How Solid State Battery Breakthrough Changes Aerospace Component Design?

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution in Aerospace

Solid state battery technology has undergone significant evolution within the aerospace sector over the past two decades. Initially developed as experimental power sources for small satellites in the early 2000s, these batteries represented a promising yet immature technology with limited practical applications in flight systems. The fundamental architecture employed ceramic or polymer electrolytes to replace traditional liquid components, addressing inherent safety concerns critical to aerospace applications.

By 2010, research institutions including NASA and the European Space Agency began dedicated programs to adapt solid state battery technology specifically for aerospace requirements. These early iterations demonstrated improved thermal stability but suffered from power density limitations that restricted their implementation to non-critical systems. The period between 2010-2015 marked crucial advancements in electrolyte composition and manufacturing techniques that gradually enhanced performance metrics.

A significant breakthrough occurred around 2017 when composite electrolytes combining ceramic and polymer materials achieved energy densities approaching 400 Wh/kg, surpassing the capabilities of advanced lithium-ion batteries while maintaining superior safety profiles. This development catalyzed increased industry investment, with major aerospace manufacturers establishing specialized research divisions focused on solid state technology integration.

The 2020s have witnessed accelerated development cycles, with solid state batteries achieving operational stability in extreme temperature environments ranging from -65°C to 150°C, addressing a critical requirement for aerospace applications. Contemporary designs incorporate multi-layer architectures that optimize power delivery while minimizing thermal management requirements, representing a fundamental shift from conventional battery systems.

Recent innovations have focused on structural integration, where battery components serve dual purposes as both energy storage and load-bearing elements. This approach has revolutionized component design philosophy, enabling the development of multifunctional structures that reduce overall system mass while maintaining or enhancing performance characteristics. Leading aerospace manufacturers have begun incorporating these batteries into flight control systems, environmental control units, and emergency power applications.

The evolution trajectory indicates continued miniaturization coupled with increased energy density, projected to reach 600-700 Wh/kg by 2025. This progression enables new design paradigms previously constrained by power system limitations. As manufacturing scalability improves, solid state batteries are transitioning from specialized applications to core power system components, fundamentally altering aerospace design approaches and enabling more electric aircraft architectures with reduced reliance on hydraulic systems.

By 2010, research institutions including NASA and the European Space Agency began dedicated programs to adapt solid state battery technology specifically for aerospace requirements. These early iterations demonstrated improved thermal stability but suffered from power density limitations that restricted their implementation to non-critical systems. The period between 2010-2015 marked crucial advancements in electrolyte composition and manufacturing techniques that gradually enhanced performance metrics.

A significant breakthrough occurred around 2017 when composite electrolytes combining ceramic and polymer materials achieved energy densities approaching 400 Wh/kg, surpassing the capabilities of advanced lithium-ion batteries while maintaining superior safety profiles. This development catalyzed increased industry investment, with major aerospace manufacturers establishing specialized research divisions focused on solid state technology integration.

The 2020s have witnessed accelerated development cycles, with solid state batteries achieving operational stability in extreme temperature environments ranging from -65°C to 150°C, addressing a critical requirement for aerospace applications. Contemporary designs incorporate multi-layer architectures that optimize power delivery while minimizing thermal management requirements, representing a fundamental shift from conventional battery systems.

Recent innovations have focused on structural integration, where battery components serve dual purposes as both energy storage and load-bearing elements. This approach has revolutionized component design philosophy, enabling the development of multifunctional structures that reduce overall system mass while maintaining or enhancing performance characteristics. Leading aerospace manufacturers have begun incorporating these batteries into flight control systems, environmental control units, and emergency power applications.

The evolution trajectory indicates continued miniaturization coupled with increased energy density, projected to reach 600-700 Wh/kg by 2025. This progression enables new design paradigms previously constrained by power system limitations. As manufacturing scalability improves, solid state batteries are transitioning from specialized applications to core power system components, fundamentally altering aerospace design approaches and enabling more electric aircraft architectures with reduced reliance on hydraulic systems.

Market Demand Analysis for Advanced Aerospace Energy Solutions

The aerospace industry is witnessing a significant shift in energy storage requirements as advanced aircraft designs, electric propulsion systems, and space exploration missions demand more efficient power solutions. Market analysis indicates that the global aerospace battery market, valued at approximately $2.5 billion in 2022, is projected to reach $7.8 billion by 2030, representing a compound annual growth rate of 15.3%. This growth is primarily driven by increasing adoption of electric and hybrid-electric propulsion systems in both commercial and military aircraft sectors.

Solid state battery technology has emerged as a critical focus area for aerospace applications due to its superior energy density, safety profile, and potential weight reduction benefits. Current market demand is particularly strong in three key segments: urban air mobility vehicles (UAM), satellite systems, and next-generation commercial aircraft. The UAM market alone is expected to require energy storage solutions for over 430,000 vehicles by 2040, creating a substantial market opportunity for advanced battery technologies.

Industry surveys reveal that aerospace manufacturers prioritize energy density improvements of at least 30-40% over current lithium-ion solutions, alongside stringent safety requirements that solid state batteries can potentially address. The elimination of flammable liquid electrolytes represents a paradigm shift in component design safety parameters, allowing engineers to reconsider traditional thermal management systems and protective enclosures that currently add significant weight to aerospace vehicles.

Weight reduction remains the primary market driver, with estimates suggesting that each kilogram reduced in battery weight can translate to $1,000-$5,000 in lifetime fuel savings for commercial aircraft. Solid state technology's potential to deliver 400-500 Wh/kg energy density (compared to current lithium-ion's 250-300 Wh/kg) represents a compelling value proposition that aerospace manufacturers are actively pursuing through increased R&D investments.

The space sector presents another high-value market segment, with requirements for batteries that can withstand extreme temperature variations and radiation exposure. Market research indicates that satellite manufacturers are willing to pay premium prices for energy storage solutions that extend operational lifespans and reduce launch costs through weight savings. The small satellite market, projected to deploy over 17,000 units by 2030, represents a particularly promising application area for solid state technology.

Regulatory trends are further accelerating market demand, with aviation authorities worldwide establishing more stringent safety standards for onboard energy storage systems. The European Union Aviation Safety Agency and Federal Aviation Administration have both signaled intentions to revise certification requirements for battery systems, potentially creating favorable conditions for solid state technology adoption as manufacturers seek compliant solutions.

Solid state battery technology has emerged as a critical focus area for aerospace applications due to its superior energy density, safety profile, and potential weight reduction benefits. Current market demand is particularly strong in three key segments: urban air mobility vehicles (UAM), satellite systems, and next-generation commercial aircraft. The UAM market alone is expected to require energy storage solutions for over 430,000 vehicles by 2040, creating a substantial market opportunity for advanced battery technologies.

Industry surveys reveal that aerospace manufacturers prioritize energy density improvements of at least 30-40% over current lithium-ion solutions, alongside stringent safety requirements that solid state batteries can potentially address. The elimination of flammable liquid electrolytes represents a paradigm shift in component design safety parameters, allowing engineers to reconsider traditional thermal management systems and protective enclosures that currently add significant weight to aerospace vehicles.

Weight reduction remains the primary market driver, with estimates suggesting that each kilogram reduced in battery weight can translate to $1,000-$5,000 in lifetime fuel savings for commercial aircraft. Solid state technology's potential to deliver 400-500 Wh/kg energy density (compared to current lithium-ion's 250-300 Wh/kg) represents a compelling value proposition that aerospace manufacturers are actively pursuing through increased R&D investments.

The space sector presents another high-value market segment, with requirements for batteries that can withstand extreme temperature variations and radiation exposure. Market research indicates that satellite manufacturers are willing to pay premium prices for energy storage solutions that extend operational lifespans and reduce launch costs through weight savings. The small satellite market, projected to deploy over 17,000 units by 2030, represents a particularly promising application area for solid state technology.

Regulatory trends are further accelerating market demand, with aviation authorities worldwide establishing more stringent safety standards for onboard energy storage systems. The European Union Aviation Safety Agency and Federal Aviation Administration have both signaled intentions to revise certification requirements for battery systems, potentially creating favorable conditions for solid state technology adoption as manufacturers seek compliant solutions.

Current Limitations and Technical Challenges in Aerospace Battery Systems

Current aerospace battery systems face significant limitations that impede the advancement of electric propulsion and onboard power systems. Conventional lithium-ion batteries used in aerospace applications suffer from energy density constraints, typically delivering 150-250 Wh/kg, which falls substantially short of the 500+ Wh/kg threshold needed for commercially viable electric aircraft. This fundamental limitation restricts flight range and payload capacity, making all-electric propulsion impractical for most commercial aviation applications.

Temperature management presents another critical challenge, as aerospace batteries must operate reliably across extreme temperature ranges from -65°C to +85°C encountered during flight. Conventional lithium-ion systems require complex thermal management systems that add considerable weight and complexity, further reducing the effective energy density of the overall power system. These thermal management requirements become particularly problematic in high-altitude operations where ambient conditions can rapidly fluctuate.

Safety concerns represent perhaps the most significant barrier to widespread adoption. The flammable liquid electrolytes in conventional batteries pose unacceptable risks in aerospace environments, where thermal runaway events could have catastrophic consequences. Current mitigation strategies involve redundant safety systems and protective enclosures that further compromise the weight efficiency of battery systems.

Cycle life and degradation patterns also present unique challenges in aerospace applications. Aircraft power systems must maintain consistent performance over thousands of cycles while adhering to strict reliability standards. Current battery technologies experience capacity fade and performance degradation that necessitates frequent replacement, creating logistical challenges and increasing operational costs for aerospace operators.

Certification and regulatory hurdles compound these technical limitations. Aviation authorities maintain stringent safety requirements that current battery technologies struggle to meet without extensive modification and protective measures. The certification process for new battery systems can take years, significantly slowing innovation cycles in aerospace power systems.

Manufacturing scalability presents additional obstacles, as aerospace-grade batteries require exceptional quality control and consistency that current production methods cannot always guarantee. The specialized nature of aerospace applications often necessitates custom battery designs that are difficult to produce economically at scale, further increasing costs and limiting adoption.

Integration challenges with existing aerospace systems create additional complexity, as battery systems must interface with aircraft power management systems, avionics, and structural components. The weight distribution, volume constraints, and electromagnetic compatibility requirements of aerospace platforms impose severe design limitations that conventional battery architectures struggle to accommodate.

Temperature management presents another critical challenge, as aerospace batteries must operate reliably across extreme temperature ranges from -65°C to +85°C encountered during flight. Conventional lithium-ion systems require complex thermal management systems that add considerable weight and complexity, further reducing the effective energy density of the overall power system. These thermal management requirements become particularly problematic in high-altitude operations where ambient conditions can rapidly fluctuate.

Safety concerns represent perhaps the most significant barrier to widespread adoption. The flammable liquid electrolytes in conventional batteries pose unacceptable risks in aerospace environments, where thermal runaway events could have catastrophic consequences. Current mitigation strategies involve redundant safety systems and protective enclosures that further compromise the weight efficiency of battery systems.

Cycle life and degradation patterns also present unique challenges in aerospace applications. Aircraft power systems must maintain consistent performance over thousands of cycles while adhering to strict reliability standards. Current battery technologies experience capacity fade and performance degradation that necessitates frequent replacement, creating logistical challenges and increasing operational costs for aerospace operators.

Certification and regulatory hurdles compound these technical limitations. Aviation authorities maintain stringent safety requirements that current battery technologies struggle to meet without extensive modification and protective measures. The certification process for new battery systems can take years, significantly slowing innovation cycles in aerospace power systems.

Manufacturing scalability presents additional obstacles, as aerospace-grade batteries require exceptional quality control and consistency that current production methods cannot always guarantee. The specialized nature of aerospace applications often necessitates custom battery designs that are difficult to produce economically at scale, further increasing costs and limiting adoption.

Integration challenges with existing aerospace systems create additional complexity, as battery systems must interface with aircraft power management systems, avionics, and structural components. The weight distribution, volume constraints, and electromagnetic compatibility requirements of aerospace platforms impose severe design limitations that conventional battery architectures struggle to accommodate.

Current Solid State Battery Integration Approaches

01 Electrode design and materials for solid-state batteries

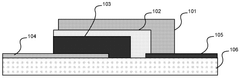

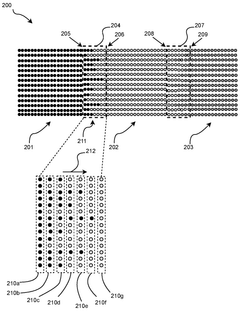

Advanced electrode designs and materials are crucial for enhancing solid-state battery performance. These innovations focus on optimizing electrode structures, incorporating novel materials, and improving interfaces between electrodes and solid electrolytes. Key developments include composite electrodes that combine active materials with solid electrolytes to enhance ion transport, structured electrodes with optimized porosity and tortuosity, and surface modifications to reduce interfacial resistance. These advancements help address challenges related to energy density, power capability, and cycle life in solid-state batteries.- Electrode design and materials for solid-state batteries: Advanced electrode designs and materials are crucial for enhancing solid-state battery performance. These innovations focus on optimizing electrode structures, incorporating novel materials like composite cathodes and anodes, and improving interfaces between electrodes and solid electrolytes. Such designs aim to increase energy density, improve cycling stability, and enhance rate capability while maintaining structural integrity during charge-discharge cycles.

- Solid electrolyte compositions and structures: Solid electrolyte development focuses on creating materials with high ionic conductivity and mechanical stability. Various compositions including ceramic, polymer, and composite electrolytes are being engineered with specific structural designs to facilitate efficient ion transport while maintaining electrochemical stability. These electrolytes are designed to prevent dendrite formation and provide better thermal stability compared to liquid electrolytes, enhancing overall battery safety and performance.

- Interface engineering and protective layers: Interface engineering involves designing protective layers and buffer zones between battery components to minimize resistance and prevent unwanted reactions. These engineered interfaces help maintain stable contact between electrodes and electrolytes, reduce impedance, and prevent degradation during cycling. Various coating technologies and interlayer designs are employed to enhance ion transport across interfaces while suppressing side reactions that could lead to capacity fade.

- Manufacturing processes and assembly techniques: Innovative manufacturing processes and assembly techniques are being developed specifically for solid-state battery components. These include advanced deposition methods, sintering processes, and precision assembly techniques that enable the creation of thin, uniform layers with excellent contact between components. Such manufacturing innovations address challenges related to scalability, cost-effectiveness, and quality control in solid-state battery production.

- Thermal management and safety features: Thermal management systems and safety features are integrated into solid-state battery designs to prevent overheating and ensure stable operation under various conditions. These designs include heat dissipation structures, temperature monitoring systems, and protective mechanisms that prevent thermal runaway. By controlling temperature distribution and incorporating fail-safe mechanisms, these features enhance the reliability and safety of solid-state batteries in diverse applications.

02 Solid electrolyte compositions and structures

Solid electrolyte compositions and structures are fundamental components that determine the performance of solid-state batteries. Innovations in this area include development of various types of solid electrolytes such as oxide-based, sulfide-based, and polymer-based materials with high ionic conductivity and low electronic conductivity. Advanced manufacturing techniques are employed to create thin, dense electrolyte layers with minimal defects. Composite electrolytes combining different materials are designed to overcome limitations of single-component systems, offering improved mechanical properties and electrochemical stability while maintaining high ionic conductivity.Expand Specific Solutions03 Interface engineering and protection layers

Interface engineering focuses on addressing the critical challenges at electrode-electrolyte interfaces in solid-state batteries. This includes developing protective coatings and interlayers to stabilize interfaces, prevent side reactions, and enhance ion transport across boundaries. Various approaches involve applying thin films of compatible materials, gradient compositions, or specialized buffer layers to mitigate interfacial resistance and prevent dendrite formation. These engineering solutions help maintain intimate contact between components during cycling, accommodate volume changes, and ensure stable long-term performance by preventing degradation mechanisms that typically occur at interfaces.Expand Specific Solutions04 Manufacturing processes and assembly techniques

Advanced manufacturing processes and assembly techniques are essential for translating solid-state battery designs into practical devices. Innovations include specialized deposition methods for thin film components, sintering techniques for ceramic electrolytes, and novel approaches for creating composite structures. Precision assembly methods address challenges related to component integration, interfacial contact, and dimensional stability. These manufacturing advances focus on scalable production while maintaining tight quality control, enabling the transition from laboratory prototypes to commercial solid-state batteries with consistent performance characteristics.Expand Specific Solutions05 Battery management and control systems

Battery management and control systems are critical for optimizing the performance and safety of solid-state batteries. These systems incorporate advanced sensing technologies to monitor battery parameters, thermal management solutions to maintain optimal operating temperatures, and sophisticated algorithms for state estimation and control. Innovations include specialized charging protocols designed for solid-state chemistry, predictive models for performance and aging, and adaptive control strategies that respond to changing conditions. These management systems help maximize energy efficiency, extend cycle life, and ensure safe operation across various usage scenarios and environmental conditions.Expand Specific Solutions

Leading Aerospace and Battery Technology Companies

Solid state battery technology is transforming aerospace component design, currently in an early growth phase with significant market expansion projected. The technology is advancing from research to commercialization, with market size expected to reach billions by 2030. Technical maturity varies across key players: established manufacturers like Murata, TDK, and LG Energy Solution lead in commercialization efforts, while Honda, BMW, and Panasonic focus on integration with aerospace systems. Research institutions including University of California and Michigan contribute fundamental breakthroughs. The Industrial Technology Research Institute and Korea Aerospace Research Institute are developing aerospace-specific applications, while PolyPlus Battery and newer entrants are advancing specialized solid-state solutions for extreme aerospace environments.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive solid-state battery platform specifically optimized for aerospace applications. Their technology employs a composite solid electrolyte system combining ceramic and polymer materials to achieve both high ionic conductivity and mechanical flexibility required in aerospace environments. The company's aerospace-grade solid-state batteries feature a silicon-carbon composite anode coupled with high-nickel cathode materials, delivering energy densities of 380-420 Wh/kg - representing a 70-90% improvement over conventional lithium-ion batteries used in aircraft systems. Their proprietary manufacturing process incorporates precision layer deposition techniques that ensure uniform solid electrolyte thickness (15-20μm), critical for maintaining consistent performance under the vibration and pressure changes experienced during flight. LG Energy Solution's aerospace solid-state batteries incorporate advanced thermal management systems designed to operate efficiently across the extreme temperature range encountered in aviation (-40°C to +70°C). The company has also developed specialized battery management systems that optimize performance and safety in aerospace applications, with redundant monitoring capabilities that meet aviation safety standards.

Strengths: Established manufacturing capabilities enable potential scale-up; comprehensive battery management systems specifically designed for aerospace applications; solid technical foundation from extensive experience in battery technology. Weaknesses: Energy density improvements still lag behind theoretical potential of solid-state technology; integration with existing aerospace electrical systems requires significant engineering adaptation; higher production costs compared to conventional lithium-ion solutions currently used in aerospace.

Safran Electrical & Power SA

Technical Solution: Safran Electrical & Power has developed a specialized solid-state battery technology specifically engineered for aerospace applications, featuring a proprietary hybrid electrolyte system. Their aerospace-grade solid-state batteries incorporate a lithium metal anode with advanced interface engineering to prevent dendrite formation during the thousands of charge-discharge cycles required in aviation applications. The company's solid electrolyte formulation combines ceramic and polymer materials to achieve both high ionic conductivity (1.5-2 mS/cm) and mechanical flexibility needed to withstand vibration and pressure changes during flight operations. Safran's solid-state batteries deliver energy densities of 320-350 Wh/kg, representing a 40-60% improvement over conventional lithium-ion batteries currently used in aircraft systems. Their manufacturing process leverages Safran's extensive aerospace manufacturing expertise, incorporating precision assembly techniques that ensure consistent quality critical for aviation applications. The battery design features integrated thermal management systems specifically optimized for the unique cooling challenges in aircraft environments, maintaining optimal operating temperatures during all flight phases. Safran has also developed specialized battery management electronics that integrate directly with aircraft power systems, enabling seamless adoption within existing aerospace electrical architectures.

Strengths: Deep integration expertise with aerospace electrical systems enables streamlined adoption; comprehensive understanding of aviation certification requirements ensures regulatory compliance; established position in aerospace supply chains facilitates market entry. Weaknesses: Energy density improvements, while significant, lag behind some specialized battery manufacturers; production scale currently limited compared to consumer electronics battery manufacturers; higher manufacturing costs due to aerospace-grade quality requirements.

Key Patents and Research in Aerospace-Grade Solid State Batteries

Electric aircraft

PatentActiveUS20240132223A1

Innovation

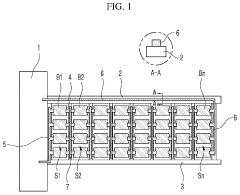

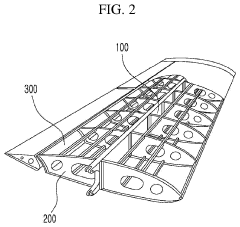

- Implementing solid state batteries as both the energy storage device and wing skin, with spars and ribs serving as structural supports for mounting and connecting the batteries in series and parallel configurations, allowing the battery surface to function as the wing skin.

A solid-state battery cell, a method of manufacturing such a solid-state battery cell, and a solid-state battery-enabled system comprising such a solid-state battery cell

PatentWO2025126004A1

Innovation

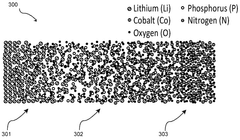

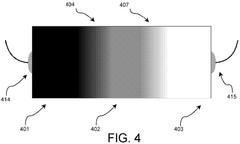

- The introduction of a solid-state battery cell design that incorporates first and second interface materials with continuous gradients in atomic composition between the anode and solid electrolyte, and between the solid electrolyte and cathode, respectively, eliminating abrupt chemical composition changes and forming a seamless connection between materials.

Weight and Space Optimization Strategies

The integration of solid-state battery technology into aerospace design necessitates comprehensive weight and space optimization strategies. Traditional lithium-ion batteries with liquid electrolytes require extensive cooling systems, protective casings, and safety mechanisms that contribute significantly to the overall weight and volume of aerospace power systems. Solid-state batteries fundamentally alter this equation by eliminating these requirements, enabling aerospace engineers to reimagine component layouts and structural designs.

Weight reduction strategies begin with the direct advantages of solid-state cells, which offer 2-3 times higher energy density than conventional batteries. This translates to either extended range capabilities with the same battery weight or maintaining current performance parameters while reducing battery mass by up to 60%. Aerospace designers can leverage this advantage by redistributing weight allowances to other critical systems or reducing overall aircraft weight to improve fuel efficiency and payload capacity.

Space optimization becomes particularly transformative when considering the flexible form factors that solid-state batteries enable. Unlike traditional cells that require standardized shapes for safety and thermal management, solid-state batteries can be manufactured in custom configurations—thin, curved, or structurally integrated. This allows for distributed power architecture where battery components can be embedded directly into aircraft structural elements such as floor panels, seat frames, or even aerodynamic surfaces.

Thermal management simplification represents another critical optimization pathway. The elimination of flammable liquid electrolytes reduces cooling requirements substantially, allowing designers to remove bulky thermal management systems. This cascading effect creates additional space savings of approximately 15-20% in the power system footprint, which can be reallocated to passenger comfort, cargo capacity, or additional instrumentation.

Integration strategies for aerospace applications focus on multifunctional design approaches where solid-state batteries serve dual purposes. For example, battery packs can be designed to provide structural support or act as ballast for center of gravity management. Some advanced concepts explore embedding solid-state cells within composite materials to create "energized structures" that simultaneously store power and bear mechanical loads.

Modular design principles are increasingly adopted to maximize the benefits of solid-state technology. By creating standardized battery modules that can be easily replaced or reconfigured, aerospace manufacturers can optimize maintenance procedures and extend aircraft service life. This approach also facilitates incremental upgrades as solid-state technology continues to evolve, preventing obsolescence of entire power systems when new battery chemistries become available.

Weight reduction strategies begin with the direct advantages of solid-state cells, which offer 2-3 times higher energy density than conventional batteries. This translates to either extended range capabilities with the same battery weight or maintaining current performance parameters while reducing battery mass by up to 60%. Aerospace designers can leverage this advantage by redistributing weight allowances to other critical systems or reducing overall aircraft weight to improve fuel efficiency and payload capacity.

Space optimization becomes particularly transformative when considering the flexible form factors that solid-state batteries enable. Unlike traditional cells that require standardized shapes for safety and thermal management, solid-state batteries can be manufactured in custom configurations—thin, curved, or structurally integrated. This allows for distributed power architecture where battery components can be embedded directly into aircraft structural elements such as floor panels, seat frames, or even aerodynamic surfaces.

Thermal management simplification represents another critical optimization pathway. The elimination of flammable liquid electrolytes reduces cooling requirements substantially, allowing designers to remove bulky thermal management systems. This cascading effect creates additional space savings of approximately 15-20% in the power system footprint, which can be reallocated to passenger comfort, cargo capacity, or additional instrumentation.

Integration strategies for aerospace applications focus on multifunctional design approaches where solid-state batteries serve dual purposes. For example, battery packs can be designed to provide structural support or act as ballast for center of gravity management. Some advanced concepts explore embedding solid-state cells within composite materials to create "energized structures" that simultaneously store power and bear mechanical loads.

Modular design principles are increasingly adopted to maximize the benefits of solid-state technology. By creating standardized battery modules that can be easily replaced or reconfigured, aerospace manufacturers can optimize maintenance procedures and extend aircraft service life. This approach also facilitates incremental upgrades as solid-state technology continues to evolve, preventing obsolescence of entire power systems when new battery chemistries become available.

Safety and Certification Requirements for Aerospace Battery Systems

The aerospace industry maintains exceptionally stringent safety standards for all components, with battery systems requiring particularly rigorous certification due to their potential failure risks. Solid state batteries must meet or exceed these requirements to gain industry acceptance, necessitating comprehensive testing protocols that evaluate performance under extreme conditions including temperature variations, pressure changes, vibration, and impact resistance.

FAA regulations in the United States (14 CFR 25.1353) and EASA requirements in Europe establish specific standards for aircraft electrical systems, including batteries. These frameworks are currently being updated to address the unique characteristics of solid state technology, focusing on thermal runaway prevention, electrical isolation, and containment strategies. Manufacturers must demonstrate compliance through extensive documentation and testing before implementation.

Risk assessment methodologies for solid state batteries in aerospace applications follow the SAE ARP4761 standard, requiring Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA). These processes identify potential failure modes, their consequences, and mitigation strategies. The absence of flammable liquid electrolytes in solid state batteries significantly improves their safety profile, potentially simplifying certification processes compared to lithium-ion alternatives.

Qualification testing for aerospace battery systems includes environmental testing (DO-160), electromagnetic compatibility assessment, and lifecycle performance evaluation. Solid state batteries must demonstrate reliability across thousands of charge-discharge cycles while maintaining performance in the harsh aerospace environment. Testing protocols typically involve accelerated aging tests, thermal cycling between extreme temperatures (-65°C to +85°C), and altitude simulation.

Redundancy requirements represent another critical certification aspect, with aerospace systems typically requiring multiple layers of protection against battery failures. This includes monitoring systems that track temperature, voltage, and current parameters in real-time, with automatic disconnection capabilities if anomalies are detected. Solid state batteries offer inherent advantages in this area due to their improved thermal stability.

Installation and maintenance procedures must also meet certification standards, with clear documentation for proper handling, installation, inspection, and replacement. The longer operational life of solid state batteries may extend maintenance intervals, but verification protocols must be established to ensure ongoing safety compliance throughout the aircraft's service life.

As the technology matures, regulatory bodies are working with industry stakeholders to develop specific certification pathways for solid state batteries in aerospace applications, recognizing their potential safety advantages while ensuring appropriate risk management frameworks are in place.

FAA regulations in the United States (14 CFR 25.1353) and EASA requirements in Europe establish specific standards for aircraft electrical systems, including batteries. These frameworks are currently being updated to address the unique characteristics of solid state technology, focusing on thermal runaway prevention, electrical isolation, and containment strategies. Manufacturers must demonstrate compliance through extensive documentation and testing before implementation.

Risk assessment methodologies for solid state batteries in aerospace applications follow the SAE ARP4761 standard, requiring Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA). These processes identify potential failure modes, their consequences, and mitigation strategies. The absence of flammable liquid electrolytes in solid state batteries significantly improves their safety profile, potentially simplifying certification processes compared to lithium-ion alternatives.

Qualification testing for aerospace battery systems includes environmental testing (DO-160), electromagnetic compatibility assessment, and lifecycle performance evaluation. Solid state batteries must demonstrate reliability across thousands of charge-discharge cycles while maintaining performance in the harsh aerospace environment. Testing protocols typically involve accelerated aging tests, thermal cycling between extreme temperatures (-65°C to +85°C), and altitude simulation.

Redundancy requirements represent another critical certification aspect, with aerospace systems typically requiring multiple layers of protection against battery failures. This includes monitoring systems that track temperature, voltage, and current parameters in real-time, with automatic disconnection capabilities if anomalies are detected. Solid state batteries offer inherent advantages in this area due to their improved thermal stability.

Installation and maintenance procedures must also meet certification standards, with clear documentation for proper handling, installation, inspection, and replacement. The longer operational life of solid state batteries may extend maintenance intervals, but verification protocols must be established to ensure ongoing safety compliance throughout the aircraft's service life.

As the technology matures, regulatory bodies are working with industry stakeholders to develop specific certification pathways for solid state batteries in aerospace applications, recognizing their potential safety advantages while ensuring appropriate risk management frameworks are in place.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!