Ammonia Fuel's Alignment with International Climate Agreements

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Development History and Objectives

Ammonia as a potential carbon-free fuel has a rich development history dating back to the early 20th century. The first significant milestone occurred in 1909 when Fritz Haber demonstrated the synthesis of ammonia from hydrogen and nitrogen, followed by Carl Bosch's industrial-scale implementation in 1913. This Haber-Bosch process remains the foundation of modern ammonia production, though it currently relies heavily on fossil fuels and accounts for approximately 1-2% of global carbon emissions.

The interest in ammonia as an energy carrier experienced a resurgence in the 1960s when the U.S. Army explored it for fuel cells in military applications. However, it wasn't until the early 2000s, amid growing climate change concerns, that ammonia gained serious attention as a potential zero-carbon fuel. The 2015 Paris Agreement, which established the goal of limiting global warming to well below 2°C above pre-industrial levels, catalyzed research into carbon-neutral energy alternatives, including ammonia.

By 2017, several major research initiatives emerged globally, including Japan's SIP Energy Carriers program, which identified ammonia as a promising hydrogen carrier. The Australian Renewable Energy Agency (ARENA) also began funding significant ammonia energy projects, recognizing its potential for renewable energy export. Concurrently, the NH3 Fuel Association has been organizing annual conferences since 2004, creating a platform for knowledge exchange among researchers, industry stakeholders, and policymakers.

The technical objectives for ammonia fuel development align with international climate agreements in several dimensions. Primary goals include developing green ammonia production methods using renewable electricity, improving ammonia combustion efficiency in engines and turbines, enhancing safety protocols for handling and storage, and reducing the cost of production to competitive levels with conventional fuels. The International Energy Agency's Net Zero by 2050 roadmap specifically identifies ammonia as a key technology for decarbonizing shipping and other hard-to-abate sectors.

Recent technological advancements have accelerated progress, with demonstration projects for ammonia-powered vessels by companies like MAN Energy Solutions and Wärtsilä. The Green Ammonia Consortium in Japan aims to establish an ammonia value chain by 2030, while the European Union's Hydrogen Strategy includes ammonia as a critical hydrogen carrier. These initiatives collectively work toward the objective of scaling ammonia fuel technology to contribute meaningfully to global decarbonization efforts by 2050, in alignment with the Paris Agreement's timeline for achieving carbon neutrality.

The interest in ammonia as an energy carrier experienced a resurgence in the 1960s when the U.S. Army explored it for fuel cells in military applications. However, it wasn't until the early 2000s, amid growing climate change concerns, that ammonia gained serious attention as a potential zero-carbon fuel. The 2015 Paris Agreement, which established the goal of limiting global warming to well below 2°C above pre-industrial levels, catalyzed research into carbon-neutral energy alternatives, including ammonia.

By 2017, several major research initiatives emerged globally, including Japan's SIP Energy Carriers program, which identified ammonia as a promising hydrogen carrier. The Australian Renewable Energy Agency (ARENA) also began funding significant ammonia energy projects, recognizing its potential for renewable energy export. Concurrently, the NH3 Fuel Association has been organizing annual conferences since 2004, creating a platform for knowledge exchange among researchers, industry stakeholders, and policymakers.

The technical objectives for ammonia fuel development align with international climate agreements in several dimensions. Primary goals include developing green ammonia production methods using renewable electricity, improving ammonia combustion efficiency in engines and turbines, enhancing safety protocols for handling and storage, and reducing the cost of production to competitive levels with conventional fuels. The International Energy Agency's Net Zero by 2050 roadmap specifically identifies ammonia as a key technology for decarbonizing shipping and other hard-to-abate sectors.

Recent technological advancements have accelerated progress, with demonstration projects for ammonia-powered vessels by companies like MAN Energy Solutions and Wärtsilä. The Green Ammonia Consortium in Japan aims to establish an ammonia value chain by 2030, while the European Union's Hydrogen Strategy includes ammonia as a critical hydrogen carrier. These initiatives collectively work toward the objective of scaling ammonia fuel technology to contribute meaningfully to global decarbonization efforts by 2050, in alignment with the Paris Agreement's timeline for achieving carbon neutrality.

Global Market Potential for Carbon-Neutral Ammonia Fuel

The global market for carbon-neutral ammonia fuel is experiencing significant growth potential, driven by the urgent need to decarbonize various sectors, particularly maritime shipping, power generation, and industrial processes. Current projections indicate that the carbon-neutral ammonia market could reach $200 billion by 2050, representing a substantial portion of the future energy mix in a net-zero emissions scenario.

Maritime shipping presents the most immediate and substantial market opportunity, as the International Maritime Organization's targets for reducing greenhouse gas emissions by at least 50% by 2050 have created strong demand for zero-carbon fuels. Ammonia's energy density advantages over hydrogen and compatibility with existing infrastructure position it as a leading contender in this sector, with potential to capture 25-30% of the marine fuel market by 2050.

The power generation sector offers another significant market avenue, particularly for regions transitioning away from coal. Japan and South Korea have emerged as early adopters, incorporating ammonia co-firing in existing thermal power plants. Japan's strategic roadmap aims for 3 million tons of ammonia use in power generation by 2030, scaling to 30 million tons by 2050, demonstrating the substantial growth trajectory in this segment.

Geographically, the market potential varies considerably. Asia-Pacific represents the largest potential market, with Japan, South Korea, and Singapore leading adoption for both maritime and power generation applications. Europe follows closely, driven by stringent emissions regulations and ambitious climate targets, particularly in Scandinavian countries and Germany where green hydrogen and ammonia initiatives receive substantial government support.

The Middle East and Australia are positioning themselves as potential production hubs due to their abundant renewable energy resources and existing export infrastructure. Saudi Arabia's NEOM project and Australia's Asian Renewable Energy Hub exemplify large-scale investments in green ammonia production capacity aimed at export markets.

Market growth is further supported by carbon pricing mechanisms being implemented globally. As carbon prices increase—currently ranging from $25-85 per ton in various markets—the economic competitiveness of carbon-neutral ammonia improves substantially against conventional fuels.

Investment trends confirm the market's potential, with over $15 billion committed to green ammonia projects globally since 2020. Major energy companies including BP, Shell, and Yara have announced significant investments in production facilities, while shipping giants Maersk and NYK Line are developing ammonia-powered vessels, indicating strong industry confidence in ammonia's future market role.

Maritime shipping presents the most immediate and substantial market opportunity, as the International Maritime Organization's targets for reducing greenhouse gas emissions by at least 50% by 2050 have created strong demand for zero-carbon fuels. Ammonia's energy density advantages over hydrogen and compatibility with existing infrastructure position it as a leading contender in this sector, with potential to capture 25-30% of the marine fuel market by 2050.

The power generation sector offers another significant market avenue, particularly for regions transitioning away from coal. Japan and South Korea have emerged as early adopters, incorporating ammonia co-firing in existing thermal power plants. Japan's strategic roadmap aims for 3 million tons of ammonia use in power generation by 2030, scaling to 30 million tons by 2050, demonstrating the substantial growth trajectory in this segment.

Geographically, the market potential varies considerably. Asia-Pacific represents the largest potential market, with Japan, South Korea, and Singapore leading adoption for both maritime and power generation applications. Europe follows closely, driven by stringent emissions regulations and ambitious climate targets, particularly in Scandinavian countries and Germany where green hydrogen and ammonia initiatives receive substantial government support.

The Middle East and Australia are positioning themselves as potential production hubs due to their abundant renewable energy resources and existing export infrastructure. Saudi Arabia's NEOM project and Australia's Asian Renewable Energy Hub exemplify large-scale investments in green ammonia production capacity aimed at export markets.

Market growth is further supported by carbon pricing mechanisms being implemented globally. As carbon prices increase—currently ranging from $25-85 per ton in various markets—the economic competitiveness of carbon-neutral ammonia improves substantially against conventional fuels.

Investment trends confirm the market's potential, with over $15 billion committed to green ammonia projects globally since 2020. Major energy companies including BP, Shell, and Yara have announced significant investments in production facilities, while shipping giants Maersk and NYK Line are developing ammonia-powered vessels, indicating strong industry confidence in ammonia's future market role.

Technical Barriers and Current State of Ammonia Fuel Technology

The current state of ammonia fuel technology presents a complex landscape of technical challenges despite its promising alignment with international climate agreements. Ammonia (NH3) contains no carbon, making it a potentially carbon-free fuel when produced using renewable energy sources. However, significant technical barriers remain before widespread adoption becomes feasible.

The production of green ammonia represents the first major hurdle. While the Haber-Bosch process has been used for over a century to synthesize ammonia, it traditionally relies on natural gas and produces substantial CO2 emissions. Transitioning to renewable-powered electrolysis for hydrogen production and subsequent ammonia synthesis requires overcoming efficiency losses and high capital costs. Current electrolyzer technologies operate at 60-80% efficiency, with further losses during the ammonia synthesis stage.

Storage and transportation infrastructure presents another critical challenge. Although ammonia can be liquefied at moderate pressure (10 bar) or refrigerated (-33°C), its corrosive nature necessitates specialized materials for containment systems. Existing natural gas and petroleum infrastructure cannot be directly repurposed without significant modifications, creating a "chicken-and-egg" problem for infrastructure development.

Combustion characteristics of ammonia fuel create additional technical barriers. Its low flame speed, high ignition energy, and narrow flammability range make it difficult to use in conventional engines. Current ammonia combustion systems often require pilot fuels or catalysts to maintain stable combustion. NOx emissions during ammonia combustion also present environmental concerns that must be addressed through advanced combustion control or post-treatment systems.

Safety considerations further complicate ammonia fuel implementation. Its toxicity requires robust safety protocols, detection systems, and training programs. The characteristic pungent odor provides natural leak detection, but proper ventilation and handling procedures remain essential for widespread deployment.

Fuel cell applications for ammonia show promise but face their own technical hurdles. Direct ammonia fuel cells remain in early development stages with low power densities and durability challenges. Cracking ammonia to hydrogen for use in conventional fuel cells adds system complexity and reduces overall efficiency.

The economic viability of ammonia fuel technology currently suffers from high production costs compared to fossil alternatives. Green ammonia production costs range from $600-1,200 per ton, significantly higher than conventional ammonia at $200-400 per ton. Achieving cost parity will require continued technological improvements, economies of scale, and potentially supportive policy frameworks aligned with climate agreements.

The production of green ammonia represents the first major hurdle. While the Haber-Bosch process has been used for over a century to synthesize ammonia, it traditionally relies on natural gas and produces substantial CO2 emissions. Transitioning to renewable-powered electrolysis for hydrogen production and subsequent ammonia synthesis requires overcoming efficiency losses and high capital costs. Current electrolyzer technologies operate at 60-80% efficiency, with further losses during the ammonia synthesis stage.

Storage and transportation infrastructure presents another critical challenge. Although ammonia can be liquefied at moderate pressure (10 bar) or refrigerated (-33°C), its corrosive nature necessitates specialized materials for containment systems. Existing natural gas and petroleum infrastructure cannot be directly repurposed without significant modifications, creating a "chicken-and-egg" problem for infrastructure development.

Combustion characteristics of ammonia fuel create additional technical barriers. Its low flame speed, high ignition energy, and narrow flammability range make it difficult to use in conventional engines. Current ammonia combustion systems often require pilot fuels or catalysts to maintain stable combustion. NOx emissions during ammonia combustion also present environmental concerns that must be addressed through advanced combustion control or post-treatment systems.

Safety considerations further complicate ammonia fuel implementation. Its toxicity requires robust safety protocols, detection systems, and training programs. The characteristic pungent odor provides natural leak detection, but proper ventilation and handling procedures remain essential for widespread deployment.

Fuel cell applications for ammonia show promise but face their own technical hurdles. Direct ammonia fuel cells remain in early development stages with low power densities and durability challenges. Cracking ammonia to hydrogen for use in conventional fuel cells adds system complexity and reduces overall efficiency.

The economic viability of ammonia fuel technology currently suffers from high production costs compared to fossil alternatives. Green ammonia production costs range from $600-1,200 per ton, significantly higher than conventional ammonia at $200-400 per ton. Achieving cost parity will require continued technological improvements, economies of scale, and potentially supportive policy frameworks aligned with climate agreements.

Current Ammonia Production and Utilization Methods

01 Ammonia as a carbon-free fuel for climate goals

Ammonia is being developed as a carbon-free alternative fuel that can help meet climate agreement targets. As a hydrogen carrier that doesn't produce CO2 when combusted, ammonia offers significant potential for reducing greenhouse gas emissions in various sectors including transportation and power generation. Its high energy density and existing infrastructure for production and distribution make it particularly attractive for decarbonization strategies aligned with international climate agreements.- Ammonia as a carbon-free fuel for climate goals: Ammonia is being developed as a carbon-free alternative fuel that can help meet climate agreement targets. As a hydrogen carrier that doesn't emit CO2 when combusted, ammonia can be used in various applications including power generation, marine propulsion, and industrial processes. Its high energy density and existing infrastructure for production and distribution make it particularly attractive for decarbonization strategies aligned with international climate agreements.

- Green ammonia production technologies: Green ammonia production methods use renewable energy sources to produce ammonia without carbon emissions. These technologies typically employ electrolysis to generate hydrogen from water, which is then combined with nitrogen from air separation units in the Haber-Bosch process. Innovations in catalysts, process efficiency, and integration with renewable energy systems are making green ammonia production more economically viable and environmentally sustainable, supporting climate agreement objectives for industrial decarbonization.

- Ammonia fuel cells and power generation: Ammonia fuel cell technologies convert ammonia directly into electricity without combustion, offering high efficiency and zero-carbon power generation. These systems can either extract hydrogen from ammonia for use in conventional fuel cells or utilize direct ammonia fuel cells. Such technologies are being developed for stationary power applications, transportation, and distributed energy systems, providing clean energy solutions that align with climate agreement goals for reducing greenhouse gas emissions.

- Ammonia in maritime transportation decarbonization: Ammonia is emerging as a promising marine fuel to decarbonize the shipping industry, which is under pressure from climate agreements to reduce emissions. Ships can be retrofitted or newly built with ammonia-compatible engines and fuel systems. The maritime sector is developing safety protocols, bunkering infrastructure, and regulatory frameworks to enable widespread adoption of ammonia as a marine fuel, supporting international maritime climate targets while utilizing existing global ammonia distribution networks.

- Carbon credit and policy frameworks for ammonia fuel: Policy frameworks and carbon credit mechanisms are being developed to incentivize the adoption of ammonia as a clean fuel. These include carbon pricing, emissions trading systems, and regulatory standards that recognize ammonia's potential contribution to climate goals. International agreements and national policies are increasingly incorporating provisions for alternative fuels like ammonia, creating economic incentives through carbon credits, subsidies, and market-based mechanisms that reward the greenhouse gas reductions achieved through ammonia fuel adoption.

02 Ammonia production technologies for reduced emissions

Advanced technologies for ammonia production are being developed to reduce the carbon footprint of the manufacturing process. These include green ammonia production using renewable energy sources, electrolysis-based systems, and catalytic processes that minimize or eliminate greenhouse gas emissions. These technologies are critical for ensuring that ammonia fuel can truly contribute to climate agreement goals by addressing emissions across the entire lifecycle from production to end use.Expand Specific Solutions03 Ammonia fuel infrastructure and distribution systems

The development of infrastructure and distribution systems for ammonia fuel is essential for its widespread adoption as a climate-friendly energy carrier. This includes specialized storage facilities, transportation networks, fueling stations, and safety protocols. Innovations in these areas are designed to overcome logistical challenges while ensuring compliance with climate agreement requirements for reducing emissions throughout the supply chain.Expand Specific Solutions04 Ammonia combustion and utilization technologies

Advanced combustion and utilization technologies are being developed to efficiently use ammonia as a fuel while minimizing harmful emissions. These include specialized engines, turbines, fuel cells, and combustion systems designed to handle ammonia's unique properties. Innovations focus on addressing challenges such as NOx emissions, combustion stability, and energy efficiency to ensure ammonia fuel use aligns with climate agreement objectives for both carbon reduction and air quality.Expand Specific Solutions05 Policy frameworks and economic models for ammonia fuel adoption

Policy frameworks and economic models are being developed to facilitate the adoption of ammonia as a climate-friendly fuel. These include carbon pricing mechanisms, regulatory standards, incentive programs, and market-based approaches that align with international climate agreements. Such frameworks aim to create favorable conditions for investment in ammonia fuel technologies while ensuring their deployment contributes effectively to meeting climate targets through standardized emissions accounting and verification methods.Expand Specific Solutions

Leading Organizations in Ammonia Fuel Research and Commercialization

Ammonia fuel's alignment with international climate agreements is currently in an early development stage, with a growing market projected to reach significant scale by 2050. The technology maturity varies across the value chain, with companies demonstrating different levels of advancement. AMOGY is pioneering ammonia-based power solutions for transportation, while established energy players like TotalEnergies, Equinor, and Sinopec are investing in production infrastructure. Mitsubishi Heavy Industries and Linde are developing critical enabling technologies. Academic institutions including King Abdullah University and Colorado School of Mines are advancing fundamental research. This diverse ecosystem reflects ammonia fuel's potential as a zero-carbon energy carrier that could significantly contribute to meeting climate targets through decarbonization of hard-to-abate sectors.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries (MHI) has developed a comprehensive ammonia fuel technology portfolio specifically designed to support international climate agreement goals. Their approach centers on ammonia co-firing technology for power generation, successfully demonstrating 20% ammonia co-firing in coal power plants with plans to achieve 100% ammonia firing by 2025[2]. This technology provides an immediate pathway to reduce carbon emissions from existing infrastructure. MHI has also developed specialized ammonia gas turbines capable of direct ammonia combustion with proprietary combustion technology that minimizes NOx emissions while maintaining thermal efficiency. Their integrated approach includes ammonia production technology utilizing renewable energy, with demonstration projects achieving carbon intensity reductions of over 80% compared to conventional methods[4]. MHI's maritime solutions include ammonia-fueled engines and fuel supply systems designed specifically for shipping applications, addressing one of the hardest-to-decarbonize sectors under international climate frameworks.

Strengths: Extensive engineering capabilities across the entire ammonia value chain; established global presence with implementation experience; strong integration with existing energy infrastructure enabling faster adoption. Weaknesses: Co-firing approach still relies partially on fossil fuels in the transition period; NOx emission control systems add complexity and cost; full implementation requires significant modifications to existing infrastructure.

Ammonia Casale SpA

Technical Solution: Ammonia Casale has developed advanced ammonia synthesis technologies specifically designed to align with international climate agreements. Their proprietary "Casale Ammonia Technology" incorporates innovative catalysts and process optimizations that reduce energy consumption by up to 30% compared to conventional methods[1]. The company has pioneered a carbon-neutral ammonia production pathway that integrates renewable hydrogen sources with their synthesis process, effectively eliminating CO2 emissions. Their technology includes advanced heat recovery systems and pressure optimization techniques that significantly improve efficiency while maintaining high production rates. Ammonia Casale has also developed blue ammonia capabilities, incorporating carbon capture technologies that can sequester up to 95% of CO2 emissions from traditional production methods[3], providing a transition pathway that aligns with Paris Agreement goals while green ammonia infrastructure develops.

Strengths: Industry-leading expertise in ammonia synthesis with decades of specialized experience; proprietary catalyst technology that improves efficiency; established global presence with implementation capabilities across multiple regions. Weaknesses: Higher initial capital costs compared to conventional systems; requires integration with renewable energy sources to achieve full climate benefits; technology transition requires significant infrastructure investment.

Key Patents and Breakthroughs in Green Ammonia Technology

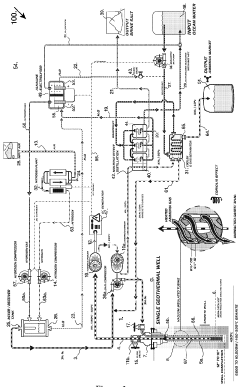

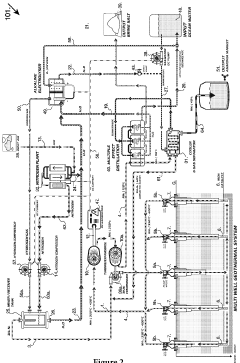

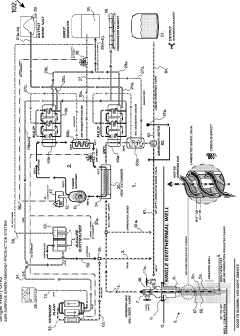

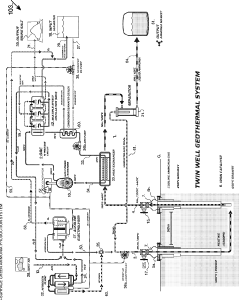

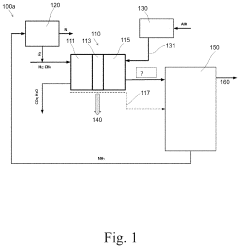

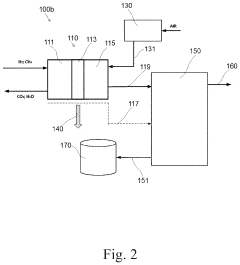

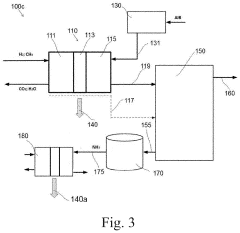

Sub-surface geothermal ammonia production system

PatentWO2023212775A1

Innovation

- A sub-surface geothermal ammonia production system that uses geothermal energy to generate low-cost baseload electricity, convert it into thermal energy, and utilize this energy to produce ammonia through a process involving hydrogen and nitrogen synthesis deep within a geothermal well, eliminating the need for supplementary electrical power and reducing safety risks.

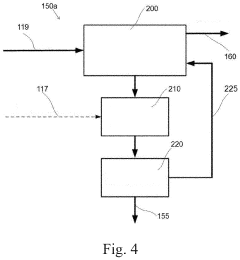

Solid oxide fuel cell arrangement generating ammonia as byproduct and utilizing ammonia as secondary fuel

PatentInactiveUS20220093950A1

Innovation

- A solid oxide fuel cell system that includes a gas separator to extract ammonia from the tail-gas stream, which can be used to fuel a secondary energy conversion device, stored, or reformed into hydrogen, utilizing heat transfer means to optimize the separation process.

International Climate Policy Framework and Ammonia Fuel Adoption

The Paris Agreement of 2015 established a global framework to limit global warming to well below 2°C, preferably to 1.5°C, compared to pre-industrial levels. This landmark agreement has catalyzed international efforts to transition away from fossil fuels toward cleaner energy alternatives. Ammonia fuel represents a promising pathway that aligns with these climate objectives, particularly due to its carbon-free combustion properties and potential to serve as a hydrogen carrier.

Under the United Nations Framework Convention on Climate Change (UNFCCC), nations have committed to Nationally Determined Contributions (NDCs) that outline their climate action plans. The adoption of ammonia fuel technology can significantly contribute to meeting these commitments, especially for hard-to-decarbonize sectors such as shipping, heavy industry, and long-haul transportation where direct electrification remains challenging.

The International Maritime Organization (IMO) has set ambitious targets to reduce greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 levels. Ammonia's potential as a marine fuel has gained substantial attention within this context, with several pilot projects already underway to test ammonia-powered vessels. These initiatives directly support the IMO's decarbonization strategy and demonstrate practical implementation of climate policy objectives.

The European Union's Green Deal and its "Fit for 55" package provide additional policy frameworks that could accelerate ammonia fuel adoption. These policies aim to reduce net greenhouse gas emissions by at least 55% by 2030, creating market incentives for low-carbon fuels like ammonia through carbon pricing mechanisms and regulatory standards.

In Asia, Japan's Strategic Energy Plan explicitly identifies ammonia as a key element in their energy transition, with targets to introduce ammonia into their fuel mix for power generation. Similarly, South Korea's Hydrogen Economy Roadmap includes provisions for ammonia as a hydrogen carrier, demonstrating regional policy alignment with ammonia fuel development.

The Clean Energy Ministerial (CEM) has established the Hydrogen Initiative, which includes ammonia as part of its focus on hydrogen-based solutions. This multilateral forum facilitates knowledge sharing and policy coordination among major economies, further embedding ammonia fuel within international climate cooperation frameworks.

For developing nations, the Climate Investment Funds and Green Climate Fund offer financial mechanisms that could support ammonia fuel infrastructure development as part of broader climate mitigation strategies, addressing the critical issue of climate finance highlighted in international agreements.

Under the United Nations Framework Convention on Climate Change (UNFCCC), nations have committed to Nationally Determined Contributions (NDCs) that outline their climate action plans. The adoption of ammonia fuel technology can significantly contribute to meeting these commitments, especially for hard-to-decarbonize sectors such as shipping, heavy industry, and long-haul transportation where direct electrification remains challenging.

The International Maritime Organization (IMO) has set ambitious targets to reduce greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 levels. Ammonia's potential as a marine fuel has gained substantial attention within this context, with several pilot projects already underway to test ammonia-powered vessels. These initiatives directly support the IMO's decarbonization strategy and demonstrate practical implementation of climate policy objectives.

The European Union's Green Deal and its "Fit for 55" package provide additional policy frameworks that could accelerate ammonia fuel adoption. These policies aim to reduce net greenhouse gas emissions by at least 55% by 2030, creating market incentives for low-carbon fuels like ammonia through carbon pricing mechanisms and regulatory standards.

In Asia, Japan's Strategic Energy Plan explicitly identifies ammonia as a key element in their energy transition, with targets to introduce ammonia into their fuel mix for power generation. Similarly, South Korea's Hydrogen Economy Roadmap includes provisions for ammonia as a hydrogen carrier, demonstrating regional policy alignment with ammonia fuel development.

The Clean Energy Ministerial (CEM) has established the Hydrogen Initiative, which includes ammonia as part of its focus on hydrogen-based solutions. This multilateral forum facilitates knowledge sharing and policy coordination among major economies, further embedding ammonia fuel within international climate cooperation frameworks.

For developing nations, the Climate Investment Funds and Green Climate Fund offer financial mechanisms that could support ammonia fuel infrastructure development as part of broader climate mitigation strategies, addressing the critical issue of climate finance highlighted in international agreements.

Infrastructure Requirements for Ammonia Fuel Implementation

The implementation of ammonia fuel systems requires substantial infrastructure development to ensure safe, efficient, and economically viable operations. Current natural gas and petroleum infrastructure cannot be directly repurposed for ammonia due to its unique physical and chemical properties, necessitating significant modifications or entirely new systems.

Storage facilities represent a critical infrastructure component, requiring specialized tanks capable of handling ammonia's corrosive nature and operating at either high pressure or low temperature. These storage solutions must be strategically located near production facilities, transportation hubs, and end-use applications to minimize logistical challenges and costs.

Transportation infrastructure presents another major consideration, with pipelines offering the most efficient method for large-scale ammonia movement. While some existing natural gas pipelines could potentially be retrofitted, most would require substantial modifications to handle ammonia's corrosive properties. Maritime shipping infrastructure for ammonia already exists due to its use as fertilizer, providing a foundation for expansion as fuel demand increases.

Distribution networks must be developed to connect production centers with end-users, requiring specialized fueling stations for transportation applications. These stations need proper safety systems, specialized handling equipment, and trained personnel to manage ammonia's toxicity risks.

Power generation facilities utilizing ammonia as fuel require purpose-built or significantly modified combustion systems. Direct ammonia combustion turbines or fuel cells designed specifically for ammonia represent emerging technologies requiring further development and standardization.

Safety infrastructure constitutes perhaps the most critical element, encompassing leak detection systems, emergency response capabilities, and comprehensive regulatory frameworks. Given ammonia's toxicity, robust safety protocols and equipment must be integrated throughout the entire supply chain.

The financial investment required for this infrastructure development is substantial, estimated at hundreds of billions of dollars globally. This necessitates coordinated public-private partnerships, government incentives, and international cooperation to achieve the scale needed for meaningful climate impact.

Regulatory frameworks must evolve to address ammonia's unique characteristics, with standardized codes for storage, transportation, and handling. International alignment of these regulations would facilitate global adoption and ensure consistent safety standards across regions implementing ammonia fuel systems.

Storage facilities represent a critical infrastructure component, requiring specialized tanks capable of handling ammonia's corrosive nature and operating at either high pressure or low temperature. These storage solutions must be strategically located near production facilities, transportation hubs, and end-use applications to minimize logistical challenges and costs.

Transportation infrastructure presents another major consideration, with pipelines offering the most efficient method for large-scale ammonia movement. While some existing natural gas pipelines could potentially be retrofitted, most would require substantial modifications to handle ammonia's corrosive properties. Maritime shipping infrastructure for ammonia already exists due to its use as fertilizer, providing a foundation for expansion as fuel demand increases.

Distribution networks must be developed to connect production centers with end-users, requiring specialized fueling stations for transportation applications. These stations need proper safety systems, specialized handling equipment, and trained personnel to manage ammonia's toxicity risks.

Power generation facilities utilizing ammonia as fuel require purpose-built or significantly modified combustion systems. Direct ammonia combustion turbines or fuel cells designed specifically for ammonia represent emerging technologies requiring further development and standardization.

Safety infrastructure constitutes perhaps the most critical element, encompassing leak detection systems, emergency response capabilities, and comprehensive regulatory frameworks. Given ammonia's toxicity, robust safety protocols and equipment must be integrated throughout the entire supply chain.

The financial investment required for this infrastructure development is substantial, estimated at hundreds of billions of dollars globally. This necessitates coordinated public-private partnerships, government incentives, and international cooperation to achieve the scale needed for meaningful climate impact.

Regulatory frameworks must evolve to address ammonia's unique characteristics, with standardized codes for storage, transportation, and handling. International alignment of these regulations would facilitate global adoption and ensure consistent safety standards across regions implementing ammonia fuel systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!