Ammonia Fuel Storage: Porosity and Leak Prevention Challenges

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Storage Background and Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition towards sustainable energy systems. With its high hydrogen density (17.6% by weight) and established handling protocols from its widespread use in agriculture and industry, ammonia presents a viable alternative to traditional fossil fuels. The historical development of ammonia as an industrial chemical dates back to the early 20th century with the Haber-Bosch process, which revolutionized fertilizer production. However, its consideration as an energy carrier is relatively recent, gaining momentum in the past two decades as climate change concerns intensified.

The evolution of ammonia fuel storage technology has progressed through several phases. Initially, industrial storage solutions were adapted for energy applications, utilizing high-pressure tanks and refrigerated vessels. As interest in ammonia as a fuel grew, specialized storage systems began to emerge, addressing the unique challenges of using ammonia in transportation and power generation contexts. Recent technological advancements have focused on improving safety, efficiency, and cost-effectiveness of storage solutions.

Current global research efforts are concentrated on overcoming the fundamental challenges of ammonia fuel storage, particularly those related to material porosity and leak prevention. These challenges are critical as ammonia is both corrosive and toxic, requiring robust containment systems. The technical objectives in this field include developing advanced materials with enhanced resistance to ammonia permeation, designing innovative sealing technologies, and creating monitoring systems capable of detecting micro-leaks before they become hazardous.

The primary goal of ammonia storage technology development is to enable widespread adoption of ammonia as a carbon-neutral fuel across multiple sectors, including maritime shipping, long-haul transportation, and grid-scale energy storage. This requires storage solutions that maintain the integrity of containment systems over extended periods, prevent material degradation due to ammonia exposure, and minimize the risk of leaks that could pose environmental or safety hazards.

Achieving these objectives necessitates a multidisciplinary approach, combining materials science, chemical engineering, mechanical design, and safety systems integration. The technical trajectory points toward increasingly sophisticated composite materials, advanced manufacturing techniques, and intelligent monitoring systems that can adapt to varying operational conditions and detect potential failures before they occur.

The successful development of reliable, efficient, and safe ammonia storage technologies stands as a critical enabler for the broader hydrogen economy, potentially unlocking significant decarbonization opportunities across multiple hard-to-abate sectors of the global economy.

The evolution of ammonia fuel storage technology has progressed through several phases. Initially, industrial storage solutions were adapted for energy applications, utilizing high-pressure tanks and refrigerated vessels. As interest in ammonia as a fuel grew, specialized storage systems began to emerge, addressing the unique challenges of using ammonia in transportation and power generation contexts. Recent technological advancements have focused on improving safety, efficiency, and cost-effectiveness of storage solutions.

Current global research efforts are concentrated on overcoming the fundamental challenges of ammonia fuel storage, particularly those related to material porosity and leak prevention. These challenges are critical as ammonia is both corrosive and toxic, requiring robust containment systems. The technical objectives in this field include developing advanced materials with enhanced resistance to ammonia permeation, designing innovative sealing technologies, and creating monitoring systems capable of detecting micro-leaks before they become hazardous.

The primary goal of ammonia storage technology development is to enable widespread adoption of ammonia as a carbon-neutral fuel across multiple sectors, including maritime shipping, long-haul transportation, and grid-scale energy storage. This requires storage solutions that maintain the integrity of containment systems over extended periods, prevent material degradation due to ammonia exposure, and minimize the risk of leaks that could pose environmental or safety hazards.

Achieving these objectives necessitates a multidisciplinary approach, combining materials science, chemical engineering, mechanical design, and safety systems integration. The technical trajectory points toward increasingly sophisticated composite materials, advanced manufacturing techniques, and intelligent monitoring systems that can adapt to varying operational conditions and detect potential failures before they occur.

The successful development of reliable, efficient, and safe ammonia storage technologies stands as a critical enabler for the broader hydrogen economy, potentially unlocking significant decarbonization opportunities across multiple hard-to-abate sectors of the global economy.

Market Analysis for Ammonia as Alternative Fuel

The global market for ammonia as an alternative fuel is experiencing significant growth driven by the urgent need for decarbonization across various sectors. Currently valued at approximately $72.5 billion, the ammonia fuel market is projected to expand at a compound annual growth rate of 6.8% through 2030, reaching an estimated market size of $115 billion. This growth trajectory is primarily fueled by ammonia's potential as a zero-carbon fuel when produced using renewable energy sources.

Transportation sectors, particularly maritime shipping, represent the most promising immediate market for ammonia fuel adoption. The International Maritime Organization's stringent emissions regulations have created a strong incentive for shipping companies to explore alternative fuels, with ammonia emerging as a leading candidate due to its energy density and existing handling infrastructure. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions have already announced significant investments in ammonia-powered vessel development.

The power generation sector presents another substantial market opportunity, with ammonia co-firing in existing coal plants gaining traction as a transitional decarbonization strategy. Countries including Japan, Australia, and several European nations have initiated pilot projects demonstrating ammonia's viability in this application. Japan's roadmap specifically targets 3 million tons of ammonia use in power generation by 2030.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for ammonia fuel adoption, driven by aggressive decarbonization policies in Japan, South Korea, and increasingly China. Europe follows closely, supported by the European Green Deal and substantial investments in hydrogen and ammonia infrastructure. North America shows growing interest, particularly in maritime applications and industrial decarbonization.

Market barriers include the current cost premium of green ammonia production, which remains 2-3 times higher than conventional ammonia. However, this gap is expected to narrow significantly by 2030 as renewable electricity costs continue to decline and electrolyzer technologies mature. Infrastructure development represents another challenge, with an estimated $30-40 billion in global investment required to establish adequate ammonia fuel distribution networks.

Consumer acceptance and safety concerns present additional market challenges, particularly regarding ammonia's toxicity and handling requirements. These concerns necessitate robust safety protocols and public education campaigns to facilitate broader market adoption. Despite these challenges, the ammonia fuel market demonstrates strong growth potential, supported by increasing corporate commitments to carbon neutrality and government policies incentivizing clean fuel adoption.

Transportation sectors, particularly maritime shipping, represent the most promising immediate market for ammonia fuel adoption. The International Maritime Organization's stringent emissions regulations have created a strong incentive for shipping companies to explore alternative fuels, with ammonia emerging as a leading candidate due to its energy density and existing handling infrastructure. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions have already announced significant investments in ammonia-powered vessel development.

The power generation sector presents another substantial market opportunity, with ammonia co-firing in existing coal plants gaining traction as a transitional decarbonization strategy. Countries including Japan, Australia, and several European nations have initiated pilot projects demonstrating ammonia's viability in this application. Japan's roadmap specifically targets 3 million tons of ammonia use in power generation by 2030.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for ammonia fuel adoption, driven by aggressive decarbonization policies in Japan, South Korea, and increasingly China. Europe follows closely, supported by the European Green Deal and substantial investments in hydrogen and ammonia infrastructure. North America shows growing interest, particularly in maritime applications and industrial decarbonization.

Market barriers include the current cost premium of green ammonia production, which remains 2-3 times higher than conventional ammonia. However, this gap is expected to narrow significantly by 2030 as renewable electricity costs continue to decline and electrolyzer technologies mature. Infrastructure development represents another challenge, with an estimated $30-40 billion in global investment required to establish adequate ammonia fuel distribution networks.

Consumer acceptance and safety concerns present additional market challenges, particularly regarding ammonia's toxicity and handling requirements. These concerns necessitate robust safety protocols and public education campaigns to facilitate broader market adoption. Despite these challenges, the ammonia fuel market demonstrates strong growth potential, supported by increasing corporate commitments to carbon neutrality and government policies incentivizing clean fuel adoption.

Current Challenges in Ammonia Storage Technology

Ammonia storage technology faces significant challenges that impede its widespread adoption as a carbon-free energy carrier. The primary technical hurdle involves the material properties of storage containers, particularly porosity issues that lead to ammonia leakage. Conventional steel tanks, while robust, exhibit microscopic pores that allow ammonia molecules to permeate over time, resulting in gradual loss of fuel and potential safety hazards. This porosity challenge is exacerbated by ammonia's small molecular size and corrosive nature, which accelerates material degradation.

Current storage systems predominantly rely on pressurized or refrigerated containment methods, both presenting distinct challenges. Pressurized systems operate at approximately 10-15 bar, requiring specialized materials to withstand pressure while preventing permeation. These systems face stress corrosion cracking issues, particularly at weld points and material interfaces. Refrigerated systems maintain ammonia at -33°C, necessitating significant energy input for cooling and presenting thermal insulation challenges that impact overall system efficiency.

Material compatibility represents another critical challenge, as ammonia's corrosive properties attack many conventional metals and polymers. Copper, brass, and zinc-containing alloys are particularly vulnerable, limiting material selection options. Current solutions employ specialized stainless steels or aluminum alloys, but these materials increase system costs substantially and still exhibit degradation over extended operational periods.

Sensor technology for leak detection presents additional complications. Existing ammonia sensors lack the sensitivity required for early detection of micro-leaks before they become significant safety concerns. The development of reliable, cost-effective sensor networks capable of continuous monitoring remains an unresolved technical challenge, particularly for distributed storage systems or mobile applications like vehicles.

Safety standards and regulatory frameworks add another layer of complexity. Current regulations for ammonia primarily address its use as a refrigerant or agricultural fertilizer rather than as an energy carrier. This regulatory gap creates uncertainty for technology developers and potential adopters, slowing implementation and investment in advanced storage solutions.

Scale-up challenges further complicate ammonia storage technology advancement. Laboratory-proven solutions often encounter unforeseen issues when implemented at industrial scale. The cost-performance balance becomes increasingly critical at larger scales, where material expenses, manufacturing complexities, and system integration challenges can render otherwise promising technologies economically unviable.

Current storage systems predominantly rely on pressurized or refrigerated containment methods, both presenting distinct challenges. Pressurized systems operate at approximately 10-15 bar, requiring specialized materials to withstand pressure while preventing permeation. These systems face stress corrosion cracking issues, particularly at weld points and material interfaces. Refrigerated systems maintain ammonia at -33°C, necessitating significant energy input for cooling and presenting thermal insulation challenges that impact overall system efficiency.

Material compatibility represents another critical challenge, as ammonia's corrosive properties attack many conventional metals and polymers. Copper, brass, and zinc-containing alloys are particularly vulnerable, limiting material selection options. Current solutions employ specialized stainless steels or aluminum alloys, but these materials increase system costs substantially and still exhibit degradation over extended operational periods.

Sensor technology for leak detection presents additional complications. Existing ammonia sensors lack the sensitivity required for early detection of micro-leaks before they become significant safety concerns. The development of reliable, cost-effective sensor networks capable of continuous monitoring remains an unresolved technical challenge, particularly for distributed storage systems or mobile applications like vehicles.

Safety standards and regulatory frameworks add another layer of complexity. Current regulations for ammonia primarily address its use as a refrigerant or agricultural fertilizer rather than as an energy carrier. This regulatory gap creates uncertainty for technology developers and potential adopters, slowing implementation and investment in advanced storage solutions.

Scale-up challenges further complicate ammonia storage technology advancement. Laboratory-proven solutions often encounter unforeseen issues when implemented at industrial scale. The cost-performance balance becomes increasingly critical at larger scales, where material expenses, manufacturing complexities, and system integration challenges can render otherwise promising technologies economically unviable.

Current Porosity and Leak Prevention Solutions

01 Porous materials for ammonia storage

Porous materials can be used in ammonia fuel storage systems to enhance storage capacity and safety. These materials, including metal-organic frameworks, zeolites, and activated carbons, provide high surface area for ammonia adsorption while reducing the risk of leakage. The porosity of these materials can be engineered to optimize ammonia uptake and release characteristics while maintaining structural integrity under various operating conditions.- Porous materials for ammonia storage: Specialized porous materials can be used in ammonia fuel storage systems to safely contain ammonia while allowing for efficient release when needed. These materials include metal-organic frameworks, zeolites, and other engineered porous structures that can adsorb ammonia molecules. The porosity of these materials is carefully controlled to maximize storage capacity while minimizing the risk of leakage. These systems often incorporate pressure and temperature management features to maintain optimal storage conditions.

- Leak detection and prevention systems: Advanced leak detection and prevention systems are essential components of ammonia fuel storage. These systems utilize sensors that can detect ammonia concentrations at very low levels, triggering automatic shutdown procedures when leaks are detected. Some designs incorporate redundant sealing mechanisms and self-healing materials that can respond to potential leak points. Continuous monitoring systems track pressure changes that might indicate developing leaks, allowing for preventive maintenance before failures occur.

- Composite materials and coatings for storage vessels: Specialized composite materials and protective coatings are developed for ammonia storage vessels to prevent corrosion and permeation. These materials often combine multiple layers with different properties to create an effective barrier against ammonia leakage. Some coatings incorporate nanomaterials that fill microscopic pores in the base material, effectively reducing porosity at the molecular level. These composite structures are designed to withstand the chemical properties of ammonia while maintaining structural integrity under varying pressure and temperature conditions.

- Valve and connection systems for leak prevention: Specialized valve and connection systems are critical for preventing leaks in ammonia fuel storage. These components incorporate multiple sealing mechanisms, including metal-to-metal seals, specialized gaskets, and precision-engineered fittings designed specifically for ammonia service. Some advanced designs feature double-containment systems where any leakage from the primary seal is captured by a secondary containment system. Quick-disconnect couplings with integrated check valves prevent ammonia release during connection and disconnection operations.

- Pressure management and safety systems: Pressure management systems are essential for safe ammonia storage, as they prevent over-pressurization that could lead to leaks or catastrophic failures. These systems incorporate pressure relief devices, expansion chambers, and temperature control mechanisms to maintain safe operating conditions. Some advanced designs feature active cooling systems that prevent pressure buildup during high ambient temperatures. Safety systems often include automated venting to specialized scrubbers or neutralization systems that can safely handle ammonia in case of emergency release.

02 Leak detection systems for ammonia storage

Advanced leak detection systems are essential for ammonia fuel storage to prevent hazardous releases. These systems incorporate sensors that can detect ammonia at low concentrations, coupled with automated alert mechanisms. Some designs feature continuous monitoring capabilities that can identify potential leaks before they become significant safety hazards, allowing for immediate response and containment measures to be implemented.Expand Specific Solutions03 Sealing technologies for ammonia containment

Specialized sealing technologies are critical for preventing ammonia leakage in storage systems. These include advanced gasket materials resistant to ammonia degradation, composite seals designed for cryogenic applications, and multi-layer sealing systems that provide redundant protection. Some innovations incorporate self-healing materials that can automatically address minor breaches before they develop into significant leaks, enhancing the overall safety and reliability of ammonia storage systems.Expand Specific Solutions04 Structural design for leak prevention

The structural design of ammonia storage systems plays a crucial role in leak prevention. Double-walled containment vessels with vacuum or inert gas monitoring in the interstitial space can provide early warning of potential breaches. Some designs incorporate stress-distribution features to minimize material fatigue at connection points and seams. Advanced manufacturing techniques ensure uniform material properties and eliminate potential weak points where leaks might develop under thermal cycling or mechanical stress.Expand Specific Solutions05 Material selection for ammonia compatibility

Selecting appropriate materials for ammonia storage systems is essential for preventing porosity-related leaks. Certain metals and alloys can experience hydrogen embrittlement or stress corrosion cracking when exposed to ammonia. Advanced materials such as specific stainless steel grades, aluminum alloys with specialized coatings, and composite materials offer superior resistance to ammonia permeation and degradation. These materials maintain their structural integrity and low porosity even after extended exposure to ammonia under varying temperature and pressure conditions.Expand Specific Solutions

Key Industry Players in Ammonia Fuel Storage

The ammonia fuel storage market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The global market size is projected to expand rapidly as ammonia gains traction as a carbon-free energy carrier, particularly in maritime and heavy transport sectors. Technologically, the field faces moderate maturity with ongoing challenges in porosity control and leak prevention. Leading players demonstrate varying approaches: AMOGY is pioneering ammonia-powered vessels and vehicles; Air Liquide and Linde bring extensive industrial gas expertise; while Mitsubishi Heavy Industries and Wärtsilä focus on maritime applications. Automotive companies like Robert Bosch and GM Global Technology are exploring ammonia for transportation, while Chinese institutions (China University of Petroleum, CNPC) are advancing fundamental research. Collaborative efforts between shipping companies (NYK Line, Nihon Shipyard) and technology providers are accelerating practical implementation solutions.

Linde GmbH

Technical Solution: Linde has developed sophisticated ammonia storage solutions that directly address porosity and leak prevention challenges through their advanced materials engineering approach. Their technology utilizes specialized stainless steel alloys with optimized nickel content to resist ammonia-induced stress corrosion cracking while maintaining structural integrity. Linde's storage systems feature proprietary multi-layered containment designs with intermediate monitoring capabilities that can detect even microscopic breaches before ammonia reaches the external environment. The company employs advanced manufacturing techniques including specialized welding processes and post-weld heat treatments that minimize the formation of micro-fractures and porosity in tank structures. Their ammonia storage solutions incorporate specialized gasket materials and sealing technologies specifically formulated to resist ammonia permeation and degradation over extended operational periods. Additionally, Linde has developed integrated safety systems that combine pressure relief, emergency shutdown, and ventilation controls specifically calibrated for ammonia's unique properties. The company's storage technology also features advanced thermal management systems that maintain optimal storage conditions while minimizing thermal stress on containment materials, thereby extending operational lifetimes and reducing leak risks.

Strengths: Extensive global experience in industrial gas handling with established infrastructure and comprehensive safety protocols developed through decades of ammonia handling experience. Their solutions benefit from integration with broader gas supply chain capabilities. Weaknesses: Traditional industrial approach may be less adaptable to novel applications compared to newer specialized companies, and systems typically require significant physical footprint.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic storage solutions for ammonia fuel that address porosity and leak prevention challenges. Their technology utilizes multi-layered containment systems with specialized materials resistant to ammonia's corrosive properties. The company employs proprietary metal alloys and composite materials with nano-scale surface treatments to minimize micro-porosity issues that typically lead to permeation and leakage. Air Liquide's storage tanks incorporate advanced vacuum insulation technology with multiple barrier layers to maintain the required low temperatures while preventing material degradation. Their systems feature real-time monitoring with distributed fiber optic sensing networks that can detect temperature anomalies and potential leak points before failure occurs. Additionally, Air Liquide has pioneered specialized sealing technologies for connection points and valves, traditionally the most vulnerable areas for ammonia leakage, using advanced elastomers and metal-to-metal sealing systems specifically engineered to withstand ammonia's chemical properties.

Strengths: Industry-leading expertise in cryogenic storage technology with global implementation capabilities and extensive experience handling hazardous gases. Their integrated monitoring systems provide superior safety performance. Weaknesses: Higher initial capital costs compared to conventional storage solutions and requires specialized maintenance protocols that may limit deployment in some regions.

Critical Patents in Ammonia Containment Materials

Ammonia storage structure and associated systems

PatentWO2014167123A8

Innovation

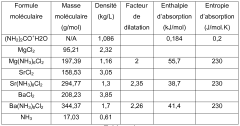

- A dual-storage structure using different alkaline-earth chloride materials with varying sorption enthalpies, porosities, and thermal conductivities, where ammonia can be selectively released by controlling the heating elements and circulation between storage parts, allowing precise monitoring and management of ammonia levels.

Ammonia storage structure and associated systems and method

PatentWO2014023840A1

Innovation

- An ammonia storage structure comprising alternating layers of powdery salt and thermally conductive material, such as expanded natural graphite, to enhance heat transfer and manage volume expansion during ammonia absorption, allowing for efficient and compact storage and release of ammonia.

Environmental Impact Assessment

Ammonia fuel storage systems present significant environmental considerations that must be thoroughly assessed to ensure sustainable implementation. When ammonia leaks occur due to porosity issues in storage materials or containment failures, immediate atmospheric impacts include the release of ammonia gas, which can cause localized air quality degradation. Ammonia is a respiratory irritant that can harm both humans and wildlife in concentrated amounts, creating potential environmental justice concerns for communities near storage facilities.

Water ecosystems face particular vulnerability to ammonia contamination. Leaked ammonia can dissolve readily in water bodies, potentially causing eutrophication through nitrogen enrichment and direct toxicity to aquatic organisms. Studies indicate that even low concentrations of ammonia can be lethal to fish and other aquatic species, disrupting ecosystem balance and biodiversity.

The environmental footprint of ammonia storage extends to soil impacts as well. Leaked ammonia can alter soil pH and nitrogen content, potentially disrupting microbial communities and affecting plant growth patterns in affected areas. These changes may persist long after the initial contamination event, requiring extensive remediation efforts.

Climate implications must also be considered in the environmental assessment framework. While ammonia itself has no direct global warming potential, the energy-intensive production processes traditionally used for ammonia synthesis contribute significantly to carbon emissions. However, when produced using renewable energy ("green ammonia"), the lifecycle environmental impact can be substantially reduced, positioning ammonia as a potentially carbon-neutral energy carrier.

Risk assessment modeling suggests that the environmental consequences of ammonia leakage vary significantly based on geographic and climatic factors. Coastal facilities present different risk profiles than inland storage sites, with considerations for marine ecosystem impacts versus freshwater or terrestrial concerns. Seasonal variations in temperature and precipitation patterns also influence dispersion and environmental persistence of leaked ammonia.

Mitigation strategies for environmental impacts include advanced leak detection systems, secondary containment structures, and emergency response protocols specifically designed for ammonia release scenarios. Environmental monitoring programs that track air, water, and soil quality around storage facilities provide essential data for ongoing impact assessment and adaptive management approaches.

Regulatory frameworks worldwide are increasingly incorporating specific environmental protection measures for ammonia fuel infrastructure, with particular emphasis on vulnerable ecosystem protection and community safety. These regulations typically mandate regular environmental impact assessments throughout the lifecycle of ammonia storage facilities.

Water ecosystems face particular vulnerability to ammonia contamination. Leaked ammonia can dissolve readily in water bodies, potentially causing eutrophication through nitrogen enrichment and direct toxicity to aquatic organisms. Studies indicate that even low concentrations of ammonia can be lethal to fish and other aquatic species, disrupting ecosystem balance and biodiversity.

The environmental footprint of ammonia storage extends to soil impacts as well. Leaked ammonia can alter soil pH and nitrogen content, potentially disrupting microbial communities and affecting plant growth patterns in affected areas. These changes may persist long after the initial contamination event, requiring extensive remediation efforts.

Climate implications must also be considered in the environmental assessment framework. While ammonia itself has no direct global warming potential, the energy-intensive production processes traditionally used for ammonia synthesis contribute significantly to carbon emissions. However, when produced using renewable energy ("green ammonia"), the lifecycle environmental impact can be substantially reduced, positioning ammonia as a potentially carbon-neutral energy carrier.

Risk assessment modeling suggests that the environmental consequences of ammonia leakage vary significantly based on geographic and climatic factors. Coastal facilities present different risk profiles than inland storage sites, with considerations for marine ecosystem impacts versus freshwater or terrestrial concerns. Seasonal variations in temperature and precipitation patterns also influence dispersion and environmental persistence of leaked ammonia.

Mitigation strategies for environmental impacts include advanced leak detection systems, secondary containment structures, and emergency response protocols specifically designed for ammonia release scenarios. Environmental monitoring programs that track air, water, and soil quality around storage facilities provide essential data for ongoing impact assessment and adaptive management approaches.

Regulatory frameworks worldwide are increasingly incorporating specific environmental protection measures for ammonia fuel infrastructure, with particular emphasis on vulnerable ecosystem protection and community safety. These regulations typically mandate regular environmental impact assessments throughout the lifecycle of ammonia storage facilities.

Regulatory Framework for Ammonia Fuel Adoption

The regulatory landscape for ammonia as a fuel is complex and evolving, with significant variations across different regions and jurisdictions. Currently, most regulations governing ammonia focus on its use as an industrial chemical rather than as a fuel, creating a regulatory gap that needs addressing for widespread adoption. The International Maritime Organization (IMO) has been at the forefront of developing safety guidelines for ammonia as a marine fuel, particularly through its International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code).

In the United States, the Environmental Protection Agency (EPA) regulates ammonia under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), but specific regulations for ammonia as a fuel remain limited. The Department of Transportation (DOT) has established requirements for the transportation of ammonia, which indirectly affects its use as a fuel.

The European Union has taken steps toward incorporating ammonia into its renewable energy framework through the Renewable Energy Directive (RED II), which recognizes ammonia as a potential carrier for hydrogen. Additionally, the EU's FuelEU Maritime initiative aims to increase the use of sustainable alternative fuels in European shipping, potentially including ammonia.

Japan has emerged as a leader in ammonia fuel regulation, developing a comprehensive roadmap for ammonia fuel adoption with specific safety standards and certification processes. Their approach includes detailed guidelines for leak prevention systems and material compatibility requirements to address porosity challenges.

Key regulatory challenges specific to ammonia's porosity and leak prevention include establishing standardized testing protocols for material compatibility, defining acceptable leak rates, and developing inspection regimes for ammonia storage systems. The toxicity of ammonia necessitates stringent safety regulations, with most jurisdictions requiring sophisticated leak detection systems, emergency response protocols, and buffer zones around ammonia storage facilities.

Certification standards for ammonia-compatible materials are being developed by organizations such as ASTM International and the International Organization for Standardization (ISO), focusing on permeation rates, material degradation, and long-term performance under various operating conditions.

For industry stakeholders, navigating this evolving regulatory landscape requires proactive engagement with regulatory bodies, participation in standard-setting processes, and investment in compliance infrastructure. As ammonia fuel adoption accelerates, regulatory frameworks are expected to become more comprehensive, addressing the specific challenges of porosity and leak prevention in ammonia storage systems.

In the United States, the Environmental Protection Agency (EPA) regulates ammonia under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), but specific regulations for ammonia as a fuel remain limited. The Department of Transportation (DOT) has established requirements for the transportation of ammonia, which indirectly affects its use as a fuel.

The European Union has taken steps toward incorporating ammonia into its renewable energy framework through the Renewable Energy Directive (RED II), which recognizes ammonia as a potential carrier for hydrogen. Additionally, the EU's FuelEU Maritime initiative aims to increase the use of sustainable alternative fuels in European shipping, potentially including ammonia.

Japan has emerged as a leader in ammonia fuel regulation, developing a comprehensive roadmap for ammonia fuel adoption with specific safety standards and certification processes. Their approach includes detailed guidelines for leak prevention systems and material compatibility requirements to address porosity challenges.

Key regulatory challenges specific to ammonia's porosity and leak prevention include establishing standardized testing protocols for material compatibility, defining acceptable leak rates, and developing inspection regimes for ammonia storage systems. The toxicity of ammonia necessitates stringent safety regulations, with most jurisdictions requiring sophisticated leak detection systems, emergency response protocols, and buffer zones around ammonia storage facilities.

Certification standards for ammonia-compatible materials are being developed by organizations such as ASTM International and the International Organization for Standardization (ISO), focusing on permeation rates, material degradation, and long-term performance under various operating conditions.

For industry stakeholders, navigating this evolving regulatory landscape requires proactive engagement with regulatory bodies, participation in standard-setting processes, and investment in compliance infrastructure. As ammonia fuel adoption accelerates, regulatory frameworks are expected to become more comprehensive, addressing the specific challenges of porosity and leak prevention in ammonia storage systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!