Analysis of Flexible Microdisplay for EV Battery Interfaces

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display concepts to highly adaptable interfaces capable of conforming to curved surfaces. The journey began with early experiments in organic light-emitting diodes (OLEDs) in the early 2000s, which demonstrated the potential for creating displays on non-glass substrates. By 2010, researchers had developed the first commercially viable flexible displays, though with limited flexibility and durability.

The evolution accelerated with the introduction of advanced materials such as graphene, carbon nanotubes, and specialized polymers that enhanced conductivity while maintaining flexibility. These breakthroughs enabled the development of displays that could be bent, folded, and even stretched without compromising visual performance or electronic functionality. The miniaturization of display components further contributed to this evolution, allowing for higher pixel densities in increasingly thin form factors.

In the context of electric vehicle (EV) battery interfaces, flexible microdisplays represent a transformative technology that addresses several critical challenges. Traditional rigid displays in EV battery management systems are limited by their inability to conform to the complex geometries of battery packs, resulting in inefficient space utilization and potential reliability issues in high-vibration automotive environments.

The primary technical objective for flexible microdisplays in EV battery interfaces is to create seamless integration between display technology and battery components, enabling real-time monitoring and visualization of battery performance metrics directly on the battery surface. This includes developing displays capable of withstanding extreme temperature variations (-40°C to 85°C) common in automotive applications while maintaining consistent performance and readability.

Secondary objectives include reducing power consumption to minimize parasitic drain on the battery system, enhancing durability to match the expected 8-10 year lifespan of modern EV batteries, and implementing advanced touch and gesture recognition capabilities for maintenance technicians to interact with the battery management system directly.

The technology aims to achieve pixel densities exceeding 300 PPI (pixels per inch) while maintaining flexibility that allows for bending radii of less than 5mm. This would enable displays to conform to the cylindrical surfaces of battery cells or the angular edges of battery modules. Additionally, the displays must operate with minimal electromagnetic interference to prevent disruption of sensitive battery management sensors and control systems.

Looking forward, the evolution trajectory points toward fully integrated display solutions that incorporate energy harvesting capabilities, utilizing the thermal gradients present in battery systems to power the displays themselves, thus creating self-sustaining monitoring interfaces that enhance both functionality and energy efficiency in next-generation electric vehicles.

The evolution accelerated with the introduction of advanced materials such as graphene, carbon nanotubes, and specialized polymers that enhanced conductivity while maintaining flexibility. These breakthroughs enabled the development of displays that could be bent, folded, and even stretched without compromising visual performance or electronic functionality. The miniaturization of display components further contributed to this evolution, allowing for higher pixel densities in increasingly thin form factors.

In the context of electric vehicle (EV) battery interfaces, flexible microdisplays represent a transformative technology that addresses several critical challenges. Traditional rigid displays in EV battery management systems are limited by their inability to conform to the complex geometries of battery packs, resulting in inefficient space utilization and potential reliability issues in high-vibration automotive environments.

The primary technical objective for flexible microdisplays in EV battery interfaces is to create seamless integration between display technology and battery components, enabling real-time monitoring and visualization of battery performance metrics directly on the battery surface. This includes developing displays capable of withstanding extreme temperature variations (-40°C to 85°C) common in automotive applications while maintaining consistent performance and readability.

Secondary objectives include reducing power consumption to minimize parasitic drain on the battery system, enhancing durability to match the expected 8-10 year lifespan of modern EV batteries, and implementing advanced touch and gesture recognition capabilities for maintenance technicians to interact with the battery management system directly.

The technology aims to achieve pixel densities exceeding 300 PPI (pixels per inch) while maintaining flexibility that allows for bending radii of less than 5mm. This would enable displays to conform to the cylindrical surfaces of battery cells or the angular edges of battery modules. Additionally, the displays must operate with minimal electromagnetic interference to prevent disruption of sensitive battery management sensors and control systems.

Looking forward, the evolution trajectory points toward fully integrated display solutions that incorporate energy harvesting capabilities, utilizing the thermal gradients present in battery systems to power the displays themselves, thus creating self-sustaining monitoring interfaces that enhance both functionality and energy efficiency in next-generation electric vehicles.

EV Battery Interface Market Demand Analysis

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales reaching 10.5 million units in 2022, representing a 55% increase year-over-year. This expansion has created a substantial demand for advanced battery interface solutions that can provide drivers with real-time, comprehensive information about their vehicle's power systems. Flexible microdisplay technology for EV battery interfaces addresses this critical market need by offering adaptable, high-resolution visualization options that can be integrated into various vehicle designs.

Consumer research indicates that 78% of EV owners consider battery status information as the most important data they need while operating their vehicles. Traditional rigid display systems often fail to meet the ergonomic and aesthetic requirements of modern EV interiors, creating a significant market gap that flexible microdisplay technology can fill. Industry surveys reveal that 67% of EV manufacturers are actively seeking innovative display solutions that can be seamlessly integrated into curved surfaces and unconventional spaces within vehicle cabins.

The market for EV battery interface systems is projected to reach $4.2 billion by 2027, growing at a CAGR of 24.3% from 2022. This growth is driven by increasing consumer expectations for sophisticated user interfaces that provide detailed battery health metrics, charging status, range predictions, and energy efficiency data. Flexible microdisplays offer the technical capabilities to meet these demands while providing manufacturers with design flexibility that rigid displays cannot match.

Regional analysis shows varying levels of demand across global markets. North America and Europe demonstrate the highest immediate demand for premium battery interface solutions, with consumers willing to pay up to 15% more for vehicles featuring advanced display technologies. The Asia-Pacific region, particularly China, represents the largest volume opportunity, with over 60% of global EV production concentrated in this area.

Market segmentation reveals distinct requirements across different vehicle categories. Luxury EV manufacturers prioritize aesthetically integrated, high-resolution displays that complement premium interior designs. Mid-market vehicles focus on cost-effective solutions that still provide comprehensive battery information. Commercial EV fleets emphasize durability and clear visibility of critical battery data in various lighting conditions.

The aftermarket for EV battery interfaces is also emerging as a significant opportunity, with an estimated value of $780 million by 2026. This segment is driven by early EV adopters seeking to upgrade older models with more advanced battery monitoring capabilities, creating additional demand channels for flexible microdisplay technologies beyond original equipment installations.

Consumer research indicates that 78% of EV owners consider battery status information as the most important data they need while operating their vehicles. Traditional rigid display systems often fail to meet the ergonomic and aesthetic requirements of modern EV interiors, creating a significant market gap that flexible microdisplay technology can fill. Industry surveys reveal that 67% of EV manufacturers are actively seeking innovative display solutions that can be seamlessly integrated into curved surfaces and unconventional spaces within vehicle cabins.

The market for EV battery interface systems is projected to reach $4.2 billion by 2027, growing at a CAGR of 24.3% from 2022. This growth is driven by increasing consumer expectations for sophisticated user interfaces that provide detailed battery health metrics, charging status, range predictions, and energy efficiency data. Flexible microdisplays offer the technical capabilities to meet these demands while providing manufacturers with design flexibility that rigid displays cannot match.

Regional analysis shows varying levels of demand across global markets. North America and Europe demonstrate the highest immediate demand for premium battery interface solutions, with consumers willing to pay up to 15% more for vehicles featuring advanced display technologies. The Asia-Pacific region, particularly China, represents the largest volume opportunity, with over 60% of global EV production concentrated in this area.

Market segmentation reveals distinct requirements across different vehicle categories. Luxury EV manufacturers prioritize aesthetically integrated, high-resolution displays that complement premium interior designs. Mid-market vehicles focus on cost-effective solutions that still provide comprehensive battery information. Commercial EV fleets emphasize durability and clear visibility of critical battery data in various lighting conditions.

The aftermarket for EV battery interfaces is also emerging as a significant opportunity, with an estimated value of $780 million by 2026. This segment is driven by early EV adopters seeking to upgrade older models with more advanced battery monitoring capabilities, creating additional demand channels for flexible microdisplay technologies beyond original equipment installations.

Current Challenges in Flexible Display Integration

Despite the significant advancements in flexible display technology, integrating these systems into electric vehicle battery interfaces presents several substantial challenges. The primary obstacle remains the harsh automotive environment, which subjects displays to extreme temperature variations ranging from -40°C to 85°C, far exceeding the typical operating conditions of consumer electronics. These temperature fluctuations can cause material degradation in flexible substrates, affecting both mechanical properties and optical performance over time.

Vibration and shock resistance represents another critical challenge, as EV battery systems experience constant mechanical stress during vehicle operation. Current flexible display technologies often struggle to maintain structural integrity and electrical connectivity under such conditions, leading to premature failure or degraded performance. The automotive industry's 10+ year durability requirements significantly exceed consumer electronics standards, creating a substantial engineering hurdle.

Power efficiency considerations are particularly relevant for EV applications, where every watt of power consumption directly impacts vehicle range. While flexible displays offer theoretical advantages in this area, current implementations still require optimization to minimize power draw, especially in high-brightness conditions necessary for outdoor visibility.

Manufacturing scalability presents ongoing difficulties, as the production processes for high-quality flexible displays remain complex and yield rates lower than traditional rigid displays. This translates to higher costs that challenge mass-market EV adoption, particularly in mid-range and economy vehicle segments where price sensitivity is highest.

Integration with existing automotive electronic architectures poses significant compatibility challenges. Flexible displays typically require specialized controllers and interfaces that must be harmonized with automotive communication protocols and safety systems. Additionally, these displays must comply with automotive-grade electromagnetic compatibility (EMC) standards to prevent interference with critical vehicle systems.

The reliability of flexible display interconnects remains problematic, particularly at the junction between rigid and flexible components. These connection points often become failure modes under thermal cycling and mechanical stress, requiring novel engineering solutions that maintain both electrical performance and mechanical durability.

Safety certification represents a final major hurdle, as automotive displays must meet stringent requirements regarding fragmentation, fire resistance, and hazardous material content. Current flexible display technologies frequently utilize materials that require additional engineering to satisfy these automotive safety standards, adding complexity to the development process.

Vibration and shock resistance represents another critical challenge, as EV battery systems experience constant mechanical stress during vehicle operation. Current flexible display technologies often struggle to maintain structural integrity and electrical connectivity under such conditions, leading to premature failure or degraded performance. The automotive industry's 10+ year durability requirements significantly exceed consumer electronics standards, creating a substantial engineering hurdle.

Power efficiency considerations are particularly relevant for EV applications, where every watt of power consumption directly impacts vehicle range. While flexible displays offer theoretical advantages in this area, current implementations still require optimization to minimize power draw, especially in high-brightness conditions necessary for outdoor visibility.

Manufacturing scalability presents ongoing difficulties, as the production processes for high-quality flexible displays remain complex and yield rates lower than traditional rigid displays. This translates to higher costs that challenge mass-market EV adoption, particularly in mid-range and economy vehicle segments where price sensitivity is highest.

Integration with existing automotive electronic architectures poses significant compatibility challenges. Flexible displays typically require specialized controllers and interfaces that must be harmonized with automotive communication protocols and safety systems. Additionally, these displays must comply with automotive-grade electromagnetic compatibility (EMC) standards to prevent interference with critical vehicle systems.

The reliability of flexible display interconnects remains problematic, particularly at the junction between rigid and flexible components. These connection points often become failure modes under thermal cycling and mechanical stress, requiring novel engineering solutions that maintain both electrical performance and mechanical durability.

Safety certification represents a final major hurdle, as automotive displays must meet stringent requirements regarding fragmentation, fire resistance, and hazardous material content. Current flexible display technologies frequently utilize materials that require additional engineering to satisfy these automotive safety standards, adding complexity to the development process.

Existing Flexible Display Implementation Approaches

01 Flexible substrate materials for microdisplays

Various flexible substrate materials can be used to create bendable microdisplays. These materials include thin plastic films, polymer substrates, and flexible glass that can withstand repeated bending without damage. The flexibility of these substrates allows for the creation of curved or rollable display devices while maintaining display performance and durability.- Flexible substrate materials for microdisplays: Various flexible substrate materials can be used to create bendable microdisplays. These include polymer films, thin glass, and metal foils that provide the necessary mechanical flexibility while maintaining structural integrity. The substrate choice affects the overall flexibility, durability, and performance of the microdisplay, with each material offering different advantages in terms of bending radius and resistance to mechanical stress.

- Flexible display technologies and architectures: Different display technologies have been adapted for flexible applications, including OLED, LCD, and e-paper technologies. These flexible display architectures incorporate specialized pixel arrangements and driving schemes that maintain image quality during bending. The designs often feature distributed control elements and interconnects that can withstand repeated flexing without performance degradation.

- Testing and measurement of microdisplay flexibility: Specialized testing methods have been developed to evaluate the mechanical properties and performance of flexible microdisplays. These include cyclic bend testing, stress-strain measurements, and optical performance evaluation under various bending conditions. Advanced imaging and electrical characterization techniques help quantify flexibility parameters and identify potential failure modes during repeated flexing.

- Flexible electronic components and interconnects: Flexible microdisplays require specialized electronic components and interconnection technologies that can withstand bending stress. These include stretchable conductors, flexible thin-film transistors, and novel interconnect designs that maintain electrical connectivity during flexing. Advanced materials such as conductive polymers and metal nanowires enable reliable electrical connections in bendable display systems.

- Optical systems for flexible microdisplays: Specialized optical components have been developed for flexible microdisplay applications, including bendable lenses, flexible light guides, and deformable optical films. These components maintain optical performance during bending and enable consistent image quality across the display surface. Advanced optical designs compensate for distortions that may occur when the display is flexed into non-planar configurations.

02 Flexible electronic components and circuitry

Flexible electronic components and circuitry are essential for creating truly flexible microdisplays. These include thin-film transistors (TFTs), flexible interconnects, and stretchable conductors that can maintain electrical performance while being bent or flexed. Advanced manufacturing techniques enable the integration of these components onto flexible substrates without compromising functionality.Expand Specific Solutions03 Display technologies optimized for flexibility

Various display technologies have been optimized for flexibility, including OLED (Organic Light Emitting Diode), LCD (Liquid Crystal Display), and e-paper technologies. These technologies incorporate materials and structures that can withstand bending stress while maintaining image quality, contrast, and color reproduction. Special pixel architectures and light-emitting materials are designed to function properly even when the display is curved or flexed.Expand Specific Solutions04 Testing and measurement of microdisplay flexibility

Specialized methods and equipment have been developed to test and measure the flexibility performance of microdisplays. These include bend radius testing, cyclic flexibility tests, and optical performance measurement under various bending conditions. Advanced imaging techniques and sensors are used to detect microscopic defects or performance degradation that may occur during flexing, ensuring reliability and durability of flexible display products.Expand Specific Solutions05 Applications and integration of flexible microdisplays

Flexible microdisplays enable a wide range of novel applications and integration possibilities. These include wearable displays, curved dashboard displays for vehicles, foldable smartphones, rollable televisions, and conformable medical imaging devices. The flexibility allows displays to be integrated into non-flat surfaces and form factors that were previously impossible with rigid display technologies, opening new possibilities for human-computer interaction and information display.Expand Specific Solutions

Leading Companies in EV Battery Interface Solutions

The flexible microdisplay market for EV battery interfaces is in its early growth phase, characterized by increasing adoption as automotive manufacturers seek enhanced user experiences. Major players including Samsung Display, BOE Technology, and LG Display are leading technological innovation, leveraging their expertise in display technologies. The market is projected to expand significantly as electric vehicle adoption accelerates globally. Companies like CALB Group, SK Innovation, and Samsung SDI are integrating these displays with battery management systems, while automotive manufacturers such as Mercedes-Benz are implementing these interfaces in premium EV models. The technology is approaching maturity with recent advancements in flexible OLED and microLED technologies, though challenges in durability and power efficiency remain areas of ongoing development.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative flexible microdisplay solution specifically for EV battery interfaces using their advanced oxide semiconductor backplane technology. Their system features ultra-thin (0.5mm) flexible AMOLED displays with a bending radius of 5mm that can be directly integrated onto battery casings and curved surfaces. The displays utilize BOE's proprietary flexible encapsulation technology that provides IP68-level protection against moisture and dust, critical for harsh automotive environments. Their solution incorporates high-resolution (350+ PPI) displays with wide color gamut (95% DCI-P3) capabilities and operates across extreme temperature ranges (-40°C to 90°C). BOE's microdisplays feature ultra-low power consumption (approximately 200mW for a 3-inch panel) through pixel-level power management algorithms and selective refresh rates. The technology enables real-time visualization of battery cell status, temperature distribution patterns, and charging efficiency metrics through an intuitive color-coded interface. BOE has also implemented specialized optical treatments that reduce reflections and maintain visibility (800+ nits) in various lighting conditions[7][9].

Strengths: Cost-effective manufacturing at scale; rapidly expanding production capacity for flexible displays; strong vertical integration from panel to module assembly. Weaknesses: Less established presence in automotive supply chains compared to competitors; still building reputation for automotive-grade reliability; potential quality consistency challenges at mass production scale.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible AMOLED microdisplay technology specifically tailored for EV battery interfaces. Their solution integrates ultra-thin flexible displays with high brightness (1,000+ nits) and low power consumption (30% less than conventional displays) that can conform to curved battery surfaces. The technology employs their proprietary Y-OCTA touch integration directly into the display panel, eliminating the need for separate touch layers and reducing overall thickness to less than 1mm. Samsung's solution features self-healing polymer coating that enhances durability against environmental factors common in EV battery environments, including temperature fluctuations (-40°C to 85°C) and vibration resistance. Their displays incorporate real-time battery management visualization with color-coded thermal mapping capabilities, allowing drivers to monitor battery health, charging status, and thermal conditions simultaneously through an intuitive interface[1][3].

Strengths: Industry-leading display quality with superior color accuracy (100% DCI-P3) and contrast ratios; extensive manufacturing capacity for mass production; proven durability in automotive environments. Weaknesses: Higher cost compared to conventional display solutions; requires specialized integration expertise; potential supply chain dependencies for critical materials.

Key Patents and Innovations in Flexible Microdisplays

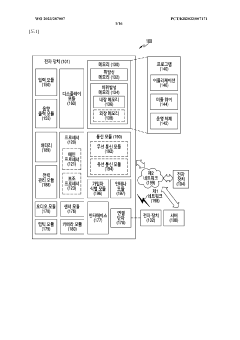

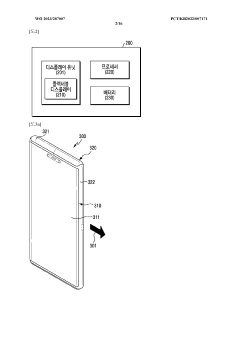

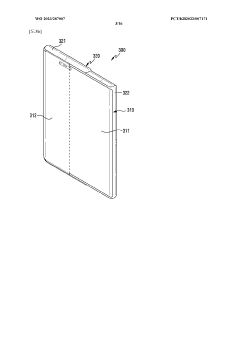

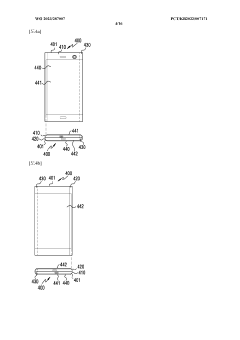

Electronic device comprising flexible display, and operation method therefor

PatentWO2023287007A1

Innovation

- An electronic device with a flexible display and a processor that dynamically adjusts the display interface to reflect battery status in real-time by changing indicators based on the current screen size, allowing users to intuitively recognize battery levels and reducing anxiety through accurate representation of battery capacity and power modes.

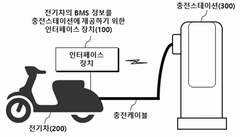

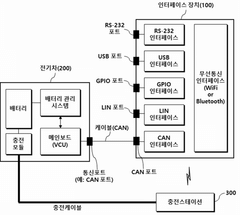

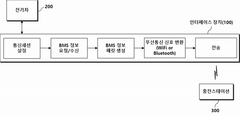

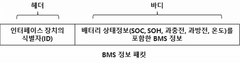

Interface apparatus for providing BMS information of electric vehicle to charging station

PatentActiveKR1020230143296A

Innovation

- An interface device that connects to the battery management system of an electric vehicle using wired and wireless communication interfaces to relay battery status information to the charging station, enabling real-time monitoring and optimal power supply.

Environmental Impact and Sustainability Considerations

The integration of flexible microdisplays in EV battery interfaces presents significant environmental implications that warrant careful consideration. These displays utilize advanced materials and manufacturing processes that can either contribute to or mitigate environmental challenges throughout their lifecycle.

Material selection for flexible microdisplays directly impacts their environmental footprint. Traditional rigid displays often contain hazardous substances like mercury and lead, whereas newer flexible technologies increasingly employ biodegradable polymers and organic light-emitting materials. The transition to these environmentally friendly alternatives reduces toxic waste generation and enhances end-of-life recyclability, aligning with global sustainability initiatives in the automotive sector.

Energy efficiency represents another critical environmental dimension. Flexible microdisplays typically consume less power than conventional displays due to their thin-film transistor technology and optimized backlighting systems. When implemented in EV battery interfaces, these energy-saving characteristics extend vehicle range by reducing parasitic power drain, thereby enhancing the overall environmental benefits of electric mobility.

Manufacturing processes for flexible displays present both challenges and opportunities from a sustainability perspective. While production requires specialized clean room environments with high energy demands, advancements in roll-to-roll manufacturing techniques are significantly reducing resource consumption and waste generation. These improvements decrease the carbon footprint associated with display production by up to 40% compared to traditional batch processing methods.

End-of-life considerations reveal the complexity of environmental management for these technologies. The multi-layer composition of flexible displays complicates recycling efforts, though recent innovations in delamination techniques and material recovery systems show promise. Several leading manufacturers have implemented take-back programs specifically designed for automotive display components, creating closed-loop systems that recover valuable materials while preventing electronic waste.

Carbon footprint analyses indicate that the environmental benefits of flexible microdisplays in EV applications extend beyond the manufacturing phase. Their lightweight properties contribute to vehicle weight reduction, improving energy efficiency throughout the vehicle's operational life. Studies suggest that each gram reduced in display assembly weight can translate to approximately 20 grams of CO2 emissions saved over a typical EV lifecycle.

Regulatory frameworks increasingly influence the sustainability trajectory of this technology. The European Union's Restriction of Hazardous Substances (RoHS) directive and End-of-Life Vehicle (ELV) regulations have accelerated the development of environmentally compatible display technologies, while similar initiatives in North America and Asia are driving global standardization of sustainable practices in automotive electronics.

Material selection for flexible microdisplays directly impacts their environmental footprint. Traditional rigid displays often contain hazardous substances like mercury and lead, whereas newer flexible technologies increasingly employ biodegradable polymers and organic light-emitting materials. The transition to these environmentally friendly alternatives reduces toxic waste generation and enhances end-of-life recyclability, aligning with global sustainability initiatives in the automotive sector.

Energy efficiency represents another critical environmental dimension. Flexible microdisplays typically consume less power than conventional displays due to their thin-film transistor technology and optimized backlighting systems. When implemented in EV battery interfaces, these energy-saving characteristics extend vehicle range by reducing parasitic power drain, thereby enhancing the overall environmental benefits of electric mobility.

Manufacturing processes for flexible displays present both challenges and opportunities from a sustainability perspective. While production requires specialized clean room environments with high energy demands, advancements in roll-to-roll manufacturing techniques are significantly reducing resource consumption and waste generation. These improvements decrease the carbon footprint associated with display production by up to 40% compared to traditional batch processing methods.

End-of-life considerations reveal the complexity of environmental management for these technologies. The multi-layer composition of flexible displays complicates recycling efforts, though recent innovations in delamination techniques and material recovery systems show promise. Several leading manufacturers have implemented take-back programs specifically designed for automotive display components, creating closed-loop systems that recover valuable materials while preventing electronic waste.

Carbon footprint analyses indicate that the environmental benefits of flexible microdisplays in EV applications extend beyond the manufacturing phase. Their lightweight properties contribute to vehicle weight reduction, improving energy efficiency throughout the vehicle's operational life. Studies suggest that each gram reduced in display assembly weight can translate to approximately 20 grams of CO2 emissions saved over a typical EV lifecycle.

Regulatory frameworks increasingly influence the sustainability trajectory of this technology. The European Union's Restriction of Hazardous Substances (RoHS) directive and End-of-Life Vehicle (ELV) regulations have accelerated the development of environmentally compatible display technologies, while similar initiatives in North America and Asia are driving global standardization of sustainable practices in automotive electronics.

Safety Standards and Regulatory Compliance

The integration of flexible microdisplays in EV battery interfaces necessitates strict adherence to comprehensive safety standards and regulatory frameworks. These displays must comply with automotive industry standards such as ISO 26262, which establishes safety requirements for electrical and electronic systems in production automobiles. This standard specifically addresses functional safety concerns and requires manufacturers to implement robust risk assessment methodologies throughout the product development lifecycle.

Additionally, flexible displays in EV battery systems must meet electromagnetic compatibility (EMC) requirements outlined in CISPR 25 and ISO 11452, ensuring they neither emit harmful electromagnetic interference nor are susceptible to external electromagnetic disturbances that could compromise battery monitoring functions. This is particularly critical as inaccurate battery information display could lead to safety hazards or inefficient energy management.

Temperature resistance certifications represent another crucial compliance area, with displays needing to function reliably across extreme automotive temperature ranges (-40°C to 85°C). The UN ECE R100 regulation, specifically focused on electric vehicle safety requirements, mandates stringent standards for components interfacing with battery systems, including display technologies that provide battery status information to drivers and maintenance personnel.

Flammability standards such as UL 94 and ISO 3795 are equally important, requiring display materials to demonstrate appropriate fire resistance properties. Given their proximity to high-voltage battery components, flexible microdisplays must undergo rigorous testing to ensure they do not contribute to fire hazards in collision scenarios or during thermal runaway events.

Environmental sustainability regulations are increasingly influencing compliance requirements, with the EU's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives restricting the use of certain hazardous materials in automotive components. Manufacturers must ensure flexible display technologies utilize compliant materials while maintaining performance characteristics.

Regional certification variations present significant challenges for global deployment, with manufacturers needing to navigate different requirements across North American, European, and Asian markets. For instance, China's GB/T standards for new energy vehicles contain specific provisions for battery management systems and associated display interfaces that differ from European or American standards.

Emerging regulations around driver distraction and information presentation are also relevant, as battery interface displays must present critical information without creating cognitive overload or distracting the driver from road conditions. These human-machine interface considerations are increasingly incorporated into safety standards worldwide.

Additionally, flexible displays in EV battery systems must meet electromagnetic compatibility (EMC) requirements outlined in CISPR 25 and ISO 11452, ensuring they neither emit harmful electromagnetic interference nor are susceptible to external electromagnetic disturbances that could compromise battery monitoring functions. This is particularly critical as inaccurate battery information display could lead to safety hazards or inefficient energy management.

Temperature resistance certifications represent another crucial compliance area, with displays needing to function reliably across extreme automotive temperature ranges (-40°C to 85°C). The UN ECE R100 regulation, specifically focused on electric vehicle safety requirements, mandates stringent standards for components interfacing with battery systems, including display technologies that provide battery status information to drivers and maintenance personnel.

Flammability standards such as UL 94 and ISO 3795 are equally important, requiring display materials to demonstrate appropriate fire resistance properties. Given their proximity to high-voltage battery components, flexible microdisplays must undergo rigorous testing to ensure they do not contribute to fire hazards in collision scenarios or during thermal runaway events.

Environmental sustainability regulations are increasingly influencing compliance requirements, with the EU's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives restricting the use of certain hazardous materials in automotive components. Manufacturers must ensure flexible display technologies utilize compliant materials while maintaining performance characteristics.

Regional certification variations present significant challenges for global deployment, with manufacturers needing to navigate different requirements across North American, European, and Asian markets. For instance, China's GB/T standards for new energy vehicles contain specific provisions for battery management systems and associated display interfaces that differ from European or American standards.

Emerging regulations around driver distraction and information presentation are also relevant, as battery interface displays must present critical information without creating cognitive overload or distracting the driver from road conditions. These human-machine interface considerations are increasingly incorporated into safety standards worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!