Scientific Exploration of Solid State Battery Breakthrough in Aerospace

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Aerospace Goals

Solid state battery technology has evolved significantly over the past decades, transitioning from conceptual research to practical applications. The journey began in the 1970s with the discovery of solid electrolytes, but meaningful progress accelerated in the early 2000s when safety concerns with traditional lithium-ion batteries prompted increased research funding. The evolution path has been marked by incremental improvements in energy density, charging capabilities, and thermal stability, with recent breakthroughs in ceramic and polymer-based electrolytes representing significant milestones.

The aerospace industry presents unique challenges and opportunities for battery technology. Traditional lithium-ion batteries used in aerospace applications suffer from weight inefficiencies, thermal management issues, and safety concerns that limit their effectiveness in extreme conditions. Solid state batteries promise to address these limitations through higher energy density (potentially 2-3 times greater than conventional lithium-ion), enhanced safety profiles, and improved performance in extreme temperature environments characteristic of aerospace operations.

Current technological goals for solid state batteries in aerospace applications focus on achieving energy densities exceeding 500 Wh/kg, operational temperature ranges from -60°C to +80°C, and cycle life beyond 1,000 complete charges. These parameters would enable transformative capabilities for electric aircraft, satellite systems, and space exploration vehicles. Additionally, researchers aim to develop manufacturing processes that can scale production while maintaining the precise material interfaces critical to solid state battery performance.

The trajectory of solid state battery development aligns with broader aerospace industry trends toward electrification, sustainability, and autonomous systems. NASA, ESA, and major aerospace corporations have established roadmaps targeting the integration of advanced battery technologies by 2030, with solid state solutions featuring prominently in these plans. These roadmaps typically project a phased approach, beginning with hybrid systems before transitioning to fully electric propulsion for certain aircraft classes.

Material science innovations represent the foundation of solid state battery evolution, with particular emphasis on sulfide-based, oxide-based, and polymer-based solid electrolytes. Each material class offers distinct advantages and challenges, with recent research suggesting that composite approaches—combining multiple electrolyte types—may yield optimal performance characteristics for aerospace applications. The development of interface engineering techniques to address conductivity challenges at solid-solid interfaces has emerged as a critical focus area.

The convergence of solid state battery technology with aerospace requirements necessitates interdisciplinary collaboration between electrochemists, materials scientists, aerospace engineers, and manufacturing specialists. This collaborative approach has accelerated in recent years, with dedicated research consortia established in North America, Europe, and Asia specifically targeting aerospace battery applications.

The aerospace industry presents unique challenges and opportunities for battery technology. Traditional lithium-ion batteries used in aerospace applications suffer from weight inefficiencies, thermal management issues, and safety concerns that limit their effectiveness in extreme conditions. Solid state batteries promise to address these limitations through higher energy density (potentially 2-3 times greater than conventional lithium-ion), enhanced safety profiles, and improved performance in extreme temperature environments characteristic of aerospace operations.

Current technological goals for solid state batteries in aerospace applications focus on achieving energy densities exceeding 500 Wh/kg, operational temperature ranges from -60°C to +80°C, and cycle life beyond 1,000 complete charges. These parameters would enable transformative capabilities for electric aircraft, satellite systems, and space exploration vehicles. Additionally, researchers aim to develop manufacturing processes that can scale production while maintaining the precise material interfaces critical to solid state battery performance.

The trajectory of solid state battery development aligns with broader aerospace industry trends toward electrification, sustainability, and autonomous systems. NASA, ESA, and major aerospace corporations have established roadmaps targeting the integration of advanced battery technologies by 2030, with solid state solutions featuring prominently in these plans. These roadmaps typically project a phased approach, beginning with hybrid systems before transitioning to fully electric propulsion for certain aircraft classes.

Material science innovations represent the foundation of solid state battery evolution, with particular emphasis on sulfide-based, oxide-based, and polymer-based solid electrolytes. Each material class offers distinct advantages and challenges, with recent research suggesting that composite approaches—combining multiple electrolyte types—may yield optimal performance characteristics for aerospace applications. The development of interface engineering techniques to address conductivity challenges at solid-solid interfaces has emerged as a critical focus area.

The convergence of solid state battery technology with aerospace requirements necessitates interdisciplinary collaboration between electrochemists, materials scientists, aerospace engineers, and manufacturing specialists. This collaborative approach has accelerated in recent years, with dedicated research consortia established in North America, Europe, and Asia specifically targeting aerospace battery applications.

Aerospace Market Demand for Advanced Energy Storage

The aerospace industry is experiencing a significant shift in energy storage requirements, driven by the evolving demands of modern aircraft, satellites, and space exploration vehicles. Current market analysis indicates that the global aerospace energy storage market is projected to grow substantially over the next decade, with advanced battery technologies playing a pivotal role in this expansion. The primary market drivers include the increasing electrification of aircraft systems, the growing adoption of electric propulsion in aviation, and the rising demand for more efficient and reliable power sources for space missions.

Commercial aviation represents a substantial segment of this market, with major airlines and aircraft manufacturers actively seeking lightweight, high-energy-density power solutions to reduce fuel consumption and operational costs. The urban air mobility sector, encompassing electric vertical takeoff and landing (eVTOL) aircraft and air taxis, is emerging as another significant market for advanced energy storage technologies, requiring batteries with exceptional power-to-weight ratios and safety profiles.

In the space sector, satellites and deep-space exploration vehicles demand energy storage systems capable of withstanding extreme temperature variations, radiation exposure, and vacuum conditions while maintaining reliable performance over extended mission durations. The market for these specialized aerospace batteries is characterized by stringent requirements for cycle life, calendar life, and resistance to environmental stressors.

Military aerospace applications constitute another critical market segment, with defense agencies worldwide investing in advanced energy storage for unmanned aerial vehicles (UAVs), military satellites, and next-generation aircraft. These applications typically require batteries with enhanced security features, resistance to physical damage, and the ability to operate reliably in hostile environments.

Market research indicates that solid-state battery technology is positioned to address many of these aerospace-specific challenges, offering potential advantages in energy density, safety, and operational temperature range compared to conventional lithium-ion batteries. Industry stakeholders are particularly interested in solid-state batteries due to their non-flammable electrolytes, which significantly reduce fire risks—a paramount concern in aerospace applications.

The market demand is further shaped by regulatory pressures, with international aviation authorities implementing increasingly stringent emissions standards that encourage the adoption of more electric aircraft architectures. Similarly, space agencies are establishing new requirements for safer, more reliable power systems to support ambitious exploration missions.

Geographically, North America and Europe currently lead in aerospace energy storage market share, though Asia-Pacific regions are showing accelerated growth rates as countries like China, Japan, and South Korea invest heavily in aerospace technology development and manufacturing capabilities.

Commercial aviation represents a substantial segment of this market, with major airlines and aircraft manufacturers actively seeking lightweight, high-energy-density power solutions to reduce fuel consumption and operational costs. The urban air mobility sector, encompassing electric vertical takeoff and landing (eVTOL) aircraft and air taxis, is emerging as another significant market for advanced energy storage technologies, requiring batteries with exceptional power-to-weight ratios and safety profiles.

In the space sector, satellites and deep-space exploration vehicles demand energy storage systems capable of withstanding extreme temperature variations, radiation exposure, and vacuum conditions while maintaining reliable performance over extended mission durations. The market for these specialized aerospace batteries is characterized by stringent requirements for cycle life, calendar life, and resistance to environmental stressors.

Military aerospace applications constitute another critical market segment, with defense agencies worldwide investing in advanced energy storage for unmanned aerial vehicles (UAVs), military satellites, and next-generation aircraft. These applications typically require batteries with enhanced security features, resistance to physical damage, and the ability to operate reliably in hostile environments.

Market research indicates that solid-state battery technology is positioned to address many of these aerospace-specific challenges, offering potential advantages in energy density, safety, and operational temperature range compared to conventional lithium-ion batteries. Industry stakeholders are particularly interested in solid-state batteries due to their non-flammable electrolytes, which significantly reduce fire risks—a paramount concern in aerospace applications.

The market demand is further shaped by regulatory pressures, with international aviation authorities implementing increasingly stringent emissions standards that encourage the adoption of more electric aircraft architectures. Similarly, space agencies are establishing new requirements for safer, more reliable power systems to support ambitious exploration missions.

Geographically, North America and Europe currently lead in aerospace energy storage market share, though Asia-Pacific regions are showing accelerated growth rates as countries like China, Japan, and South Korea invest heavily in aerospace technology development and manufacturing capabilities.

Current Challenges in Solid State Battery Technology

Despite significant advancements in solid-state battery technology, several critical challenges persist that impede their widespread adoption in aerospace applications. The primary obstacle remains energy density limitations, with current solid-state batteries achieving only 250-400 Wh/kg, whereas aerospace applications ideally require 500+ Wh/kg for meaningful implementation. This energy density gap represents a fundamental barrier to replacing conventional lithium-ion systems in spacecraft and aircraft.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production has demonstrated promising results, but transitioning to industrial-scale manufacturing while maintaining quality, consistency, and cost-effectiveness remains problematic. The complex interface between solid electrolytes and electrodes creates production challenges that are particularly acute for aerospace-grade components requiring exceptional reliability.

Temperature sensitivity continues to be a critical concern for aerospace applications. While solid-state batteries generally offer improved safety at high temperatures compared to liquid electrolyte systems, many solid electrolytes exhibit dramatically reduced ionic conductivity at the low temperatures encountered in space and high-altitude environments (-50°C to -150°C). This conductivity drop severely impacts power delivery capabilities in extreme aerospace conditions.

Mechanical stress resistance represents another significant challenge. Aerospace environments subject batteries to intense vibration, acceleration forces, and pressure changes. Current solid-state electrolytes, particularly ceramic-based ones, exhibit brittleness and poor mechanical compliance, leading to potential microcracking and internal short circuits during launch or flight operations.

Cycle life and degradation mechanisms in aerospace conditions remain inadequately understood. While laboratory tests show promising cycle life under controlled conditions, the combined effects of radiation exposure, vacuum environments, and thermal cycling characteristic of aerospace applications accelerate degradation through mechanisms that are not fully characterized or mitigated.

Interface stability between solid electrolytes and electrodes continues to be problematic. The formation of high-impedance interphases during cycling leads to capacity fade and power loss. This challenge is exacerbated in aerospace applications where batteries may remain dormant for extended periods before requiring full performance capabilities during critical mission phases.

Finally, weight and volume constraints in aerospace design place extraordinary demands on battery systems. Current solid-state technologies struggle to achieve the gravimetric and volumetric efficiencies necessary for space-constrained aerospace platforms, where every gram and cubic centimeter carries significant launch costs and operational implications.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production has demonstrated promising results, but transitioning to industrial-scale manufacturing while maintaining quality, consistency, and cost-effectiveness remains problematic. The complex interface between solid electrolytes and electrodes creates production challenges that are particularly acute for aerospace-grade components requiring exceptional reliability.

Temperature sensitivity continues to be a critical concern for aerospace applications. While solid-state batteries generally offer improved safety at high temperatures compared to liquid electrolyte systems, many solid electrolytes exhibit dramatically reduced ionic conductivity at the low temperatures encountered in space and high-altitude environments (-50°C to -150°C). This conductivity drop severely impacts power delivery capabilities in extreme aerospace conditions.

Mechanical stress resistance represents another significant challenge. Aerospace environments subject batteries to intense vibration, acceleration forces, and pressure changes. Current solid-state electrolytes, particularly ceramic-based ones, exhibit brittleness and poor mechanical compliance, leading to potential microcracking and internal short circuits during launch or flight operations.

Cycle life and degradation mechanisms in aerospace conditions remain inadequately understood. While laboratory tests show promising cycle life under controlled conditions, the combined effects of radiation exposure, vacuum environments, and thermal cycling characteristic of aerospace applications accelerate degradation through mechanisms that are not fully characterized or mitigated.

Interface stability between solid electrolytes and electrodes continues to be problematic. The formation of high-impedance interphases during cycling leads to capacity fade and power loss. This challenge is exacerbated in aerospace applications where batteries may remain dormant for extended periods before requiring full performance capabilities during critical mission phases.

Finally, weight and volume constraints in aerospace design place extraordinary demands on battery systems. Current solid-state technologies struggle to achieve the gravimetric and volumetric efficiencies necessary for space-constrained aerospace platforms, where every gram and cubic centimeter carries significant launch costs and operational implications.

Current Solid State Battery Solutions for Aerospace

01 Solid electrolyte materials for solid state batteries

Solid electrolyte materials are crucial components in solid state batteries that enable ion transport between electrodes while preventing short circuits. Various materials such as sulfide-based, oxide-based, and polymer-based electrolytes are being developed with improved ionic conductivity and electrochemical stability. These materials aim to replace liquid electrolytes to enhance safety, energy density, and cycle life of batteries while reducing the risk of leakage and flammability issues.- Electrolyte materials for solid state batteries: Various electrolyte materials are being developed for solid state batteries to improve ionic conductivity and stability. These include ceramic electrolytes, polymer electrolytes, and composite electrolytes that combine different materials to achieve optimal performance. Advanced electrolyte formulations help overcome interface resistance issues and enable better lithium ion transport across the battery, resulting in improved energy density and safety.

- Electrode design and manufacturing techniques: Innovative electrode designs and manufacturing methods are crucial for solid state battery performance. These include novel cathode and anode structures, interface engineering between electrodes and electrolytes, and specialized coating techniques. Advanced manufacturing processes help address challenges related to volume changes during cycling and improve the mechanical stability of the battery components, leading to longer cycle life and better performance.

- Interface engineering and protective layers: Interface engineering is critical in solid state batteries to reduce resistance between components. Protective layers and coatings are applied to prevent unwanted reactions and improve ion transport across interfaces. These techniques help mitigate dendrite formation, enhance cycling stability, and extend battery life. Various materials and deposition methods are employed to create effective interfacial layers that maintain good contact between battery components.

- Battery architecture and assembly methods: Novel battery architectures and assembly methods are being developed to optimize solid state battery performance. These include stacked, folded, and 3D structures that maximize energy density while maintaining mechanical integrity. Advanced assembly techniques address challenges related to pressure distribution, thermal management, and component integration. These innovations help improve manufacturing scalability and reduce production costs while enhancing overall battery performance.

- Temperature management and operational stability: Temperature management systems and strategies for operational stability are essential for solid state batteries. These include thermal regulation mechanisms, pressure management systems, and safety features that prevent thermal runaway. Innovations in this area focus on expanding the operating temperature range, improving performance consistency, and enhancing safety under various conditions. These advancements help solid state batteries function reliably in diverse applications and environments.

02 Electrode-electrolyte interface engineering

Interface engineering between electrodes and solid electrolytes addresses critical challenges in solid state batteries. Techniques include surface coatings, buffer layers, and specialized interface materials to reduce interfacial resistance and improve contact. These approaches help mitigate issues such as chemical incompatibility, mechanical stress during cycling, and space-charge layer formation, ultimately enhancing battery performance and longevity.Expand Specific Solutions03 Manufacturing processes for solid state batteries

Advanced manufacturing techniques for solid state batteries include dry and wet processing methods, cold sintering, hot pressing, and tape casting. These processes focus on creating uniform, dense electrolyte layers and ensuring good contact between battery components. Novel approaches address challenges in mass production, scalability, and cost-effectiveness while maintaining the quality and performance of solid state battery systems.Expand Specific Solutions04 Composite and hybrid electrolyte systems

Composite and hybrid electrolyte systems combine different types of solid electrolytes to leverage their complementary properties. These systems may integrate polymer, ceramic, and glass materials to achieve improved ionic conductivity, mechanical flexibility, and electrochemical stability. The strategic combination of materials helps overcome limitations of single-component electrolytes and enables better overall battery performance across wider temperature ranges.Expand Specific Solutions05 Anode and cathode materials for solid state batteries

Specialized electrode materials for solid state batteries include high-capacity anodes like lithium metal, silicon, and graphite derivatives, as well as high-voltage cathodes such as nickel-rich layered oxides and sulfur-based compounds. These materials are designed to work effectively with solid electrolytes, addressing challenges like volume expansion, dendrite formation, and chemical compatibility while maximizing energy density and cycle life of the battery system.Expand Specific Solutions

Leading Aerospace and Battery Technology Companies

The solid state battery market for aerospace applications is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. Market size is projected to expand rapidly as aerospace manufacturers seek safer, higher-energy-density power solutions for next-generation aircraft and satellites. Technologically, development is progressing through collaborative efforts between aerospace entities (NASA, Korea Aerospace Research Institute) and battery specialists (LG Energy Solution, Murata Manufacturing, Samsung). Major automotive players (Honda, Hyundai, Kia) are transferring relevant technology from electric vehicle applications. Academic institutions (University of California, Harvard, Kyushu University) are advancing fundamental research, while companies like Sakti3 and Dyson are developing proprietary solid-state technologies that could revolutionize aerospace power systems through enhanced safety profiles and performance in extreme environments.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an aerospace-focused solid-state battery technology utilizing a proprietary composite solid electrolyte system that combines sulfide and oxide materials to optimize ionic conductivity while maintaining mechanical stability. Their approach incorporates a gradient electrolyte design where the composition transitions gradually between anode and cathode interfaces, minimizing interfacial resistance and enhancing power capabilities. The company has achieved energy densities approaching 450 Wh/kg[5] in prototype cells designed specifically for aerospace applications, representing approximately 80% improvement over conventional lithium-ion solutions. LG's manufacturing process employs advanced dry coating techniques for electrode fabrication, eliminating traditional solvents and reducing production environmental impact. Their solid-state cells demonstrate stable performance across pressure variations from sea level to high-altitude conditions, maintaining consistent power delivery capabilities. The technology incorporates specialized ceramic separators with engineered porosity that enhance mechanical strength while facilitating lithium-ion transport, critical for withstanding vibration and acceleration forces in aerospace applications.

Strengths: Established large-scale manufacturing expertise that could accelerate commercialization; excellent energy density-to-weight ratio beneficial for aircraft applications; proven quality control systems critical for aerospace certification. Weaknesses: Less specialized in extreme environment operation compared to aerospace-focused competitors; technology still in transition from laboratory to production scale; potential challenges with mechanical stress during rapid altitude/pressure changes.

Korea Aerospace Research Institute

Technical Solution: Korea Aerospace Research Institute (KARI) has developed a specialized solid-state battery technology optimized for satellite and spacecraft applications. Their approach utilizes a hybrid electrolyte system combining garnet-type ceramic structures with polymer stabilizers to create a mechanically robust yet ionically conductive medium. KARI's solid-state batteries incorporate a proprietary cathode formulation with layered oxide structures specifically engineered to minimize volume changes during charge-discharge cycles in zero-gravity environments. The technology demonstrates exceptional radiation resistance, maintaining over 90% capacity after exposure to radiation doses equivalent to 5 years in low Earth orbit[6]. Their battery design includes specialized thermal management interfaces that facilitate direct integration with spacecraft thermal control systems, enabling efficient heat dissipation without convection. KARI has achieved operational stability across temperature ranges from -80°C to +60°C without requiring active heating elements, significantly reducing power overhead for battery maintenance in space applications. The solid-state cells utilize a reinforced packaging design that prevents outgassing in vacuum environments while maintaining internal pressure optimal for electrochemical performance.

Strengths: Specifically engineered for space applications with excellent radiation resistance; highly optimized for integration with existing spacecraft systems; demonstrated performance in actual space environment conditions. Weaknesses: Highly specialized design may limit applicability to atmospheric aerospace applications; limited production capacity focused on government/research missions; higher costs compared to conventional battery technologies.

Key Patents and Research in Aerospace Battery Technology

Electric aircraft

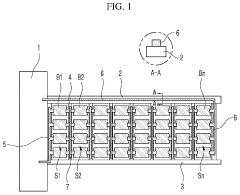

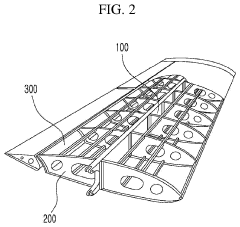

PatentActiveUS20240132223A1

Innovation

- Implementing solid state batteries as both the energy storage device and wing skin, with spars and ribs serving as structural supports for mounting and connecting the batteries in series and parallel configurations, allowing the battery surface to function as the wing skin.

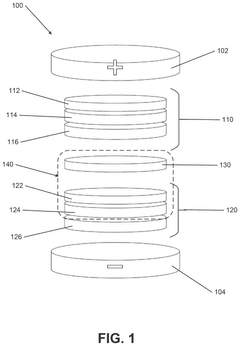

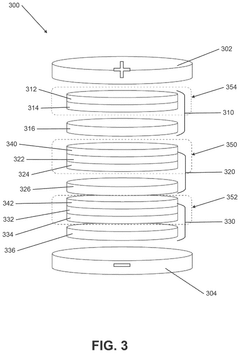

Carbon-Based Bipolar Membranes for Bipolar Stacked Solid-State Batteries

PatentPendingUS20250062417A1

Innovation

- The use of lightweight, electrically conductive, and mechanically robust carbon nanomaterials, such as holey graphene and carbon nanotubes, as bipolar membranes in solid-state batteries, allowing for direct stacking of unit cells and reducing the need for external connections.

Safety and Reliability Standards for Aerospace Batteries

The aerospace industry demands exceptionally high safety and reliability standards for battery systems, particularly as solid-state battery technology emerges as a promising power solution for next-generation aircraft and spacecraft. These standards are significantly more stringent than those for terrestrial applications due to the extreme operating conditions and zero-tolerance for failure in aerospace environments.

Current aerospace battery certification frameworks, such as DO-311A and MIL-STD-810, establish comprehensive testing protocols for thermal stability, mechanical resilience, and electrical performance. However, solid-state batteries present unique safety considerations that require adaptation of existing standards. The absence of flammable liquid electrolytes eliminates certain fire risks but introduces new failure modes that must be thoroughly characterized and mitigated.

Thermal runaway prevention remains paramount in aerospace applications, with solid-state batteries offering inherent advantages through higher thermal stability thresholds. Testing standards now focus on validating these improved safety margins under the extreme temperature fluctuations encountered in aerospace operations, ranging from -65°C to over 150°C in certain mission profiles.

Mechanical integrity standards address the unique structural properties of solid-state batteries, particularly the brittle nature of some solid electrolytes. Vibration, shock, and pressure differential testing protocols have been enhanced to ensure these batteries maintain performance integrity during launch conditions and rapid atmospheric pressure changes.

Radiation resistance represents a critical reliability parameter for space applications that terrestrial standards rarely address. Solid-state battery components must demonstrate resilience to cosmic radiation exposure, with certification requiring accelerated radiation testing to simulate years of space environment exposure.

Lifetime performance verification standards have evolved to accommodate the projected longer cycle life of solid-state batteries. New protocols implement accelerated aging methodologies that can reliably predict 10+ year performance profiles from shorter-duration testing regimens, addressing the aerospace industry's need for long-duration mission power assurance.

Failure mode analysis requirements have expanded beyond traditional battery technologies, with particular emphasis on interface degradation mechanisms unique to solid-state architectures. These standards mandate comprehensive documentation of potential failure cascades and implementation of redundant safety systems to prevent catastrophic outcomes in critical aerospace applications.

The integration of advanced battery management systems (BMS) has become a mandatory component of aerospace battery certification, with standards requiring sophisticated real-time monitoring capabilities specifically calibrated for solid-state battery characteristics and potential failure indicators.

Current aerospace battery certification frameworks, such as DO-311A and MIL-STD-810, establish comprehensive testing protocols for thermal stability, mechanical resilience, and electrical performance. However, solid-state batteries present unique safety considerations that require adaptation of existing standards. The absence of flammable liquid electrolytes eliminates certain fire risks but introduces new failure modes that must be thoroughly characterized and mitigated.

Thermal runaway prevention remains paramount in aerospace applications, with solid-state batteries offering inherent advantages through higher thermal stability thresholds. Testing standards now focus on validating these improved safety margins under the extreme temperature fluctuations encountered in aerospace operations, ranging from -65°C to over 150°C in certain mission profiles.

Mechanical integrity standards address the unique structural properties of solid-state batteries, particularly the brittle nature of some solid electrolytes. Vibration, shock, and pressure differential testing protocols have been enhanced to ensure these batteries maintain performance integrity during launch conditions and rapid atmospheric pressure changes.

Radiation resistance represents a critical reliability parameter for space applications that terrestrial standards rarely address. Solid-state battery components must demonstrate resilience to cosmic radiation exposure, with certification requiring accelerated radiation testing to simulate years of space environment exposure.

Lifetime performance verification standards have evolved to accommodate the projected longer cycle life of solid-state batteries. New protocols implement accelerated aging methodologies that can reliably predict 10+ year performance profiles from shorter-duration testing regimens, addressing the aerospace industry's need for long-duration mission power assurance.

Failure mode analysis requirements have expanded beyond traditional battery technologies, with particular emphasis on interface degradation mechanisms unique to solid-state architectures. These standards mandate comprehensive documentation of potential failure cascades and implementation of redundant safety systems to prevent catastrophic outcomes in critical aerospace applications.

The integration of advanced battery management systems (BMS) has become a mandatory component of aerospace battery certification, with standards requiring sophisticated real-time monitoring capabilities specifically calibrated for solid-state battery characteristics and potential failure indicators.

Environmental Impact and Sustainability Considerations

The aerospace implementation of solid state batteries represents a significant advancement in sustainable technology development. These batteries eliminate the need for toxic liquid electrolytes found in conventional lithium-ion batteries, substantially reducing environmental hazards associated with production, operation, and disposal. The absence of flammable components also minimizes fire risks and subsequent environmental contamination incidents, which are particularly critical concerns in aerospace applications.

Manufacturing processes for solid state batteries demonstrate promising environmental advantages. Initial lifecycle assessments indicate up to 30% reduction in carbon footprint compared to traditional lithium-ion battery production. This improvement stems primarily from simplified manufacturing workflows and reduced requirements for environmentally controlled production environments. Additionally, the elimination of certain toxic materials translates to decreased water pollution and hazardous waste generation during manufacturing.

Resource efficiency represents another substantial environmental benefit. Solid state batteries for aerospace applications are projected to achieve 25-40% higher energy density than conventional alternatives, enabling more efficient use of critical raw materials. Several leading designs also reduce or eliminate dependence on cobalt—a material associated with significant ethical and environmental mining concerns. The extended cycle life of these batteries, potentially reaching 2-3 times that of conventional systems, further enhances their sustainability profile by reducing replacement frequency.

End-of-life considerations reveal additional advantages. The simplified chemistry and construction of solid state batteries facilitates more straightforward recycling processes. Research indicates recovery rates for key materials could reach 90% or higher, compared to 50-70% for conventional lithium-ion technologies. This circular economy potential significantly reduces the environmental burden associated with battery disposal and raw material extraction.

When specifically applied to aerospace, these batteries contribute to overall system sustainability through weight reduction and improved energy efficiency. Preliminary studies suggest aircraft implementing solid state battery technology could achieve 5-8% fuel consumption reduction through weight savings alone. For electric aerospace applications, the higher energy density translates directly to extended range or reduced battery mass requirements, optimizing resource utilization across the entire vehicle system.

Climate resilience considerations also favor solid state technology. These batteries demonstrate superior performance stability across extreme temperature ranges encountered in aerospace environments, reducing energy waste from climate control systems previously required to maintain optimal battery operating conditions.

Manufacturing processes for solid state batteries demonstrate promising environmental advantages. Initial lifecycle assessments indicate up to 30% reduction in carbon footprint compared to traditional lithium-ion battery production. This improvement stems primarily from simplified manufacturing workflows and reduced requirements for environmentally controlled production environments. Additionally, the elimination of certain toxic materials translates to decreased water pollution and hazardous waste generation during manufacturing.

Resource efficiency represents another substantial environmental benefit. Solid state batteries for aerospace applications are projected to achieve 25-40% higher energy density than conventional alternatives, enabling more efficient use of critical raw materials. Several leading designs also reduce or eliminate dependence on cobalt—a material associated with significant ethical and environmental mining concerns. The extended cycle life of these batteries, potentially reaching 2-3 times that of conventional systems, further enhances their sustainability profile by reducing replacement frequency.

End-of-life considerations reveal additional advantages. The simplified chemistry and construction of solid state batteries facilitates more straightforward recycling processes. Research indicates recovery rates for key materials could reach 90% or higher, compared to 50-70% for conventional lithium-ion technologies. This circular economy potential significantly reduces the environmental burden associated with battery disposal and raw material extraction.

When specifically applied to aerospace, these batteries contribute to overall system sustainability through weight reduction and improved energy efficiency. Preliminary studies suggest aircraft implementing solid state battery technology could achieve 5-8% fuel consumption reduction through weight savings alone. For electric aerospace applications, the higher energy density translates directly to extended range or reduced battery mass requirements, optimizing resource utilization across the entire vehicle system.

Climate resilience considerations also favor solid state technology. These batteries demonstrate superior performance stability across extreme temperature ranges encountered in aerospace environments, reducing energy waste from climate control systems previously required to maintain optimal battery operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!