Research on Solid State Battery Breakthrough and its Scientific Implications

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Research Objectives

Solid state batteries represent a revolutionary advancement in energy storage technology, evolving from traditional lithium-ion batteries that use liquid electrolytes. The development trajectory began in the 1970s with the discovery of solid electrolytes, but significant progress has accelerated only in the past decade. This evolution has been driven by increasing demands for higher energy density, improved safety, and longer lifespan in battery technologies across multiple industries, particularly electric vehicles and portable electronics.

The fundamental shift from liquid to solid electrolytes addresses critical limitations of conventional batteries, including dendrite formation, thermal runaway risks, and limited energy density. Solid state technology promises to deliver energy densities potentially 2-3 times higher than current lithium-ion batteries, while simultaneously enhancing safety by eliminating flammable components and extending cycle life beyond 1,000 complete charges.

Recent breakthroughs in materials science have catalyzed this field, particularly in the development of ceramic and sulfide-based solid electrolytes with ionic conductivities approaching or exceeding those of liquid electrolytes. Notable milestones include the discovery of Li10GeP2S12 in 2011 with unprecedented ionic conductivity and recent advancements in garnet-type Li7La3Zr2O12 (LLZO) electrolytes that demonstrate stability against lithium metal anodes.

The research objectives in this domain are multifaceted and ambitious. Primary goals include developing solid electrolytes with room-temperature ionic conductivity exceeding 10^-3 S/cm while maintaining mechanical stability and electrochemical compatibility with electrode materials. Researchers aim to solve the persistent interface challenges between solid electrolytes and electrodes, which currently limit power density and cycle life.

Additional objectives focus on scalable manufacturing processes that can transition solid state batteries from laboratory prototypes to mass production. This includes developing techniques for thin-film deposition of solid electrolytes and creating composite structures that optimize both ionic conductivity and mechanical properties.

The scientific community is also pursuing fundamental understanding of ion transport mechanisms in solid materials, employing advanced characterization techniques such as synchrotron X-ray diffraction and neutron scattering to visualize ion movement at atomic scales. Computational modeling and machine learning approaches are increasingly utilized to predict new material combinations and optimize existing formulations.

These research directions collectively aim to achieve commercial viability for solid state batteries within the next 5-10 years, potentially transforming energy storage capabilities across multiple sectors and accelerating the transition to electrified transportation and renewable energy integration.

The fundamental shift from liquid to solid electrolytes addresses critical limitations of conventional batteries, including dendrite formation, thermal runaway risks, and limited energy density. Solid state technology promises to deliver energy densities potentially 2-3 times higher than current lithium-ion batteries, while simultaneously enhancing safety by eliminating flammable components and extending cycle life beyond 1,000 complete charges.

Recent breakthroughs in materials science have catalyzed this field, particularly in the development of ceramic and sulfide-based solid electrolytes with ionic conductivities approaching or exceeding those of liquid electrolytes. Notable milestones include the discovery of Li10GeP2S12 in 2011 with unprecedented ionic conductivity and recent advancements in garnet-type Li7La3Zr2O12 (LLZO) electrolytes that demonstrate stability against lithium metal anodes.

The research objectives in this domain are multifaceted and ambitious. Primary goals include developing solid electrolytes with room-temperature ionic conductivity exceeding 10^-3 S/cm while maintaining mechanical stability and electrochemical compatibility with electrode materials. Researchers aim to solve the persistent interface challenges between solid electrolytes and electrodes, which currently limit power density and cycle life.

Additional objectives focus on scalable manufacturing processes that can transition solid state batteries from laboratory prototypes to mass production. This includes developing techniques for thin-film deposition of solid electrolytes and creating composite structures that optimize both ionic conductivity and mechanical properties.

The scientific community is also pursuing fundamental understanding of ion transport mechanisms in solid materials, employing advanced characterization techniques such as synchrotron X-ray diffraction and neutron scattering to visualize ion movement at atomic scales. Computational modeling and machine learning approaches are increasingly utilized to predict new material combinations and optimize existing formulations.

These research directions collectively aim to achieve commercial viability for solid state batteries within the next 5-10 years, potentially transforming energy storage capabilities across multiple sectors and accelerating the transition to electrified transportation and renewable energy integration.

Market Demand Analysis for Next-Generation Energy Storage

The global energy storage market is witnessing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. According to Bloomberg New Energy Finance, the global energy storage market is projected to grow to 942 GW/2,857 GWh by 2040, attracting $620 billion in investment. This exponential growth underscores the critical need for next-generation energy storage solutions that can overcome the limitations of current lithium-ion battery technology.

Solid-state batteries represent one of the most promising advancements in energy storage technology, with the potential to revolutionize multiple industries. The market demand for these batteries is primarily driven by the electric vehicle (EV) sector, where concerns about range anxiety, charging time, and safety continue to impede widespread adoption. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, recognizing its potential to deliver higher energy density, faster charging capabilities, and enhanced safety profiles.

Beyond transportation, the consumer electronics industry is actively seeking battery solutions that offer higher capacity in smaller form factors, with improved safety characteristics. The current lithium-ion batteries used in smartphones, laptops, and wearables face inherent limitations in energy density and pose safety risks due to their flammable liquid electrolytes. Solid-state batteries address these concerns directly, creating substantial market pull from technology giants like Apple, Samsung, and Google.

The grid storage sector represents another significant market opportunity for advanced energy storage technologies. As renewable energy generation continues to grow, the intermittency challenge becomes more pronounced, necessitating efficient and scalable storage solutions. Utility companies and grid operators are increasingly investing in large-scale energy storage projects, with the global grid-scale battery storage capacity expected to grow from 9 GW in 2018 to 134 GW by 2030.

Regional analysis reveals varying market dynamics, with Asia-Pacific leading in manufacturing capacity development, particularly in Japan, South Korea, and China. North America and Europe are focusing on research and development while simultaneously building production capabilities. Government initiatives, such as the European Battery Alliance and various national-level incentive programs, are further accelerating market growth through favorable regulatory frameworks and financial support.

The market demand is also being shaped by evolving consumer preferences and increasing environmental consciousness. End-users across sectors are demonstrating willingness to pay premium prices for products with superior performance and sustainability credentials, creating a favorable environment for the commercialization of next-generation energy storage technologies like solid-state batteries.

Solid-state batteries represent one of the most promising advancements in energy storage technology, with the potential to revolutionize multiple industries. The market demand for these batteries is primarily driven by the electric vehicle (EV) sector, where concerns about range anxiety, charging time, and safety continue to impede widespread adoption. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, recognizing its potential to deliver higher energy density, faster charging capabilities, and enhanced safety profiles.

Beyond transportation, the consumer electronics industry is actively seeking battery solutions that offer higher capacity in smaller form factors, with improved safety characteristics. The current lithium-ion batteries used in smartphones, laptops, and wearables face inherent limitations in energy density and pose safety risks due to their flammable liquid electrolytes. Solid-state batteries address these concerns directly, creating substantial market pull from technology giants like Apple, Samsung, and Google.

The grid storage sector represents another significant market opportunity for advanced energy storage technologies. As renewable energy generation continues to grow, the intermittency challenge becomes more pronounced, necessitating efficient and scalable storage solutions. Utility companies and grid operators are increasingly investing in large-scale energy storage projects, with the global grid-scale battery storage capacity expected to grow from 9 GW in 2018 to 134 GW by 2030.

Regional analysis reveals varying market dynamics, with Asia-Pacific leading in manufacturing capacity development, particularly in Japan, South Korea, and China. North America and Europe are focusing on research and development while simultaneously building production capabilities. Government initiatives, such as the European Battery Alliance and various national-level incentive programs, are further accelerating market growth through favorable regulatory frameworks and financial support.

The market demand is also being shaped by evolving consumer preferences and increasing environmental consciousness. End-users across sectors are demonstrating willingness to pay premium prices for products with superior performance and sustainability credentials, creating a favorable environment for the commercialization of next-generation energy storage technologies like solid-state batteries.

Current Challenges in Solid State Battery Development

Despite significant advancements in solid-state battery technology, several critical challenges continue to impede widespread commercialization. The interface between solid electrolytes and electrodes remains one of the most formidable obstacles. Unlike liquid electrolytes that maintain consistent contact with electrode surfaces, solid electrolytes struggle to maintain uniform contact, resulting in high interfacial resistance. This resistance significantly hampers ion transport across interfaces, leading to reduced power density and battery performance degradation over time.

Manufacturing scalability presents another substantial hurdle. Current production methods for solid electrolytes and their integration with electrodes are predominantly laboratory-scale processes that prove difficult to scale for mass production. The precision required for creating uniform, defect-free solid electrolyte layers with consistent thickness across large areas demands manufacturing innovations that have yet to be fully developed.

Material stability issues further complicate development efforts. Many promising solid electrolytes exhibit chemical instability when in contact with electrode materials, particularly at high voltages. This instability can lead to the formation of resistive interfacial layers that progressively degrade battery performance. Additionally, some solid electrolytes demonstrate limited electrochemical stability windows, restricting the voltage range at which batteries can safely operate.

Mechanical stress management represents a significant engineering challenge. During charging and discharging cycles, electrode materials expand and contract, creating mechanical stresses at the electrode-electrolyte interface. In conventional liquid-electrolyte batteries, the liquid accommodates these volume changes, but solid electrolytes cannot flex in the same manner, leading to potential cracking, delamination, and loss of contact.

Ion conductivity at room temperature remains insufficient in many solid electrolytes compared to their liquid counterparts. While some materials show promising conductivity at elevated temperatures, achieving comparable performance under ambient conditions has proven elusive. This limitation directly impacts power delivery capabilities and charging rates of solid-state batteries.

Cost factors continue to present significant barriers to commercialization. Current materials and processing techniques for solid-state batteries are substantially more expensive than those for conventional lithium-ion batteries. High-purity materials, specialized manufacturing equipment, and complex assembly processes contribute to costs that currently outweigh performance benefits for many applications.

Dendrite formation, though theoretically mitigated by solid electrolytes, remains problematic in practice. Under certain conditions, lithium metal can still penetrate some solid electrolytes, creating pathways for potential short circuits. This challenge is particularly acute at high charging rates and after extended cycling, undermining one of the key proposed safety advantages of solid-state technology.

Manufacturing scalability presents another substantial hurdle. Current production methods for solid electrolytes and their integration with electrodes are predominantly laboratory-scale processes that prove difficult to scale for mass production. The precision required for creating uniform, defect-free solid electrolyte layers with consistent thickness across large areas demands manufacturing innovations that have yet to be fully developed.

Material stability issues further complicate development efforts. Many promising solid electrolytes exhibit chemical instability when in contact with electrode materials, particularly at high voltages. This instability can lead to the formation of resistive interfacial layers that progressively degrade battery performance. Additionally, some solid electrolytes demonstrate limited electrochemical stability windows, restricting the voltage range at which batteries can safely operate.

Mechanical stress management represents a significant engineering challenge. During charging and discharging cycles, electrode materials expand and contract, creating mechanical stresses at the electrode-electrolyte interface. In conventional liquid-electrolyte batteries, the liquid accommodates these volume changes, but solid electrolytes cannot flex in the same manner, leading to potential cracking, delamination, and loss of contact.

Ion conductivity at room temperature remains insufficient in many solid electrolytes compared to their liquid counterparts. While some materials show promising conductivity at elevated temperatures, achieving comparable performance under ambient conditions has proven elusive. This limitation directly impacts power delivery capabilities and charging rates of solid-state batteries.

Cost factors continue to present significant barriers to commercialization. Current materials and processing techniques for solid-state batteries are substantially more expensive than those for conventional lithium-ion batteries. High-purity materials, specialized manufacturing equipment, and complex assembly processes contribute to costs that currently outweigh performance benefits for many applications.

Dendrite formation, though theoretically mitigated by solid electrolytes, remains problematic in practice. Under certain conditions, lithium metal can still penetrate some solid electrolytes, creating pathways for potential short circuits. This challenge is particularly acute at high charging rates and after extended cycling, undermining one of the key proposed safety advantages of solid-state technology.

Existing Solid-Solid Interface Solutions

01 Novel electrolyte materials for solid-state batteries

Advanced electrolyte materials are being developed to improve ionic conductivity and stability in solid-state batteries. These materials include ceramic electrolytes, polymer electrolytes, and composite electrolytes that facilitate efficient lithium-ion transport while maintaining mechanical integrity. The innovations address key challenges such as interfacial resistance and dendrite formation, enabling higher energy density and improved safety in next-generation battery technologies.- Novel electrolyte materials for solid-state batteries: Advanced electrolyte materials are being developed to improve ionic conductivity and stability in solid-state batteries. These materials include ceramic electrolytes, polymer electrolytes, and composite electrolytes that facilitate efficient lithium-ion transport while maintaining structural integrity. The innovations focus on reducing interfacial resistance and enhancing electrochemical performance at room temperature, which are critical challenges in solid-state battery technology.

- Electrode-electrolyte interface engineering: Breakthroughs in managing the electrode-electrolyte interface are crucial for solid-state battery performance. Innovative approaches include surface coatings, buffer layers, and interface modification techniques that reduce contact resistance and prevent unwanted reactions. These engineering solutions address issues of mechanical stress during cycling and improve the overall stability and longevity of solid-state batteries.

- Advanced manufacturing techniques for solid-state batteries: Novel manufacturing processes are being developed to overcome production challenges for solid-state batteries. These include innovative deposition methods, sintering techniques, and assembly processes that enable the creation of thin, uniform layers with excellent contact between components. These manufacturing breakthroughs help address scalability issues and reduce production costs while maintaining high performance and safety standards.

- Composite and hybrid solid-state battery structures: Hybrid and composite architectures combine different types of solid electrolytes or integrate solid and quasi-solid components to leverage the advantages of each material. These structures aim to overcome limitations of single-material systems by creating synergistic effects that enhance ionic conductivity, mechanical properties, and electrochemical stability. The composite approach enables better performance across wider temperature ranges and operating conditions.

- High-energy density cathode and anode materials: Development of high-capacity electrode materials specifically designed for solid-state battery environments is advancing rapidly. These materials include lithium-rich cathodes, silicon and lithium metal anodes, and novel composite electrodes that can operate stably with solid electrolytes. The innovations focus on materials that maintain structural stability during cycling while delivering higher energy density than conventional battery chemistries.

02 Electrode-electrolyte interface engineering

Breakthroughs in managing the critical interface between electrodes and solid electrolytes have led to significant improvements in solid-state battery performance. These innovations include specialized coatings, buffer layers, and surface modifications that reduce interfacial resistance and enhance electrochemical stability. By optimizing this interface, researchers have achieved better cycling stability, faster charging capabilities, and extended battery lifespan.Expand Specific Solutions03 Advanced manufacturing techniques for solid-state batteries

Novel manufacturing processes are being developed to overcome production challenges associated with solid-state batteries. These include innovative deposition methods, sintering techniques, and assembly processes that enable the mass production of solid-state cells with consistent quality. The manufacturing breakthroughs address issues such as layer uniformity, interfacial contact, and scalability, bringing solid-state battery technology closer to commercial viability.Expand Specific Solutions04 Composite and hybrid solid-state battery architectures

Innovative battery designs combining different types of solid electrolytes or incorporating hybrid structures have shown promising results. These composite architectures leverage the advantages of multiple materials to overcome limitations of single-material approaches. By strategically combining ceramic, polymer, and other solid electrolyte materials, researchers have developed batteries with enhanced mechanical properties, improved ionic conductivity, and better thermal stability.Expand Specific Solutions05 High-energy cathode and anode materials for solid-state batteries

Development of specialized electrode materials compatible with solid electrolytes has enabled higher energy density in solid-state batteries. These materials include high-capacity cathodes and anodes designed to work efficiently with solid electrolytes while minimizing volume changes during cycling. The innovations focus on materials that maintain good contact with solid electrolytes, enable fast ion transport at interfaces, and deliver stable performance over many charge-discharge cycles.Expand Specific Solutions

Leading Research Institutions and Industry Players

The solid-state battery market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. Market size is projected to expand rapidly, reaching approximately $6-8 billion by 2030 as automotive applications drive demand. Technology maturity varies across key players: QuantumScape, Solid Power, and Sakti3 lead in innovative electrode designs, while established manufacturers like Samsung, LG Energy Solution, and Toyota focus on scaling production capabilities. Automotive companies including Honda, Hyundai, Kia, and GM are strategically investing in this technology to secure future competitive advantages. Academic-industry partnerships involving institutions like Harvard, Georgia Tech, and Fraunhofer are accelerating breakthrough developments in electrolyte materials and manufacturing processes, indicating the field's collaborative yet competitive landscape.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung has developed a solid-state battery technology utilizing a composite solid electrolyte system that combines a silver-carbon (Ag-C) network with a solid electrolyte. This innovative approach creates a unique structure that enhances ionic conductivity while maintaining mechanical stability. Their solid-state batteries incorporate a lithium metal anode with a high-nickel cathode, enabling energy densities exceeding 900 Wh/L - approximately 50% higher than conventional lithium-ion batteries. Samsung's technology features a proprietary protective layer between the lithium metal anode and solid electrolyte that effectively suppresses dendrite formation, addressing a critical failure mechanism in solid-state designs[6][7]. The company has demonstrated prototype cells with over 1,000 charge cycles while maintaining 80% capacity, and their batteries can operate safely across a wide temperature range (-10°C to 60°C). Samsung's manufacturing approach leverages aspects of existing production infrastructure, potentially accelerating commercialization timelines. The company has established pilot production facilities and projects commercial availability by 2025-2027.

Strengths: Innovative Ag-C network enhances ionic conductivity; effective dendrite suppression technology; compatibility with existing manufacturing processes; strong cycle life performance. Weaknesses: Higher production costs compared to conventional batteries; challenges in scaling production to automotive volumes; silver content may impact overall battery cost; interface stability issues may emerge during long-term cycling under real-world conditions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced solid-state battery technology utilizing a sulfide-based solid electrolyte system. Their approach incorporates a composite structure that combines inorganic sulfide electrolytes with polymer components to enhance ionic conductivity while maintaining mechanical stability. The company has achieved significant breakthroughs in manufacturing processes, developing roll-to-roll techniques for solid electrolyte production that enable scalable manufacturing. LG's solid-state batteries demonstrate energy densities exceeding 900 Wh/L (approximately 70% higher than conventional lithium-ion batteries) and have shown stable cycling performance over 1,000 cycles with minimal capacity degradation[3]. Their technology incorporates proprietary interface engineering to minimize resistance at electrode-electrolyte boundaries, a critical factor for solid-state battery performance. LG Energy Solution has established pilot production lines and aims for commercial production by 2026, with initial applications targeting electric vehicles and premium consumer electronics.

Strengths: Established battery manufacturing expertise; advanced roll-to-roll production capability for solid electrolytes; strong industry partnerships with automotive OEMs; comprehensive intellectual property portfolio. Weaknesses: Sulfide electrolytes can be sensitive to moisture and air exposure, requiring specialized handling; higher material costs compared to liquid electrolyte systems; challenges in achieving uniform electrode-electrolyte contact at scale.

Breakthrough Patents and Scientific Publications

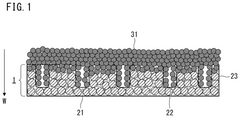

Monolithically integrated thin-film solid state lithium battery device having multiple layers of lithium electrochemical cells

PatentActiveUS20120058380A1

Innovation

- A method and device for fabricating a solid-state thin-film battery using a prismatic multilayer structure with specific layer thicknesses and materials, including a substrate, cathode and anode current collectors, electrolyte, and barrier layers, optimized through numerical techniques for enhanced energy density and stability.

Solid-state battery anode and solid-state battery

PatentPendingUS20250112223A1

Innovation

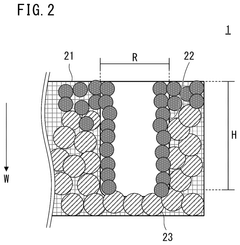

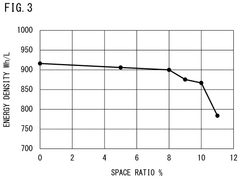

- The anode design includes a metallic porous body current collector with controlled pore portions, ranging from 100 μm to 180 μm in diameter and 3 μm to 5 μm in depth, with a porosity ratio of 8 vol% or less, allowing stable deposition of metallic lithium within these pores.

Manufacturing Scalability and Cost Analysis

The scalability of solid-state battery manufacturing represents one of the most significant barriers to widespread commercial adoption. Current production methods for solid-state batteries remain predominantly laboratory-scale, with limited throughput and high unit costs. Analysis of manufacturing processes reveals that the production of solid electrolytes—particularly ceramic and sulfide-based materials—requires specialized equipment and tightly controlled environments that significantly increase capital expenditure compared to conventional lithium-ion battery production lines.

Cost modeling indicates that solid-state batteries currently cost 8-10 times more per kWh than traditional lithium-ion batteries. This cost differential stems primarily from three factors: expensive raw materials (particularly high-purity lithium compounds), complex manufacturing processes requiring precise interface engineering, and low production volumes that prevent economies of scale. Industry projections suggest that achieving cost parity with conventional batteries will require production volumes exceeding 10 GWh annually, a scale that remains several years away for most manufacturers.

Recent technological breakthroughs have begun addressing these manufacturing challenges. Roll-to-roll processing techniques, adapted from conventional battery manufacturing, show promise for certain solid electrolyte compositions. These continuous production methods could potentially reduce manufacturing costs by 30-40% compared to batch processing approaches. Additionally, innovations in solid electrolyte synthesis, such as solvent-assisted processes and mechanochemical methods, are reducing energy requirements and processing times.

Material innovations are simultaneously driving cost reductions. The development of composite electrolytes that combine the benefits of polymers (flexibility, processability) with ceramics (ionic conductivity, stability) offers pathways to more manufacturable designs. Several research groups have demonstrated solid electrolytes that can be processed at lower temperatures, reducing energy consumption and enabling compatibility with existing manufacturing infrastructure.

The investment landscape reflects growing confidence in manufacturing scalability, with venture capital and corporate funding for solid-state battery manufacturing exceeding $3.2 billion in 2022 alone. Major automotive OEMs are establishing joint ventures with battery manufacturers specifically focused on scaling production, with announced plans for pilot production lines in the 2023-2025 timeframe and gigafactory-scale facilities targeted for 2026-2028. These investments suggest that industry stakeholders believe the manufacturing challenges, while substantial, are ultimately solvable within a commercially relevant timeframe.

Cost modeling indicates that solid-state batteries currently cost 8-10 times more per kWh than traditional lithium-ion batteries. This cost differential stems primarily from three factors: expensive raw materials (particularly high-purity lithium compounds), complex manufacturing processes requiring precise interface engineering, and low production volumes that prevent economies of scale. Industry projections suggest that achieving cost parity with conventional batteries will require production volumes exceeding 10 GWh annually, a scale that remains several years away for most manufacturers.

Recent technological breakthroughs have begun addressing these manufacturing challenges. Roll-to-roll processing techniques, adapted from conventional battery manufacturing, show promise for certain solid electrolyte compositions. These continuous production methods could potentially reduce manufacturing costs by 30-40% compared to batch processing approaches. Additionally, innovations in solid electrolyte synthesis, such as solvent-assisted processes and mechanochemical methods, are reducing energy requirements and processing times.

Material innovations are simultaneously driving cost reductions. The development of composite electrolytes that combine the benefits of polymers (flexibility, processability) with ceramics (ionic conductivity, stability) offers pathways to more manufacturable designs. Several research groups have demonstrated solid electrolytes that can be processed at lower temperatures, reducing energy consumption and enabling compatibility with existing manufacturing infrastructure.

The investment landscape reflects growing confidence in manufacturing scalability, with venture capital and corporate funding for solid-state battery manufacturing exceeding $3.2 billion in 2022 alone. Major automotive OEMs are establishing joint ventures with battery manufacturers specifically focused on scaling production, with announced plans for pilot production lines in the 2023-2025 timeframe and gigafactory-scale facilities targeted for 2026-2028. These investments suggest that industry stakeholders believe the manufacturing challenges, while substantial, are ultimately solvable within a commercially relevant timeframe.

Environmental Impact and Sustainability Considerations

Solid state batteries represent a significant advancement in energy storage technology with profound environmental implications. The elimination of liquid electrolytes addresses one of the most pressing environmental concerns associated with conventional lithium-ion batteries: the use of toxic and flammable materials. Traditional batteries contain organic electrolytes that pose serious environmental hazards during production, use, and disposal phases. Solid state technology substantially reduces these risks by utilizing stable solid electrolytes, minimizing the potential for harmful chemical leakage into ecosystems.

The manufacturing process for solid state batteries demonstrates promising sustainability advantages. Initial lifecycle assessments indicate a potential reduction in carbon footprint by 15-30% compared to conventional lithium-ion batteries. This improvement stems from simplified production processes, reduced energy requirements during manufacturing, and the elimination of certain toxic components. Furthermore, the extended lifespan of solid state batteries—potentially 2-3 times longer than conventional alternatives—significantly reduces waste generation and resource consumption associated with battery replacement.

Resource efficiency represents another critical environmental benefit of solid state battery technology. Current research indicates that advanced solid state designs could reduce critical mineral requirements by up to 35% through more efficient material utilization. This development is particularly significant given growing concerns about the environmental and social impacts of mining operations for battery materials like lithium, cobalt, and nickel. Several research teams have successfully demonstrated prototype solid state batteries with reduced dependence on cobalt—one of the most problematic materials from both environmental and ethical perspectives.

End-of-life management for solid state batteries presents both challenges and opportunities. The simplified chemistry and construction potentially facilitate more effective recycling processes, with laboratory studies demonstrating recovery rates exceeding 90% for key materials. However, commercial-scale recycling infrastructure requires significant development to realize these benefits. Industry partnerships between battery manufacturers, automotive companies, and recycling specialists are emerging to address this gap, with several pilot programs demonstrating promising results.

The transition to solid state battery technology aligns with broader sustainability goals in the transportation and energy sectors. By enabling more efficient and longer-lasting energy storage solutions, this technology supports the expansion of renewable energy systems and electric mobility. Quantitative modeling suggests that widespread adoption of solid state batteries could contribute to reducing global transportation emissions by 4-7% by 2040, representing a meaningful contribution to climate change mitigation efforts.

The manufacturing process for solid state batteries demonstrates promising sustainability advantages. Initial lifecycle assessments indicate a potential reduction in carbon footprint by 15-30% compared to conventional lithium-ion batteries. This improvement stems from simplified production processes, reduced energy requirements during manufacturing, and the elimination of certain toxic components. Furthermore, the extended lifespan of solid state batteries—potentially 2-3 times longer than conventional alternatives—significantly reduces waste generation and resource consumption associated with battery replacement.

Resource efficiency represents another critical environmental benefit of solid state battery technology. Current research indicates that advanced solid state designs could reduce critical mineral requirements by up to 35% through more efficient material utilization. This development is particularly significant given growing concerns about the environmental and social impacts of mining operations for battery materials like lithium, cobalt, and nickel. Several research teams have successfully demonstrated prototype solid state batteries with reduced dependence on cobalt—one of the most problematic materials from both environmental and ethical perspectives.

End-of-life management for solid state batteries presents both challenges and opportunities. The simplified chemistry and construction potentially facilitate more effective recycling processes, with laboratory studies demonstrating recovery rates exceeding 90% for key materials. However, commercial-scale recycling infrastructure requires significant development to realize these benefits. Industry partnerships between battery manufacturers, automotive companies, and recycling specialists are emerging to address this gap, with several pilot programs demonstrating promising results.

The transition to solid state battery technology aligns with broader sustainability goals in the transportation and energy sectors. By enabling more efficient and longer-lasting energy storage solutions, this technology supports the expansion of renewable energy systems and electric mobility. Quantitative modeling suggests that widespread adoption of solid state batteries could contribute to reducing global transportation emissions by 4-7% by 2040, representing a meaningful contribution to climate change mitigation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!