Exploring the Influence of Solid State Battery Breakthrough on Electronics Standards

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid State Battery Evolution and Objectives

Solid state battery technology has evolved significantly over the past few decades, transitioning from theoretical concepts to increasingly viable commercial solutions. The journey began in the 1970s with the discovery of solid electrolytes, but meaningful progress accelerated in the early 2000s when safety concerns with traditional lithium-ion batteries prompted renewed interest in solid-state alternatives. This evolution has been characterized by persistent efforts to overcome key technical challenges, particularly related to electrolyte conductivity, interface stability, and manufacturing scalability.

The fundamental advantage of solid state batteries lies in their replacement of flammable liquid electrolytes with solid materials, offering enhanced safety, higher energy density, and potentially longer lifespan. Recent breakthroughs in ceramic and polymer-based electrolytes have demonstrated ionic conductivities approaching those of liquid electrolytes, marking a critical milestone in the technology's development trajectory.

Current technological objectives focus on several key areas. First, improving room-temperature ionic conductivity remains paramount, with researchers targeting conductivity values exceeding 10^-3 S/cm to enable practical applications. Second, addressing the solid-solid interface challenges between electrodes and electrolytes represents a critical hurdle, as poor contact leads to increased resistance and reduced performance. Third, developing cost-effective manufacturing processes suitable for mass production is essential for commercial viability.

The evolution of solid state battery technology is increasingly intertwined with electronics standards development. As these batteries approach commercial readiness, there is growing recognition of the need for standardized testing protocols, safety certifications, and interface specifications. The unique characteristics of solid state batteries—including different thermal behaviors, voltage profiles, and charging requirements—necessitate revisions to existing electronics standards that were primarily developed for liquid-electrolyte systems.

Looking forward, the technological roadmap for solid state batteries aims to achieve energy densities exceeding 500 Wh/kg by 2025, with cost targets below $100/kWh to enable mass-market adoption. Parallel objectives include extending cycle life beyond 1,000 full charge-discharge cycles and reducing charging times to under 15 minutes without compromising safety or longevity.

The convergence of these technological objectives with evolving electronics standards represents a critical inflection point. As solid state batteries move from laboratory demonstrations to commercial products, their integration into electronic devices will require significant adaptation of existing standards and potentially the development of entirely new regulatory frameworks to address their unique characteristics and capabilities.

The fundamental advantage of solid state batteries lies in their replacement of flammable liquid electrolytes with solid materials, offering enhanced safety, higher energy density, and potentially longer lifespan. Recent breakthroughs in ceramic and polymer-based electrolytes have demonstrated ionic conductivities approaching those of liquid electrolytes, marking a critical milestone in the technology's development trajectory.

Current technological objectives focus on several key areas. First, improving room-temperature ionic conductivity remains paramount, with researchers targeting conductivity values exceeding 10^-3 S/cm to enable practical applications. Second, addressing the solid-solid interface challenges between electrodes and electrolytes represents a critical hurdle, as poor contact leads to increased resistance and reduced performance. Third, developing cost-effective manufacturing processes suitable for mass production is essential for commercial viability.

The evolution of solid state battery technology is increasingly intertwined with electronics standards development. As these batteries approach commercial readiness, there is growing recognition of the need for standardized testing protocols, safety certifications, and interface specifications. The unique characteristics of solid state batteries—including different thermal behaviors, voltage profiles, and charging requirements—necessitate revisions to existing electronics standards that were primarily developed for liquid-electrolyte systems.

Looking forward, the technological roadmap for solid state batteries aims to achieve energy densities exceeding 500 Wh/kg by 2025, with cost targets below $100/kWh to enable mass-market adoption. Parallel objectives include extending cycle life beyond 1,000 full charge-discharge cycles and reducing charging times to under 15 minutes without compromising safety or longevity.

The convergence of these technological objectives with evolving electronics standards represents a critical inflection point. As solid state batteries move from laboratory demonstrations to commercial products, their integration into electronic devices will require significant adaptation of existing standards and potentially the development of entirely new regulatory frameworks to address their unique characteristics and capabilities.

Market Demand Analysis for Advanced Battery Technologies

The global market for advanced battery technologies is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and renewable energy storage systems. Current projections indicate the advanced battery market will reach approximately $168 billion by 2030, with solid-state batteries potentially capturing a significant portion of this value. This growth trajectory is supported by compound annual growth rates exceeding 25% in key application segments.

Consumer electronics manufacturers are increasingly demanding batteries with higher energy density, faster charging capabilities, and enhanced safety profiles. The current lithium-ion battery limitations—particularly regarding energy density ceiling of about 300 Wh/kg and safety concerns—have created substantial market pull for solid-state alternatives that promise to deliver energy densities potentially exceeding 500 Wh/kg while eliminating flammability risks.

The automotive sector represents the most significant demand driver, with major manufacturers committing billions to electrification strategies. Market research indicates that range anxiety remains the primary barrier to EV adoption, with 78% of potential buyers citing battery performance as their top concern. Solid-state technology directly addresses this pain point by potentially increasing driving ranges by 50-80% compared to conventional lithium-ion solutions.

Industrial and grid-scale storage applications constitute another rapidly expanding market segment, projected to grow at 32% annually through 2028. The demand for longer duration storage solutions with improved safety characteristics makes solid-state technology particularly attractive for these applications, where the cost of battery failure or safety incidents can be extraordinarily high.

Regional analysis reveals differentiated market demands, with North American and European markets prioritizing performance and safety, while Asian markets demonstrate greater price sensitivity. However, all regions show strong interest in solid-state technology's potential to revolutionize electronics standards and enable new product categories previously constrained by battery limitations.

Consumer surveys indicate willingness to pay premiums of 15-20% for devices with significantly improved battery performance, particularly in premium smartphone and laptop segments. This price elasticity suggests solid-state batteries could command substantial market share even during early commercialization phases when costs remain higher than conventional alternatives.

The regulatory landscape is further accelerating demand, with several jurisdictions implementing increasingly stringent safety standards for battery-powered devices. The European Union's proposed Battery Regulation and similar initiatives in North America create regulatory tailwinds for solid-state technology adoption, as manufacturers seek compliant solutions that can meet both performance and safety requirements.

Consumer electronics manufacturers are increasingly demanding batteries with higher energy density, faster charging capabilities, and enhanced safety profiles. The current lithium-ion battery limitations—particularly regarding energy density ceiling of about 300 Wh/kg and safety concerns—have created substantial market pull for solid-state alternatives that promise to deliver energy densities potentially exceeding 500 Wh/kg while eliminating flammability risks.

The automotive sector represents the most significant demand driver, with major manufacturers committing billions to electrification strategies. Market research indicates that range anxiety remains the primary barrier to EV adoption, with 78% of potential buyers citing battery performance as their top concern. Solid-state technology directly addresses this pain point by potentially increasing driving ranges by 50-80% compared to conventional lithium-ion solutions.

Industrial and grid-scale storage applications constitute another rapidly expanding market segment, projected to grow at 32% annually through 2028. The demand for longer duration storage solutions with improved safety characteristics makes solid-state technology particularly attractive for these applications, where the cost of battery failure or safety incidents can be extraordinarily high.

Regional analysis reveals differentiated market demands, with North American and European markets prioritizing performance and safety, while Asian markets demonstrate greater price sensitivity. However, all regions show strong interest in solid-state technology's potential to revolutionize electronics standards and enable new product categories previously constrained by battery limitations.

Consumer surveys indicate willingness to pay premiums of 15-20% for devices with significantly improved battery performance, particularly in premium smartphone and laptop segments. This price elasticity suggests solid-state batteries could command substantial market share even during early commercialization phases when costs remain higher than conventional alternatives.

The regulatory landscape is further accelerating demand, with several jurisdictions implementing increasingly stringent safety standards for battery-powered devices. The European Union's proposed Battery Regulation and similar initiatives in North America create regulatory tailwinds for solid-state technology adoption, as manufacturers seek compliant solutions that can meet both performance and safety requirements.

Current Challenges in Solid State Battery Development

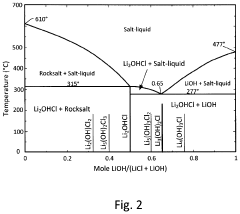

Despite significant advancements in solid-state battery technology, several critical challenges continue to impede widespread commercialization and standardization efforts. The most persistent obstacle remains the solid electrolyte interface, where issues of ionic conductivity at room temperature significantly lag behind conventional liquid electrolytes. Current solid electrolytes achieve conductivities of 10^-4 to 10^-3 S/cm, whereas commercial applications require at least 10^-2 S/cm for practical operation.

Manufacturing scalability presents another formidable challenge. Laboratory-scale production methods for solid-state batteries often involve complex processes that are difficult to translate to mass production environments. The precision required for creating uniform, defect-free interfaces between solid components demands manufacturing tolerances that exceed current industrial capabilities, resulting in high production costs and yield issues.

Mechanical stability during cycling represents a significant technical hurdle. The volume changes that occur during lithium intercalation and de-intercalation create mechanical stresses at the electrode-electrolyte interfaces. These stresses can lead to contact loss, increased internal resistance, and ultimately, premature battery failure. Current solutions involving pressure application are impractical for many consumer electronics applications where space and weight constraints are paramount.

Dendrite formation, contrary to early expectations, remains problematic even in solid-state configurations. Recent research has demonstrated that lithium metal can still penetrate certain solid electrolytes along grain boundaries or through microscopic defects, creating potential short-circuit risks. This challenges the fundamental safety advantage often attributed to solid-state technology.

Cost factors continue to inhibit commercial viability. Current manufacturing processes for high-quality solid electrolytes and specialized electrode materials involve expensive precursors and energy-intensive production methods. The cost per kWh for prototype solid-state batteries remains 5-8 times higher than conventional lithium-ion batteries, placing them beyond practical implementation for most consumer electronics applications.

Temperature sensitivity presents additional complications for standardization efforts. Many promising solid electrolyte materials exhibit optimal performance only within narrow temperature ranges, limiting their applicability across diverse operating environments. This variability complicates the development of universal standards that could accelerate industry adoption.

Cycle life and long-term stability data remain insufficient for establishing reliable standards. While laboratory prototypes have demonstrated promising initial performance, degradation mechanisms specific to solid-state configurations are not fully characterized. The lack of accelerated testing protocols validated for solid-state systems further complicates efforts to predict lifetime performance and establish appropriate warranty and reliability standards.

Manufacturing scalability presents another formidable challenge. Laboratory-scale production methods for solid-state batteries often involve complex processes that are difficult to translate to mass production environments. The precision required for creating uniform, defect-free interfaces between solid components demands manufacturing tolerances that exceed current industrial capabilities, resulting in high production costs and yield issues.

Mechanical stability during cycling represents a significant technical hurdle. The volume changes that occur during lithium intercalation and de-intercalation create mechanical stresses at the electrode-electrolyte interfaces. These stresses can lead to contact loss, increased internal resistance, and ultimately, premature battery failure. Current solutions involving pressure application are impractical for many consumer electronics applications where space and weight constraints are paramount.

Dendrite formation, contrary to early expectations, remains problematic even in solid-state configurations. Recent research has demonstrated that lithium metal can still penetrate certain solid electrolytes along grain boundaries or through microscopic defects, creating potential short-circuit risks. This challenges the fundamental safety advantage often attributed to solid-state technology.

Cost factors continue to inhibit commercial viability. Current manufacturing processes for high-quality solid electrolytes and specialized electrode materials involve expensive precursors and energy-intensive production methods. The cost per kWh for prototype solid-state batteries remains 5-8 times higher than conventional lithium-ion batteries, placing them beyond practical implementation for most consumer electronics applications.

Temperature sensitivity presents additional complications for standardization efforts. Many promising solid electrolyte materials exhibit optimal performance only within narrow temperature ranges, limiting their applicability across diverse operating environments. This variability complicates the development of universal standards that could accelerate industry adoption.

Cycle life and long-term stability data remain insufficient for establishing reliable standards. While laboratory prototypes have demonstrated promising initial performance, degradation mechanisms specific to solid-state configurations are not fully characterized. The lack of accelerated testing protocols validated for solid-state systems further complicates efforts to predict lifetime performance and establish appropriate warranty and reliability standards.

Current Electronics Standards Adaptation Approaches

01 Safety and testing standards for solid-state batteries

Safety and testing standards are crucial for solid-state batteries to ensure their reliable and safe operation in electronic devices. These standards include protocols for thermal stability testing, mechanical integrity assessment, and electrical safety evaluation. Standardized testing methods help manufacturers validate battery performance under various conditions and ensure compliance with industry requirements for consumer electronics and automotive applications.- Safety and testing standards for solid state batteries: Safety and testing standards are crucial for solid state batteries to ensure their reliability and performance. These standards include protocols for thermal stability testing, mechanical integrity assessment, and electrical safety evaluation. Standardized testing methods help in comparing different solid state battery technologies and ensuring they meet industry requirements for safe operation in electronic devices.

- Electrode interface design standards: Standards for electrode interface design in solid state batteries focus on optimizing the contact between solid electrolytes and electrodes. These standards address issues such as interfacial resistance, mechanical stability during cycling, and chemical compatibility between components. Proper interface design is critical for achieving high energy density, fast charging capabilities, and long cycle life in solid state battery systems.

- Electrolyte composition and performance standards: Standards for solid electrolyte materials define the required ionic conductivity, electrochemical stability window, and mechanical properties. These standards ensure that solid electrolytes can effectively transport ions while maintaining stability against lithium metal anodes and high-voltage cathodes. Performance metrics include temperature range operability, resistance to dendrite formation, and compatibility with manufacturing processes.

- Manufacturing process standardization: Standardization of manufacturing processes for solid state batteries ensures consistency in production and quality control. These standards cover aspects such as layer deposition techniques, assembly protocols, and quality assurance methods. Manufacturing standards address challenges in scaling production while maintaining performance, including specifications for cleanroom environments, material handling, and process validation.

- Integration standards for electronic devices: Integration standards define how solid state batteries interface with electronic systems, including form factors, connection protocols, and thermal management requirements. These standards ensure compatibility with existing electronic architectures while leveraging the unique advantages of solid state technology. They address power management, battery management systems, and safety circuits specifically designed for solid state battery characteristics.

02 Electrode interface design standards

Standards for electrode interface design in solid-state batteries focus on optimizing the contact between solid electrolytes and electrodes. These standards address issues such as interfacial resistance, mechanical stability, and chemical compatibility. Proper interface design is essential for maximizing ion transport efficiency and preventing degradation during cycling, which directly impacts battery performance and longevity in electronic applications.Expand Specific Solutions03 Electrolyte composition and performance standards

Standards for solid electrolyte materials in batteries define requirements for ionic conductivity, electrochemical stability, and mechanical properties. These standards ensure that solid electrolytes meet minimum performance thresholds for electronic applications while maintaining safety. Standardized testing protocols for electrolyte evaluation help in comparing different materials and formulations across the industry, facilitating innovation while maintaining quality benchmarks.Expand Specific Solutions04 Manufacturing process standardization

Manufacturing standards for solid-state batteries establish consistent production methods and quality control processes. These standards cover aspects such as material purity requirements, layer deposition techniques, assembly protocols, and defect detection methodologies. Standardized manufacturing processes are essential for scaling up production while maintaining consistent performance and reliability of solid-state batteries for various electronic applications.Expand Specific Solutions05 Integration standards with electronic systems

Integration standards define requirements for incorporating solid-state batteries into electronic devices and systems. These standards address electrical connections, thermal management interfaces, form factors, and communication protocols between battery management systems and host devices. Standardized integration approaches ensure compatibility across different manufacturers and applications, facilitating the adoption of solid-state battery technology in consumer electronics, medical devices, and industrial systems.Expand Specific Solutions

Leading Companies in Solid State Battery Innovation

The solid state battery market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. Market size is projected to expand rapidly, reaching approximately $6-8 billion by 2030, driven by increasing demand for high-energy density solutions in electronics and electric vehicles. Technologically, the field is advancing from laboratory prototypes toward commercial viability, with companies at varying stages of development. Leading players include established electronics manufacturers (Samsung Electronics, Murata Manufacturing, Panasonic), automotive companies (Hyundai, Kia), and specialized battery developers (CATL, LG Energy Solution, Sila Nanotechnologies). University research partnerships (Michigan, Georgia Tech, Central South) are accelerating innovation, while companies like QuantumScape and Solid Power are pushing toward commercialization with significant industry backing.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an advanced solid-state battery technology utilizing a multi-layered ceramic-polymer composite electrolyte system. Their approach combines the high ionic conductivity of ceramic materials with the flexibility and processability of polymers, creating a solid electrolyte that achieves conductivities of 5-7 mS/cm at room temperature. Panasonic's manufacturing innovation includes a proprietary "sheet-to-sheet" production process that enables precise control of layer thickness and interface quality. Their solid-state batteries incorporate a specialized lithium metal anode protection layer that prevents dendrite formation while enabling high energy density. Panasonic has also developed new electrode formulations specifically optimized for solid-state operation, with modified binders and conductive additives that maintain intimate contact with the solid electrolyte during cycling. This technology has demonstrated over 1,000 cycles with minimal capacity degradation in prototype cells.

Strengths: Excellent cycling stability suitable for consumer electronics applications; manufacturing process is adaptable to existing production facilities; enhanced safety profile eliminates thermal runaway concerns. Weaknesses: Higher material costs compared to conventional lithium-ion batteries; temperature sensitivity may limit performance in extreme conditions; integration challenges with existing battery management systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed a first-generation solid-state battery technology called Condensed Battery that uses a condensed matter electrolyte structure. This technology achieves energy densities of up to 500 Wh/kg, significantly higher than conventional lithium-ion batteries. CATL's approach involves a novel composite electrolyte system that combines inorganic solid electrolytes with specialized polymers to create a stable interface between electrodes. Their manufacturing process integrates existing production lines with new deposition techniques for the solid electrolyte layers, allowing for scalable production while maintaining compatibility with current electronics standards. CATL has also developed proprietary interface engineering techniques to address the common solid-state battery challenge of high interfacial resistance, enabling faster charging capabilities and longer cycle life compared to conventional batteries.

Strengths: High energy density (500 Wh/kg) provides longer device operation; manufacturing process leverages existing production infrastructure, reducing implementation costs; improved safety with non-flammable electrolytes. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; potential challenges with low-temperature performance; interface stability issues may still affect long-term cycling performance.

Key Patents and Research in Solid State Battery Technology

Method of manufacturing a solid-state lithium battery and a battery manufactured by the method

PatentActiveUS20230044416A1

Innovation

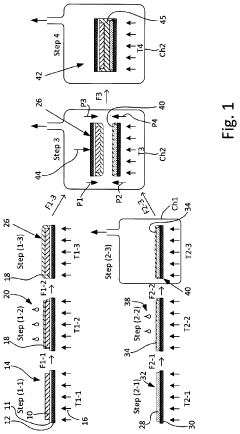

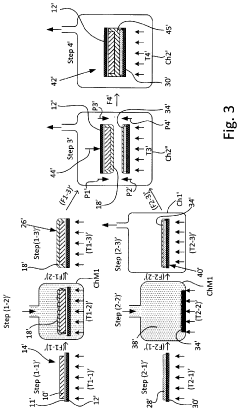

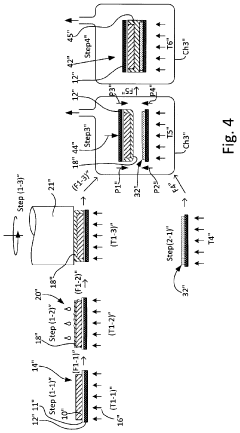

- A method involving the coating of anode and cathode units with solid-state electrolyte precursors, followed by pressing them together at elevated temperatures and mechanical pressure to form a pre-final solid-state battery unit, with controlled heating and pressure to manage redundant water and hydrogen, ensuring the formation of an integral solid-state electrolyte.

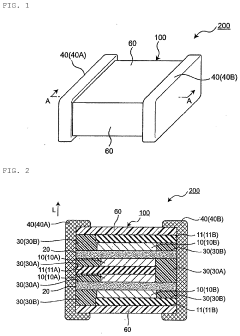

Solid state battery

PatentPendingUS20220320590A1

Innovation

- A solid state battery design incorporating a positive electrode active material with a specific lattice plane spacing of 4.800 Å or more at a positive electrode potential of 4.55 V, which maintains stability and reduces contraction, thereby preventing peeling and improving cycle characteristics.

Regulatory Framework for Next-Generation Battery Implementation

The regulatory landscape for solid-state battery technology is rapidly evolving as these breakthrough energy storage solutions approach commercial viability. Current regulatory frameworks primarily address traditional lithium-ion batteries, creating a significant gap in standards specifically designed for solid-state technology. This regulatory vacuum presents both challenges and opportunities for industry stakeholders and policymakers alike.

International standards organizations including ISO, IEC, and UL are actively developing new testing protocols and safety standards tailored to solid-state battery characteristics. These efforts focus on addressing the unique properties of solid electrolytes, which eliminate many flammability concerns associated with liquid electrolytes but introduce new considerations regarding mechanical stability and interface dynamics.

Safety certification requirements represent a critical component of the regulatory framework. While solid-state batteries offer inherent safety advantages through reduced fire risk, regulatory bodies must establish appropriate testing methodologies to verify performance under extreme conditions, thermal runaway resistance, and long-term stability. The European Union's Battery Directive and similar regulations in North America and Asia are undergoing revisions to incorporate solid-state specific provisions.

Transportation regulations present another key regulatory consideration. Current dangerous goods regulations (UN 38.3) for battery shipping were designed primarily for liquid-electrolyte systems. Regulatory bodies including IATA, IMO, and DOT are evaluating how solid-state technologies may qualify for less restrictive shipping classifications, potentially reducing logistics costs and expanding market access.

Environmental compliance frameworks are simultaneously evolving to address the lifecycle management of solid-state batteries. The EU's proposed Battery Regulation emphasizes sustainability metrics including carbon footprint declarations, ethical sourcing requirements, and end-of-life recycling provisions. These regulations will significantly impact solid-state battery manufacturers' material selection and production processes.

Interoperability standards represent another regulatory frontier. As solid-state batteries enter consumer electronics markets, standards bodies must establish protocols ensuring compatibility across devices and charging infrastructure. This includes defining communication protocols between battery management systems and host devices to optimize performance and longevity.

Regulatory harmonization across global markets remains a significant challenge. Divergent approaches between major economic regions could create market fragmentation and increase compliance costs. Industry consortia and international standards organizations are working to promote regulatory convergence, though geopolitical considerations and regional industrial policies continue to influence regulatory development.

International standards organizations including ISO, IEC, and UL are actively developing new testing protocols and safety standards tailored to solid-state battery characteristics. These efforts focus on addressing the unique properties of solid electrolytes, which eliminate many flammability concerns associated with liquid electrolytes but introduce new considerations regarding mechanical stability and interface dynamics.

Safety certification requirements represent a critical component of the regulatory framework. While solid-state batteries offer inherent safety advantages through reduced fire risk, regulatory bodies must establish appropriate testing methodologies to verify performance under extreme conditions, thermal runaway resistance, and long-term stability. The European Union's Battery Directive and similar regulations in North America and Asia are undergoing revisions to incorporate solid-state specific provisions.

Transportation regulations present another key regulatory consideration. Current dangerous goods regulations (UN 38.3) for battery shipping were designed primarily for liquid-electrolyte systems. Regulatory bodies including IATA, IMO, and DOT are evaluating how solid-state technologies may qualify for less restrictive shipping classifications, potentially reducing logistics costs and expanding market access.

Environmental compliance frameworks are simultaneously evolving to address the lifecycle management of solid-state batteries. The EU's proposed Battery Regulation emphasizes sustainability metrics including carbon footprint declarations, ethical sourcing requirements, and end-of-life recycling provisions. These regulations will significantly impact solid-state battery manufacturers' material selection and production processes.

Interoperability standards represent another regulatory frontier. As solid-state batteries enter consumer electronics markets, standards bodies must establish protocols ensuring compatibility across devices and charging infrastructure. This includes defining communication protocols between battery management systems and host devices to optimize performance and longevity.

Regulatory harmonization across global markets remains a significant challenge. Divergent approaches between major economic regions could create market fragmentation and increase compliance costs. Industry consortia and international standards organizations are working to promote regulatory convergence, though geopolitical considerations and regional industrial policies continue to influence regulatory development.

Safety and Performance Benchmarking Methodologies

The evolution of solid-state battery technology necessitates robust safety and performance benchmarking methodologies to ensure standardization across the electronics industry. Current benchmarking approaches for lithium-ion batteries prove inadequate for solid-state technologies due to fundamental differences in electrochemical behavior, thermal characteristics, and failure modes.

Standardized testing protocols for solid-state batteries must address unique safety parameters including mechanical integrity under stress, interfacial stability between solid electrolytes and electrodes, and dendrite formation resistance. These parameters require new measurement techniques that can accurately assess the structural stability of solid electrolytes under various operating conditions.

Performance benchmarking for solid-state batteries demands evaluation metrics beyond traditional capacity and cycle life measurements. Key indicators should include ionic conductivity across temperature ranges, power density capabilities, and energy efficiency under variable loads. The absence of liquid electrolytes eliminates certain safety concerns but introduces new performance variables that must be quantified through standardized methodologies.

Accelerated aging tests represent a significant challenge in benchmarking solid-state batteries. Unlike conventional batteries, solid-state systems may exhibit different degradation mechanisms, requiring the development of new protocols that can accurately predict long-term performance and safety characteristics within reasonable testing timeframes.

Thermal runaway resistance testing methodologies need substantial revision for solid-state technologies. While these batteries demonstrate inherently higher thermal stability, standardized tests must still verify performance under extreme conditions, including mechanical puncture, external heating, and electrical abuse scenarios that reflect real-world usage patterns.

Interoperability testing frameworks must be established to ensure solid-state batteries can function seamlessly with existing electronic systems. This includes standardized interfaces for power management systems, charging protocols, and battery management systems that can properly monitor and control solid-state battery parameters.

International harmonization of these benchmarking methodologies presents another challenge. Collaborative efforts between standards organizations, industry leaders, and research institutions are essential to develop globally accepted testing protocols that facilitate market adoption while ensuring consumer safety and performance reliability across diverse electronic applications.

Standardized testing protocols for solid-state batteries must address unique safety parameters including mechanical integrity under stress, interfacial stability between solid electrolytes and electrodes, and dendrite formation resistance. These parameters require new measurement techniques that can accurately assess the structural stability of solid electrolytes under various operating conditions.

Performance benchmarking for solid-state batteries demands evaluation metrics beyond traditional capacity and cycle life measurements. Key indicators should include ionic conductivity across temperature ranges, power density capabilities, and energy efficiency under variable loads. The absence of liquid electrolytes eliminates certain safety concerns but introduces new performance variables that must be quantified through standardized methodologies.

Accelerated aging tests represent a significant challenge in benchmarking solid-state batteries. Unlike conventional batteries, solid-state systems may exhibit different degradation mechanisms, requiring the development of new protocols that can accurately predict long-term performance and safety characteristics within reasonable testing timeframes.

Thermal runaway resistance testing methodologies need substantial revision for solid-state technologies. While these batteries demonstrate inherently higher thermal stability, standardized tests must still verify performance under extreme conditions, including mechanical puncture, external heating, and electrical abuse scenarios that reflect real-world usage patterns.

Interoperability testing frameworks must be established to ensure solid-state batteries can function seamlessly with existing electronic systems. This includes standardized interfaces for power management systems, charging protocols, and battery management systems that can properly monitor and control solid-state battery parameters.

International harmonization of these benchmarking methodologies presents another challenge. Collaborative efforts between standards organizations, industry leaders, and research institutions are essential to develop globally accepted testing protocols that facilitate market adoption while ensuring consumer safety and performance reliability across diverse electronic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!