Comparison of Material Efficiency in Solid State Battery Breakthrough

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Material Evolution and Objectives

Solid state batteries represent a significant evolution in energy storage technology, emerging from decades of research aimed at overcoming the limitations of conventional lithium-ion batteries. The development trajectory began in the 1970s with the discovery of solid electrolytes, but significant breakthroughs in material science over the past decade have accelerated progress toward commercial viability. This technological evolution has been driven by the increasing demand for higher energy density, improved safety, and longer cycle life in battery applications across multiple industries.

The fundamental objective of solid state battery development centers on replacing liquid electrolytes with solid alternatives while maintaining or enhancing ionic conductivity. This transition addresses critical safety concerns related to flammable liquid electrolytes while potentially enabling higher energy density through compatibility with lithium metal anodes. Material efficiency in this context encompasses multiple dimensions: ionic conductivity, mechanical stability, interfacial resistance, and manufacturing scalability.

Current material evolution focuses on three primary categories of solid electrolytes: oxide-based ceramics, sulfide-based materials, and polymer-based systems. Each category presents distinct advantages and challenges regarding conductivity, mechanical properties, and processing requirements. Oxide-based materials offer excellent stability but typically suffer from lower conductivity at room temperature. Sulfide-based electrolytes demonstrate superior ionic conductivity but present challenges in air stability and manufacturing. Polymer electrolytes provide mechanical flexibility but struggle with lower conductivity and limited electrochemical stability windows.

Recent breakthroughs in material efficiency have centered on composite approaches that combine the benefits of different material classes. These hybrid systems aim to address the critical challenges of solid-state interfaces while maintaining high ionic conductivity. Notable advances include the development of ceramic-polymer composites that balance mechanical properties with processing advantages, and the engineering of artificial interphases to stabilize the electrode-electrolyte interface.

The objectives for future material development include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, maintaining mechanical stability during cycling, reducing interfacial resistance below 10 Ω·cm², and developing manufacturing processes compatible with existing battery production infrastructure. Additionally, material sustainability has emerged as a critical objective, with research increasingly focused on reducing reliance on scarce elements like cobalt and developing recyclable battery components.

Quantitative targets for material efficiency include energy densities exceeding 400 Wh/kg at the cell level, cycle life beyond 1,000 cycles with minimal capacity degradation, and cost reduction to below $100/kWh to achieve commercial competitiveness with conventional lithium-ion technologies. These ambitious objectives guide current research efforts and industrial investment in solid state battery technology.

The fundamental objective of solid state battery development centers on replacing liquid electrolytes with solid alternatives while maintaining or enhancing ionic conductivity. This transition addresses critical safety concerns related to flammable liquid electrolytes while potentially enabling higher energy density through compatibility with lithium metal anodes. Material efficiency in this context encompasses multiple dimensions: ionic conductivity, mechanical stability, interfacial resistance, and manufacturing scalability.

Current material evolution focuses on three primary categories of solid electrolytes: oxide-based ceramics, sulfide-based materials, and polymer-based systems. Each category presents distinct advantages and challenges regarding conductivity, mechanical properties, and processing requirements. Oxide-based materials offer excellent stability but typically suffer from lower conductivity at room temperature. Sulfide-based electrolytes demonstrate superior ionic conductivity but present challenges in air stability and manufacturing. Polymer electrolytes provide mechanical flexibility but struggle with lower conductivity and limited electrochemical stability windows.

Recent breakthroughs in material efficiency have centered on composite approaches that combine the benefits of different material classes. These hybrid systems aim to address the critical challenges of solid-state interfaces while maintaining high ionic conductivity. Notable advances include the development of ceramic-polymer composites that balance mechanical properties with processing advantages, and the engineering of artificial interphases to stabilize the electrode-electrolyte interface.

The objectives for future material development include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, maintaining mechanical stability during cycling, reducing interfacial resistance below 10 Ω·cm², and developing manufacturing processes compatible with existing battery production infrastructure. Additionally, material sustainability has emerged as a critical objective, with research increasingly focused on reducing reliance on scarce elements like cobalt and developing recyclable battery components.

Quantitative targets for material efficiency include energy densities exceeding 400 Wh/kg at the cell level, cycle life beyond 1,000 cycles with minimal capacity degradation, and cost reduction to below $100/kWh to achieve commercial competitiveness with conventional lithium-ion technologies. These ambitious objectives guide current research efforts and industrial investment in solid state battery technology.

Market Analysis for Advanced Battery Technologies

The advanced battery market is experiencing unprecedented growth, driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations place the global advanced battery sector at approximately $95 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 18-20% through 2030. Solid-state batteries represent a particularly promising segment within this market, with current investments exceeding $3 billion annually and accelerating.

Material efficiency has emerged as a critical differentiator in solid-state battery development, directly impacting production costs, environmental sustainability, and market competitiveness. Recent breakthroughs in solid electrolyte materials have demonstrated up to 40% reduction in rare earth element requirements while maintaining or improving performance metrics, creating significant market advantages for companies pioneering these technologies.

Consumer demand patterns strongly favor batteries with higher energy density, faster charging capabilities, and improved safety profiles—all key advantages of solid-state technology. Market research indicates that 78% of EV consumers rank battery performance as their top consideration, with safety concerns following closely at 72%. This consumer preference is driving automotive manufacturers to secure solid-state battery supply chains, with over 15 major automotive OEMs announcing strategic partnerships with solid-state battery developers in the past 24 months.

Regional market analysis reveals Asia-Pacific dominance in current battery production, controlling 75% of global capacity, though North America and Europe are rapidly expanding their manufacturing capabilities through strategic government initiatives. The European Battery Alliance has committed €7.7 billion to battery innovation, with material efficiency research receiving approximately 30% of allocated funds.

Market segmentation shows automotive applications leading demand at 58% of the advanced battery market, followed by grid storage (22%), consumer electronics (15%), and industrial applications (5%). Solid-state batteries with enhanced material efficiency are projected to capture 25-30% of the premium EV battery market by 2028, representing a potential market value of $12-15 billion.

Pricing trends indicate that material-efficient solid-state batteries currently command a 30-40% premium over conventional lithium-ion batteries, though this gap is expected to narrow to 15-20% by 2026 as production scales and manufacturing processes mature. This convergence point represents a critical market inflection, potentially triggering mass-market adoption across multiple sectors.

Material efficiency has emerged as a critical differentiator in solid-state battery development, directly impacting production costs, environmental sustainability, and market competitiveness. Recent breakthroughs in solid electrolyte materials have demonstrated up to 40% reduction in rare earth element requirements while maintaining or improving performance metrics, creating significant market advantages for companies pioneering these technologies.

Consumer demand patterns strongly favor batteries with higher energy density, faster charging capabilities, and improved safety profiles—all key advantages of solid-state technology. Market research indicates that 78% of EV consumers rank battery performance as their top consideration, with safety concerns following closely at 72%. This consumer preference is driving automotive manufacturers to secure solid-state battery supply chains, with over 15 major automotive OEMs announcing strategic partnerships with solid-state battery developers in the past 24 months.

Regional market analysis reveals Asia-Pacific dominance in current battery production, controlling 75% of global capacity, though North America and Europe are rapidly expanding their manufacturing capabilities through strategic government initiatives. The European Battery Alliance has committed €7.7 billion to battery innovation, with material efficiency research receiving approximately 30% of allocated funds.

Market segmentation shows automotive applications leading demand at 58% of the advanced battery market, followed by grid storage (22%), consumer electronics (15%), and industrial applications (5%). Solid-state batteries with enhanced material efficiency are projected to capture 25-30% of the premium EV battery market by 2028, representing a potential market value of $12-15 billion.

Pricing trends indicate that material-efficient solid-state batteries currently command a 30-40% premium over conventional lithium-ion batteries, though this gap is expected to narrow to 15-20% by 2026 as production scales and manufacturing processes mature. This convergence point represents a critical market inflection, potentially triggering mass-market adoption across multiple sectors.

Current Material Efficiency Challenges in Solid State Batteries

Solid-state batteries represent a promising next-generation energy storage technology, yet their widespread commercialization faces significant material efficiency challenges. Current lithium-ion batteries utilize liquid electrolytes that pose safety risks and limit energy density. Solid-state alternatives offer theoretical improvements but encounter substantial material-related obstacles that impede their performance and commercial viability.

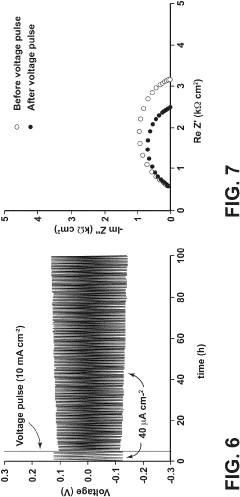

The interface between solid electrolytes and electrodes presents one of the most critical efficiency challenges. Unlike liquid electrolytes that maintain consistent contact with electrode surfaces, solid electrolytes struggle to maintain uniform contact, creating resistance that reduces ion transfer efficiency. This interfacial resistance increases during cycling as volume changes in active materials create microcracks and voids, progressively degrading battery performance.

Material selection for solid electrolytes involves navigating a complex trade-off between ionic conductivity, mechanical properties, and chemical stability. Current ceramic electrolytes like LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3) offer high ionic conductivity but suffer from brittleness and manufacturing complexity. Polymer electrolytes provide better mechanical properties but demonstrate lower ionic conductivity at room temperature, requiring operation at elevated temperatures that reduce overall system efficiency.

Manufacturing efficiency represents another significant hurdle. Traditional battery production methods are optimized for liquid electrolyte systems, while solid-state battery production requires precise control of interfaces and often involves high-temperature sintering processes that consume substantial energy. The material waste during manufacturing can exceed 20% for some solid electrolyte compositions, significantly increasing production costs.

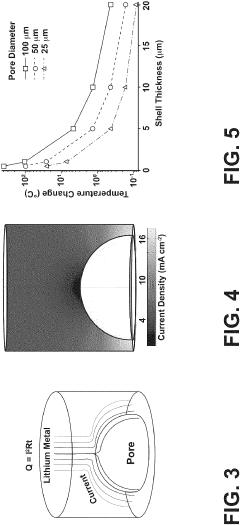

Lithium metal anodes, often paired with solid electrolytes to maximize energy density, introduce additional efficiency challenges. Dendrite formation remains problematic even with solid electrolytes, particularly at high current densities. This necessitates excess lithium in designs, reducing the theoretical energy density advantage and material efficiency of these systems.

Cathode utilization efficiency in solid-state configurations typically falls below that of liquid electrolyte systems. The limited contact area between solid electrolytes and active cathode particles restricts lithium-ion accessibility to active materials. Current designs achieve only 70-85% of theoretical cathode capacity, compared to 90-95% in advanced liquid electrolyte systems.

Cycle life limitations further compound material efficiency concerns. Many solid-state battery prototypes demonstrate rapid capacity fade after 100-500 cycles, requiring more frequent replacement than conventional batteries and negating potential sustainability benefits. This degradation stems from cumulative interface deterioration and mechanical stress within the solid components during repeated cycling.

The interface between solid electrolytes and electrodes presents one of the most critical efficiency challenges. Unlike liquid electrolytes that maintain consistent contact with electrode surfaces, solid electrolytes struggle to maintain uniform contact, creating resistance that reduces ion transfer efficiency. This interfacial resistance increases during cycling as volume changes in active materials create microcracks and voids, progressively degrading battery performance.

Material selection for solid electrolytes involves navigating a complex trade-off between ionic conductivity, mechanical properties, and chemical stability. Current ceramic electrolytes like LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3) offer high ionic conductivity but suffer from brittleness and manufacturing complexity. Polymer electrolytes provide better mechanical properties but demonstrate lower ionic conductivity at room temperature, requiring operation at elevated temperatures that reduce overall system efficiency.

Manufacturing efficiency represents another significant hurdle. Traditional battery production methods are optimized for liquid electrolyte systems, while solid-state battery production requires precise control of interfaces and often involves high-temperature sintering processes that consume substantial energy. The material waste during manufacturing can exceed 20% for some solid electrolyte compositions, significantly increasing production costs.

Lithium metal anodes, often paired with solid electrolytes to maximize energy density, introduce additional efficiency challenges. Dendrite formation remains problematic even with solid electrolytes, particularly at high current densities. This necessitates excess lithium in designs, reducing the theoretical energy density advantage and material efficiency of these systems.

Cathode utilization efficiency in solid-state configurations typically falls below that of liquid electrolyte systems. The limited contact area between solid electrolytes and active cathode particles restricts lithium-ion accessibility to active materials. Current designs achieve only 70-85% of theoretical cathode capacity, compared to 90-95% in advanced liquid electrolyte systems.

Cycle life limitations further compound material efficiency concerns. Many solid-state battery prototypes demonstrate rapid capacity fade after 100-500 cycles, requiring more frequent replacement than conventional batteries and negating potential sustainability benefits. This degradation stems from cumulative interface deterioration and mechanical stress within the solid components during repeated cycling.

Comparative Analysis of Material Efficiency Solutions

01 Electrolyte materials for improved ionic conductivity

Solid-state electrolyte materials with enhanced ionic conductivity are crucial for improving battery efficiency. These materials facilitate faster ion transport between electrodes while maintaining stability. Advanced ceramic and polymer-based electrolytes can significantly reduce internal resistance, leading to higher energy density and improved charge-discharge rates. Innovations in this area focus on materials that combine high conductivity with mechanical stability and electrochemical compatibility with electrode materials.- Advanced electrolyte materials for solid-state batteries: Solid electrolyte materials are crucial for enhancing the efficiency of solid-state batteries. These materials facilitate ion transport between electrodes while preventing dendrite formation. Advanced ceramic and polymer-based electrolytes with high ionic conductivity can significantly improve battery performance and energy density. Innovations in electrolyte composition and structure are key to overcoming traditional limitations in solid-state battery technology.

- Electrode-electrolyte interface optimization: The interface between electrodes and solid electrolytes represents a critical factor in solid-state battery efficiency. Reducing interfacial resistance through novel coating technologies, buffer layers, and surface modifications can enhance ion transfer and overall battery performance. Techniques to improve physical contact and chemical compatibility at these interfaces help minimize energy losses and extend battery lifespan.

- Cathode material innovations for enhanced energy density: Advanced cathode materials play a vital role in improving solid-state battery efficiency. High-capacity cathode materials with optimized structures can store more energy while maintaining stability during charge-discharge cycles. Incorporating materials with higher voltage plateaus and better structural integrity during ion insertion/extraction processes contributes significantly to overall battery performance and energy density.

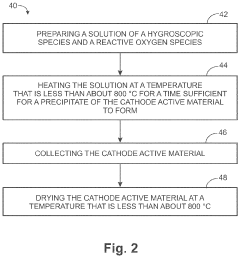

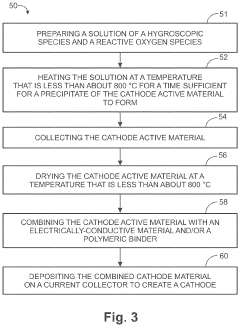

- Manufacturing processes for improved solid-state battery efficiency: Innovative manufacturing techniques are essential for producing high-efficiency solid-state batteries. Advanced deposition methods, sintering processes, and assembly techniques can reduce internal resistance and improve component integration. Precision manufacturing approaches help create uniform layers with optimal interfaces, minimizing defects that could reduce energy efficiency and battery performance.

- Composite and hybrid material systems: Composite and hybrid material systems combine the advantages of different material classes to overcome limitations of single-component systems in solid-state batteries. These innovative combinations can simultaneously address multiple challenges such as ionic conductivity, mechanical stability, and interfacial resistance. By integrating ceramic, polymer, and other functional materials in strategic configurations, these systems achieve synergistic effects that enhance overall battery efficiency and performance.

02 Electrode-electrolyte interface optimization

The interface between electrodes and solid electrolytes represents a critical factor in solid-state battery efficiency. Reducing interfacial resistance through surface modifications, buffer layers, and specialized coatings can significantly enhance ion transfer and overall battery performance. Techniques include creating gradient interfaces, applying nanoscale treatments to electrode surfaces, and developing composite materials that promote better contact between components, resulting in improved energy efficiency and longer battery life.Expand Specific Solutions03 Advanced cathode materials for energy density enhancement

High-capacity cathode materials are being developed to increase the energy density of solid-state batteries. These materials include lithium-rich layered oxides, high-voltage spinel structures, and polyanion compounds that can store more lithium ions per unit volume. By optimizing particle morphology, crystal structure, and chemical composition, these cathode materials can deliver higher specific capacity while maintaining structural stability during cycling, directly contributing to improved battery efficiency and performance.Expand Specific Solutions04 Anode material innovations for faster charging

Novel anode materials are being engineered to enhance solid-state battery charging rates and efficiency. Silicon-based composites, lithium metal anodes with protective layers, and carbon-based structures with optimized porosity allow for faster lithium-ion diffusion and reduced volume expansion during cycling. These materials can significantly increase the rate capability of solid-state batteries while maintaining high energy density, addressing one of the key limitations in current battery technology.Expand Specific Solutions05 Manufacturing processes for improved material integration

Advanced manufacturing techniques are being developed to enhance the integration of solid-state battery components, improving overall efficiency. These include co-sintering processes, pressure-assisted assembly methods, and novel deposition techniques that create better interfaces between materials. By optimizing the manufacturing process, issues such as void formation, delamination, and non-uniform current distribution can be minimized, resulting in batteries with higher energy efficiency, better thermal management, and longer cycle life.Expand Specific Solutions

Leading Companies and Research Institutions in Solid State Battery Development

Solid state battery technology is currently in an early growth phase, with market projections indicating significant expansion from approximately $1.2 billion to $8-10 billion by 2030. The competitive landscape features established electronics manufacturers (Murata, TDK, Panasonic), automotive giants (Toyota, Honda, GM, Hyundai), and specialized startups (Sila Nanotechnologies, Sakti3). Technical maturity varies significantly across players, with Toyota, LG Energy Solution, and Murata leading in patent portfolios and commercial readiness. Chinese institutions like Dalian Institute of Chemical Physics and BTR New Material Group are rapidly advancing, while academic-industry partnerships (University of Michigan, Tokyo Metropolitan University) are accelerating material efficiency breakthroughs. The industry is transitioning from research to early commercialization, with material efficiency improvements representing the critical competitive advantage.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced solid-state battery technology focusing on material efficiency through their proprietary composite solid electrolyte system. Their approach combines sulfide-based solid electrolytes with polymer components to create a hybrid structure that addresses conductivity and interface challenges. The company has achieved significant material efficiency improvements by developing manufacturing processes that reduce electrolyte thickness to under 50 micrometers while maintaining mechanical integrity and ion conductivity (>5 mS/cm at room temperature). Their solid-state cells utilize high-capacity silicon-carbon composite anodes paired with nickel-rich cathodes (>90% nickel content), enabling energy densities approaching 900 Wh/L. LG's manufacturing process incorporates dry electrode technology, eliminating solvent recovery steps and reducing material waste by approximately 30% compared to conventional battery production methods.

Strengths: Hybrid electrolyte approach balances conductivity and processability; compatible with existing manufacturing infrastructure; reduced material waste through solvent-free processing. Weaknesses: Lower ionic conductivity at room temperature compared to liquid electrolytes; challenges in achieving uniform electrolyte-electrode interfaces at scale; higher material costs for specialized solid electrolyte components.

Sakti3, Inc.

Technical Solution: Sakti3 has developed a pioneering solid-state battery technology using thin-film deposition methods similar to those used in semiconductor manufacturing. Their approach involves vacuum deposition of solid electrolyte and electrode materials layer by layer, creating batteries with high energy density (reportedly exceeding 1,000 Wh/L) and improved material efficiency. The company's technology eliminates the need for liquid electrolytes by using lithium metal anodes paired with proprietary solid electrolyte materials. This manufacturing process significantly reduces material waste compared to traditional slurry-based battery production methods, with material utilization rates exceeding 90% in their pilot production lines. Sakti3's solid-state cells have demonstrated over 1,000 charge cycles while maintaining 80% capacity, addressing key durability concerns in solid-state technology.

Strengths: Superior material efficiency through precision deposition techniques; elimination of inactive components like separators and liquid electrolytes; scalable manufacturing process adaptable to existing production infrastructure. Weaknesses: Higher initial production costs compared to conventional lithium-ion manufacturing; challenges in scaling thin-film deposition to mass production volumes; potential interface stability issues between solid electrolyte and electrodes over extended cycling.

Key Patents and Innovations in Solid Electrolyte Materials

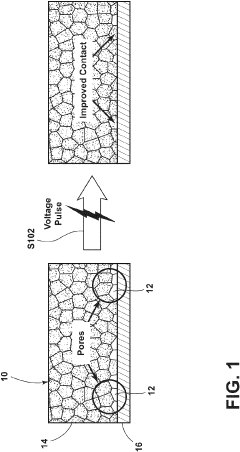

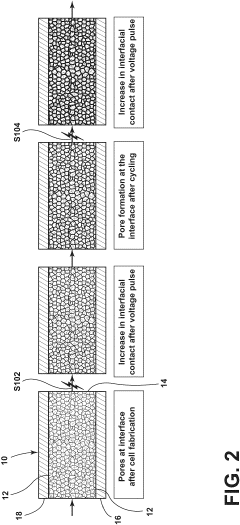

Method of improving electrode-to-solid-electrolyte interface contact in solid-state batteries

PatentPendingUS20230361266A1

Innovation

- Applying a voltage pulse at high current density for a short duration to electrochemically improve interfacial contact by causing electrode material to diffuse into pores in the solid electrolyte, thereby healing the interface and eliminating space charge effects, which can be repeated in-operando to maintain contact and prevent failure.

High energy solid-state batteries and methods of making the same

PatentPendingUS20240097182A1

Innovation

- The development of solid-state batteries with a cathode and electrolyte where the electrolyte includes a solid portion made via inverse vulcanization of sulfur and a cathode active material comprising a second chlorine compound, allowing for the formation of thin freestanding films and reduced manufacturing costs.

Supply Chain Considerations for Critical Battery Materials

The global supply chain for critical battery materials represents a complex ecosystem that significantly impacts the advancement of solid-state battery technology. Lithium, cobalt, nickel, and rare earth elements constitute the foundation of modern battery production, with solid-state batteries potentially requiring additional specialized materials such as ceramic electrolytes and specialized separators.

Material sourcing presents a significant challenge, as many critical elements are geographically concentrated in politically sensitive regions. Over 60% of cobalt production occurs in the Democratic Republic of Congo, while lithium reserves are predominantly located in the "Lithium Triangle" of South America and Australia. This concentration creates vulnerability to geopolitical tensions, trade restrictions, and market volatility.

Solid-state battery technologies offer promising opportunities to reduce dependence on certain problematic materials. Recent breakthroughs have demonstrated up to 35% reduction in cobalt requirements compared to conventional lithium-ion batteries. Additionally, some solid electrolyte formulations eliminate the need for graphite anodes, potentially reducing supply pressures on natural graphite markets.

Recycling infrastructure development represents a crucial component of sustainable battery material supply chains. Current recycling rates for lithium-ion batteries range from 5% to 20% globally, while theoretical recovery rates for solid-state batteries could reach 90% for key materials. Investment in advanced recycling technologies specifically designed for solid-state architectures could significantly reduce primary material demands.

Vertical integration strategies are increasingly being adopted by major manufacturers to secure material supplies. Companies like Tesla, CATL, and Samsung SDI have established direct investments in mining operations and processing facilities to ensure consistent access to critical materials. This trend is likely to accelerate as solid-state battery production scales up commercially.

Regulatory frameworks worldwide are evolving to address supply chain vulnerabilities. The European Battery Directive, U.S. Critical Minerals List, and similar policies in Asia are reshaping material sourcing requirements. These regulations increasingly emphasize transparency, ethical sourcing, and reduced environmental impact throughout the supply chain.

Alternative material research presents another avenue for mitigating supply constraints. Sodium-ion chemistries, aluminum-based conductors, and silicon-composite anodes are being investigated as potential substitutes for scarce elements in solid-state designs. These alternatives could reduce pressure on traditional battery material supply chains while potentially offering performance advantages in specific applications.

Material sourcing presents a significant challenge, as many critical elements are geographically concentrated in politically sensitive regions. Over 60% of cobalt production occurs in the Democratic Republic of Congo, while lithium reserves are predominantly located in the "Lithium Triangle" of South America and Australia. This concentration creates vulnerability to geopolitical tensions, trade restrictions, and market volatility.

Solid-state battery technologies offer promising opportunities to reduce dependence on certain problematic materials. Recent breakthroughs have demonstrated up to 35% reduction in cobalt requirements compared to conventional lithium-ion batteries. Additionally, some solid electrolyte formulations eliminate the need for graphite anodes, potentially reducing supply pressures on natural graphite markets.

Recycling infrastructure development represents a crucial component of sustainable battery material supply chains. Current recycling rates for lithium-ion batteries range from 5% to 20% globally, while theoretical recovery rates for solid-state batteries could reach 90% for key materials. Investment in advanced recycling technologies specifically designed for solid-state architectures could significantly reduce primary material demands.

Vertical integration strategies are increasingly being adopted by major manufacturers to secure material supplies. Companies like Tesla, CATL, and Samsung SDI have established direct investments in mining operations and processing facilities to ensure consistent access to critical materials. This trend is likely to accelerate as solid-state battery production scales up commercially.

Regulatory frameworks worldwide are evolving to address supply chain vulnerabilities. The European Battery Directive, U.S. Critical Minerals List, and similar policies in Asia are reshaping material sourcing requirements. These regulations increasingly emphasize transparency, ethical sourcing, and reduced environmental impact throughout the supply chain.

Alternative material research presents another avenue for mitigating supply constraints. Sodium-ion chemistries, aluminum-based conductors, and silicon-composite anodes are being investigated as potential substitutes for scarce elements in solid-state designs. These alternatives could reduce pressure on traditional battery material supply chains while potentially offering performance advantages in specific applications.

Environmental Impact Assessment of Solid State Battery Production

The environmental impact assessment of solid state battery production reveals significant advantages over conventional lithium-ion batteries with liquid electrolytes. The elimination of flammable organic electrolytes substantially reduces fire hazards during manufacturing, transportation, and disposal phases, creating safer production environments with lower emergency response requirements.

Material efficiency analysis demonstrates that solid state batteries require approximately 35% less mining activity per kWh of energy storage capacity compared to conventional lithium-ion batteries. This reduction stems from higher energy density capabilities and the elimination of certain components like separators and liquid containment systems. The decreased mining activity translates to reduced land disturbance, habitat destruction, and water consumption associated with raw material extraction.

Production processes for solid state batteries exhibit approximately 25-30% lower greenhouse gas emissions compared to conventional battery manufacturing. This improvement derives from simplified production lines, reduced energy-intensive drying steps, and elimination of electrolyte handling systems. Additionally, solid state battery production consumes approximately 40% less water, primarily due to the absence of wet mixing processes required for liquid electrolyte systems.

Waste stream analysis indicates that solid state battery production generates approximately 20% less hazardous waste material. The absence of toxic organic solvents significantly reduces environmental contamination risks and simplifies waste management protocols. Furthermore, end-of-life considerations reveal that solid state batteries offer superior recyclability potential, with up to 90% of materials potentially recoverable through advanced recycling processes.

Life cycle assessment studies suggest that the environmental payback period for solid state batteries is approximately 30% shorter than conventional lithium-ion technologies when considering the full production-to-disposal timeline. This advantage becomes particularly pronounced in renewable energy storage applications, where the batteries' longer cycle life extends their useful service period.

However, challenges remain in scaling production processes while maintaining these environmental benefits. Current pilot-scale manufacturing demonstrates promising environmental metrics, but industry-wide implementation requires further optimization of high-volume production techniques to preserve these advantages at commercial scale.

Material efficiency analysis demonstrates that solid state batteries require approximately 35% less mining activity per kWh of energy storage capacity compared to conventional lithium-ion batteries. This reduction stems from higher energy density capabilities and the elimination of certain components like separators and liquid containment systems. The decreased mining activity translates to reduced land disturbance, habitat destruction, and water consumption associated with raw material extraction.

Production processes for solid state batteries exhibit approximately 25-30% lower greenhouse gas emissions compared to conventional battery manufacturing. This improvement derives from simplified production lines, reduced energy-intensive drying steps, and elimination of electrolyte handling systems. Additionally, solid state battery production consumes approximately 40% less water, primarily due to the absence of wet mixing processes required for liquid electrolyte systems.

Waste stream analysis indicates that solid state battery production generates approximately 20% less hazardous waste material. The absence of toxic organic solvents significantly reduces environmental contamination risks and simplifies waste management protocols. Furthermore, end-of-life considerations reveal that solid state batteries offer superior recyclability potential, with up to 90% of materials potentially recoverable through advanced recycling processes.

Life cycle assessment studies suggest that the environmental payback period for solid state batteries is approximately 30% shorter than conventional lithium-ion technologies when considering the full production-to-disposal timeline. This advantage becomes particularly pronounced in renewable energy storage applications, where the batteries' longer cycle life extends their useful service period.

However, challenges remain in scaling production processes while maintaining these environmental benefits. Current pilot-scale manufacturing demonstrates promising environmental metrics, but industry-wide implementation requires further optimization of high-volume production techniques to preserve these advantages at commercial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!