Solid State Battery Breakthrough: Electrolyte Stability and Performance

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Research Objectives

Solid state batteries represent a significant evolution in energy storage technology, emerging from the limitations of conventional lithium-ion batteries that utilize liquid electrolytes. The development trajectory began in the 1970s with the discovery of fast ion conductors, followed by incremental advancements in solid electrolyte materials throughout the 1980s and 1990s. The early 2000s marked a pivotal shift with the introduction of lithium superionic conductors, catalyzing renewed interest in solid-state technology.

The technological progression accelerated dramatically after 2010, with breakthrough discoveries in ceramic and sulfide-based electrolytes demonstrating ionic conductivities comparable to liquid counterparts. This period witnessed substantial investments from automotive manufacturers and technology companies, recognizing the transformative potential of solid-state batteries for electric mobility applications.

Current research focuses predominantly on addressing the critical challenges of electrolyte stability and performance optimization. The interface between solid electrolytes and electrodes presents persistent challenges, including mechanical stress during cycling, chemical incompatibility, and formation of resistive layers that impede ion transport. These issues directly impact battery longevity, power density, and safety characteristics.

The primary technical objectives in this domain include developing electrolyte materials with enhanced ionic conductivity at room temperature (>10^-3 S/cm), improving mechanical properties to maintain electrode contact during cycling, and ensuring chemical stability against lithium metal anodes. Additionally, researchers aim to establish scalable manufacturing processes that can transition laboratory successes to commercial production.

Recent advancements have explored composite electrolytes combining polymers with ceramic materials, novel interface engineering approaches, and advanced characterization techniques to understand degradation mechanisms at atomic scales. These efforts represent convergent strategies toward overcoming the fundamental limitations of current solid electrolyte systems.

The research landscape is increasingly oriented toward practical implementation challenges, with emphasis on cycle life extension beyond 1,000 cycles, fast charging capabilities (80% capacity in under 15 minutes), and operation across wider temperature ranges (-20°C to 60°C). These parameters are considered essential benchmarks for commercial viability in automotive and grid storage applications.

Looking forward, the field is progressing toward multifunctional electrolyte designs that simultaneously address conductivity, stability, and manufacturability concerns. The ultimate goal remains developing solid-state batteries that deliver significant improvements in energy density (>400 Wh/kg), safety, and lifespan compared to conventional lithium-ion technologies, while maintaining competitive production costs.

The technological progression accelerated dramatically after 2010, with breakthrough discoveries in ceramic and sulfide-based electrolytes demonstrating ionic conductivities comparable to liquid counterparts. This period witnessed substantial investments from automotive manufacturers and technology companies, recognizing the transformative potential of solid-state batteries for electric mobility applications.

Current research focuses predominantly on addressing the critical challenges of electrolyte stability and performance optimization. The interface between solid electrolytes and electrodes presents persistent challenges, including mechanical stress during cycling, chemical incompatibility, and formation of resistive layers that impede ion transport. These issues directly impact battery longevity, power density, and safety characteristics.

The primary technical objectives in this domain include developing electrolyte materials with enhanced ionic conductivity at room temperature (>10^-3 S/cm), improving mechanical properties to maintain electrode contact during cycling, and ensuring chemical stability against lithium metal anodes. Additionally, researchers aim to establish scalable manufacturing processes that can transition laboratory successes to commercial production.

Recent advancements have explored composite electrolytes combining polymers with ceramic materials, novel interface engineering approaches, and advanced characterization techniques to understand degradation mechanisms at atomic scales. These efforts represent convergent strategies toward overcoming the fundamental limitations of current solid electrolyte systems.

The research landscape is increasingly oriented toward practical implementation challenges, with emphasis on cycle life extension beyond 1,000 cycles, fast charging capabilities (80% capacity in under 15 minutes), and operation across wider temperature ranges (-20°C to 60°C). These parameters are considered essential benchmarks for commercial viability in automotive and grid storage applications.

Looking forward, the field is progressing toward multifunctional electrolyte designs that simultaneously address conductivity, stability, and manufacturability concerns. The ultimate goal remains developing solid-state batteries that deliver significant improvements in energy density (>400 Wh/kg), safety, and lifespan compared to conventional lithium-ion technologies, while maintaining competitive production costs.

Market Demand Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. Advanced energy storage solutions, particularly solid-state batteries with enhanced electrolyte stability, are positioned at the forefront of this market evolution. Current projections indicate that the global advanced battery market will reach $240 billion by 2027, with solid-state technologies potentially capturing 15-20% of this market within the next decade.

Consumer electronics continues to be a significant driver for advanced battery technologies, with demand for longer-lasting, faster-charging, and safer batteries growing at approximately 8% annually. Smartphone manufacturers are actively seeking solid-state solutions that can provide 30-50% higher energy density while eliminating safety concerns associated with conventional lithium-ion batteries.

The electric vehicle (EV) sector represents the most promising growth area for solid-state battery technology. With global EV sales projected to reach 26 million units by 2030, automotive manufacturers are investing heavily in next-generation battery technologies. Major automakers including Toyota, Volkswagen, and BMW have committed over $13.5 billion collectively toward solid-state battery development, specifically targeting electrolyte stability improvements.

Grid-scale energy storage presents another substantial market opportunity, with installed capacity expected to grow from 17 GWh in 2021 to over 400 GWh by 2030. Utility companies are increasingly recognizing the value of advanced batteries with stable electrolytes for managing renewable energy integration and grid stabilization.

Consumer surveys indicate growing awareness and demand for safer battery technologies, with 78% of potential EV buyers citing battery safety as a "very important" consideration. This sentiment has intensified following widely publicized incidents involving conventional lithium-ion battery fires, creating a market pull for solid-state alternatives with stable electrolytes.

Regulatory trends are further accelerating market demand, with several jurisdictions implementing stricter safety standards for energy storage systems. The European Union's proposed Battery Regulation includes specific provisions for battery safety and sustainability, potentially creating regulatory advantages for solid-state technologies with stable electrolytes.

Investment patterns reflect this growing market demand, with venture capital funding for solid-state battery startups reaching $3.6 billion in 2022 alone. This represents a 165% increase compared to 2020 figures, demonstrating strong investor confidence in the commercial potential of these advanced energy storage solutions.

Consumer electronics continues to be a significant driver for advanced battery technologies, with demand for longer-lasting, faster-charging, and safer batteries growing at approximately 8% annually. Smartphone manufacturers are actively seeking solid-state solutions that can provide 30-50% higher energy density while eliminating safety concerns associated with conventional lithium-ion batteries.

The electric vehicle (EV) sector represents the most promising growth area for solid-state battery technology. With global EV sales projected to reach 26 million units by 2030, automotive manufacturers are investing heavily in next-generation battery technologies. Major automakers including Toyota, Volkswagen, and BMW have committed over $13.5 billion collectively toward solid-state battery development, specifically targeting electrolyte stability improvements.

Grid-scale energy storage presents another substantial market opportunity, with installed capacity expected to grow from 17 GWh in 2021 to over 400 GWh by 2030. Utility companies are increasingly recognizing the value of advanced batteries with stable electrolytes for managing renewable energy integration and grid stabilization.

Consumer surveys indicate growing awareness and demand for safer battery technologies, with 78% of potential EV buyers citing battery safety as a "very important" consideration. This sentiment has intensified following widely publicized incidents involving conventional lithium-ion battery fires, creating a market pull for solid-state alternatives with stable electrolytes.

Regulatory trends are further accelerating market demand, with several jurisdictions implementing stricter safety standards for energy storage systems. The European Union's proposed Battery Regulation includes specific provisions for battery safety and sustainability, potentially creating regulatory advantages for solid-state technologies with stable electrolytes.

Investment patterns reflect this growing market demand, with venture capital funding for solid-state battery startups reaching $3.6 billion in 2022 alone. This represents a 165% increase compared to 2020 figures, demonstrating strong investor confidence in the commercial potential of these advanced energy storage solutions.

Current Challenges in Electrolyte Stability and Interface Management

Despite significant advancements in solid-state battery technology, electrolyte stability and interface management remain critical challenges impeding commercial viability. Current solid electrolytes face fundamental limitations in ionic conductivity, with most materials achieving only 10^-4 to 10^-3 S/cm at room temperature—significantly lower than liquid electrolytes (10^-2 S/cm). This conductivity gap necessitates operation at elevated temperatures, complicating practical applications.

Interface stability between solid electrolytes and electrodes presents another major hurdle. The solid-solid interfaces often suffer from poor contact and high impedance, resulting in capacity fade and reduced cycle life. Chemical incompatibility at these interfaces leads to the formation of interphases with high resistance, particularly at the cathode-electrolyte interface where transition metal dissolution and oxygen release can degrade the electrolyte.

Mechanical stability issues further complicate development efforts. Volume changes during cycling (up to 300% for silicon anodes) create mechanical stress that can fracture the electrolyte or delaminate interfaces. This problem is exacerbated by the inherent brittleness of ceramic electrolytes, with fracture toughness values typically below 1 MPa·m^1/2, compared to >20 MPa·m^1/2 for structural ceramics.

Manufacturing scalability presents additional challenges. Current fabrication methods for solid electrolytes often require high-temperature sintering (>1000°C) and precisely controlled atmospheres, making mass production costly and complex. The need for thin electrolyte layers (<50 μm) with uniform properties and minimal defects further complicates manufacturing processes.

Dendrite growth, contrary to early assumptions, remains problematic even in solid electrolytes. Recent studies have demonstrated that lithium dendrites can propagate through grain boundaries in polycrystalline electrolytes under certain current densities (>0.5-1 mA/cm²), leading to internal short circuits and safety concerns.

Environmental stability poses another significant challenge, as many promising solid electrolytes (particularly sulfides) are highly reactive with atmospheric moisture, necessitating stringent handling protocols and protective measures during manufacturing and assembly.

Cost factors also impede commercialization, with current solid-state battery prototypes estimated at 2-5 times the cost of conventional lithium-ion batteries, primarily due to expensive electrolyte materials and complex processing requirements. The industry consensus suggests that cost parity with conventional batteries remains at least 5-7 years away, contingent upon significant breakthroughs in materials and manufacturing.

Interface stability between solid electrolytes and electrodes presents another major hurdle. The solid-solid interfaces often suffer from poor contact and high impedance, resulting in capacity fade and reduced cycle life. Chemical incompatibility at these interfaces leads to the formation of interphases with high resistance, particularly at the cathode-electrolyte interface where transition metal dissolution and oxygen release can degrade the electrolyte.

Mechanical stability issues further complicate development efforts. Volume changes during cycling (up to 300% for silicon anodes) create mechanical stress that can fracture the electrolyte or delaminate interfaces. This problem is exacerbated by the inherent brittleness of ceramic electrolytes, with fracture toughness values typically below 1 MPa·m^1/2, compared to >20 MPa·m^1/2 for structural ceramics.

Manufacturing scalability presents additional challenges. Current fabrication methods for solid electrolytes often require high-temperature sintering (>1000°C) and precisely controlled atmospheres, making mass production costly and complex. The need for thin electrolyte layers (<50 μm) with uniform properties and minimal defects further complicates manufacturing processes.

Dendrite growth, contrary to early assumptions, remains problematic even in solid electrolytes. Recent studies have demonstrated that lithium dendrites can propagate through grain boundaries in polycrystalline electrolytes under certain current densities (>0.5-1 mA/cm²), leading to internal short circuits and safety concerns.

Environmental stability poses another significant challenge, as many promising solid electrolytes (particularly sulfides) are highly reactive with atmospheric moisture, necessitating stringent handling protocols and protective measures during manufacturing and assembly.

Cost factors also impede commercialization, with current solid-state battery prototypes estimated at 2-5 times the cost of conventional lithium-ion batteries, primarily due to expensive electrolyte materials and complex processing requirements. The industry consensus suggests that cost parity with conventional batteries remains at least 5-7 years away, contingent upon significant breakthroughs in materials and manufacturing.

Current Approaches to Enhance Electrolyte-Electrode Interface Stability

01 Solid electrolyte materials for enhanced stability

Various solid electrolyte materials can be used to enhance the stability of solid-state batteries. These materials include ceramic electrolytes, polymer electrolytes, and composite electrolytes that combine different materials to achieve optimal properties. The selection of appropriate solid electrolyte materials is crucial for preventing dendrite formation, improving interfacial contact, and ensuring long-term stability under various operating conditions.- Solid electrolyte composition and structure: The composition and structure of solid electrolytes significantly impact battery performance. Various materials including ceramic, polymer, and composite electrolytes can be engineered with specific crystal structures and morphologies to enhance ionic conductivity while maintaining mechanical integrity. These solid electrolytes can be designed with optimized grain boundaries and interfaces to facilitate lithium ion transport while preventing dendrite formation, ultimately improving both stability and performance of solid-state batteries.

- Interface engineering and stability enhancement: Interface engineering between the solid electrolyte and electrodes is crucial for battery stability. Techniques include surface coatings, buffer layers, and gradient interfaces that minimize interfacial resistance and prevent unwanted chemical reactions. These approaches help maintain stable solid-electrolyte interfaces during cycling, reducing degradation mechanisms and extending battery life while enabling higher operating voltages and improved safety characteristics.

- Additives and dopants for performance enhancement: Incorporating specific additives and dopants into solid electrolytes can significantly improve their electrochemical properties. These materials can enhance ionic conductivity, mechanical strength, and chemical stability. Strategic doping with elements such as aluminum, zirconium, or tantalum can stabilize crystal structures, suppress side reactions, and create favorable ion transport pathways, resulting in solid-state batteries with improved cycling performance and longer lifespans.

- Temperature and environmental stability: Solid-state electrolytes must maintain performance across a wide temperature range and environmental conditions. Advanced formulations can provide thermal stability at both high and low temperatures, enabling broader operating windows than conventional liquid electrolytes. These materials are engineered to resist degradation from humidity, oxygen exposure, and thermal cycling, ensuring consistent performance in various applications from consumer electronics to electric vehicles and grid storage.

- Manufacturing processes and scalability: Novel manufacturing techniques for solid electrolytes focus on achieving consistent quality at scale. Methods include advanced sintering processes, solution-based synthesis, and thin-film deposition techniques that enable precise control over microstructure and composition. These processes aim to reduce defects, enhance uniformity, and lower production costs while maintaining the critical properties needed for high-performance solid-state batteries, addressing key challenges in commercialization.

02 Interface engineering for improved performance

Interface engineering techniques are employed to improve the performance of solid-state batteries by enhancing the contact between the electrolyte and electrodes. These techniques include surface modifications, buffer layers, and specialized coatings that reduce interfacial resistance and improve ion transport across boundaries. Proper interface engineering helps to maintain stable electrochemical performance and prevents degradation during cycling.Expand Specific Solutions03 Additives and dopants for electrolyte enhancement

Various additives and dopants can be incorporated into solid electrolytes to enhance their ionic conductivity, mechanical properties, and electrochemical stability. These additives can modify the crystal structure, create additional ion transport pathways, or stabilize the electrolyte against side reactions. The strategic use of dopants can significantly improve the overall performance and longevity of solid-state batteries.Expand Specific Solutions04 Temperature and pressure effects on electrolyte performance

The performance of solid-state electrolytes is significantly influenced by operating temperature and pressure conditions. Research focuses on developing electrolytes that maintain high ionic conductivity and stability across a wide temperature range. Additionally, manufacturing processes that optimize pressure during cell assembly can improve interfacial contact and reduce resistance, leading to better overall battery performance and reliability.Expand Specific Solutions05 Novel fabrication methods for improved electrolyte integration

Advanced fabrication techniques are being developed to improve the integration of solid electrolytes into battery structures. These methods include co-sintering processes, thin-film deposition, 3D printing, and other novel approaches that enable better control over electrolyte thickness, uniformity, and interfacial properties. Improved fabrication methods lead to enhanced mechanical integrity, reduced internal resistance, and better cycling performance in solid-state batteries.Expand Specific Solutions

Leading Companies and Research Institutions in Solid State Battery Development

The solid-state battery market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. Market size is projected to expand rapidly, reaching approximately $6-8 billion by 2030, driven by electric vehicle adoption and consumer electronics applications. Technologically, the field remains in development with varying maturity levels across competitors. Leading players like QuantumScape, Toyota, and Samsung SDI are advancing electrolyte stability solutions, while established battery manufacturers including Murata, TDK, and BYD are leveraging their manufacturing expertise. Research institutions such as McGill University and CNRS are contributing fundamental breakthroughs. Chinese companies like SVOLT and Capchem are rapidly scaling capabilities, while automotive manufacturers Honda, Hyundai, and FAW are integrating vertically to secure battery technology access.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an innovative solid-state battery technology utilizing a silver-carbon (Ag-C) composite layer as an anode protective layer to enhance electrolyte stability. Their approach addresses the critical interface challenges between solid electrolytes and electrodes by implementing a silver-carbon nanocomposite that facilitates stable lithium-ion transport while preventing unwanted side reactions. The company's solid electrolyte formulation incorporates a sulfide-based material with high ionic conductivity (>5 mS/cm at room temperature) and improved mechanical properties to accommodate volume changes during cycling. Samsung's technology has demonstrated a significant breakthrough in cycle life, achieving over 1,000 charge-discharge cycles with approximately 89% capacity retention. Their prototype cells have reached energy densities of 900Wh/L, which represents a substantial improvement over conventional lithium-ion batteries while maintaining operational stability across a wide temperature range.

Strengths: The Ag-C composite layer effectively suppresses lithium dendrite formation, enhancing safety and longevity. Their sulfide-based electrolyte achieves high ionic conductivity without compromising mechanical stability. Weaknesses: The use of silver increases material costs compared to conventional batteries, and the manufacturing process requires extremely precise control of moisture and oxygen levels during production, creating scalability challenges for mass production.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology, which represents their approach to solid-state battery development with enhanced electrolyte stability. While not a true solid-state battery yet, their current LFP (lithium iron phosphate) Blade Battery incorporates semi-solid electrolyte components and serves as their technological stepping stone toward full solid-state solutions. BYD's research focuses on lithium garnet-type solid electrolytes (LLZO) with modifications to improve room-temperature ionic conductivity. Their approach includes surface coating technologies to stabilize the electrolyte-electrode interfaces and reduce interfacial resistance. BYD has demonstrated prototype solid-state cells with energy densities exceeding 350 Wh/kg and significantly improved thermal stability compared to conventional lithium-ion batteries. Their solid electrolyte formulation incorporates proprietary additives that enhance mechanical properties while maintaining high ionic conductivity, addressing key challenges in electrolyte stability during repeated charge-discharge cycles.

Strengths: BYD's vertical integration allows for controlled development from materials to finished batteries, their approach builds upon proven manufacturing techniques, and their solid electrolyte formulation demonstrates excellent thermal stability. Weaknesses: Their true solid-state technology remains in development phase with commercialization timeline extending beyond competitors, and current energy density achievements, while impressive, still lag behind some laboratory demonstrations from specialized solid-state battery companies.

Critical Patents and Innovations in Solid Electrolyte Materials

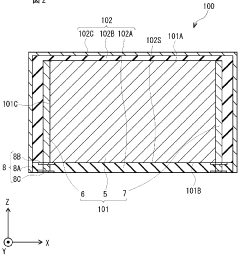

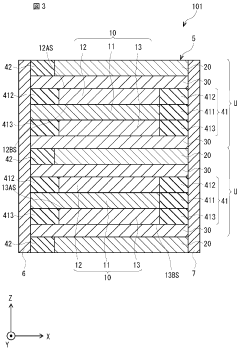

Solid-state electrolyte for solid-state battery, solid-state battery, and battery package

PatentWO2023190650A1

Innovation

- A solid electrolyte for solid batteries is developed, comprising a lithium salt solid electrolyte portion with an inverted perovskite structure and a non-lithium compound portion, such as metal oxides or nitrides, which are ionically bonded to enhance ionic conductivity and chemical stability, and are processed using methods like hot isostatic pressing to create a stable and efficient battery configuration.

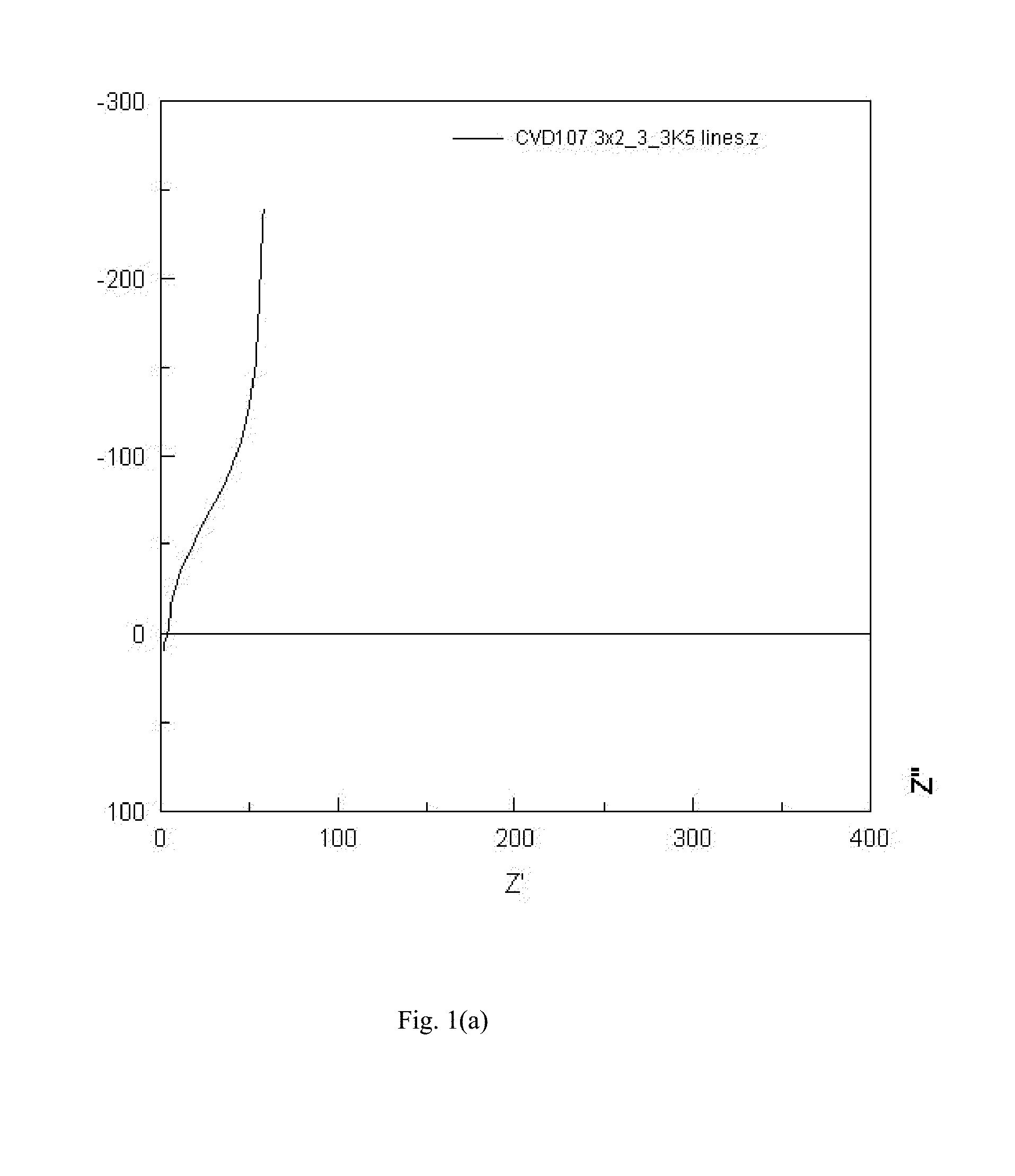

Amorphous ionically-conductive metal oxides, method of preparation, and battery

PatentInactiveUS20150180001A1

Innovation

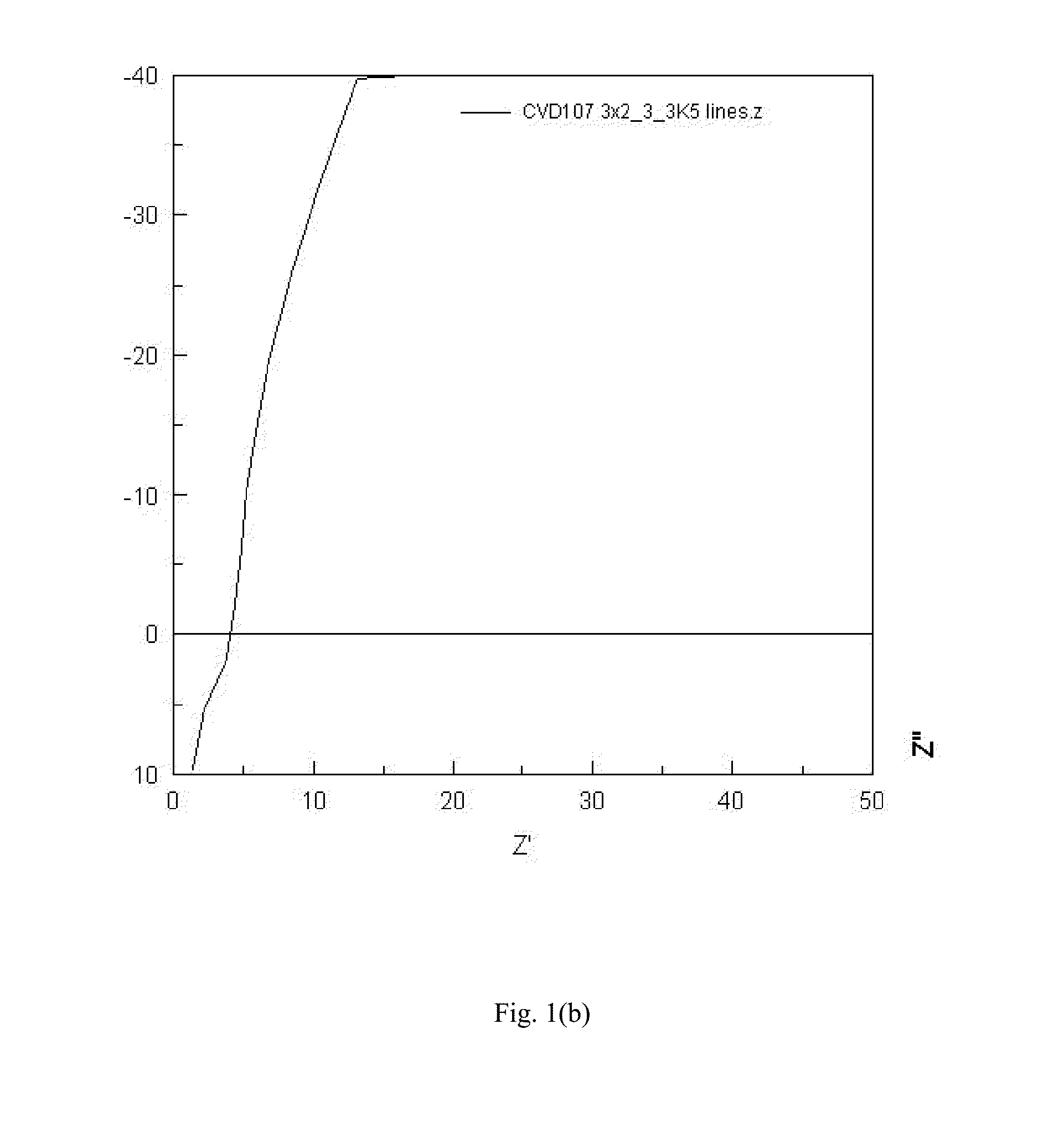

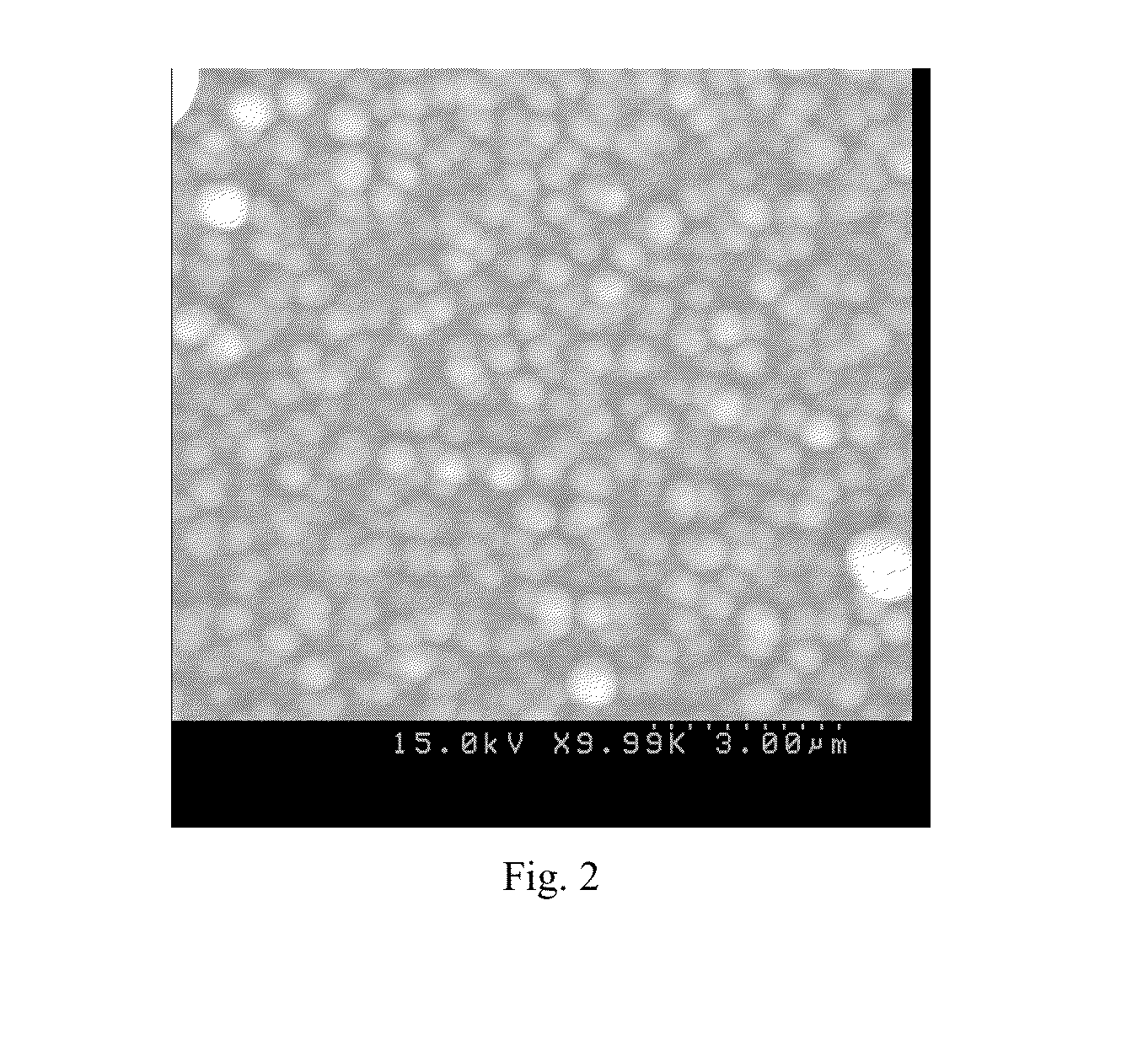

- A method for synthesizing amorphous ionically conductive metal oxides using chemical vapor deposition (CVD), specifically lithium lanthanum zirconium oxide (LLZO), which involves introducing precursor gases and materials into a CVD reactor to deposit a thin, defect-free film on a substrate, offering high ionic conductivity and stability without adverse reactions with lithium.

Manufacturing Scalability and Cost Reduction Strategies

The scalability of solid-state battery manufacturing represents a critical challenge in transitioning from laboratory prototypes to commercial production. Current manufacturing processes for solid electrolytes often involve complex synthesis methods requiring precise temperature control, specialized equipment, and extensive quality control measures. These factors contribute significantly to the high production costs that currently limit market penetration.

Material costs remain a substantial barrier, with high-purity precursors for solid electrolytes commanding premium prices. For instance, lithium compounds used in LLZO (lithium lanthanum zirconium oxide) and LGPS (lithium germanium phosphorus sulfide) electrolytes can cost 5-10 times more than materials used in conventional liquid electrolytes. Strategic partnerships with material suppliers and long-term procurement agreements offer potential pathways to cost reduction.

Process optimization presents significant opportunities for improving manufacturing economics. Techniques such as co-sintering of cathode and electrolyte layers can reduce processing steps and energy consumption. Additionally, roll-to-roll manufacturing adaptations for solid-state architectures could dramatically increase throughput while reducing unit costs. Early adopters of these techniques have reported potential cost reductions of 30-40% at scale.

Equipment standardization represents another crucial strategy. Currently, much of the manufacturing equipment for solid-state batteries is custom-built, driving up capital expenditures. Industry consortia working toward equipment standardization could create economies of scale in manufacturing infrastructure. Companies like Toyota and Quantumscape have made significant investments in developing proprietary manufacturing equipment that could eventually be licensed or commercialized.

Yield improvement initiatives are essential for cost-effective production. Current manufacturing processes for solid electrolytes often suffer from yield issues, with rejection rates as high as 30-40% in some production environments. Advanced in-line quality control systems utilizing machine learning algorithms for defect detection could substantially improve yields and reduce waste.

Vertical integration strategies are being pursued by several major players to control costs throughout the supply chain. By bringing critical aspects of production in-house, companies can reduce markup costs and ensure consistent quality. However, this approach requires substantial capital investment and may not be viable for smaller market entrants.

As production volumes increase, economies of scale will naturally drive down costs. Industry analysts project that reaching gigawatt-hour scale production could reduce manufacturing costs by 60-70% compared to current pilot production levels, potentially bringing solid-state batteries to price parity with conventional lithium-ion technologies by the end of this decade.

Material costs remain a substantial barrier, with high-purity precursors for solid electrolytes commanding premium prices. For instance, lithium compounds used in LLZO (lithium lanthanum zirconium oxide) and LGPS (lithium germanium phosphorus sulfide) electrolytes can cost 5-10 times more than materials used in conventional liquid electrolytes. Strategic partnerships with material suppliers and long-term procurement agreements offer potential pathways to cost reduction.

Process optimization presents significant opportunities for improving manufacturing economics. Techniques such as co-sintering of cathode and electrolyte layers can reduce processing steps and energy consumption. Additionally, roll-to-roll manufacturing adaptations for solid-state architectures could dramatically increase throughput while reducing unit costs. Early adopters of these techniques have reported potential cost reductions of 30-40% at scale.

Equipment standardization represents another crucial strategy. Currently, much of the manufacturing equipment for solid-state batteries is custom-built, driving up capital expenditures. Industry consortia working toward equipment standardization could create economies of scale in manufacturing infrastructure. Companies like Toyota and Quantumscape have made significant investments in developing proprietary manufacturing equipment that could eventually be licensed or commercialized.

Yield improvement initiatives are essential for cost-effective production. Current manufacturing processes for solid electrolytes often suffer from yield issues, with rejection rates as high as 30-40% in some production environments. Advanced in-line quality control systems utilizing machine learning algorithms for defect detection could substantially improve yields and reduce waste.

Vertical integration strategies are being pursued by several major players to control costs throughout the supply chain. By bringing critical aspects of production in-house, companies can reduce markup costs and ensure consistent quality. However, this approach requires substantial capital investment and may not be viable for smaller market entrants.

As production volumes increase, economies of scale will naturally drive down costs. Industry analysts project that reaching gigawatt-hour scale production could reduce manufacturing costs by 60-70% compared to current pilot production levels, potentially bringing solid-state batteries to price parity with conventional lithium-ion technologies by the end of this decade.

Safety and Environmental Advantages of Solid State Battery Technology

Solid state battery technology represents a significant advancement in energy storage safety compared to conventional lithium-ion batteries with liquid electrolytes. The elimination of flammable liquid electrolytes substantially reduces fire and explosion risks, addressing one of the most critical safety concerns in current battery technologies. This inherent safety advantage makes solid state batteries particularly valuable for applications in electric vehicles, where battery integrity during accidents is paramount.

The thermal stability of solid electrolytes allows solid state batteries to operate across a wider temperature range without degradation or safety compromises. Unlike conventional batteries that may experience thermal runaway at high temperatures, solid state batteries maintain structural integrity and performance even under extreme thermal conditions, reducing cooling system requirements and enhancing overall system reliability.

From an environmental perspective, solid state battery technology offers several compelling advantages. Many solid electrolyte materials being developed are less toxic than the organic solvents used in conventional lithium-ion batteries, reducing environmental hazards during manufacturing, use, and disposal. The potential for longer cycle life and greater durability also means fewer batteries need to be produced and disposed of over time, decreasing resource consumption and waste generation.

The manufacturing processes for solid state batteries potentially require fewer environmentally harmful chemicals and solvents. As production scales up and techniques are refined, the environmental footprint of battery manufacturing could be significantly reduced compared to current technologies. Additionally, the higher energy density of solid state batteries may lead to more efficient use of critical materials like lithium, cobalt, and nickel.

End-of-life considerations also favor solid state batteries, as their components may be easier to separate and recycle compared to conventional batteries with liquid electrolytes. This characteristic could facilitate more efficient material recovery and reduce the environmental impact of battery disposal, contributing to circular economy principles in the energy storage sector.

The safety and environmental benefits of solid state battery technology extend beyond the batteries themselves to the broader energy ecosystem. By enabling safer and more efficient energy storage, these batteries can accelerate the adoption of renewable energy sources and electric transportation, indirectly contributing to reduced greenhouse gas emissions and fossil fuel dependence on a global scale.

The thermal stability of solid electrolytes allows solid state batteries to operate across a wider temperature range without degradation or safety compromises. Unlike conventional batteries that may experience thermal runaway at high temperatures, solid state batteries maintain structural integrity and performance even under extreme thermal conditions, reducing cooling system requirements and enhancing overall system reliability.

From an environmental perspective, solid state battery technology offers several compelling advantages. Many solid electrolyte materials being developed are less toxic than the organic solvents used in conventional lithium-ion batteries, reducing environmental hazards during manufacturing, use, and disposal. The potential for longer cycle life and greater durability also means fewer batteries need to be produced and disposed of over time, decreasing resource consumption and waste generation.

The manufacturing processes for solid state batteries potentially require fewer environmentally harmful chemicals and solvents. As production scales up and techniques are refined, the environmental footprint of battery manufacturing could be significantly reduced compared to current technologies. Additionally, the higher energy density of solid state batteries may lead to more efficient use of critical materials like lithium, cobalt, and nickel.

End-of-life considerations also favor solid state batteries, as their components may be easier to separate and recycle compared to conventional batteries with liquid electrolytes. This characteristic could facilitate more efficient material recovery and reduce the environmental impact of battery disposal, contributing to circular economy principles in the energy storage sector.

The safety and environmental benefits of solid state battery technology extend beyond the batteries themselves to the broader energy ecosystem. By enabling safer and more efficient energy storage, these batteries can accelerate the adoption of renewable energy sources and electric transportation, indirectly contributing to reduced greenhouse gas emissions and fossil fuel dependence on a global scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!