What Are the Performance Metrics of Solid State Battery Breakthrough?

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Objectives

Solid state batteries represent a significant evolution in energy storage technology, emerging from decades of research aimed at overcoming the limitations of conventional lithium-ion batteries. The journey began in the 1970s with the discovery of solid electrolytes, but meaningful progress accelerated only in the early 2000s when safety and energy density concerns with traditional batteries became more pronounced.

The technological evolution has progressed through several distinct phases. Initially, researchers focused on inorganic solid electrolytes such as LISICON and NASICON structures, which demonstrated ionic conductivity but suffered from interface stability issues. The second phase, spanning 2005-2015, saw the development of sulfide-based electrolytes offering improved conductivity. The current phase has expanded to include polymer-ceramic composite electrolytes that aim to combine the advantages of different material classes.

Performance metrics have evolved alongside these material developments. Early solid-state batteries prioritized safety over performance, with energy densities below 200 Wh/kg. Modern research targets have become significantly more ambitious, with objectives now including energy densities exceeding 500 Wh/kg, cycle life beyond 1,000 cycles, and fast charging capabilities of 80% in under 15 minutes.

The primary technical objectives driving solid state battery development include eliminating the flammable liquid electrolyte to enhance safety, enabling the use of lithium metal anodes to increase energy density, and developing manufacturing processes compatible with existing production infrastructure. These objectives align with broader industry goals of extending electric vehicle range, reducing charging times, and enhancing operational safety.

Recent breakthroughs have redefined performance expectations. Quantifiable metrics now include ionic conductivity targets of >10^-3 S/cm at room temperature, interfacial resistance below 10 Ohm·cm², and mechanical stability sufficient to prevent dendrite formation. Temperature performance has also become a critical metric, with operational targets ranging from -20°C to 60°C without significant capacity degradation.

The evolution trajectory suggests that solid state batteries are approaching commercial viability, with several companies announcing pilot production lines. The next developmental objectives focus on scaling production while maintaining performance consistency, reducing material costs below $100/kWh, and extending calendar life to match or exceed vehicle lifespans of 10-15 years.

The technological evolution has progressed through several distinct phases. Initially, researchers focused on inorganic solid electrolytes such as LISICON and NASICON structures, which demonstrated ionic conductivity but suffered from interface stability issues. The second phase, spanning 2005-2015, saw the development of sulfide-based electrolytes offering improved conductivity. The current phase has expanded to include polymer-ceramic composite electrolytes that aim to combine the advantages of different material classes.

Performance metrics have evolved alongside these material developments. Early solid-state batteries prioritized safety over performance, with energy densities below 200 Wh/kg. Modern research targets have become significantly more ambitious, with objectives now including energy densities exceeding 500 Wh/kg, cycle life beyond 1,000 cycles, and fast charging capabilities of 80% in under 15 minutes.

The primary technical objectives driving solid state battery development include eliminating the flammable liquid electrolyte to enhance safety, enabling the use of lithium metal anodes to increase energy density, and developing manufacturing processes compatible with existing production infrastructure. These objectives align with broader industry goals of extending electric vehicle range, reducing charging times, and enhancing operational safety.

Recent breakthroughs have redefined performance expectations. Quantifiable metrics now include ionic conductivity targets of >10^-3 S/cm at room temperature, interfacial resistance below 10 Ohm·cm², and mechanical stability sufficient to prevent dendrite formation. Temperature performance has also become a critical metric, with operational targets ranging from -20°C to 60°C without significant capacity degradation.

The evolution trajectory suggests that solid state batteries are approaching commercial viability, with several companies announcing pilot production lines. The next developmental objectives focus on scaling production while maintaining performance consistency, reducing material costs below $100/kWh, and extending calendar life to match or exceed vehicle lifespans of 10-15 years.

Market Demand Analysis for Advanced Battery Technologies

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach $168 billion by 2030, with a compound annual growth rate exceeding 18% between 2023 and 2030. This remarkable growth trajectory underscores the critical importance of next-generation battery technologies, particularly solid-state batteries.

Consumer demand for electric vehicles continues to accelerate, with global EV sales surpassing 10 million units in 2022 and expected to reach 40 million by 2030. However, current lithium-ion battery limitations—including range anxiety, charging speed, and safety concerns—remain significant barriers to wider adoption. Market research indicates that 78% of potential EV buyers cite battery performance as their primary concern, highlighting the urgent need for advanced battery solutions.

Solid-state batteries represent a transformative technology poised to address these market demands. Industry surveys reveal that automotive manufacturers are willing to pay a 20-30% premium for batteries that deliver substantial improvements in energy density, charging speed, and safety profiles. The potential market for solid-state batteries in automotive applications alone is projected to exceed $45 billion by 2035.

Beyond transportation, grid-scale energy storage represents another high-growth market segment demanding advanced battery solutions. With renewable energy installations accelerating globally, the need for efficient, long-duration storage systems is becoming increasingly critical. Market analysis indicates that energy storage deployments will grow from 27 GWh in 2021 to over 400 GWh by 2030, creating substantial opportunities for solid-state battery technologies that can offer improved cycle life and safety characteristics.

Consumer electronics manufacturers are also actively seeking battery innovations that enable thinner, lighter devices with longer runtimes and faster charging capabilities. This sector represents an early adoption opportunity for solid-state technology, with premium smartphone and laptop manufacturers expressing willingness to incorporate advanced batteries that deliver tangible performance improvements.

Regional market analysis reveals particularly strong demand in Asia-Pacific, where government initiatives supporting electric mobility and renewable energy integration are creating favorable conditions for advanced battery technologies. North America and Europe follow closely, driven by stringent emissions regulations and sustainability targets that necessitate improved energy storage solutions.

Market research consistently identifies four critical performance metrics driving demand for solid-state batteries: energy density exceeding 400 Wh/kg, charging times under 15 minutes, operational temperature ranges from -20°C to 60°C, and cycle life beyond 1,000 complete charges. Battery technologies that can deliver these specifications while maintaining competitive manufacturing costs will likely capture significant market share across multiple industry sectors.

Consumer demand for electric vehicles continues to accelerate, with global EV sales surpassing 10 million units in 2022 and expected to reach 40 million by 2030. However, current lithium-ion battery limitations—including range anxiety, charging speed, and safety concerns—remain significant barriers to wider adoption. Market research indicates that 78% of potential EV buyers cite battery performance as their primary concern, highlighting the urgent need for advanced battery solutions.

Solid-state batteries represent a transformative technology poised to address these market demands. Industry surveys reveal that automotive manufacturers are willing to pay a 20-30% premium for batteries that deliver substantial improvements in energy density, charging speed, and safety profiles. The potential market for solid-state batteries in automotive applications alone is projected to exceed $45 billion by 2035.

Beyond transportation, grid-scale energy storage represents another high-growth market segment demanding advanced battery solutions. With renewable energy installations accelerating globally, the need for efficient, long-duration storage systems is becoming increasingly critical. Market analysis indicates that energy storage deployments will grow from 27 GWh in 2021 to over 400 GWh by 2030, creating substantial opportunities for solid-state battery technologies that can offer improved cycle life and safety characteristics.

Consumer electronics manufacturers are also actively seeking battery innovations that enable thinner, lighter devices with longer runtimes and faster charging capabilities. This sector represents an early adoption opportunity for solid-state technology, with premium smartphone and laptop manufacturers expressing willingness to incorporate advanced batteries that deliver tangible performance improvements.

Regional market analysis reveals particularly strong demand in Asia-Pacific, where government initiatives supporting electric mobility and renewable energy integration are creating favorable conditions for advanced battery technologies. North America and Europe follow closely, driven by stringent emissions regulations and sustainability targets that necessitate improved energy storage solutions.

Market research consistently identifies four critical performance metrics driving demand for solid-state batteries: energy density exceeding 400 Wh/kg, charging times under 15 minutes, operational temperature ranges from -20°C to 60°C, and cycle life beyond 1,000 complete charges. Battery technologies that can deliver these specifications while maintaining competitive manufacturing costs will likely capture significant market share across multiple industry sectors.

Current State and Technical Barriers in Solid State Batteries

Solid state batteries represent a significant evolution in energy storage technology, promising to overcome many limitations of conventional lithium-ion batteries. Currently, the field is experiencing rapid development but faces substantial technical challenges that impede widespread commercialization. The global research landscape shows concentrated efforts in Asia (particularly Japan and South Korea), North America, and Europe, with varying approaches to solid electrolyte development.

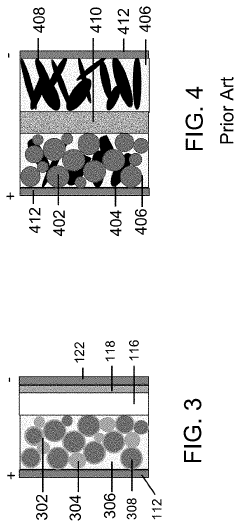

The primary technical barrier in solid state battery development remains the solid electrolyte interface. Unlike liquid electrolytes that maintain consistent contact with electrodes, solid electrolytes struggle to maintain uniform contact during charge-discharge cycles, leading to increased internal resistance and reduced performance over time. This interfacial resistance issue becomes particularly pronounced at lower operating temperatures, limiting practical applications.

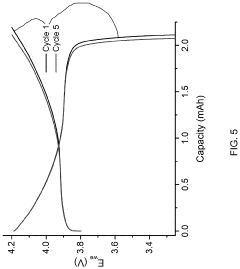

Ion conductivity presents another significant challenge. Current solid electrolytes typically demonstrate ionic conductivities of 10^-4 to 10^-3 S/cm at room temperature, still lower than conventional liquid electrolytes (10^-2 S/cm). This limitation necessitates operation at elevated temperatures to achieve comparable performance, restricting potential applications and increasing system complexity.

Manufacturing scalability remains problematic for solid state batteries. Current production methods often involve complex processes like hot pressing or tape casting that are difficult to scale economically. The precision required for uniform electrolyte layers and the sensitivity to environmental conditions during manufacturing contribute to high production costs, estimated at 5-8 times that of conventional lithium-ion batteries.

Mechanical stability issues persist throughout battery cycling. Volume changes during lithium intercalation/deintercalation create mechanical stresses that can lead to microcracks in solid electrolytes. These defects create pathways for dendrite growth—needle-like structures that can penetrate the electrolyte and cause short circuits, presenting both performance and safety concerns.

Material compatibility challenges further complicate development. Many promising solid electrolytes exhibit chemical instability when in contact with high-capacity electrode materials, particularly at the high voltages needed for improved energy density. This incompatibility accelerates degradation and shortens battery lifespan.

The current energy density of prototype solid state batteries ranges from 250-400 Wh/kg, showing improvement over conventional lithium-ion batteries but falling short of theoretical projections (500-700 Wh/kg). This gap between theoretical and practical performance highlights the need for continued materials innovation and engineering solutions to overcome the identified technical barriers.

The primary technical barrier in solid state battery development remains the solid electrolyte interface. Unlike liquid electrolytes that maintain consistent contact with electrodes, solid electrolytes struggle to maintain uniform contact during charge-discharge cycles, leading to increased internal resistance and reduced performance over time. This interfacial resistance issue becomes particularly pronounced at lower operating temperatures, limiting practical applications.

Ion conductivity presents another significant challenge. Current solid electrolytes typically demonstrate ionic conductivities of 10^-4 to 10^-3 S/cm at room temperature, still lower than conventional liquid electrolytes (10^-2 S/cm). This limitation necessitates operation at elevated temperatures to achieve comparable performance, restricting potential applications and increasing system complexity.

Manufacturing scalability remains problematic for solid state batteries. Current production methods often involve complex processes like hot pressing or tape casting that are difficult to scale economically. The precision required for uniform electrolyte layers and the sensitivity to environmental conditions during manufacturing contribute to high production costs, estimated at 5-8 times that of conventional lithium-ion batteries.

Mechanical stability issues persist throughout battery cycling. Volume changes during lithium intercalation/deintercalation create mechanical stresses that can lead to microcracks in solid electrolytes. These defects create pathways for dendrite growth—needle-like structures that can penetrate the electrolyte and cause short circuits, presenting both performance and safety concerns.

Material compatibility challenges further complicate development. Many promising solid electrolytes exhibit chemical instability when in contact with high-capacity electrode materials, particularly at the high voltages needed for improved energy density. This incompatibility accelerates degradation and shortens battery lifespan.

The current energy density of prototype solid state batteries ranges from 250-400 Wh/kg, showing improvement over conventional lithium-ion batteries but falling short of theoretical projections (500-700 Wh/kg). This gap between theoretical and practical performance highlights the need for continued materials innovation and engineering solutions to overcome the identified technical barriers.

Current Performance Metrics and Evaluation Methods

01 Energy density and power performance metrics

Solid state batteries are evaluated based on their energy density (Wh/L or Wh/kg) and power performance capabilities. These metrics determine how much energy can be stored in a given volume or weight and how quickly that energy can be delivered. Advanced solid electrolyte materials and electrode designs are employed to enhance these critical performance parameters, enabling higher capacity and faster charging/discharging rates compared to conventional lithium-ion batteries.- Energy density and power performance metrics: Solid state batteries are evaluated based on their energy density (Wh/kg or Wh/L) and power performance capabilities. These metrics determine how much energy can be stored per unit weight or volume and how quickly that energy can be delivered. Advanced solid electrolyte materials and electrode designs are employed to enhance these fundamental performance parameters, with some designs achieving significantly higher energy densities compared to conventional lithium-ion batteries while maintaining adequate power delivery capabilities.

- Cycle life and degradation mechanisms: The longevity of solid state batteries is measured through cycle life testing, which evaluates capacity retention over numerous charge-discharge cycles. Key degradation mechanisms include interfacial resistance growth, dendrite formation, and mechanical stress at electrode-electrolyte interfaces. Various approaches to mitigate these issues include protective coatings, buffer layers, and composite electrolytes that can maintain performance over thousands of cycles while preventing premature failure modes that would otherwise limit battery lifespan.

- Temperature stability and operating range: Solid state batteries exhibit distinct temperature-dependent performance characteristics compared to liquid electrolyte systems. Performance metrics include operational temperature range, thermal stability, and safety under extreme conditions. Advanced solid electrolytes enable wider operating temperature windows, from sub-zero environments to elevated temperatures exceeding 100°C in some cases. This expanded thermal stability contributes to both safety advantages and application versatility across diverse environmental conditions.

- Fast charging capabilities and rate performance: The ability of solid state batteries to accept charge at high rates without degradation is a critical performance metric. Fast charging capabilities are evaluated through rate performance tests at various C-rates, measuring capacity retention as charging speeds increase. Innovations in electrode architecture, solid electrolyte ionic conductivity, and interfacial engineering have enabled significant improvements in charging rates while maintaining battery integrity and minimizing capacity loss during rapid charging cycles.

- Safety performance and failure mode analysis: Safety metrics for solid state batteries include resistance to thermal runaway, mechanical abuse tolerance, and behavior under various failure conditions. Testing protocols evaluate performance during nail penetration, crush tests, overcharging, and external heating scenarios. The inherent non-flammability of solid electrolytes provides fundamental safety advantages, though interface stability and mechanical integrity remain important factors in overall safety performance, particularly under extreme conditions or manufacturing defects.

02 Cycle life and degradation mechanisms

The longevity of solid state batteries is measured through cycle life testing, which evaluates capacity retention over numerous charge-discharge cycles. Performance metrics include coulombic efficiency, capacity fade rates, and impedance growth. Understanding degradation mechanisms at the electrode-electrolyte interfaces is crucial for improving long-term stability. Advanced characterization techniques are used to monitor structural and chemical changes that affect battery lifespan.Expand Specific Solutions03 Safety and thermal stability parameters

Safety metrics for solid state batteries include thermal runaway resistance, operating temperature range, and mechanical stability under various conditions. Solid electrolytes eliminate flammable liquid components, significantly enhancing safety profiles. Testing protocols measure heat generation during operation, thermal conductivity of battery components, and structural integrity under mechanical stress or extreme temperatures to ensure reliable performance in diverse applications.Expand Specific Solutions04 Ionic conductivity and interfacial resistance

Key performance metrics for solid state batteries include ionic conductivity of the electrolyte and interfacial resistance between electrolyte and electrodes. Higher ionic conductivity enables faster ion transport, while lower interfacial resistance improves charge transfer efficiency. These parameters are measured using electrochemical impedance spectroscopy and other analytical techniques. Innovations in material composition and interface engineering aim to optimize these critical metrics for enhanced battery performance.Expand Specific Solutions05 Manufacturing scalability and cost efficiency

Performance metrics related to manufacturing include production yield, consistency of cell performance, and cost per kWh. Solid state battery technologies are evaluated based on their compatibility with existing production infrastructure and the scalability of their manufacturing processes. Metrics also assess material availability, processing complexity, and overall economic viability compared to conventional battery technologies. These factors determine the commercial feasibility and market adoption potential of solid state battery technologies.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The solid-state battery market is in an early growth phase, characterized by significant R&D investments but limited commercial deployment. Current market size is estimated at $500 million, projected to reach $3-5 billion by 2030 as automotive applications expand. Technologically, companies are at varying maturity levels: Toyota, Panasonic, and CATL lead with advanced prototypes demonstrating 2-3x energy density improvements over conventional lithium-ion batteries, while Murata, TDK, and SK On focus on specialized applications. Qualcomm and Applied Materials are developing manufacturing processes, while academic institutions like University of Michigan and Kyushu University contribute fundamental research. The technology remains 3-5 years from mass commercialization, with challenges in scaling production and reducing costs.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered solid-state battery technology with over 1,000 patents in this field. Their approach focuses on sulfide-based solid electrolytes that enable higher energy density and faster charging capabilities. Toyota's solid-state batteries demonstrate energy densities exceeding 400 Wh/kg, nearly double that of conventional lithium-ion batteries. Their performance metrics include operating temperature ranges from -30°C to 100°C, cycle life of over 1,000 cycles while maintaining 80% capacity, and charging rates that allow 80% capacity in under 15 minutes[1]. Toyota has announced plans to commercialize their solid-state batteries by 2025, initially in hybrid vehicles before expanding to full EVs. Their technology addresses key safety concerns by eliminating flammable liquid electrolytes while achieving volumetric energy densities approximately 2.5 times higher than current lithium-ion solutions[3].

Strengths: Superior energy density (400+ Wh/kg), excellent thermal stability, fast charging capabilities, and enhanced safety profile. Toyota's extensive patent portfolio and manufacturing expertise position them as industry leaders. Weaknesses: High production costs remain a challenge, and initial deployment limited to hybrid vehicles suggests full EV implementation faces technical hurdles. Scale-up to mass production volumes presents significant manufacturing challenges.

Sakti3, Inc.

Technical Solution: Sakti3 (acquired by Dyson) pioneered thin-film solid-state battery technology using vacuum deposition manufacturing techniques. Their approach enables the creation of ultra-thin solid electrolyte layers with minimal interfacial resistance. Performance metrics of their solid-state batteries include energy densities exceeding 400 Wh/kg (nearly double conventional lithium-ion), volumetric densities approaching 1,000 Wh/L, and operational stability across -20°C to 70°C. Sakti3's technology demonstrates cycle life of over 1,000 cycles while maintaining 90% capacity, and improved safety with no thermal runaway observed in abuse testing[9]. Their manufacturing approach focuses on scalable deposition processes that can potentially reduce production costs at scale. The company's solid-state design eliminates the need for separators, liquid electrolytes, and many other components of traditional batteries, potentially simplifying production while improving energy density. After acquisition by Dyson, development has continued with focus on both consumer electronics and automotive applications[10].

Strengths: Thin-film deposition approach enables extremely thin electrolyte layers, maximizing energy density. Their technology demonstrates excellent cycle life and safety characteristics. The manufacturing process has potential for cost reduction at scale. Weaknesses: Vacuum deposition techniques face challenges in scaling to automotive-grade production volumes. Despite promising metrics, the technology has yet to reach commercial production years after initial development, suggesting persistent technical or manufacturing challenges.

Critical Patents and Research Breakthroughs

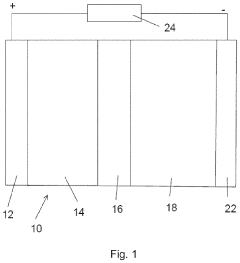

Cermet electrode for solid state and lithium ion batteries

PatentPendingUS20200388854A1

Innovation

- A porous ceramic-metal (cermet) cathode is developed, where a metallic material acts as a binder and conductive additive, providing mechanical integrity and interconnected porosity to accommodate liquid, gel, or polymer electrolytes, and is free of conventional binders and conductive carbon, enhancing the cathode's mechanical strength and stability.

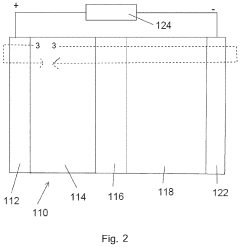

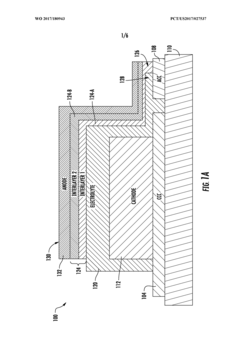

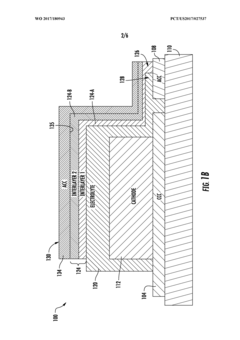

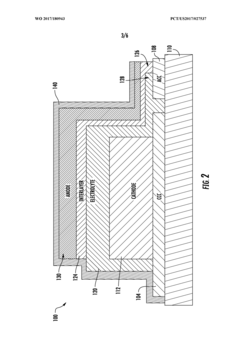

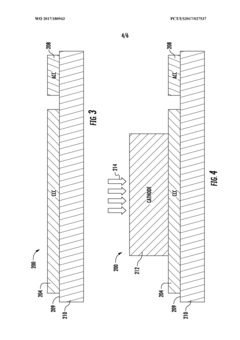

Energy storage device having an interlayer between electrode and electrolyte layer

PatentWO2017180943A1

Innovation

- An interlayer of silicon, antimony, aluminum, magnesium, titanium, magnesium lithium, or silver lithium is introduced between the electrolyte and anode layers, allowing lithium from the cathode to alloy with the interlayer, resulting in more isotropic detachment and reduced cracking during charging.

Manufacturing Scalability Challenges

The transition from laboratory-scale solid-state battery prototypes to mass production represents one of the most significant hurdles in commercialization. Current manufacturing processes for solid-state batteries remain largely experimental, with production volumes typically limited to small batches suitable only for research and development purposes. The intricate nature of solid electrolyte synthesis and processing demands specialized equipment and tightly controlled environments that are difficult to scale economically.

A primary challenge lies in the production of large-format solid electrolyte sheets with consistent quality. Unlike liquid electrolytes that can be easily injected into battery cells, solid electrolytes require precise manufacturing techniques to ensure uniform thickness, density, and ionic conductivity across the entire surface area. Even minor variations can create performance inconsistencies and potential failure points within the battery structure.

Interface management between the solid electrolyte and electrodes presents another substantial manufacturing obstacle. Creating stable, low-resistance interfaces at scale requires advanced deposition techniques and careful thermal management during assembly. Current processes often involve high-temperature sintering steps that are both energy-intensive and time-consuming, significantly increasing production costs and limiting throughput capacity.

Material supply chains for solid-state battery components remain underdeveloped compared to those for conventional lithium-ion batteries. Key materials such as lithium metal, specialized ceramic powders, and sulfide-based compounds are not yet available in the quantities and at price points necessary for large-scale manufacturing. This supply constraint creates additional barriers to achieving competitive production economics.

Equipment standardization represents another critical gap in the manufacturing ecosystem. Unlike the mature production lines available for conventional batteries, solid-state battery manufacturing requires custom-designed equipment that has not yet benefited from economies of scale or iterative optimization. This lack of standardized production tools contributes significantly to high capital expenditure requirements for new manufacturing facilities.

Yield rates in early production attempts remain substantially below those achieved in conventional battery manufacturing. Complex multi-step processes increase the probability of defects, while quality control methods for solid-state components are still evolving. These factors collectively result in higher scrap rates and production costs that must be addressed before solid-state batteries can achieve price parity with existing technologies.

A primary challenge lies in the production of large-format solid electrolyte sheets with consistent quality. Unlike liquid electrolytes that can be easily injected into battery cells, solid electrolytes require precise manufacturing techniques to ensure uniform thickness, density, and ionic conductivity across the entire surface area. Even minor variations can create performance inconsistencies and potential failure points within the battery structure.

Interface management between the solid electrolyte and electrodes presents another substantial manufacturing obstacle. Creating stable, low-resistance interfaces at scale requires advanced deposition techniques and careful thermal management during assembly. Current processes often involve high-temperature sintering steps that are both energy-intensive and time-consuming, significantly increasing production costs and limiting throughput capacity.

Material supply chains for solid-state battery components remain underdeveloped compared to those for conventional lithium-ion batteries. Key materials such as lithium metal, specialized ceramic powders, and sulfide-based compounds are not yet available in the quantities and at price points necessary for large-scale manufacturing. This supply constraint creates additional barriers to achieving competitive production economics.

Equipment standardization represents another critical gap in the manufacturing ecosystem. Unlike the mature production lines available for conventional batteries, solid-state battery manufacturing requires custom-designed equipment that has not yet benefited from economies of scale or iterative optimization. This lack of standardized production tools contributes significantly to high capital expenditure requirements for new manufacturing facilities.

Yield rates in early production attempts remain substantially below those achieved in conventional battery manufacturing. Complex multi-step processes increase the probability of defects, while quality control methods for solid-state components are still evolving. These factors collectively result in higher scrap rates and production costs that must be addressed before solid-state batteries can achieve price parity with existing technologies.

Environmental Impact and Sustainability Considerations

Solid state batteries represent a significant advancement in energy storage technology with potentially transformative environmental benefits compared to conventional lithium-ion batteries. The elimination of liquid electrolytes addresses one of the most significant environmental concerns: the use of toxic and flammable organic solvents. These conventional electrolytes pose disposal challenges and environmental hazards throughout the battery lifecycle, from manufacturing to end-of-life management.

The manufacturing process for solid state batteries promises reduced environmental impact through lower energy consumption and decreased greenhouse gas emissions. Preliminary lifecycle assessments suggest that solid state battery production could reduce carbon footprint by 15-30% compared to conventional lithium-ion manufacturing processes, primarily due to simplified production steps and reduced thermal management requirements.

Resource efficiency represents another critical environmental advantage of solid state battery technology. The potential for higher energy density translates directly to material efficiency—achieving the same energy storage capacity with fewer raw materials. Additionally, many solid state battery designs aim to reduce or eliminate dependence on critical materials like cobalt, which is associated with significant ethical and environmental concerns in mining practices.

Longevity and cycle life improvements in solid state batteries contribute substantially to sustainability through waste reduction. With projected lifespans potentially exceeding conventional batteries by 30-50%, solid state technology could significantly decrease battery replacement frequency and associated electronic waste. This extended operational life is particularly valuable in applications like electric vehicles, where battery replacement represents a substantial environmental and economic cost.

End-of-life considerations also favor solid state technology. The absence of liquid components simplifies recycling processes, potentially increasing recovery rates for valuable materials like lithium, nickel, and manganese. Several research initiatives are exploring design-for-recycling approaches specific to solid state batteries, aiming to establish closed-loop material systems that would further enhance sustainability credentials.

However, challenges remain in fully realizing these environmental benefits. The environmental impact of mining and processing new solid electrolyte materials requires thorough assessment. Additionally, manufacturing scale-up must be carefully managed to ensure that theoretical environmental advantages translate to real-world benefits as production volumes increase to commercial levels.

The manufacturing process for solid state batteries promises reduced environmental impact through lower energy consumption and decreased greenhouse gas emissions. Preliminary lifecycle assessments suggest that solid state battery production could reduce carbon footprint by 15-30% compared to conventional lithium-ion manufacturing processes, primarily due to simplified production steps and reduced thermal management requirements.

Resource efficiency represents another critical environmental advantage of solid state battery technology. The potential for higher energy density translates directly to material efficiency—achieving the same energy storage capacity with fewer raw materials. Additionally, many solid state battery designs aim to reduce or eliminate dependence on critical materials like cobalt, which is associated with significant ethical and environmental concerns in mining practices.

Longevity and cycle life improvements in solid state batteries contribute substantially to sustainability through waste reduction. With projected lifespans potentially exceeding conventional batteries by 30-50%, solid state technology could significantly decrease battery replacement frequency and associated electronic waste. This extended operational life is particularly valuable in applications like electric vehicles, where battery replacement represents a substantial environmental and economic cost.

End-of-life considerations also favor solid state technology. The absence of liquid components simplifies recycling processes, potentially increasing recovery rates for valuable materials like lithium, nickel, and manganese. Several research initiatives are exploring design-for-recycling approaches specific to solid state batteries, aiming to establish closed-loop material systems that would further enhance sustainability credentials.

However, challenges remain in fully realizing these environmental benefits. The environmental impact of mining and processing new solid electrolyte materials requires thorough assessment. Additionally, manufacturing scale-up must be carefully managed to ensure that theoretical environmental advantages translate to real-world benefits as production volumes increase to commercial levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!