CO₂ capture sorbents from raw material extraction through manufacturing, use, and disposal. These assessments consider energy inputs, emissions during production, regeneration requirements, and end-of-life scenarios to determine the net environmental impact of different sorbent technologies. This approach helps identify sorbents that provide the best balance between capture efficiency and minimal carbon footprint.

- Energy-efficient regeneration processes for CO₂ sorbents: Innovative regeneration processes are developed to reduce the energy requirements and associated carbon emissions when regenerating CO₂ capture sorbents. These include low-temperature regeneration techniques, pressure-swing approaches, and novel heating methods that minimize energy consumption. By reducing the energy needed for sorbent regeneration, the overall carbon footprint of the capture process is significantly decreased.

- Integration of renewable energy in CO₂ capture systems: CO₂ capture systems are designed to integrate with renewable energy sources to power sorbent regeneration and other energy-intensive processes. This integration includes solar thermal energy, wind power, geothermal energy, and waste heat recovery systems. By utilizing renewable energy instead of fossil fuels, the carbon footprint associated with sorbent regeneration is substantially reduced, improving the net carbon benefit of the capture process.

- Direct air capture sorbent optimization for carbon footprint reduction: Specialized sorbents for direct air capture (DAC) applications are optimized to minimize their carbon footprint while maximizing CO₂ removal from ambient air. These optimizations include increasing sorbent durability to extend useful life, improving CO₂ selectivity to reduce energy requirements, and developing manufacturing processes with lower environmental impacts. The goal is to ensure that the carbon removed through DAC significantly exceeds the carbon emitted during the sorbent's production and operation.

02 Life cycle assessment of CO₂ capture sorbent production

Life cycle assessment methodologies are applied to evaluate the carbon footprint of sorbent production processes. These assessments consider energy inputs, raw material extraction, manufacturing processes, and transportation requirements. By analyzing the entire production chain, researchers can identify carbon hotspots and optimize manufacturing routes to reduce the overall environmental impact of sorbent production while maintaining or improving capture performance.Expand Specific Solutions03 Regeneration energy requirements and carbon footprint trade-offs

The energy required for sorbent regeneration significantly impacts the overall carbon footprint of capture systems. Innovative approaches focus on reducing regeneration temperatures and energy inputs while maintaining capture capacity. These include novel material designs, process optimizations, and integration with renewable energy sources. The trade-offs between capture efficiency, regeneration energy, and overall carbon footprint are carefully balanced to develop more sustainable carbon capture solutions.Expand Specific Solutions04 Sorbent durability and lifetime carbon impact

The durability and operational lifetime of CO₂ capture sorbents directly affect their overall carbon footprint. Materials engineered for extended cycling stability and resistance to degradation reduce the frequency of replacement and associated environmental impacts. Research focuses on enhancing mechanical strength, chemical stability, and resistance to contaminants to maximize sorbent lifetime while maintaining capture performance, thereby reducing the cumulative carbon footprint over the operational life of carbon capture systems.Expand Specific Solutions05 Integration of waste materials in sorbent production

Industrial and agricultural waste materials can be repurposed as precursors for CO₂ capture sorbents, significantly reducing the carbon footprint associated with sorbent production. These waste-derived sorbents utilize materials that would otherwise require disposal, creating a circular economy approach to carbon capture. The process involves converting waste materials through various treatments to create effective CO₂ capture materials, thereby addressing both waste management and carbon capture challenges simultaneously.Expand Specific Solutions

Leading Companies in Carbon Capture Industry

The CO₂ capture sorbent market is in an early growth phase, characterized by increasing commercial deployment but still evolving technology maturity. The global carbon capture market is projected to reach approximately $7-10 billion by 2030, driven by stringent emission regulations and net-zero commitments. Leading companies like Climeworks AG and Global Thermostat are pioneering direct air capture technologies, while established energy corporations including Saudi Aramco, BASF, and Sinopec are developing industrial-scale solutions. Academic institutions such as MIT, Tsinghua University, and Arizona State University are advancing fundamental research in novel sorbent materials. The competitive landscape features collaboration between research institutions and industry players, with varying approaches to sorbent technology ranging from solid adsorbents to chemical absorption systems, indicating a dynamic but not yet fully consolidated market.

Climeworks AG

Technical Solution: Climeworks has developed a Direct Air Capture (DAC) technology that uses solid sorbent materials to selectively capture CO₂ from ambient air. Their modular collectors draw air through a filter where proprietary aminopolymer sorbents bind with CO₂ molecules. Once saturated, the collectors are heated to approximately 100°C, releasing concentrated CO₂ that can be permanently stored underground or utilized in various applications. Climeworks operates the world's first commercial DAC plant in Switzerland and launched Orca in Iceland in 2021, currently the world's largest direct air capture and storage facility with an annual capacity of 4,000 tons of CO₂ removal[1]. Their technology achieves high purity CO₂ capture (>99%) and integrates with geothermal energy sources in Iceland to minimize the carbon footprint of the capture process itself[2]. The company has secured significant funding and partnerships with corporations like Microsoft and Shopify to scale their technology.

Strengths: Proven commercial-scale implementation with operational plants; modular design allows for flexible deployment and scaling; integration with renewable energy sources reduces operational carbon footprint; high CO₂ purity output suitable for storage or utilization. Weaknesses: High energy requirements for sorbent regeneration; relatively high cost per ton of CO₂ captured compared to point-source capture; current capacity remains limited compared to global emissions scale.

Global Thermostat Operations LLC

Technical Solution: Global Thermostat has pioneered a unique CO₂ capture technology using porous, honeycomb ceramic monoliths coated with proprietary amine-based chemical sorbents. Their system can extract CO₂ directly from ambient air (Direct Air Capture) or from industrial flue gas streams at concentrations ranging from 2% to 20%. The process operates through a temperature-swing adsorption cycle where ambient or waste heat (85-100°C) is used to release the captured CO₂ for subsequent compression and utilization. A key innovation is their ability to use low-grade waste heat from industrial processes or renewable sources, significantly reducing the energy penalty associated with carbon capture[3]. Global Thermostat's modular design allows for scalable implementation, with each commercial unit capable of capturing approximately 35,000-40,000 tons of CO₂ annually. The company has demonstrated successful pilot operations at SRI International in Menlo Park and a commercial demonstration plant in Huntsville, Alabama[4], achieving capture costs reportedly in the $100-150 per ton range.

Strengths: Versatile technology applicable to both direct air capture and point-source emissions; efficient use of low-grade waste heat reduces operational costs and energy requirements; modular design enables flexible deployment across different scales and settings; relatively lower energy requirements compared to some competing technologies. Weaknesses: Still faces challenges in scaling to gigaton levels needed for meaningful climate impact; capital costs remain significant; requires reliable heat sources for optimal operation; technology performance may vary under different environmental conditions.

Key Innovations in Sorbent Material Science

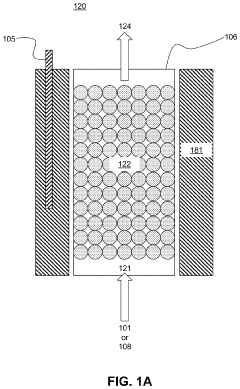

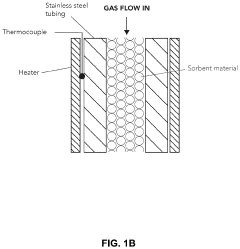

Co2 capture using carbonate sorbents

PatentPendingUS20230182073A1

Innovation

- The use of non-deliquescent metal carbonates like calcium carbonate as sorbents in CO2 capture systems, which reduce waste and energy consumption by minimizing water condensation and sorbent loss, and the regeneration and recycling of spent sorbents through decomposition and granulation, allowing for efficient CO2 capture from both point sources and air.

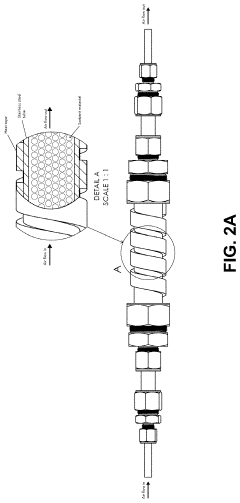

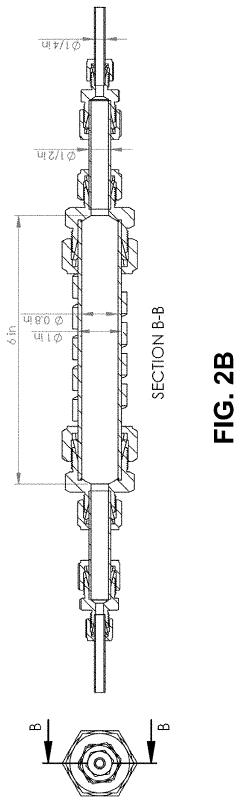

Pellets of sorbent suitable for carbon dioxide capture

PatentPendingUS20210252481A1

Innovation

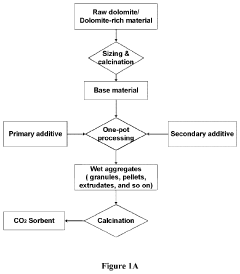

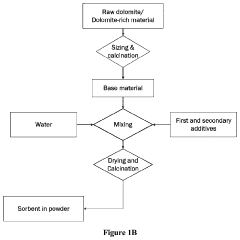

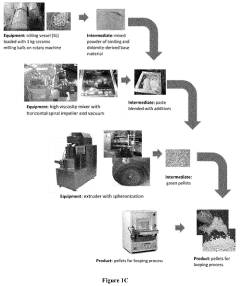

- Preparation of CaO-based sorbent pellets using dolomite with the addition of two different metal ions (Al or Mg, and a transition metal or lanthanide) through a one-pot process, which enhances CO2 capture performance and stability across multiple cycles.

Regulatory Framework for Carbon Capture

The regulatory landscape for carbon capture technologies has evolved significantly over the past decade, creating both opportunities and challenges for CO₂ capture sorbent development and implementation. At the international level, the Paris Agreement established a framework requiring signatory nations to commit to reducing greenhouse gas emissions, indirectly stimulating investment in carbon capture technologies including advanced sorbent materials.

In the United States, the 45Q tax credit has emerged as a pivotal policy mechanism, offering up to $50 per metric ton of CO₂ permanently sequestered and $35 per ton for CO₂ utilized in enhanced oil recovery or other applications. This financial incentive has catalyzed research and development in high-performance, cost-effective sorbent materials that can maximize capture efficiency while minimizing operational costs.

The European Union has implemented the Emissions Trading System (ETS), creating a market-based approach to carbon reduction. The system's increasing carbon prices—reaching over €80 per ton in 2022—have significantly improved the economic viability of sorbent-based capture systems. Additionally, the EU Innovation Fund provides substantial financial support for demonstration projects featuring novel sorbent technologies.

Regulatory standards for sorbent materials themselves are still evolving. Current frameworks primarily focus on capture efficiency requirements rather than specific material properties. However, emerging regulations are beginning to address environmental and health impacts of sorbent production, use, and disposal. The ISO 14064 standards for greenhouse gas accounting provide methodologies for quantifying the emissions reduction achieved through sorbent-based capture systems.

Developing nations are establishing their own regulatory approaches, often with support from international climate finance mechanisms. China's national emissions trading scheme, launched in 2021, represents the world's largest carbon market and creates significant potential for sorbent technology deployment in the country's extensive industrial sector.

Regulatory uncertainty remains a significant challenge for sorbent technology developers. The long development cycles for new materials (typically 5-10 years) often exceed political cycles, creating investment risk. Industry stakeholders have advocated for more consistent, technology-neutral regulatory frameworks that focus on performance metrics rather than prescribing specific technological approaches.

Future regulatory developments are likely to include more stringent capture efficiency requirements, lifecycle assessment standards for sorbent materials, and potentially mandatory carbon capture requirements for certain industrial sectors. These evolving frameworks will continue to shape the research priorities and commercial viability of next-generation CO₂ capture sorbents.

In the United States, the 45Q tax credit has emerged as a pivotal policy mechanism, offering up to $50 per metric ton of CO₂ permanently sequestered and $35 per ton for CO₂ utilized in enhanced oil recovery or other applications. This financial incentive has catalyzed research and development in high-performance, cost-effective sorbent materials that can maximize capture efficiency while minimizing operational costs.

The European Union has implemented the Emissions Trading System (ETS), creating a market-based approach to carbon reduction. The system's increasing carbon prices—reaching over €80 per ton in 2022—have significantly improved the economic viability of sorbent-based capture systems. Additionally, the EU Innovation Fund provides substantial financial support for demonstration projects featuring novel sorbent technologies.

Regulatory standards for sorbent materials themselves are still evolving. Current frameworks primarily focus on capture efficiency requirements rather than specific material properties. However, emerging regulations are beginning to address environmental and health impacts of sorbent production, use, and disposal. The ISO 14064 standards for greenhouse gas accounting provide methodologies for quantifying the emissions reduction achieved through sorbent-based capture systems.

Developing nations are establishing their own regulatory approaches, often with support from international climate finance mechanisms. China's national emissions trading scheme, launched in 2021, represents the world's largest carbon market and creates significant potential for sorbent technology deployment in the country's extensive industrial sector.

Regulatory uncertainty remains a significant challenge for sorbent technology developers. The long development cycles for new materials (typically 5-10 years) often exceed political cycles, creating investment risk. Industry stakeholders have advocated for more consistent, technology-neutral regulatory frameworks that focus on performance metrics rather than prescribing specific technological approaches.

Future regulatory developments are likely to include more stringent capture efficiency requirements, lifecycle assessment standards for sorbent materials, and potentially mandatory carbon capture requirements for certain industrial sectors. These evolving frameworks will continue to shape the research priorities and commercial viability of next-generation CO₂ capture sorbents.

Economic Viability of Sorbent Technologies

The economic viability of CO₂ capture sorbent technologies represents a critical factor in their widespread adoption for carbon footprint reduction. Current market analyses indicate that the cost-effectiveness of these technologies varies significantly based on sorbent type, application context, and scale of implementation. Traditional amine-based sorbents, while technically mature, often present economic challenges due to their high regeneration energy requirements and degradation rates, resulting in operational costs ranging from $40-80 per ton of CO₂ captured.

Novel materials such as metal-organic frameworks (MOFs) and porous polymers demonstrate promising cost reduction potential, with recent advancements reducing production costs by approximately 30-45% compared to first-generation sorbents. However, these materials still face scalability challenges that impact their economic feasibility in industrial applications. The economy of scale significantly influences viability, with large-scale operations typically achieving 25-40% lower cost per ton of CO₂ captured compared to smaller installations.

Life-cycle cost analysis reveals that sorbent durability and regeneration efficiency are key economic drivers. Materials with extended operational lifespans (>1000 cycles) and lower regeneration energy requirements (<2.5 GJ/ton CO₂) demonstrate substantially improved economic profiles. Recent innovations in regeneration processes have reduced energy penalties by up to 20%, enhancing overall economic performance.

Market mechanisms and carbon pricing policies significantly impact economic viability. Regions with carbon prices exceeding $50-60 per ton create favorable conditions for sorbent technology deployment. The European Union's Emissions Trading System and similar emerging frameworks in Asia and North America are gradually improving the business case for these technologies, though price volatility remains a challenge for long-term investment planning.

Integration with existing industrial processes offers additional economic benefits through heat recovery and operational synergies. Co-location with industrial facilities can reduce implementation costs by 15-30% through shared infrastructure and energy utilization. Furthermore, the potential for revenue generation through enhanced oil recovery or conversion of captured CO₂ into value-added products improves the overall economic equation.

Investment costs for sorbent-based capture systems have decreased by approximately 35% over the past decade, with projections suggesting further reductions of 20-30% by 2030 as technologies mature and manufacturing processes improve. This trend, coupled with increasing regulatory pressures and corporate sustainability commitments, is gradually shifting the economic calculus in favor of wider adoption of CO₂ capture sorbent technologies across multiple industrial sectors.

Novel materials such as metal-organic frameworks (MOFs) and porous polymers demonstrate promising cost reduction potential, with recent advancements reducing production costs by approximately 30-45% compared to first-generation sorbents. However, these materials still face scalability challenges that impact their economic feasibility in industrial applications. The economy of scale significantly influences viability, with large-scale operations typically achieving 25-40% lower cost per ton of CO₂ captured compared to smaller installations.

Life-cycle cost analysis reveals that sorbent durability and regeneration efficiency are key economic drivers. Materials with extended operational lifespans (>1000 cycles) and lower regeneration energy requirements (<2.5 GJ/ton CO₂) demonstrate substantially improved economic profiles. Recent innovations in regeneration processes have reduced energy penalties by up to 20%, enhancing overall economic performance.

Market mechanisms and carbon pricing policies significantly impact economic viability. Regions with carbon prices exceeding $50-60 per ton create favorable conditions for sorbent technology deployment. The European Union's Emissions Trading System and similar emerging frameworks in Asia and North America are gradually improving the business case for these technologies, though price volatility remains a challenge for long-term investment planning.

Integration with existing industrial processes offers additional economic benefits through heat recovery and operational synergies. Co-location with industrial facilities can reduce implementation costs by 15-30% through shared infrastructure and energy utilization. Furthermore, the potential for revenue generation through enhanced oil recovery or conversion of captured CO₂ into value-added products improves the overall economic equation.

Investment costs for sorbent-based capture systems have decreased by approximately 35% over the past decade, with projections suggesting further reductions of 20-30% by 2030 as technologies mature and manufacturing processes improve. This trend, coupled with increasing regulatory pressures and corporate sustainability commitments, is gradually shifting the economic calculus in favor of wider adoption of CO₂ capture sorbent technologies across multiple industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!