How Solid State Battery Breakthrough Propels Market Innovation?

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Objectives

Solid state batteries represent a revolutionary advancement in energy storage technology, evolving from traditional lithium-ion batteries that use liquid electrolytes. The development trajectory began in the 1970s with initial research into solid electrolytes, but significant progress has only materialized in the last decade. This evolution has been driven by increasing demands for higher energy density, improved safety, and longer lifespan in battery technologies across multiple industries.

The fundamental breakthrough in solid state battery technology lies in replacing liquid electrolytes with solid materials, eliminating many safety concerns associated with conventional batteries while potentially offering substantial performance improvements. This transition addresses critical limitations of traditional lithium-ion batteries, including thermal runaway risks, limited energy density, and degradation over time.

Recent technological milestones include the development of ceramic and sulfide-based solid electrolytes with ionic conductivity comparable to liquid electrolytes, novel electrode-electrolyte interface engineering to reduce resistance, and manufacturing processes that enable practical production scaling. These advancements have accelerated particularly since 2018, with several major research institutions and corporations reporting significant breakthroughs in material science and production techniques.

The primary objectives of current solid state battery research focus on achieving commercial viability through several key parameters. Energy density targets exceed 400 Wh/kg and 1,000 Wh/L, substantially surpassing today's lithium-ion batteries. Cycle life goals of 1,000+ cycles at 80% capacity retention would represent a major improvement in battery longevity. Fast charging capabilities aim to reach 80% capacity in under 15 minutes without degradation issues.

Cost reduction represents another critical objective, with researchers targeting production costs below $100/kWh to achieve price parity with conventional batteries. Safety improvements aim to eliminate thermal runaway risks entirely, while operating temperature ranges seek to expand functionality from -40°C to +80°C for broader application potential.

The technology evolution trajectory suggests solid state batteries will likely progress through several generations before reaching full commercial maturity. First-generation products with hybrid electrolytes are beginning to enter specialized markets, while second-generation technologies with fully solid architectures are advancing through research pipelines. Third-generation solid state batteries incorporating lithium metal anodes and advanced cathode materials represent the ultimate goal, potentially delivering energy densities approaching theoretical limits.

The fundamental breakthrough in solid state battery technology lies in replacing liquid electrolytes with solid materials, eliminating many safety concerns associated with conventional batteries while potentially offering substantial performance improvements. This transition addresses critical limitations of traditional lithium-ion batteries, including thermal runaway risks, limited energy density, and degradation over time.

Recent technological milestones include the development of ceramic and sulfide-based solid electrolytes with ionic conductivity comparable to liquid electrolytes, novel electrode-electrolyte interface engineering to reduce resistance, and manufacturing processes that enable practical production scaling. These advancements have accelerated particularly since 2018, with several major research institutions and corporations reporting significant breakthroughs in material science and production techniques.

The primary objectives of current solid state battery research focus on achieving commercial viability through several key parameters. Energy density targets exceed 400 Wh/kg and 1,000 Wh/L, substantially surpassing today's lithium-ion batteries. Cycle life goals of 1,000+ cycles at 80% capacity retention would represent a major improvement in battery longevity. Fast charging capabilities aim to reach 80% capacity in under 15 minutes without degradation issues.

Cost reduction represents another critical objective, with researchers targeting production costs below $100/kWh to achieve price parity with conventional batteries. Safety improvements aim to eliminate thermal runaway risks entirely, while operating temperature ranges seek to expand functionality from -40°C to +80°C for broader application potential.

The technology evolution trajectory suggests solid state batteries will likely progress through several generations before reaching full commercial maturity. First-generation products with hybrid electrolytes are beginning to enter specialized markets, while second-generation technologies with fully solid architectures are advancing through research pipelines. Third-generation solid state batteries incorporating lithium metal anodes and advanced cathode materials represent the ultimate goal, potentially delivering energy densities approaching theoretical limits.

Market Demand Analysis for Advanced Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the convergence of renewable energy integration, electric vehicle adoption, and grid modernization initiatives. Current projections indicate the advanced energy storage market will reach $546 billion by 2035, with a compound annual growth rate exceeding 20% between 2023 and 2030. This remarkable expansion reflects the critical need for next-generation battery technologies that can overcome the limitations of conventional lithium-ion batteries.

Solid-state battery technology has emerged as a particularly promising solution, attracting significant attention from both industry stakeholders and investors. The demand for solid-state batteries is primarily fueled by the electric vehicle sector, where concerns about range anxiety, charging times, and safety continue to influence consumer adoption rates. Automotive manufacturers are actively seeking battery technologies that can deliver greater energy density, faster charging capabilities, and enhanced safety profiles to accelerate EV market penetration.

Consumer electronics represents another substantial market segment driving demand for advanced energy storage solutions. As devices become increasingly sophisticated and power-hungry, manufacturers require batteries that can deliver longer operational times while maintaining compact form factors. The potential for solid-state batteries to offer 2-3 times the energy density of conventional lithium-ion cells positions them as an ideal candidate for next-generation portable electronics.

Grid-scale energy storage applications constitute a rapidly expanding market opportunity, particularly as renewable energy sources like wind and solar achieve greater penetration in global electricity generation. The intermittent nature of these renewable sources necessitates robust storage solutions that can effectively manage supply-demand imbalances and provide grid stability services. Solid-state batteries, with their potential for longer cycle life and improved safety characteristics, are increasingly viewed as viable alternatives to current grid storage technologies.

Regional market analysis reveals varying demand patterns across different geographies. Asia-Pacific currently dominates the advanced energy storage market, with China, Japan, and South Korea leading in both manufacturing capacity and technology development. North America and Europe follow closely, driven by aggressive decarbonization policies and substantial investments in clean energy infrastructure.

Consumer and regulatory pressures are further accelerating market demand for safer battery technologies. Following several high-profile incidents involving conventional lithium-ion batteries, safety has become a paramount concern across all application domains. Solid-state batteries, which eliminate flammable liquid electrolytes, offer a compelling value proposition in addressing these safety concerns while simultaneously delivering performance improvements.

Market forecasts indicate that solid-state batteries could capture up to 40% of the premium battery market by 2030, with initial commercialization focusing on high-value applications where performance and safety advantages justify premium pricing. As manufacturing scales and costs decrease, broader market penetration across multiple sectors is anticipated, potentially revolutionizing the entire energy storage landscape.

Solid-state battery technology has emerged as a particularly promising solution, attracting significant attention from both industry stakeholders and investors. The demand for solid-state batteries is primarily fueled by the electric vehicle sector, where concerns about range anxiety, charging times, and safety continue to influence consumer adoption rates. Automotive manufacturers are actively seeking battery technologies that can deliver greater energy density, faster charging capabilities, and enhanced safety profiles to accelerate EV market penetration.

Consumer electronics represents another substantial market segment driving demand for advanced energy storage solutions. As devices become increasingly sophisticated and power-hungry, manufacturers require batteries that can deliver longer operational times while maintaining compact form factors. The potential for solid-state batteries to offer 2-3 times the energy density of conventional lithium-ion cells positions them as an ideal candidate for next-generation portable electronics.

Grid-scale energy storage applications constitute a rapidly expanding market opportunity, particularly as renewable energy sources like wind and solar achieve greater penetration in global electricity generation. The intermittent nature of these renewable sources necessitates robust storage solutions that can effectively manage supply-demand imbalances and provide grid stability services. Solid-state batteries, with their potential for longer cycle life and improved safety characteristics, are increasingly viewed as viable alternatives to current grid storage technologies.

Regional market analysis reveals varying demand patterns across different geographies. Asia-Pacific currently dominates the advanced energy storage market, with China, Japan, and South Korea leading in both manufacturing capacity and technology development. North America and Europe follow closely, driven by aggressive decarbonization policies and substantial investments in clean energy infrastructure.

Consumer and regulatory pressures are further accelerating market demand for safer battery technologies. Following several high-profile incidents involving conventional lithium-ion batteries, safety has become a paramount concern across all application domains. Solid-state batteries, which eliminate flammable liquid electrolytes, offer a compelling value proposition in addressing these safety concerns while simultaneously delivering performance improvements.

Market forecasts indicate that solid-state batteries could capture up to 40% of the premium battery market by 2030, with initial commercialization focusing on high-value applications where performance and safety advantages justify premium pricing. As manufacturing scales and costs decrease, broader market penetration across multiple sectors is anticipated, potentially revolutionizing the entire energy storage landscape.

Current Challenges in Solid State Battery Development

Despite significant advancements in solid-state battery technology, several critical challenges continue to impede widespread commercialization and market adoption. The most persistent obstacle remains the interface stability between solid electrolytes and electrodes. Unlike liquid electrolytes that maintain consistent contact with electrode surfaces, solid electrolytes struggle to maintain uniform contact during charging and discharging cycles, leading to increased impedance and accelerated performance degradation over time.

Manufacturing scalability presents another formidable challenge. Current laboratory-scale production methods for solid-state batteries involve complex processes that are difficult to translate to mass production environments. The precision required for layer uniformity and interface quality control becomes exponentially more difficult at industrial scales, resulting in high production costs that currently exceed $250-400 per kWh compared to $100-150 per kWh for conventional lithium-ion batteries.

Material limitations further complicate development efforts. Many promising solid electrolytes exhibit excellent ionic conductivity but suffer from mechanical brittleness, making them vulnerable to fracturing during battery assembly or operation. Ceramic-based electrolytes, while offering superior conductivity, are particularly susceptible to mechanical failure, necessitating complex composite approaches that introduce additional manufacturing complexities.

Dendrite formation, though theoretically mitigated in solid-state designs, remains problematic in practice. Under high current densities or after repeated cycling, lithium metal can still penetrate through microscopic defects in solid electrolytes, creating short circuits that compromise both performance and safety. Recent research has shown that even ceramic electrolytes with theoretical densities exceeding 99.5% can develop dendrite propagation paths under certain operating conditions.

Temperature sensitivity continues to challenge practical applications. Many solid electrolytes demonstrate optimal conductivity only at elevated temperatures (60-80°C), limiting their functionality in ambient conditions. Conversely, some systems that perform well at room temperature show significant conductivity drops at low temperatures, restricting their viability in automotive applications in cold climates.

Cycle life limitations represent another significant hurdle. While solid-state batteries show promising initial performance, maintaining capacity retention beyond 500-1000 cycles remains challenging due to progressive interface degradation. This falls short of the 2000+ cycles typically required for automotive applications, necessitating further innovation in interface engineering and materials science.

Addressing these interconnected challenges requires coordinated research efforts across materials science, manufacturing engineering, and electrochemistry domains. Recent breakthroughs in composite electrolytes and interface modification techniques show promise, but significant work remains before solid-state batteries can fulfill their theoretical potential in commercial applications.

Manufacturing scalability presents another formidable challenge. Current laboratory-scale production methods for solid-state batteries involve complex processes that are difficult to translate to mass production environments. The precision required for layer uniformity and interface quality control becomes exponentially more difficult at industrial scales, resulting in high production costs that currently exceed $250-400 per kWh compared to $100-150 per kWh for conventional lithium-ion batteries.

Material limitations further complicate development efforts. Many promising solid electrolytes exhibit excellent ionic conductivity but suffer from mechanical brittleness, making them vulnerable to fracturing during battery assembly or operation. Ceramic-based electrolytes, while offering superior conductivity, are particularly susceptible to mechanical failure, necessitating complex composite approaches that introduce additional manufacturing complexities.

Dendrite formation, though theoretically mitigated in solid-state designs, remains problematic in practice. Under high current densities or after repeated cycling, lithium metal can still penetrate through microscopic defects in solid electrolytes, creating short circuits that compromise both performance and safety. Recent research has shown that even ceramic electrolytes with theoretical densities exceeding 99.5% can develop dendrite propagation paths under certain operating conditions.

Temperature sensitivity continues to challenge practical applications. Many solid electrolytes demonstrate optimal conductivity only at elevated temperatures (60-80°C), limiting their functionality in ambient conditions. Conversely, some systems that perform well at room temperature show significant conductivity drops at low temperatures, restricting their viability in automotive applications in cold climates.

Cycle life limitations represent another significant hurdle. While solid-state batteries show promising initial performance, maintaining capacity retention beyond 500-1000 cycles remains challenging due to progressive interface degradation. This falls short of the 2000+ cycles typically required for automotive applications, necessitating further innovation in interface engineering and materials science.

Addressing these interconnected challenges requires coordinated research efforts across materials science, manufacturing engineering, and electrochemistry domains. Recent breakthroughs in composite electrolytes and interface modification techniques show promise, but significant work remains before solid-state batteries can fulfill their theoretical potential in commercial applications.

Current Solid State Battery Design Solutions

01 Novel electrolyte materials for solid-state batteries

Recent breakthroughs in solid-state battery technology include the development of novel electrolyte materials that offer improved ionic conductivity and stability. These materials enable faster ion transport between electrodes while maintaining structural integrity, addressing key challenges in solid-state battery performance. Advanced solid electrolytes include ceramic, polymer, and composite materials that demonstrate superior electrochemical properties compared to conventional liquid electrolytes, while eliminating safety concerns associated with flammable components.- Novel electrolyte materials for solid-state batteries: Advanced electrolyte materials are being developed to improve ionic conductivity and stability in solid-state batteries. These include ceramic electrolytes, polymer electrolytes, and composite electrolytes that offer superior ion transport properties while maintaining mechanical integrity. These novel electrolytes address key challenges in solid-state battery technology by enabling faster charging, higher energy density, and improved safety compared to conventional liquid electrolyte batteries.

- Interface engineering for solid-state battery performance: Interface engineering focuses on optimizing the contact between solid electrolytes and electrodes to reduce resistance and improve battery performance. Techniques include surface coatings, buffer layers, and specialized manufacturing processes that enhance the solid-solid interfaces. These innovations help minimize impedance, prevent dendrite formation, and ensure stable cycling performance, which are critical factors for the commercial viability of solid-state batteries.

- Advanced cathode materials for high-energy solid-state batteries: Breakthrough cathode materials are being developed specifically for solid-state battery applications. These include high-capacity layered oxides, sulfur-based cathodes, and composite structures that enable higher energy density. The cathode innovations focus on materials that are compatible with solid electrolytes while delivering improved capacity, voltage stability, and cycle life compared to traditional lithium-ion battery cathodes.

- Manufacturing processes for solid-state battery production: Novel manufacturing techniques are being developed to enable cost-effective and scalable production of solid-state batteries. These include advanced deposition methods, sintering processes, and assembly techniques that address the challenges of producing thin, uniform layers of solid electrolytes and ensuring good contact between components. These manufacturing innovations are crucial for transitioning solid-state battery technology from laboratory prototypes to commercial products.

- Anode innovations for dendrite-free solid-state batteries: Innovative anode designs and materials are being developed to prevent lithium dendrite formation and improve the stability of solid-state batteries. These include structured lithium metal anodes, silicon-based composites, and protective interface layers that enable high capacity while maintaining safety. These anode innovations address one of the major challenges in solid-state battery technology by preventing internal short circuits while maximizing energy density.

02 Interface engineering for improved electrode-electrolyte contact

A significant breakthrough in solid-state battery technology involves interface engineering to enhance the contact between electrodes and solid electrolytes. This approach addresses the critical challenge of high interfacial resistance that typically limits solid-state battery performance. By developing novel coating technologies, surface treatments, and interlayers, researchers have successfully reduced interfacial resistance, improved mechanical stability, and enhanced electrochemical performance, leading to batteries with higher energy density and longer cycle life.Expand Specific Solutions03 Advanced manufacturing techniques for solid-state batteries

Innovative manufacturing techniques represent a significant breakthrough in solid-state battery production. These include novel deposition methods, sintering processes, and assembly techniques that enable the fabrication of thin, uniform layers with excellent contact between components. Advanced manufacturing approaches help overcome challenges related to scalability and cost-effectiveness, bringing solid-state batteries closer to commercial viability. These techniques also address issues of mechanical stress during cycling and enable the production of batteries with complex architectures.Expand Specific Solutions04 High-performance cathode and anode materials for solid-state systems

Breakthroughs in electrode materials specifically designed for solid-state battery systems have significantly advanced the field. These include high-capacity cathode materials that are compatible with solid electrolytes and novel anode designs that prevent dendrite formation while maintaining high energy density. The development of these specialized electrode materials addresses challenges related to volume changes during cycling, chemical compatibility with solid electrolytes, and long-term stability, resulting in solid-state batteries with improved performance metrics.Expand Specific Solutions05 Composite and hybrid solid-state battery architectures

A major breakthrough in solid-state battery technology involves the development of composite and hybrid architectures that combine different types of solid electrolytes or integrate solid and quasi-solid components. These innovative designs leverage the advantages of multiple materials to overcome limitations of single-material approaches. Composite architectures can simultaneously address issues of ionic conductivity, mechanical stability, and interfacial resistance, resulting in batteries with superior performance characteristics including higher energy density, improved safety, and extended cycle life.Expand Specific Solutions

Leading Companies in Solid State Battery Innovation

The solid-state battery market is currently in its early growth phase, characterized by significant R&D investments but limited commercial deployment. With a projected market size reaching $8-10 billion by 2030, this technology represents a transformative opportunity in energy storage. Technical maturity varies across key players: established manufacturers like Murata, Samsung Electro-Mechanics, and Panasonic lead in materials development; automotive companies including BYD, Honda, and FAW are accelerating integration efforts; while specialized innovators such as Sakti3 and Farasis Energy focus on breakthrough technologies. Research institutions like Central South University and CNRS provide fundamental scientific advancements. The competitive landscape features intense patent activity and strategic partnerships as companies position themselves for the anticipated shift from lithium-ion to solid-state technology, with Asian manufacturers currently holding technological leadership.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung has developed a solid-state battery technology utilizing a silver-carbon (Ag-C) composite anode and a high-conductivity sulfide-based solid electrolyte. Their approach addresses dendrite formation issues through a specialized protective layer between the lithium metal anode and the solid electrolyte. Samsung's technology enables the use of lithium metal anodes without the safety risks typically associated with them, potentially achieving energy densities up to 900 Wh/L. The company has implemented a scalable manufacturing process that builds upon their existing battery production infrastructure while incorporating new techniques specific to solid-state assembly. Samsung researchers have demonstrated prototype cells with over 1,000 charge-discharge cycles while maintaining 80% capacity, indicating promising longevity. The company has invested significantly in materials research, particularly focusing on sulfide electrolytes that offer high ionic conductivity at room temperature, a critical factor for practical solid-state battery implementation.

Strengths: Extensive manufacturing expertise and infrastructure; innovative approach to dendrite suppression; integration potential with existing Samsung electronics ecosystem; strong materials science capabilities. Weaknesses: Sulfide electrolytes can be sensitive to moisture and air, requiring specialized handling; challenges in scaling production while maintaining material purity; competition from other major electronics manufacturers pursuing similar technologies.

Sakti3, Inc.

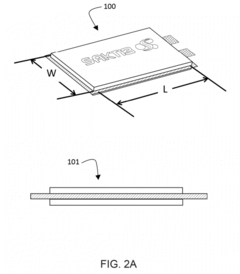

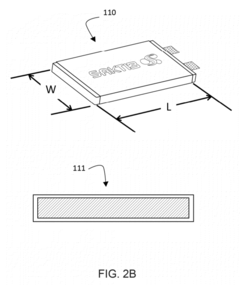

Technical Solution: Sakti3 has pioneered a solid-state battery technology using thin-film deposition methods similar to those in semiconductor manufacturing. Their approach involves depositing lithium-based materials layer by layer to create solid-state cells without liquid electrolytes. The company's technology utilizes a ceramic electrolyte material that enables higher energy density (reportedly up to 400 Wh/kg) compared to conventional lithium-ion batteries. Sakti3's manufacturing process employs vacuum deposition techniques to create extremely thin, uniform layers of cathode, electrolyte, and anode materials, allowing for precise control over battery architecture. This method eliminates the need for separators and liquid electrolytes found in traditional batteries, significantly reducing fire risks and improving thermal stability. The company was acquired by Dyson in 2015 for $90 million, indicating the high value placed on their solid-state technology.

Strengths: Higher energy density than conventional lithium-ion batteries; enhanced safety through elimination of flammable liquid electrolytes; potential for longer cycle life due to reduced degradation mechanisms. Weaknesses: Manufacturing scalability challenges with vacuum deposition processes; higher production costs compared to established battery technologies; potential interface stability issues between solid electrolyte and electrode materials.

Key Patents and Research Breakthroughs

Monolithically integrated thin-film solid state lithium battery device having multiple layers of lithium electrochemical cells

PatentActiveUS20120058380A1

Innovation

- A method and device for fabricating a solid-state thin-film battery using a prismatic multilayer structure with specific layer thicknesses and materials, including a substrate, cathode and anode current collectors, electrolyte, and barrier layers, optimized through numerical techniques for enhanced energy density and stability.

High-capacity solid-state lithium-ion battery with enhanced safety for electric vehicles

PatentPendingIN202341070197A

Innovation

- A high-capacity solid-state lithium-ion battery design utilizing advanced materials and engineering techniques to ensure safety, performance, and efficient ion conductivity across a broad temperature range, addressing dendrite formation, flammability, and manufacturing complexities through innovative electrode designs and manufacturing processes.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of solid-state batteries represents one of the most significant barriers to their widespread commercial adoption. Current production methods remain largely laboratory-focused, with limited capacity for mass production that would be necessary to compete with conventional lithium-ion batteries. The transition from small-scale prototypes to gigafactory-level production requires substantial process engineering innovations and capital investment, estimated at $80-100 million per GWh of production capacity.

Key manufacturing challenges include the precise deposition of ultra-thin solid electrolyte layers, which must maintain uniform thickness and be free of defects that could lead to internal short circuits. The interface between the solid electrolyte and electrodes presents another critical manufacturing hurdle, requiring specialized techniques to ensure proper contact and minimize resistance. Industry analysts estimate that current solid-state battery manufacturing costs range from $250-400 per kWh, significantly higher than the $100-150 per kWh for conventional lithium-ion batteries.

Cost reduction pathways are emerging through materials innovation and process optimization. The replacement of expensive materials like lithium metal with more abundant alternatives could reduce raw material costs by 30-40%. Similarly, advances in ceramic electrolyte synthesis methods have demonstrated potential cost reductions of 25-35% through simplified production processes and reduced energy requirements.

Learning curve effects are expected to drive substantial cost improvements as production scales. Industry projections suggest that manufacturing costs could decrease by 15-20% with each doubling of production volume, potentially reaching cost parity with conventional lithium-ion batteries by 2028-2030, assuming continued investment and technological progress.

Equipment suppliers are developing specialized manufacturing tools specifically designed for solid-state battery production, including advanced ceramic sintering equipment, precision deposition systems, and automated quality control mechanisms. These purpose-built systems are expected to improve yield rates from current levels of 70-80% to over 95% at scale, significantly reducing per-unit costs.

Strategic partnerships between battery developers, automotive OEMs, and manufacturing equipment suppliers are accelerating the industrialization timeline. Joint ventures announced in 2022-2023 have committed over $5 billion to establish pilot production lines with capacities of 1-5 GWh, serving as proving grounds for manufacturing processes before full-scale commercialization.

Key manufacturing challenges include the precise deposition of ultra-thin solid electrolyte layers, which must maintain uniform thickness and be free of defects that could lead to internal short circuits. The interface between the solid electrolyte and electrodes presents another critical manufacturing hurdle, requiring specialized techniques to ensure proper contact and minimize resistance. Industry analysts estimate that current solid-state battery manufacturing costs range from $250-400 per kWh, significantly higher than the $100-150 per kWh for conventional lithium-ion batteries.

Cost reduction pathways are emerging through materials innovation and process optimization. The replacement of expensive materials like lithium metal with more abundant alternatives could reduce raw material costs by 30-40%. Similarly, advances in ceramic electrolyte synthesis methods have demonstrated potential cost reductions of 25-35% through simplified production processes and reduced energy requirements.

Learning curve effects are expected to drive substantial cost improvements as production scales. Industry projections suggest that manufacturing costs could decrease by 15-20% with each doubling of production volume, potentially reaching cost parity with conventional lithium-ion batteries by 2028-2030, assuming continued investment and technological progress.

Equipment suppliers are developing specialized manufacturing tools specifically designed for solid-state battery production, including advanced ceramic sintering equipment, precision deposition systems, and automated quality control mechanisms. These purpose-built systems are expected to improve yield rates from current levels of 70-80% to over 95% at scale, significantly reducing per-unit costs.

Strategic partnerships between battery developers, automotive OEMs, and manufacturing equipment suppliers are accelerating the industrialization timeline. Joint ventures announced in 2022-2023 have committed over $5 billion to establish pilot production lines with capacities of 1-5 GWh, serving as proving grounds for manufacturing processes before full-scale commercialization.

Environmental Impact and Sustainability Considerations

The transition to solid-state battery technology represents a significant advancement in sustainable energy storage solutions. Unlike conventional lithium-ion batteries that rely on liquid electrolytes containing flammable and environmentally harmful components, solid-state batteries utilize solid electrolytes that are inherently safer and more environmentally benign. This fundamental design difference eliminates the need for toxic and flammable organic solvents, substantially reducing the risk of environmental contamination during production, use, and disposal phases.

From a lifecycle perspective, solid-state batteries demonstrate promising environmental advantages. The manufacturing process potentially requires fewer hazardous materials and generates less toxic waste. Research indicates that the carbon footprint associated with solid-state battery production could be significantly lower than conventional batteries, particularly when considering the extended lifespan and improved efficiency of these advanced energy storage systems.

The enhanced durability and longer operational life of solid-state batteries directly contribute to sustainability goals by reducing replacement frequency and associated resource consumption. Current projections suggest that solid-state batteries may achieve 2-3 times the lifespan of traditional lithium-ion counterparts, dramatically decreasing electronic waste generation and resource depletion rates in the battery sector.

Recycling considerations also favor solid-state technology. The absence of liquid components simplifies the end-of-life recovery process, potentially enabling more efficient reclamation of valuable materials like lithium, cobalt, and nickel. Several leading manufacturers are already developing specialized recycling protocols specifically designed for solid-state battery architectures, anticipating the eventual commercial-scale deployment of these technologies.

Energy density improvements inherent to solid-state designs further enhance their environmental profile. Higher energy density translates to more efficient use of raw materials per unit of energy stored, reducing resource extraction pressures. Additionally, when deployed in electric vehicles, the extended range capabilities directly contribute to transportation sector decarbonization efforts by accelerating the transition away from fossil fuel dependence.

Water conservation represents another environmental benefit, as solid-state manufacturing processes typically require less water than conventional battery production. This advantage becomes particularly significant in regions facing water scarcity challenges, where industrial water consumption creates competition with agricultural and residential needs.

From a lifecycle perspective, solid-state batteries demonstrate promising environmental advantages. The manufacturing process potentially requires fewer hazardous materials and generates less toxic waste. Research indicates that the carbon footprint associated with solid-state battery production could be significantly lower than conventional batteries, particularly when considering the extended lifespan and improved efficiency of these advanced energy storage systems.

The enhanced durability and longer operational life of solid-state batteries directly contribute to sustainability goals by reducing replacement frequency and associated resource consumption. Current projections suggest that solid-state batteries may achieve 2-3 times the lifespan of traditional lithium-ion counterparts, dramatically decreasing electronic waste generation and resource depletion rates in the battery sector.

Recycling considerations also favor solid-state technology. The absence of liquid components simplifies the end-of-life recovery process, potentially enabling more efficient reclamation of valuable materials like lithium, cobalt, and nickel. Several leading manufacturers are already developing specialized recycling protocols specifically designed for solid-state battery architectures, anticipating the eventual commercial-scale deployment of these technologies.

Energy density improvements inherent to solid-state designs further enhance their environmental profile. Higher energy density translates to more efficient use of raw materials per unit of energy stored, reducing resource extraction pressures. Additionally, when deployed in electric vehicles, the extended range capabilities directly contribute to transportation sector decarbonization efforts by accelerating the transition away from fossil fuel dependence.

Water conservation represents another environmental benefit, as solid-state manufacturing processes typically require less water than conventional battery production. This advantage becomes particularly significant in regions facing water scarcity challenges, where industrial water consumption creates competition with agricultural and residential needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!