ALD Precursor Safety And Handling Best Practices

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Precursor Evolution and Safety Objectives

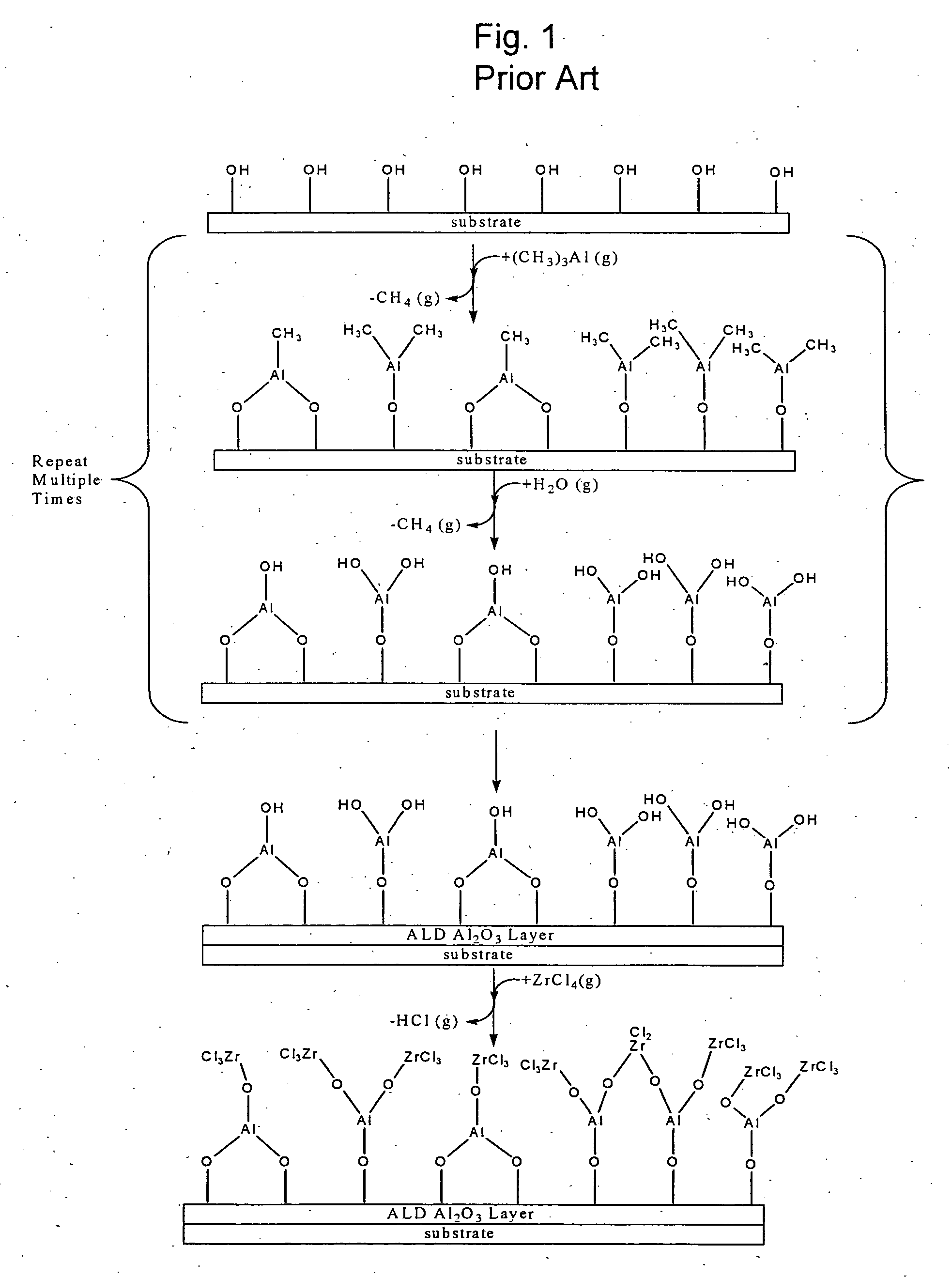

Atomic Layer Deposition (ALD) precursor technology has evolved significantly since its inception in the 1970s, transitioning from simple compounds to increasingly sophisticated and specialized molecules designed for specific applications. The early precursors were primarily based on metal halides and alkyls, which offered limited performance and posed significant safety challenges due to their pyrophoric nature and high reactivity. As semiconductor manufacturing advanced, the demand for more precise thin film deposition drove the development of safer, more efficient precursor chemicals.

The evolution of ALD precursors has been marked by several key milestones. In the 1990s, the introduction of metal-organic compounds represented a significant advancement, offering improved film quality and process control. The 2000s witnessed the emergence of amino-based precursors, which provided enhanced thermal stability and reduced reactivity with air and moisture. Recent developments have focused on creating precursors with higher vapor pressure, longer shelf life, and reduced environmental impact.

Safety considerations have been paramount throughout this evolution. Early incidents involving highly reactive precursors led to stringent safety protocols and the pursuit of inherently safer chemicals. The industry has gradually shifted from pyrophoric compounds to air-stable alternatives wherever possible, significantly reducing handling risks while maintaining deposition performance.

Current safety objectives in ALD precursor development focus on multiple dimensions. First, chemical stability aims to reduce reactivity with air, moisture, and container materials during storage and transport. Second, toxicity reduction addresses both acute exposure risks and long-term environmental concerns. Third, thermal stability improvements prevent decomposition during storage and enable more consistent deposition processes.

The semiconductor industry's push toward atomic-scale precision in increasingly complex device architectures has intensified the need for specialized precursors. This has created a tension between performance requirements and safety considerations, as some applications still require highly reactive compounds to achieve desired film properties.

Regulatory frameworks have also evolved alongside precursor technology. International standards such as REACH in Europe and similar regulations in North America and Asia have established increasingly stringent requirements for chemical safety documentation, exposure limits, and handling protocols. These regulations have become important drivers in precursor development, pushing manufacturers to invest in safer alternatives.

The ultimate objective in ALD precursor evolution is to achieve an optimal balance between performance, cost-effectiveness, and safety. This includes developing compounds that deliver excellent film quality and conformality while minimizing risks throughout the supply chain from manufacturing to end use.

The evolution of ALD precursors has been marked by several key milestones. In the 1990s, the introduction of metal-organic compounds represented a significant advancement, offering improved film quality and process control. The 2000s witnessed the emergence of amino-based precursors, which provided enhanced thermal stability and reduced reactivity with air and moisture. Recent developments have focused on creating precursors with higher vapor pressure, longer shelf life, and reduced environmental impact.

Safety considerations have been paramount throughout this evolution. Early incidents involving highly reactive precursors led to stringent safety protocols and the pursuit of inherently safer chemicals. The industry has gradually shifted from pyrophoric compounds to air-stable alternatives wherever possible, significantly reducing handling risks while maintaining deposition performance.

Current safety objectives in ALD precursor development focus on multiple dimensions. First, chemical stability aims to reduce reactivity with air, moisture, and container materials during storage and transport. Second, toxicity reduction addresses both acute exposure risks and long-term environmental concerns. Third, thermal stability improvements prevent decomposition during storage and enable more consistent deposition processes.

The semiconductor industry's push toward atomic-scale precision in increasingly complex device architectures has intensified the need for specialized precursors. This has created a tension between performance requirements and safety considerations, as some applications still require highly reactive compounds to achieve desired film properties.

Regulatory frameworks have also evolved alongside precursor technology. International standards such as REACH in Europe and similar regulations in North America and Asia have established increasingly stringent requirements for chemical safety documentation, exposure limits, and handling protocols. These regulations have become important drivers in precursor development, pushing manufacturers to invest in safer alternatives.

The ultimate objective in ALD precursor evolution is to achieve an optimal balance between performance, cost-effectiveness, and safety. This includes developing compounds that deliver excellent film quality and conformality while minimizing risks throughout the supply chain from manufacturing to end use.

Market Analysis for Safe ALD Precursor Solutions

The global market for Atomic Layer Deposition (ALD) precursors is experiencing robust growth, driven by increasing demand in semiconductor manufacturing, microelectronics, and emerging applications in energy storage and conversion technologies. The market for safe ALD precursor solutions is projected to reach $1.2 billion by 2027, growing at a compound annual growth rate of 12.8% from 2022 to 2027.

The semiconductor industry remains the largest consumer of ALD precursors, accounting for approximately 65% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and the increasing complexity of semiconductor devices requiring precise atomic-level deposition processes. The demand for high-k dielectric materials and metal gates in advanced logic devices has particularly fueled the growth of ALD precursor consumption.

Regional analysis reveals that Asia-Pacific dominates the market with over 50% share, primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and China. North America follows with approximately 25% market share, driven by advanced research and development activities and the presence of major precursor suppliers.

Safety concerns have become a significant market driver, with manufacturers increasingly willing to pay premium prices for precursors with improved safety profiles. This trend is evidenced by the 18% price premium commanded by safer alternatives to traditional hazardous precursors such as trimethylaluminum (TMA) and titanium tetrachloride (TiCl4).

The market for safety equipment and handling systems for ALD precursors is growing in parallel, estimated at $320 million in 2022 with projected growth to $580 million by 2027. This includes specialized storage containers, delivery systems, and monitoring equipment designed to minimize exposure risks and prevent accidents.

End-user analysis indicates that integrated device manufacturers (IDMs) and foundries collectively account for 70% of the safe ALD precursor solutions market. Research institutions represent a smaller but growing segment at 15%, while emerging applications in energy, optics, and medical devices constitute the remaining 15%.

Customer surveys indicate that safety considerations now rank as the second most important factor in precursor selection decisions, after performance characteristics but ahead of cost considerations. This represents a significant shift from five years ago when safety ranked fourth in importance, highlighting the growing emphasis on workplace safety and environmental responsibility in the semiconductor industry.

The semiconductor industry remains the largest consumer of ALD precursors, accounting for approximately 65% of the total market share. This dominance is attributed to the continuous miniaturization of electronic components and the increasing complexity of semiconductor devices requiring precise atomic-level deposition processes. The demand for high-k dielectric materials and metal gates in advanced logic devices has particularly fueled the growth of ALD precursor consumption.

Regional analysis reveals that Asia-Pacific dominates the market with over 50% share, primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and China. North America follows with approximately 25% market share, driven by advanced research and development activities and the presence of major precursor suppliers.

Safety concerns have become a significant market driver, with manufacturers increasingly willing to pay premium prices for precursors with improved safety profiles. This trend is evidenced by the 18% price premium commanded by safer alternatives to traditional hazardous precursors such as trimethylaluminum (TMA) and titanium tetrachloride (TiCl4).

The market for safety equipment and handling systems for ALD precursors is growing in parallel, estimated at $320 million in 2022 with projected growth to $580 million by 2027. This includes specialized storage containers, delivery systems, and monitoring equipment designed to minimize exposure risks and prevent accidents.

End-user analysis indicates that integrated device manufacturers (IDMs) and foundries collectively account for 70% of the safe ALD precursor solutions market. Research institutions represent a smaller but growing segment at 15%, while emerging applications in energy, optics, and medical devices constitute the remaining 15%.

Customer surveys indicate that safety considerations now rank as the second most important factor in precursor selection decisions, after performance characteristics but ahead of cost considerations. This represents a significant shift from five years ago when safety ranked fourth in importance, highlighting the growing emphasis on workplace safety and environmental responsibility in the semiconductor industry.

Current Challenges in ALD Precursor Handling

Despite significant advancements in Atomic Layer Deposition (ALD) technology, the handling of precursors remains one of the most challenging aspects of the process. ALD precursors often exhibit extreme reactivity with moisture and oxygen, presenting substantial safety hazards and technical difficulties during transportation, storage, and usage. Many precursors are pyrophoric, meaning they can spontaneously ignite when exposed to air, while others are corrosive or toxic, requiring specialized containment systems and handling protocols.

The volatility characteristics of precursors create a delicate balance between effective delivery and safety management. Insufficient volatility leads to poor film growth rates and uniformity issues, while excessive volatility complicates safe handling and precise dosing control. This challenge is particularly pronounced with solid precursors that have low vapor pressures, often necessitating elevated temperatures that may accelerate decomposition or create additional safety risks.

Cross-contamination between precursors represents another significant challenge, as even trace amounts of contamination can compromise film quality and device performance. The industry currently lacks standardized protocols for preventing cross-contamination during precursor transfers and system maintenance, leading to inconsistent practices across manufacturing facilities.

The environmental impact of precursor handling has gained increasing attention as ALD applications expand. Many precursors contain heavy metals or other environmentally harmful substances, creating disposal challenges and potential regulatory complications. The absence of comprehensive recycling or neutralization methods for spent precursors contributes to the environmental footprint of ALD processes.

Supply chain stability presents an ongoing challenge, with many high-performance precursors being produced by a limited number of suppliers. This concentration creates vulnerability to disruptions and price volatility, particularly for specialized precursors used in cutting-edge applications. The proprietary nature of many precursor formulations further complicates supply chain management and quality control efforts.

Scalability issues emerge as ALD transitions from research environments to high-volume manufacturing. Handling large quantities of reactive precursors safely and efficiently requires sophisticated engineering controls and monitoring systems that may not be fully developed. The capital investment required for these safety systems can be prohibitive for smaller manufacturers, creating barriers to entry in the ALD market.

Training and knowledge transfer regarding safe precursor handling remains inconsistent across the industry. The specialized nature of ALD precursor safety often results in knowledge silos within organizations, with critical safety information not being effectively communicated to all stakeholders involved in the handling process.

The volatility characteristics of precursors create a delicate balance between effective delivery and safety management. Insufficient volatility leads to poor film growth rates and uniformity issues, while excessive volatility complicates safe handling and precise dosing control. This challenge is particularly pronounced with solid precursors that have low vapor pressures, often necessitating elevated temperatures that may accelerate decomposition or create additional safety risks.

Cross-contamination between precursors represents another significant challenge, as even trace amounts of contamination can compromise film quality and device performance. The industry currently lacks standardized protocols for preventing cross-contamination during precursor transfers and system maintenance, leading to inconsistent practices across manufacturing facilities.

The environmental impact of precursor handling has gained increasing attention as ALD applications expand. Many precursors contain heavy metals or other environmentally harmful substances, creating disposal challenges and potential regulatory complications. The absence of comprehensive recycling or neutralization methods for spent precursors contributes to the environmental footprint of ALD processes.

Supply chain stability presents an ongoing challenge, with many high-performance precursors being produced by a limited number of suppliers. This concentration creates vulnerability to disruptions and price volatility, particularly for specialized precursors used in cutting-edge applications. The proprietary nature of many precursor formulations further complicates supply chain management and quality control efforts.

Scalability issues emerge as ALD transitions from research environments to high-volume manufacturing. Handling large quantities of reactive precursors safely and efficiently requires sophisticated engineering controls and monitoring systems that may not be fully developed. The capital investment required for these safety systems can be prohibitive for smaller manufacturers, creating barriers to entry in the ALD market.

Training and knowledge transfer regarding safe precursor handling remains inconsistent across the industry. The specialized nature of ALD precursor safety often results in knowledge silos within organizations, with critical safety information not being effectively communicated to all stakeholders involved in the handling process.

Established Safety Handling Protocols for ALD Precursors

01 Safe handling and storage of ALD precursors

ALD precursors often require specific handling and storage conditions to maintain their stability and prevent hazardous reactions. This includes using specialized containers, maintaining appropriate temperature and humidity levels, and implementing proper ventilation systems. Safety protocols may involve the use of inert atmospheres, such as nitrogen or argon, to prevent unwanted reactions with oxygen or moisture. Proper training for personnel handling these materials is essential to minimize risks associated with toxic, pyrophoric, or otherwise hazardous precursors.- Safe storage and transportation of ALD precursors: ALD precursors often require special storage and transportation conditions to maintain their stability and prevent hazardous reactions. This includes using specialized containers with appropriate temperature control, pressure regulation, and inert gas environments. Proper labeling and handling protocols are essential during transportation to prevent accidents and ensure compliance with safety regulations. Some precursors may require refrigeration or protection from moisture and air to maintain their chemical integrity.

- Exposure control and personal protection measures: Working with ALD precursors requires specific personal protective equipment (PPE) and exposure control measures. This includes the use of appropriate gloves, respiratory protection, eye protection, and protective clothing. Engineering controls such as fume hoods, local exhaust ventilation, and closed handling systems are implemented to minimize exposure risks. Regular monitoring of exposure levels and implementation of emergency response procedures for accidental releases are also critical components of a comprehensive safety program.

- Chemical compatibility and reactivity management: ALD precursors can exhibit high reactivity with various materials, necessitating careful management of chemical compatibility. This involves selecting appropriate materials for containers, delivery lines, and process equipment that won't degrade or react with the precursors. Understanding potential incompatibilities with other chemicals used in the process is essential to prevent unwanted reactions. Detailed reactivity data and compatibility charts are used to guide safe handling practices and prevent incidents caused by chemical interactions.

- Specialized delivery systems and equipment: Safe handling of ALD precursors requires specialized delivery systems designed to minimize exposure and contamination risks. These systems include automated precursor delivery units with precise temperature and flow control, specialized valves and fittings resistant to corrosion, and sealed transfer mechanisms to prevent leaks. Advanced monitoring systems are incorporated to detect pressure changes, leaks, or other abnormalities that could indicate safety issues. Regular maintenance and inspection protocols ensure the continued safe operation of these specialized handling systems.

- Waste management and disposal procedures: Proper disposal of ALD precursor waste materials is critical for environmental and safety compliance. This includes neutralization procedures for reactive precursors, specialized containment for toxic or environmentally harmful substances, and appropriate labeling of waste containers. Recycling and recovery processes may be implemented for certain precursors to reduce waste and environmental impact. Compliance with local, national, and international regulations governing hazardous waste disposal is essential, requiring detailed documentation and proper handling throughout the disposal process.

02 Delivery systems for volatile and reactive precursors

Specialized delivery systems are crucial for the safe and efficient transport of ALD precursors from storage containers to deposition chambers. These systems often incorporate features such as heated delivery lines to prevent condensation, precise flow control mechanisms, and leak detection capabilities. For highly reactive or pyrophoric precursors, advanced containment technologies may be employed, including sealed ampoules, bubblers with carrier gases, or direct liquid injection systems. These delivery methods help maintain precursor purity while minimizing exposure risks to operators.Expand Specific Solutions03 Purification and quality control of ALD precursors

Ensuring the purity and quality of ALD precursors is essential for both safety and process reliability. Purification techniques may include distillation, sublimation, or chemical treatments to remove impurities that could cause unwanted reactions or compromise film quality. Quality control protocols typically involve analytical methods such as gas chromatography, mass spectrometry, or nuclear magnetic resonance spectroscopy to verify precursor composition and purity. Regular testing and certification of precursors help prevent process variations and potential safety incidents during handling and deposition.Expand Specific Solutions04 Environmental and health considerations for ALD chemicals

ALD precursors may present various environmental and health hazards that require specific mitigation strategies. This includes proper waste management procedures for unused precursors and byproducts, emission control systems to prevent release of harmful substances, and comprehensive risk assessments. Personal protective equipment requirements typically include chemical-resistant gloves, lab coats, and respiratory protection appropriate for the specific precursors being handled. Safety data sheets must be readily available, and emergency response protocols should be established for spills, leaks, or accidental exposures.Expand Specific Solutions05 Novel precursor formulations with enhanced safety profiles

Research efforts are focused on developing new ALD precursor formulations with improved safety characteristics while maintaining or enhancing deposition performance. These innovations include designing less pyrophoric alternatives to traditional precursors, creating more thermally stable compounds, and formulating precursors with reduced toxicity. Some approaches involve the use of adducts or chemical modifications that render precursors safer to handle while preserving their reactivity during the deposition process. These safer alternatives can reduce the need for specialized handling equipment and simplify safety protocols.Expand Specific Solutions

Leading Manufacturers and Suppliers in ALD Precursor Industry

The ALD precursor safety and handling landscape is evolving rapidly as the semiconductor industry matures, with the market expected to grow significantly due to increasing demand for advanced microelectronics. Currently, the industry is in a growth phase with established players like ASM International, Applied Materials, and Lam Research leading technical innovation in precursor safety protocols. Emerging companies such as Picosun and Beneq are advancing specialized safety handling systems, while semiconductor manufacturers like TSMC, Intel, and Micron are implementing rigorous internal safety standards. The technology maturity varies across applications, with major chemical suppliers including Linde and Praxair developing increasingly sophisticated containment and delivery systems to address the unique challenges of highly reactive and potentially hazardous ALD precursors.

ASM International NV

Technical Solution: ASM International has developed comprehensive ALD precursor safety protocols centered around their proprietary Safe Delivery Source (SDS) technology. This system enables the safe handling of highly reactive and potentially hazardous ALD precursors by containing them in specialized vessels designed to minimize exposure risks. Their approach includes advanced engineering controls such as automated precursor delivery systems with multiple redundant safety features, real-time monitoring of process parameters, and specialized containment solutions for different precursor chemistries. ASM has implemented a hierarchical safety framework that addresses the entire precursor lifecycle from transportation to disposal, with particular emphasis on preventing chemical exposure through sophisticated gas cabinet designs with integrated leak detection and emergency shutdown capabilities. Their safety practices include detailed risk assessments for each precursor type, specialized training programs for personnel, and documented emergency response procedures tailored to specific chemical hazards.

Strengths: Industry-leading containment technology specifically designed for highly reactive ALD precursors; comprehensive lifecycle management approach; extensive experience with diverse precursor chemistries. Weaknesses: Proprietary systems may require significant capital investment; specialized training requirements for operators; system complexity may increase maintenance demands.

Picosun Oy

Technical Solution: Picosun has pioneered ALD precursor safety through their PICOSAFE™ handling system, specifically engineered for the unique challenges of atomic layer deposition chemicals. Their approach integrates precursor-specific safety measures throughout their ALD reactor designs, with particular attention to the safe delivery of highly reactive organometallics and halide compounds. Picosun's technology incorporates specialized precursor cylinders with proprietary valve designs that minimize exposure risks during connections and disconnections. Their safety protocols include automated purging sequences before maintenance activities, temperature-controlled precursor lines to prevent condensation or decomposition, and advanced gas abatement systems for process exhaust. Picosun has developed specific handling procedures for different precursor categories (solid, liquid, gas) with corresponding safety equipment requirements and has implemented comprehensive training programs for end-users focusing on chemical-specific hazards and emergency response procedures. Their systems feature integrated safety interlocks that prevent unsafe operating conditions and automated monitoring of critical parameters with alarm functions.

Strengths: Specialized expertise in ALD-specific safety challenges; integrated approach combining equipment design and operational protocols; extensive experience with diverse precursor types including highly reactive compounds. Weaknesses: Solutions primarily focused on their own equipment ecosystem; may require adaptation for integration with other manufacturers' systems; specialized components can increase maintenance complexity.

Critical Patents and Innovations in Precursor Safety Systems

Precursors for atomic layer deposition

PatentInactiveUS20100055321A1

Innovation

- Development of new ALD precursors with mixed ligands, including sterically hindered ligands with metal-nitrogen bonds, and partially hydrated nitrates or mixed nitrate and halide precursors that exhibit self-limiting growth, enhanced stability, and reduced contamination, allowing for deposition at lower temperatures and improved purity.

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

PatentInactiveUS20060040054A1

Innovation

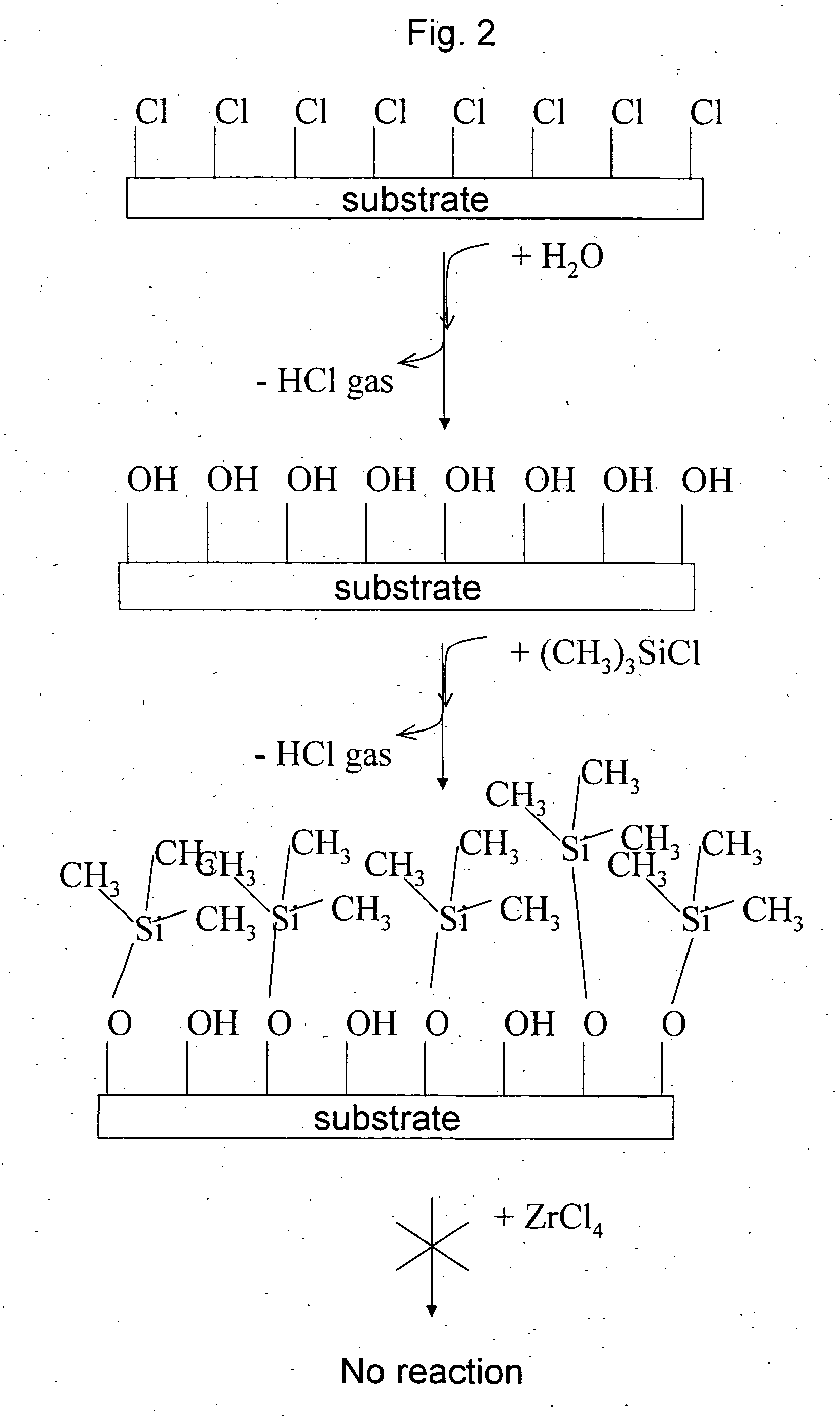

- Passivating the internal surfaces of the ALD reactor by using compounds that render them hydrophobic and non-reactive with precursors, preventing the formation of OH or NH groups, thereby reducing deposition buildup and particle shedding.

Environmental Impact and Sustainability Considerations

The environmental impact of Atomic Layer Deposition (ALD) precursors extends far beyond their immediate application in semiconductor manufacturing. These chemicals, while essential for creating high-performance electronic components, present significant sustainability challenges throughout their lifecycle. Many ALD precursors contain heavy metals, halogens, or other environmentally persistent compounds that can accumulate in ecosystems if improperly managed.

Waste management represents a critical concern in ALD processes. Unreacted precursors and byproducts must undergo specialized treatment before disposal to prevent soil and groundwater contamination. Advanced abatement systems, including scrubbers and thermal oxidizers, have become standard equipment in facilities utilizing ALD technology, reducing harmful emissions by up to 99% in optimal configurations.

Energy consumption associated with precursor synthesis, purification, and handling also contributes significantly to the environmental footprint of ALD processes. The production of high-purity precursors often requires energy-intensive distillation and purification steps. Recent innovations in green chemistry approaches have demonstrated potential for reducing this energy demand by 30-40% through catalytic synthesis routes and alternative purification methods.

The semiconductor industry has begun implementing closed-loop systems for precursor management, recovering and recycling unreacted materials where chemically feasible. These systems not only reduce waste but can decrease raw material consumption by 15-25% in continuous production environments. Additionally, manufacturers are increasingly exploring biodegradable packaging and container systems designed specifically for ALD precursors, minimizing disposal issues.

Climate impact considerations have driven research into precursors with lower global warming potential. Traditional ALD processes often utilize compounds with high atmospheric lifetimes and significant greenhouse effects. Next-generation precursors being developed incorporate molecular structures designed to break down more readily in the atmosphere, reducing their climate forcing potential by orders of magnitude compared to first-generation alternatives.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations and similar initiatives in Asia and North America have established increasingly stringent requirements for chemical registration, risk assessment, and lifecycle management of industrial chemicals including ALD precursors. Companies demonstrating leadership in sustainable precursor handling not only ensure regulatory compliance but often realize competitive advantages through improved operational efficiency and reduced liability risks.

Waste management represents a critical concern in ALD processes. Unreacted precursors and byproducts must undergo specialized treatment before disposal to prevent soil and groundwater contamination. Advanced abatement systems, including scrubbers and thermal oxidizers, have become standard equipment in facilities utilizing ALD technology, reducing harmful emissions by up to 99% in optimal configurations.

Energy consumption associated with precursor synthesis, purification, and handling also contributes significantly to the environmental footprint of ALD processes. The production of high-purity precursors often requires energy-intensive distillation and purification steps. Recent innovations in green chemistry approaches have demonstrated potential for reducing this energy demand by 30-40% through catalytic synthesis routes and alternative purification methods.

The semiconductor industry has begun implementing closed-loop systems for precursor management, recovering and recycling unreacted materials where chemically feasible. These systems not only reduce waste but can decrease raw material consumption by 15-25% in continuous production environments. Additionally, manufacturers are increasingly exploring biodegradable packaging and container systems designed specifically for ALD precursors, minimizing disposal issues.

Climate impact considerations have driven research into precursors with lower global warming potential. Traditional ALD processes often utilize compounds with high atmospheric lifetimes and significant greenhouse effects. Next-generation precursors being developed incorporate molecular structures designed to break down more readily in the atmosphere, reducing their climate forcing potential by orders of magnitude compared to first-generation alternatives.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations and similar initiatives in Asia and North America have established increasingly stringent requirements for chemical registration, risk assessment, and lifecycle management of industrial chemicals including ALD precursors. Companies demonstrating leadership in sustainable precursor handling not only ensure regulatory compliance but often realize competitive advantages through improved operational efficiency and reduced liability risks.

Regulatory Compliance Framework for ALD Materials

The regulatory landscape for Atomic Layer Deposition (ALD) precursors spans multiple jurisdictions and frameworks, necessitating a comprehensive understanding for organizations involved in their manufacture, transport, storage, and use. At the international level, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard communication elements that many ALD precursors must comply with, including specific labeling requirements and safety data sheet formats.

In the United States, ALD materials fall under the regulatory purview of multiple agencies. The Occupational Safety and Health Administration (OSHA) enforces the Hazard Communication Standard (29 CFR 1910.1200), which requires proper labeling, safety data sheets, and employee training for hazardous chemicals. The Environmental Protection Agency (EPA) regulates ALD precursors through the Toxic Substances Control Act (TSCA), particularly for new chemical substances that may require Pre-Manufacturing Notifications (PMNs).

For transportation compliance, the Department of Transportation (DOT) classifies many ALD precursors as hazardous materials under 49 CFR, imposing specific packaging, labeling, and shipping documentation requirements. Pyrophoric precursors, common in ALD processes, face particularly stringent transportation regulations due to their spontaneous ignition hazards.

The European Union's regulatory framework presents additional compliance challenges through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation. ALD material manufacturers must register substances produced or imported in quantities over one ton annually, with more comprehensive data requirements at higher volume thresholds.

Asian markets have developed their own chemical regulatory systems, with Japan's Chemical Substances Control Law (CSCL), China's Measures for Environmental Management of New Chemical Substances, and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) all requiring specific registrations and approvals for ALD precursors.

Facility-level compliance for ALD operations typically involves adherence to local fire codes, building regulations, and environmental permits. Many jurisdictions require specific ventilation standards, gas detection systems, and emergency response plans for facilities handling reactive or toxic precursors. Waste management regulations govern the disposal of spent precursors and byproducts, with many classified as hazardous waste requiring specialized handling and documentation.

Organizations working with ALD materials must implement robust compliance management systems that track regulatory changes across relevant jurisdictions, maintain current safety data sheets, ensure proper chemical inventories, and provide regular employee training on safe handling procedures and emergency protocols.

In the United States, ALD materials fall under the regulatory purview of multiple agencies. The Occupational Safety and Health Administration (OSHA) enforces the Hazard Communication Standard (29 CFR 1910.1200), which requires proper labeling, safety data sheets, and employee training for hazardous chemicals. The Environmental Protection Agency (EPA) regulates ALD precursors through the Toxic Substances Control Act (TSCA), particularly for new chemical substances that may require Pre-Manufacturing Notifications (PMNs).

For transportation compliance, the Department of Transportation (DOT) classifies many ALD precursors as hazardous materials under 49 CFR, imposing specific packaging, labeling, and shipping documentation requirements. Pyrophoric precursors, common in ALD processes, face particularly stringent transportation regulations due to their spontaneous ignition hazards.

The European Union's regulatory framework presents additional compliance challenges through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation. ALD material manufacturers must register substances produced or imported in quantities over one ton annually, with more comprehensive data requirements at higher volume thresholds.

Asian markets have developed their own chemical regulatory systems, with Japan's Chemical Substances Control Law (CSCL), China's Measures for Environmental Management of New Chemical Substances, and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) all requiring specific registrations and approvals for ALD precursors.

Facility-level compliance for ALD operations typically involves adherence to local fire codes, building regulations, and environmental permits. Many jurisdictions require specific ventilation standards, gas detection systems, and emergency response plans for facilities handling reactive or toxic precursors. Waste management regulations govern the disposal of spent precursors and byproducts, with many classified as hazardous waste requiring specialized handling and documentation.

Organizations working with ALD materials must implement robust compliance management systems that track regulatory changes across relevant jurisdictions, maintain current safety data sheets, ensure proper chemical inventories, and provide regular employee training on safe handling procedures and emergency protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!