Analysis of Electrically Conductive Polymers in Solid State Battery Breakthrough

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymers Background and Research Objectives

Electrically conductive polymers represent a revolutionary class of materials that combine the electrical properties of metals with the processing advantages and mechanical flexibility of polymers. Since their discovery in the 1970s with polyacetylene, these materials have evolved from scientific curiosities to critical components in various technological applications. The field has witnessed significant advancements through the development of polypyrrole, polyaniline, and poly(3,4-ethylenedioxythiophene) (PEDOT), each offering unique electrical conductivity properties while maintaining polymer characteristics.

The evolution of conductive polymers has been marked by key milestones, including the 2000 Nobel Prize in Chemistry awarded to Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa for their pioneering work. Over the past decade, research has shifted from fundamental understanding to application-specific optimization, particularly in energy storage technologies where traditional materials face inherent limitations.

In the context of solid-state batteries, conductive polymers present a promising alternative to conventional liquid electrolytes and inorganic solid electrolytes. The current technological trajectory indicates growing interest in utilizing these materials to address critical challenges in battery technology, including safety concerns, energy density limitations, and charging speed constraints.

The primary research objectives for conductive polymers in solid-state battery applications center on several key areas. First, enhancing ionic conductivity at room temperature remains a significant challenge, as most polymer electrolytes currently require elevated temperatures to achieve practical conductivity levels. Second, improving the electrochemical stability window to prevent degradation during repeated charge-discharge cycles is essential for long-term battery performance.

Additionally, research aims to optimize the mechanical properties of these polymers to maintain good contact with electrodes while preventing dendrite formation—a common failure mode in solid-state batteries. The development of scalable synthesis methods that maintain consistent material properties is another critical objective, as commercial viability depends on reliable manufacturing processes.

The integration of conductive polymers with other battery components presents unique interface challenges that must be addressed. Research is focused on creating stable polymer-electrode interfaces that minimize resistance and maintain performance over thousands of cycles. Furthermore, understanding the fundamental structure-property relationships in these materials will enable rational design approaches rather than empirical optimization.

Our technical research aims to systematically investigate these aspects, with particular emphasis on novel polymer architectures that incorporate both electronic and ionic conductivity pathways. The ultimate goal is to develop conductive polymer systems that enable solid-state batteries with energy densities exceeding 400 Wh/kg, cycle life beyond 1,000 cycles, and operation across a wide temperature range from -20°C to 60°C.

The evolution of conductive polymers has been marked by key milestones, including the 2000 Nobel Prize in Chemistry awarded to Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa for their pioneering work. Over the past decade, research has shifted from fundamental understanding to application-specific optimization, particularly in energy storage technologies where traditional materials face inherent limitations.

In the context of solid-state batteries, conductive polymers present a promising alternative to conventional liquid electrolytes and inorganic solid electrolytes. The current technological trajectory indicates growing interest in utilizing these materials to address critical challenges in battery technology, including safety concerns, energy density limitations, and charging speed constraints.

The primary research objectives for conductive polymers in solid-state battery applications center on several key areas. First, enhancing ionic conductivity at room temperature remains a significant challenge, as most polymer electrolytes currently require elevated temperatures to achieve practical conductivity levels. Second, improving the electrochemical stability window to prevent degradation during repeated charge-discharge cycles is essential for long-term battery performance.

Additionally, research aims to optimize the mechanical properties of these polymers to maintain good contact with electrodes while preventing dendrite formation—a common failure mode in solid-state batteries. The development of scalable synthesis methods that maintain consistent material properties is another critical objective, as commercial viability depends on reliable manufacturing processes.

The integration of conductive polymers with other battery components presents unique interface challenges that must be addressed. Research is focused on creating stable polymer-electrode interfaces that minimize resistance and maintain performance over thousands of cycles. Furthermore, understanding the fundamental structure-property relationships in these materials will enable rational design approaches rather than empirical optimization.

Our technical research aims to systematically investigate these aspects, with particular emphasis on novel polymer architectures that incorporate both electronic and ionic conductivity pathways. The ultimate goal is to develop conductive polymer systems that enable solid-state batteries with energy densities exceeding 400 Wh/kg, cycle life beyond 1,000 cycles, and operation across a wide temperature range from -20°C to 60°C.

Market Analysis for Solid State Battery Technologies

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple sectors. Current market valuations place the global solid-state battery market at approximately $500 million in 2023, with projections indicating potential growth to reach $8-10 billion by 2030, representing a compound annual growth rate (CAGR) of over 34% during this forecast period.

Electric vehicles represent the primary market driver, accounting for nearly 60% of the projected demand. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with commercial deployment timelines set between 2025-2028. This automotive push is complemented by growing demand in consumer electronics, where manufacturers seek batteries with improved safety profiles and higher energy densities.

Regional analysis reveals Asia-Pacific as the dominant market, holding approximately 45% market share, with Japan and South Korea leading in patent applications and commercial development. North America follows at 30% market share, while Europe represents 20% with particularly strong government-backed research initiatives.

The integration of electrically conductive polymers in solid-state batteries represents a significant market opportunity, potentially addressing key challenges in current solid electrolyte systems. Market research indicates that polymer-based solid-state batteries could capture up to 25% of the total solid-state battery market by 2028, particularly in applications requiring flexible form factors.

Investor confidence in the sector is evidenced by venture capital funding exceeding $1.2 billion in 2022 alone, directed specifically toward solid-state battery startups. Strategic partnerships between material science companies and battery manufacturers have increased by 65% since 2020, indicating strong commercial interest in accelerating development cycles.

Market barriers include high manufacturing costs, with current production expenses estimated at 2-3 times those of conventional lithium-ion batteries. Additionally, scaling challenges persist, with limited production capacity restricting market penetration in mass-market applications. Industry analysts predict price parity with conventional batteries could be achieved by 2027-2028, contingent upon successful commercialization of next-generation manufacturing processes.

Customer demand analysis reveals safety as the primary purchase driver (cited by 78% of potential industrial customers), followed by energy density improvements (65%) and charging speed (52%). This aligns perfectly with the value proposition of electrically conductive polymer-enhanced solid-state batteries, positioning this technology segment for potential market leadership.

Electric vehicles represent the primary market driver, accounting for nearly 60% of the projected demand. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with commercial deployment timelines set between 2025-2028. This automotive push is complemented by growing demand in consumer electronics, where manufacturers seek batteries with improved safety profiles and higher energy densities.

Regional analysis reveals Asia-Pacific as the dominant market, holding approximately 45% market share, with Japan and South Korea leading in patent applications and commercial development. North America follows at 30% market share, while Europe represents 20% with particularly strong government-backed research initiatives.

The integration of electrically conductive polymers in solid-state batteries represents a significant market opportunity, potentially addressing key challenges in current solid electrolyte systems. Market research indicates that polymer-based solid-state batteries could capture up to 25% of the total solid-state battery market by 2028, particularly in applications requiring flexible form factors.

Investor confidence in the sector is evidenced by venture capital funding exceeding $1.2 billion in 2022 alone, directed specifically toward solid-state battery startups. Strategic partnerships between material science companies and battery manufacturers have increased by 65% since 2020, indicating strong commercial interest in accelerating development cycles.

Market barriers include high manufacturing costs, with current production expenses estimated at 2-3 times those of conventional lithium-ion batteries. Additionally, scaling challenges persist, with limited production capacity restricting market penetration in mass-market applications. Industry analysts predict price parity with conventional batteries could be achieved by 2027-2028, contingent upon successful commercialization of next-generation manufacturing processes.

Customer demand analysis reveals safety as the primary purchase driver (cited by 78% of potential industrial customers), followed by energy density improvements (65%) and charging speed (52%). This aligns perfectly with the value proposition of electrically conductive polymer-enhanced solid-state batteries, positioning this technology segment for potential market leadership.

Current Challenges in Conductive Polymer Integration

Despite the promising potential of electrically conductive polymers in solid-state battery applications, several significant challenges impede their widespread integration. The primary obstacle remains the inherent trade-off between ionic and electronic conductivity. While high electronic conductivity is essential for electrode performance, it can simultaneously promote internal short circuits within the battery structure. This fundamental contradiction requires sophisticated material engineering approaches that have yet to be fully optimized.

Interface stability presents another critical challenge. Conductive polymers often exhibit poor electrochemical stability at the electrode-electrolyte interface, leading to degradation during charge-discharge cycles. This degradation manifests as capacity fade and reduced battery lifespan, particularly at elevated temperatures or high voltage operations. The formation of solid-electrolyte interphase (SEI) layers further complicates this issue, as these layers can impede ion transport while simultaneously protecting against further degradation.

Manufacturing scalability constitutes a significant barrier to commercial implementation. Current synthesis methods for high-performance conductive polymers typically involve complex processes with multiple steps, expensive catalysts, and stringent environmental controls. These factors substantially increase production costs and limit industrial-scale manufacturing capabilities. Additionally, batch-to-batch consistency remains problematic, with minor variations in synthesis conditions leading to significant differences in polymer performance characteristics.

Mechanical property limitations further restrict application potential. Many conductive polymers exhibit insufficient mechanical strength and flexibility to withstand the volumetric changes that occur during battery cycling. This mechanical instability can lead to contact loss between battery components, resulting in increased internal resistance and performance deterioration over time. Efforts to enhance mechanical properties through cross-linking or composite formation often come at the expense of conductivity.

Environmental stability represents another unresolved challenge. Conductive polymers frequently demonstrate sensitivity to oxygen, moisture, and UV radiation, necessitating complex encapsulation strategies that add cost and complexity to battery designs. Long-term stability under various operating conditions remains inadequately characterized, creating uncertainty regarding battery lifespan in real-world applications.

Finally, integration with existing battery manufacturing infrastructure poses significant technical hurdles. Current production lines are optimized for conventional materials, and the introduction of conductive polymers often requires substantial modifications to established processes. This incompatibility creates resistance to adoption among established manufacturers who must balance innovation against capital investment requirements and production disruption risks.

Interface stability presents another critical challenge. Conductive polymers often exhibit poor electrochemical stability at the electrode-electrolyte interface, leading to degradation during charge-discharge cycles. This degradation manifests as capacity fade and reduced battery lifespan, particularly at elevated temperatures or high voltage operations. The formation of solid-electrolyte interphase (SEI) layers further complicates this issue, as these layers can impede ion transport while simultaneously protecting against further degradation.

Manufacturing scalability constitutes a significant barrier to commercial implementation. Current synthesis methods for high-performance conductive polymers typically involve complex processes with multiple steps, expensive catalysts, and stringent environmental controls. These factors substantially increase production costs and limit industrial-scale manufacturing capabilities. Additionally, batch-to-batch consistency remains problematic, with minor variations in synthesis conditions leading to significant differences in polymer performance characteristics.

Mechanical property limitations further restrict application potential. Many conductive polymers exhibit insufficient mechanical strength and flexibility to withstand the volumetric changes that occur during battery cycling. This mechanical instability can lead to contact loss between battery components, resulting in increased internal resistance and performance deterioration over time. Efforts to enhance mechanical properties through cross-linking or composite formation often come at the expense of conductivity.

Environmental stability represents another unresolved challenge. Conductive polymers frequently demonstrate sensitivity to oxygen, moisture, and UV radiation, necessitating complex encapsulation strategies that add cost and complexity to battery designs. Long-term stability under various operating conditions remains inadequately characterized, creating uncertainty regarding battery lifespan in real-world applications.

Finally, integration with existing battery manufacturing infrastructure poses significant technical hurdles. Current production lines are optimized for conventional materials, and the introduction of conductive polymers often requires substantial modifications to established processes. This incompatibility creates resistance to adoption among established manufacturers who must balance innovation against capital investment requirements and production disruption risks.

Current Technical Solutions for Polymer-Based Solid Electrolytes

01 Conductive polymer compositions and synthesis methods

Various methods for synthesizing electrically conductive polymers with enhanced conductivity properties. These include chemical and electrochemical polymerization techniques, doping processes, and novel synthesis routes that can produce polymers with controlled morphology and improved electrical performance. The synthesis methods focus on creating polymers with optimized molecular structures that facilitate electron transport through the polymer chains.- Conductive polymer compositions and synthesis methods: Various methods for synthesizing electrically conductive polymers with enhanced conductivity properties. These include chemical and electrochemical polymerization techniques, doping processes, and novel synthesis routes that can produce polymers with controlled morphology and electrical characteristics. The synthesis methods focus on creating polymers with optimized molecular structures that facilitate electron transport through the polymer chains.

- Doping strategies to enhance polymer conductivity: Doping is a critical process for increasing the electrical conductivity of polymers. Various dopants, including metal ions, acids, and organic compounds, can be incorporated into polymer structures to create charge carriers. The type, concentration, and distribution of dopants significantly affect the resulting conductivity. Advanced doping strategies include co-doping with multiple agents and controlled spatial distribution of dopants within the polymer matrix.

- Nanocomposite conductive polymers: Incorporating nanomaterials such as carbon nanotubes, graphene, metal nanoparticles, or conductive nanofillers into polymer matrices creates nanocomposites with significantly enhanced electrical conductivity. These nanocomposites benefit from the synergistic effects between the polymer and nanomaterials, creating efficient electron pathways. The dispersion quality and interfacial interactions between the nanomaterials and polymer matrix are crucial factors affecting the overall conductivity of these composite materials.

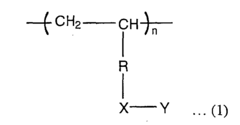

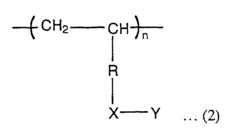

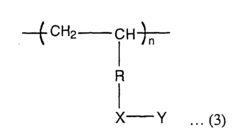

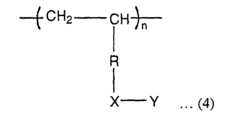

- Structure-property relationships in conductive polymers: The molecular structure, chain conformation, crystallinity, and morphology of conductive polymers directly influence their electrical conductivity. Polymers with extended conjugation, planar structures, and ordered arrangements typically exhibit higher conductivity. Understanding these structure-property relationships enables the design of polymers with tailored electrical properties for specific applications. Factors such as molecular weight, chain length, and intermolecular interactions play significant roles in determining conductivity.

- Measurement and characterization techniques for polymer conductivity: Various methods for accurately measuring and characterizing the electrical conductivity of polymers are essential for research and quality control. These include four-point probe techniques, impedance spectroscopy, Hall effect measurements, and specialized approaches for thin films or nanostructured materials. Advanced characterization techniques help understand conductivity mechanisms, charge carrier mobility, and the influence of environmental factors on the electrical properties of conductive polymers.

02 Doping strategies to enhance polymer conductivity

Doping is a critical process for increasing the electrical conductivity of polymers. Various dopants including ions, metal particles, and organic compounds can be incorporated into polymer matrices to create charge carriers. The type, concentration, and distribution of dopants significantly affect the resulting conductivity. Advanced doping strategies focus on achieving stable, high-conductivity polymers through controlled doping processes and novel dopant materials.Expand Specific Solutions03 Nanostructured conductive polymer composites

Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into conductive polymers creates hybrid materials with enhanced electrical properties. These nanostructured composites benefit from the synergistic effects between the polymer matrix and nanomaterials, resulting in improved conductivity, mechanical strength, and stability. The interface between the nanomaterials and polymer plays a crucial role in determining the overall electrical performance of these composites.Expand Specific Solutions04 Applications of conductive polymers in electronic devices

Electrically conductive polymers are increasingly used in various electronic applications including sensors, actuators, displays, and energy storage devices. Their flexibility, processability, and tunable electrical properties make them attractive alternatives to traditional conductive materials. Recent developments focus on optimizing polymer conductivity for specific applications, such as flexible electronics, organic photovoltaics, and bioelectronic interfaces.Expand Specific Solutions05 Stability and environmental factors affecting polymer conductivity

The electrical conductivity of conductive polymers can be significantly affected by environmental factors such as temperature, humidity, and exposure to oxygen or UV light. Research focuses on developing polymers with stable conductivity under various conditions through chemical modifications, protective coatings, or composite structures. Understanding and mitigating degradation mechanisms is crucial for creating conductive polymers with long-term stability for practical applications.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

The electrically conductive polymers market for solid-state batteries is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as solid-state battery technology matures, driven by demand for safer, higher-capacity energy storage solutions. Technologically, companies are at varying stages of development: established players like LG Energy Solution, Sony, and Panasonic are advancing commercial applications, while specialized innovators such as Ionic Materials and Blue Current are pioneering breakthrough polymer electrolyte formulations. Research institutions including SINANO and University of California are contributing fundamental advances. Japanese corporations (NEC, Sumitomo Chemical) and European research organizations (CNRS, Fraunhofer) are also making significant contributions, creating a globally competitive landscape with increasing patent activity and strategic partnerships.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a composite polymer electrolyte system for solid-state batteries that combines the benefits of polymer flexibility with ceramic filler enhancement. Their technology utilizes a polyethylene oxide (PEO) base matrix modified with proprietary additives and nano-sized ceramic particles to achieve ionic conductivity approaching 10^-3 S/cm at operating temperatures. The company has integrated this conductive polymer system with their existing high-nickel cathode technology and silicon-carbon composite anodes to create solid-state cells with energy densities exceeding 400 Wh/kg. LG's approach includes surface modification of the polymer-electrode interfaces using specialized conductive coatings to minimize interfacial resistance. Their manufacturing process adapts existing production lines with modified coating and lamination steps, allowing for gradual transition from conventional to solid-state technology without requiring entirely new production facilities.

Strengths: Leverages existing battery manufacturing expertise and infrastructure; achieves good balance between mechanical properties and ionic conductivity; demonstrates promising cycle life in prototype cells; benefits from LG's established supply chain and quality control systems. Weaknesses: Temperature-dependent performance may require thermal management solutions; higher processing complexity compared to liquid electrolyte systems; potential challenges in achieving uniform polymer-ceramic composite distribution at scale.

Ionic Materials Inc.

Technical Solution: Ionic Materials has developed a revolutionary solid polymer electrolyte platform that enables solid-state batteries with superior performance. Their proprietary polymer conducts ions at room temperature and is compatible with lithium and other high-energy electrode chemistries. The polymer electrolyte allows for the replacement of flammable liquid electrolytes with a non-flammable solid, enhancing safety while maintaining high ionic conductivity (>1 mS/cm at room temperature). Their technology enables the use of lithium metal anodes, potentially increasing energy density by 50% compared to conventional lithium-ion batteries. The polymer's mechanical properties also help suppress dendrite formation, addressing a critical failure mode in solid-state batteries. Ionic Materials' platform is designed to work with existing battery manufacturing infrastructure, reducing implementation barriers for mass production.

Strengths: Superior safety profile with non-flammable materials; compatibility with lithium metal anodes for higher energy density; room temperature operation without heating requirements; adaptable to existing manufacturing processes. Weaknesses: Relatively new technology with limited long-term performance data; potential challenges in scaling production while maintaining consistent polymer properties; possible higher initial manufacturing costs compared to conventional electrolytes.

Key Patents and Scientific Breakthroughs in Conductive Polymers

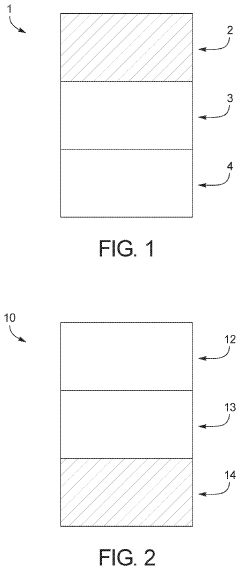

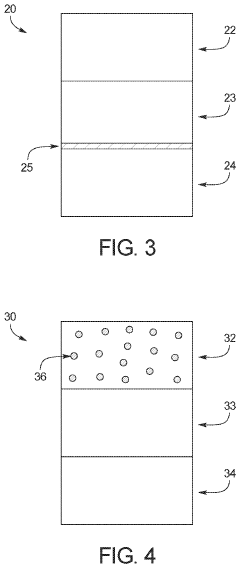

Conductive polymer material for solid-state battery

PatentActiveUS20200251737A1

Innovation

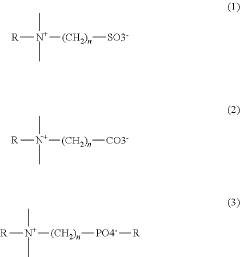

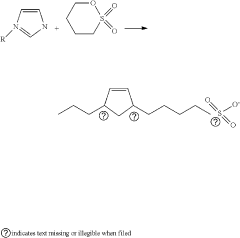

- A conductive polymer material is introduced, comprising an electrically conducting monomer and a zwitterionic sulfonate chemically attached, which is incorporated into the electrodes to enhance lithium ion conduction and reduce contact resistance between the anode and electrolyte.

Ion-conductive polymer, solid polyelectrolyte, and cell employing the same

PatentInactiveEP1508578A1

Innovation

- An ion conductive polymer with stereospecific structures, such as syndiotactic or isotactic structures, is introduced into a matrix polymer, enhancing ionic conductivity and cation transport numbers by incorporating anionic groups with high dissociation, resulting in a solid polymer electrolyte with improved crystallinity and ion mobility.

Environmental Impact and Sustainability Considerations

The integration of electrically conductive polymers in solid-state battery technology presents significant environmental and sustainability advantages over conventional lithium-ion batteries with liquid electrolytes. These polymers enable the development of batteries with reduced environmental footprint throughout their lifecycle, from raw material extraction to end-of-life management.

The manufacturing process for conductive polymer-based solid-state batteries typically requires less energy consumption compared to traditional battery production. This energy efficiency stems from lower processing temperatures and simplified production steps, resulting in reduced greenhouse gas emissions during manufacturing. Additionally, these polymers often utilize more abundant and less environmentally problematic materials than those required for conventional lithium-ion batteries, decreasing the environmental impact associated with mining operations.

Solid-state batteries incorporating conductive polymers demonstrate enhanced safety profiles by eliminating flammable liquid electrolytes, thereby reducing the risk of thermal runaway and hazardous chemical leakage. This safety improvement not only protects users but also minimizes environmental contamination risks in case of accidents or improper disposal. The inherent stability of these materials contributes to longer battery lifespans, addressing the growing electronic waste challenge by extending replacement cycles.

From a lifecycle perspective, conductive polymer-based solid-state batteries offer promising recyclability advantages. The homogeneous solid structure potentially simplifies the separation and recovery of valuable materials at end-of-life, improving recycling efficiency compared to conventional batteries with multiple liquid and solid components. Research indicates that certain conductive polymers can be reclaimed through less chemically intensive processes, further reducing the environmental burden of battery recycling operations.

The scalability of conductive polymer technology also presents opportunities for more sustainable battery production. As manufacturing processes mature, these materials could enable more distributed, less resource-intensive battery production facilities. This distributed manufacturing model could reduce transportation-related emissions in the battery supply chain while creating opportunities for localized circular economy initiatives around battery production and recycling.

Despite these advantages, challenges remain in optimizing the environmental performance of conductive polymers in battery applications. Current research focuses on developing synthesis methods that minimize the use of toxic solvents and reagents, as well as improving the biodegradability of polymer components where feasible. Life cycle assessment studies are increasingly important to quantify the comparative environmental benefits of these emerging battery technologies across different impact categories and use scenarios.

The manufacturing process for conductive polymer-based solid-state batteries typically requires less energy consumption compared to traditional battery production. This energy efficiency stems from lower processing temperatures and simplified production steps, resulting in reduced greenhouse gas emissions during manufacturing. Additionally, these polymers often utilize more abundant and less environmentally problematic materials than those required for conventional lithium-ion batteries, decreasing the environmental impact associated with mining operations.

Solid-state batteries incorporating conductive polymers demonstrate enhanced safety profiles by eliminating flammable liquid electrolytes, thereby reducing the risk of thermal runaway and hazardous chemical leakage. This safety improvement not only protects users but also minimizes environmental contamination risks in case of accidents or improper disposal. The inherent stability of these materials contributes to longer battery lifespans, addressing the growing electronic waste challenge by extending replacement cycles.

From a lifecycle perspective, conductive polymer-based solid-state batteries offer promising recyclability advantages. The homogeneous solid structure potentially simplifies the separation and recovery of valuable materials at end-of-life, improving recycling efficiency compared to conventional batteries with multiple liquid and solid components. Research indicates that certain conductive polymers can be reclaimed through less chemically intensive processes, further reducing the environmental burden of battery recycling operations.

The scalability of conductive polymer technology also presents opportunities for more sustainable battery production. As manufacturing processes mature, these materials could enable more distributed, less resource-intensive battery production facilities. This distributed manufacturing model could reduce transportation-related emissions in the battery supply chain while creating opportunities for localized circular economy initiatives around battery production and recycling.

Despite these advantages, challenges remain in optimizing the environmental performance of conductive polymers in battery applications. Current research focuses on developing synthesis methods that minimize the use of toxic solvents and reagents, as well as improving the biodegradability of polymer components where feasible. Life cycle assessment studies are increasingly important to quantify the comparative environmental benefits of these emerging battery technologies across different impact categories and use scenarios.

Manufacturing Scalability and Cost Analysis

The scalability of electrically conductive polymer manufacturing represents a critical factor in determining the commercial viability of solid-state battery technologies. Current production methods for conductive polymers such as PEDOT:PSS, polyaniline, and polypyrrole remain predominantly laboratory-scale, with significant challenges in transitioning to mass production. Industry analysis indicates that batch-to-batch consistency presents a major hurdle, with variations in electrical conductivity often exceeding 15% between production runs.

Cost structures for conductive polymer synthesis reveal that raw materials constitute approximately 40-50% of total production expenses, with specialized monomers being particularly cost-intensive. Processing costs account for an additional 30-35%, primarily due to energy-intensive polymerization and purification steps. Recent advancements in continuous flow synthesis techniques have demonstrated potential cost reductions of 25-30% compared to traditional batch processing, though implementation at industrial scale remains limited.

Equipment requirements for scaled manufacturing present another significant barrier. Specialized reactors capable of precise temperature control (±1°C) and inert atmosphere maintenance are essential for consistent polymer quality. Capital expenditure for a medium-scale production line (100-500 kg/month) typically ranges between $2-5 million, representing a substantial investment barrier for new market entrants.

Environmental considerations also impact manufacturing economics, with solvent recovery systems adding 15-20% to initial capital costs but potentially reducing operational expenses by 10-15% over a five-year period. Regulatory compliance costs vary significantly by region, with stricter requirements in Europe and North America compared to emerging markets.

Recent innovations in manufacturing techniques show promising directions for cost reduction. Roll-to-roll processing methods have demonstrated up to 40% reduction in production costs for thin-film conductive polymer applications. Additionally, water-based synthesis routes are emerging as environmentally friendly alternatives to traditional organic solvent-based methods, potentially reducing both production costs and environmental impact.

Comparative cost analysis between conductive polymer and traditional lithium-ion battery components indicates that at current production scales, conductive polymer materials remain 2.5-3.5 times more expensive per kWh of storage capacity. However, sensitivity analysis suggests that with production volumes exceeding 10,000 metric tons annually, costs could approach parity with conventional materials, particularly when accounting for the enhanced safety and performance benefits of solid-state configurations.

Cost structures for conductive polymer synthesis reveal that raw materials constitute approximately 40-50% of total production expenses, with specialized monomers being particularly cost-intensive. Processing costs account for an additional 30-35%, primarily due to energy-intensive polymerization and purification steps. Recent advancements in continuous flow synthesis techniques have demonstrated potential cost reductions of 25-30% compared to traditional batch processing, though implementation at industrial scale remains limited.

Equipment requirements for scaled manufacturing present another significant barrier. Specialized reactors capable of precise temperature control (±1°C) and inert atmosphere maintenance are essential for consistent polymer quality. Capital expenditure for a medium-scale production line (100-500 kg/month) typically ranges between $2-5 million, representing a substantial investment barrier for new market entrants.

Environmental considerations also impact manufacturing economics, with solvent recovery systems adding 15-20% to initial capital costs but potentially reducing operational expenses by 10-15% over a five-year period. Regulatory compliance costs vary significantly by region, with stricter requirements in Europe and North America compared to emerging markets.

Recent innovations in manufacturing techniques show promising directions for cost reduction. Roll-to-roll processing methods have demonstrated up to 40% reduction in production costs for thin-film conductive polymer applications. Additionally, water-based synthesis routes are emerging as environmentally friendly alternatives to traditional organic solvent-based methods, potentially reducing both production costs and environmental impact.

Comparative cost analysis between conductive polymer and traditional lithium-ion battery components indicates that at current production scales, conductive polymer materials remain 2.5-3.5 times more expensive per kWh of storage capacity. However, sensitivity analysis suggests that with production volumes exceeding 10,000 metric tons annually, costs could approach parity with conventional materials, particularly when accounting for the enhanced safety and performance benefits of solid-state configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!