How Flexible Microdisplays Contribute to Energy-efficient Designs

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid glass-based displays to malleable substrates that can bend, fold, and conform to various surfaces. The journey began in the early 2000s with the development of organic light-emitting diode (OLED) technology, which eliminated the need for rigid backlighting systems required by traditional LCD displays.

By 2010, researchers had successfully demonstrated the first truly flexible displays using plastic substrates, though these early prototypes suffered from limited durability and resolution. The breakthrough came around 2013-2015 when manufacturers developed specialized thin-film transistor (TFT) backplanes that could maintain electrical performance while being physically flexed, enabling the commercialization of curved displays in consumer electronics.

The evolution accelerated with the introduction of advanced materials such as polyimide films and graphene-based conductors, which provided both flexibility and enhanced electrical properties. These innovations allowed for the creation of ultra-thin displays with thickness below 100 micrometers, dramatically reducing weight and power consumption compared to conventional displays.

Recent advancements have focused on addressing key challenges including mechanical stress resistance, pixel density in flexible formats, and manufacturing scalability. The integration of microLED technology with flexible substrates represents the latest frontier, promising unprecedented energy efficiency while maintaining flexibility.

The primary objective of flexible microdisplay technology development is to enable new form factors and applications that were previously impossible with rigid displays, while simultaneously reducing energy consumption. This includes creating displays that can be integrated into wearable devices, smart textiles, and conformable surfaces without compromising on visual performance or battery life.

Energy efficiency stands as a central goal in this technological evolution. By eliminating rigid components and leveraging materials with lower activation energy requirements, flexible displays can operate at significantly reduced power levels. The target is to achieve displays that consume less than 1mW/cm² while maintaining visibility in various lighting conditions.

Another key objective is enhancing durability under repeated flexing cycles. Current technology aims to withstand 200,000+ folding cycles without degradation in display quality or electrical performance, a critical requirement for practical applications in foldable devices and wearable technology.

The technology roadmap also prioritizes manufacturing scalability, with the goal of transitioning from laboratory demonstrations to mass-production techniques that can deliver flexible displays at competitive price points. This includes developing roll-to-roll processing methods that significantly reduce production costs while maintaining precise tolerances required for high-resolution displays.

By 2010, researchers had successfully demonstrated the first truly flexible displays using plastic substrates, though these early prototypes suffered from limited durability and resolution. The breakthrough came around 2013-2015 when manufacturers developed specialized thin-film transistor (TFT) backplanes that could maintain electrical performance while being physically flexed, enabling the commercialization of curved displays in consumer electronics.

The evolution accelerated with the introduction of advanced materials such as polyimide films and graphene-based conductors, which provided both flexibility and enhanced electrical properties. These innovations allowed for the creation of ultra-thin displays with thickness below 100 micrometers, dramatically reducing weight and power consumption compared to conventional displays.

Recent advancements have focused on addressing key challenges including mechanical stress resistance, pixel density in flexible formats, and manufacturing scalability. The integration of microLED technology with flexible substrates represents the latest frontier, promising unprecedented energy efficiency while maintaining flexibility.

The primary objective of flexible microdisplay technology development is to enable new form factors and applications that were previously impossible with rigid displays, while simultaneously reducing energy consumption. This includes creating displays that can be integrated into wearable devices, smart textiles, and conformable surfaces without compromising on visual performance or battery life.

Energy efficiency stands as a central goal in this technological evolution. By eliminating rigid components and leveraging materials with lower activation energy requirements, flexible displays can operate at significantly reduced power levels. The target is to achieve displays that consume less than 1mW/cm² while maintaining visibility in various lighting conditions.

Another key objective is enhancing durability under repeated flexing cycles. Current technology aims to withstand 200,000+ folding cycles without degradation in display quality or electrical performance, a critical requirement for practical applications in foldable devices and wearable technology.

The technology roadmap also prioritizes manufacturing scalability, with the goal of transitioning from laboratory demonstrations to mass-production techniques that can deliver flexible displays at competitive price points. This includes developing roll-to-roll processing methods that significantly reduce production costs while maintaining precise tolerances required for high-resolution displays.

Market Demand Analysis for Energy-efficient Display Solutions

The global market for energy-efficient display solutions has witnessed substantial growth in recent years, driven by increasing consumer demand for portable electronic devices with longer battery life and reduced environmental impact. Flexible microdisplays represent a significant advancement in this domain, offering unprecedented opportunities for energy conservation while maintaining or enhancing display performance.

Consumer electronics manufacturers are increasingly prioritizing energy efficiency as a key differentiator in their product offerings. Market research indicates that devices featuring energy-efficient displays command premium pricing and enjoy higher consumer satisfaction ratings due to extended battery life. This trend is particularly pronounced in wearable technology, where flexible microdisplays enable form factors previously unattainable with rigid display technologies.

The healthcare sector presents another substantial market opportunity for energy-efficient flexible displays. Medical wearables and monitoring devices require displays that consume minimal power while providing clear visual information in various lighting conditions. The market for these specialized medical display applications is projected to grow significantly as remote patient monitoring becomes more prevalent in healthcare delivery systems worldwide.

Automotive applications represent a rapidly expanding market segment for energy-efficient display solutions. As vehicles incorporate more digital interfaces and heads-up displays, the demand for displays that minimize power consumption without compromising visibility has intensified. Flexible microdisplays offer advantages in this context through their adaptability to curved surfaces and reduced power requirements.

Enterprise and industrial markets are also showing increased interest in energy-efficient display technologies. Portable field equipment, logistics management devices, and industrial control systems benefit from displays that extend operational time between charges while functioning reliably in challenging environmental conditions. The industrial sector values the durability and reduced maintenance requirements associated with energy-efficient display solutions.

The military and aerospace sectors constitute specialized but lucrative markets for advanced display technologies. These applications demand extreme reliability, performance in harsh conditions, and minimal power consumption. Flexible microdisplays that can withstand vibration, temperature extremes, and maintain functionality with limited power resources are particularly valuable in these contexts.

Emerging markets in developing economies represent significant growth potential for energy-efficient display technologies. As these regions experience rapid technological adoption with limited power infrastructure, devices that maximize battery life through efficient displays gain competitive advantage. The combination of affordability and energy efficiency is particularly compelling in these market environments.

Consumer electronics manufacturers are increasingly prioritizing energy efficiency as a key differentiator in their product offerings. Market research indicates that devices featuring energy-efficient displays command premium pricing and enjoy higher consumer satisfaction ratings due to extended battery life. This trend is particularly pronounced in wearable technology, where flexible microdisplays enable form factors previously unattainable with rigid display technologies.

The healthcare sector presents another substantial market opportunity for energy-efficient flexible displays. Medical wearables and monitoring devices require displays that consume minimal power while providing clear visual information in various lighting conditions. The market for these specialized medical display applications is projected to grow significantly as remote patient monitoring becomes more prevalent in healthcare delivery systems worldwide.

Automotive applications represent a rapidly expanding market segment for energy-efficient display solutions. As vehicles incorporate more digital interfaces and heads-up displays, the demand for displays that minimize power consumption without compromising visibility has intensified. Flexible microdisplays offer advantages in this context through their adaptability to curved surfaces and reduced power requirements.

Enterprise and industrial markets are also showing increased interest in energy-efficient display technologies. Portable field equipment, logistics management devices, and industrial control systems benefit from displays that extend operational time between charges while functioning reliably in challenging environmental conditions. The industrial sector values the durability and reduced maintenance requirements associated with energy-efficient display solutions.

The military and aerospace sectors constitute specialized but lucrative markets for advanced display technologies. These applications demand extreme reliability, performance in harsh conditions, and minimal power consumption. Flexible microdisplays that can withstand vibration, temperature extremes, and maintain functionality with limited power resources are particularly valuable in these contexts.

Emerging markets in developing economies represent significant growth potential for energy-efficient display technologies. As these regions experience rapid technological adoption with limited power infrastructure, devices that maximize battery life through efficient displays gain competitive advantage. The combination of affordability and energy efficiency is particularly compelling in these market environments.

Current State and Challenges in Flexible Microdisplay Technology

Flexible microdisplay technology has witnessed significant advancements globally over the past decade, with major research institutions and corporations in Asia, North America, and Europe making substantial contributions. Currently, the technology has evolved from early prototype stages to commercial viability in select applications. OLED-based flexible displays dominate the market, while emerging technologies such as micro-LED and quantum dot displays are gaining traction for their superior energy efficiency and form factor advantages.

The global landscape shows distinct regional specializations: East Asian manufacturers (particularly in South Korea, Japan, and Taiwan) lead in mass production capabilities; North American companies excel in innovative materials and system integration; European research centers focus on novel substrate technologies and sustainable manufacturing processes. This distribution creates a complex ecosystem of competition and collaboration across the value chain.

Despite impressive progress, flexible microdisplay technology faces several critical challenges that impede broader adoption in energy-efficient designs. Material limitations remain a primary concern, as current flexible substrates struggle to match the thermal stability and barrier properties of rigid alternatives while maintaining flexibility. This creates inherent trade-offs between performance and form factor.

Power consumption optimization presents another significant hurdle. While flexible displays offer theoretical energy advantages through reduced backlighting requirements and potential for ambient light utilization, practical implementations often suffer from higher power needs due to compensation circuits addressing non-uniform electrical characteristics across bent surfaces. The industry has yet to fully resolve these inconsistencies at scale.

Manufacturing complexity constitutes a substantial barrier to widespread adoption. Current production processes for flexible displays involve intricate deposition techniques, precise temperature control, and specialized handling equipment. Yield rates remain lower than those for conventional displays, driving up costs and limiting mass-market penetration for energy-efficient applications.

Durability and reliability issues persist as flexible displays undergo repeated bending cycles. Mechanical stress at fold points creates microcracks in conductive layers and degradation of organic materials, leading to shortened operational lifespans compared to rigid alternatives. This undermines the sustainability benefits that energy-efficient designs aim to achieve.

Integration challenges with other system components further complicate implementation. Flexible batteries, circuits, and sensors must evolve in parallel with display technology to realize truly flexible, energy-efficient devices. The current ecosystem shows uneven development across these complementary technologies, creating bottlenecks in product design.

Standardization remains inadequate across the industry, with competing technical approaches and proprietary solutions fragmenting the market. This lack of unified standards hampers interoperability and slows adoption in energy-conscious applications where system-level optimization is crucial.

The global landscape shows distinct regional specializations: East Asian manufacturers (particularly in South Korea, Japan, and Taiwan) lead in mass production capabilities; North American companies excel in innovative materials and system integration; European research centers focus on novel substrate technologies and sustainable manufacturing processes. This distribution creates a complex ecosystem of competition and collaboration across the value chain.

Despite impressive progress, flexible microdisplay technology faces several critical challenges that impede broader adoption in energy-efficient designs. Material limitations remain a primary concern, as current flexible substrates struggle to match the thermal stability and barrier properties of rigid alternatives while maintaining flexibility. This creates inherent trade-offs between performance and form factor.

Power consumption optimization presents another significant hurdle. While flexible displays offer theoretical energy advantages through reduced backlighting requirements and potential for ambient light utilization, practical implementations often suffer from higher power needs due to compensation circuits addressing non-uniform electrical characteristics across bent surfaces. The industry has yet to fully resolve these inconsistencies at scale.

Manufacturing complexity constitutes a substantial barrier to widespread adoption. Current production processes for flexible displays involve intricate deposition techniques, precise temperature control, and specialized handling equipment. Yield rates remain lower than those for conventional displays, driving up costs and limiting mass-market penetration for energy-efficient applications.

Durability and reliability issues persist as flexible displays undergo repeated bending cycles. Mechanical stress at fold points creates microcracks in conductive layers and degradation of organic materials, leading to shortened operational lifespans compared to rigid alternatives. This undermines the sustainability benefits that energy-efficient designs aim to achieve.

Integration challenges with other system components further complicate implementation. Flexible batteries, circuits, and sensors must evolve in parallel with display technology to realize truly flexible, energy-efficient devices. The current ecosystem shows uneven development across these complementary technologies, creating bottlenecks in product design.

Standardization remains inadequate across the industry, with competing technical approaches and proprietary solutions fragmenting the market. This lack of unified standards hampers interoperability and slows adoption in energy-conscious applications where system-level optimization is crucial.

Current Energy-efficient Flexible Display Implementation Approaches

01 Low-power display technologies for flexible microdisplays

Various low-power display technologies are employed in flexible microdisplays to enhance energy efficiency. These include electrophoretic displays, OLED displays with optimized pixel structures, and bistable display technologies that maintain images with minimal power consumption. These technologies significantly reduce the energy requirements of flexible microdisplays while maintaining display quality and performance in portable and wearable applications.- Low-power display technologies for flexible microdisplays: Various low-power display technologies are employed in flexible microdisplays to enhance energy efficiency. These include electrophoretic displays, OLED (Organic Light Emitting Diode) technologies, and bistable display mechanisms that require power only when changing states. These technologies significantly reduce power consumption compared to traditional display technologies, making them ideal for portable and wearable applications where battery life is critical.

- Power management systems for flexible displays: Advanced power management systems are integrated into flexible microdisplays to optimize energy usage. These systems include adaptive brightness control, selective pixel activation, and power-saving modes that adjust display parameters based on content and ambient conditions. Some implementations feature intelligent power distribution circuits that minimize energy loss and maximize battery efficiency during operation.

- Flexible substrate materials enhancing energy efficiency: Novel substrate materials used in flexible microdisplays contribute to improved energy efficiency. These materials include ultra-thin polymers, composite substrates, and specialized films that require less power to maintain display functionality. The physical properties of these substrates allow for better thermal management and reduced energy dissipation, resulting in lower overall power consumption during operation.

- Energy harvesting and storage solutions: Integrated energy harvesting and storage technologies enhance the self-sustainability of flexible microdisplays. These solutions include photovoltaic elements, piezoelectric components, and thin-film batteries directly incorporated into the display structure. Such integration allows the displays to capture ambient energy from light, movement, or heat, supplementing traditional power sources and extending operational time between charges.

- Efficient driving circuits and control algorithms: Specialized driving circuits and control algorithms are developed to minimize power consumption in flexible microdisplays. These include low-voltage driving schemes, refresh rate optimization techniques, and content-adaptive control systems that adjust power usage based on displayed information. Advanced semiconductor technologies and circuit designs reduce switching losses and standby power, significantly improving overall energy efficiency.

02 Power management systems for flexible displays

Advanced power management systems are integrated into flexible microdisplays to optimize energy consumption. These systems include adaptive brightness control based on ambient light conditions, selective pixel activation, and power-saving modes that reduce refresh rates during periods of low activity. Such power management techniques can significantly extend battery life in portable devices featuring flexible microdisplays.Expand Specific Solutions03 Flexible substrate materials for energy-efficient displays

Novel substrate materials are developed specifically for flexible microdisplays to improve energy efficiency. These materials include ultra-thin polymers, composite substrates with enhanced thermal management properties, and materials with optimized electrical characteristics. The choice of substrate material directly impacts power consumption by affecting display driving voltages and thermal dissipation requirements.Expand Specific Solutions04 Energy harvesting integration with flexible displays

Flexible microdisplays are being integrated with energy harvesting technologies to improve overall energy efficiency. These systems incorporate photovoltaic elements, piezoelectric materials, or thermal energy harvesters directly into the display structure or its housing. This approach allows the display to partially power itself by capturing ambient energy, reducing dependence on battery power and extending operational time.Expand Specific Solutions05 Circuit design optimization for flexible display power efficiency

Advanced circuit designs are implemented to minimize power consumption in flexible microdisplays. These include low-voltage driving circuits, energy-efficient backplane architectures, and optimized timing controllers. The circuit designs focus on reducing switching losses, minimizing leakage currents, and implementing power-gating techniques to shut down inactive portions of the display, resulting in significant energy savings during operation.Expand Specific Solutions

Key Industry Players in Flexible Microdisplay Manufacturing

The flexible microdisplay market is currently in a growth phase, with increasing adoption across energy-efficient applications. Market size is expanding rapidly, projected to reach significant value as consumer electronics manufacturers seek power-saving display solutions. Technologically, Samsung Electronics and LG Electronics lead innovation with advanced OLED flexible display technologies, while BOE Technology and E Ink Corporation have made substantial progress in energy-efficient e-paper displays. Intel and Semiconductor Energy Laboratory are advancing in semiconductor integration for lower power consumption. Companies like Tianma Microelectronics and China Star Optoelectronics are rapidly closing the technology gap with competitive offerings. The ecosystem shows varying maturity levels, with established players focusing on commercialization while newer entrants concentrate on R&D to overcome technical challenges in balancing flexibility with energy efficiency.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered flexible AMOLED technology through their Y-OCTA (Youm On-Cell Touch AMOLED) process that integrates the touch sensor directly onto the display panel rather than as a separate layer. Their flexible microdisplays utilize ultra-thin film encapsulation (TFE) technology with a thickness of less than 1mm, enabling significant power efficiency improvements of up to 30% compared to conventional rigid displays[1]. Samsung's flexible displays incorporate LTPO (Low-Temperature Polycrystalline Oxide) backplane technology that allows for variable refresh rates (1-120Hz), dynamically adjusting power consumption based on content requirements[2]. Their latest generation employs eco-square pixel structure that reduces power consumption by up to 25% while maintaining brightness levels[3]. Samsung has also developed specialized polarizer-free structures that improve outdoor visibility while reducing the overall power requirements of the display system.

Strengths: Industry-leading production capacity and yield rates for flexible OLED panels; proprietary pixel architecture optimized for power efficiency; advanced variable refresh rate implementation. Weaknesses: Higher production costs compared to conventional displays; limited flexibility in extremely cold environments; potential color shift issues at extreme viewing angles in some implementations.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed crystalline oxide semiconductor technology for flexible displays that enables significantly lower power consumption. Their CAAC-OS (C-Axis Aligned Crystalline Oxide Semiconductor) technology provides extremely low off-state leakage current (10^-24 A/μm), which is critical for energy efficiency in microdisplays[1]. SEL's flexible display technology incorporates oxide TFTs with mobility exceeding 10 cm²/Vs while maintaining stability under bending conditions with radii as small as 1mm[2]. Their displays utilize a unique dual-gate TFT structure that allows for precise control of threshold voltage, reducing power consumption during active matrix driving. SEL has also pioneered ultra-low power memory-in-pixel technology that can retain images with minimal refresh requirements, reducing power consumption by up to 40% in static image scenarios[3]. Their flexible microdisplays achieve high aperture ratios exceeding 60%, maximizing light transmission efficiency.

Strengths: Industry-leading oxide semiconductor technology with exceptional stability; ultra-low leakage current characteristics; innovative memory-in-pixel technology for static image power savings. Weaknesses: Limited mass production capabilities compared to larger display manufacturers; higher initial production costs; technology primarily licensed to other manufacturers rather than produced in-house.

Core Innovations in Low-power Flexible Display Technologies

Microdisplay

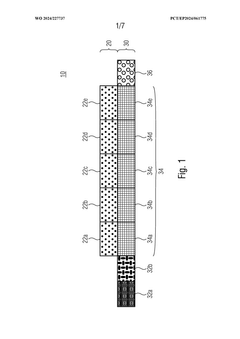

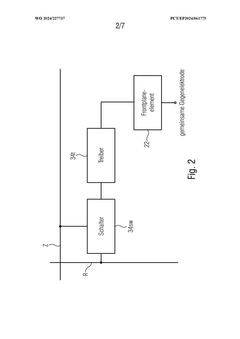

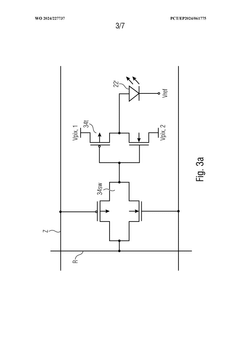

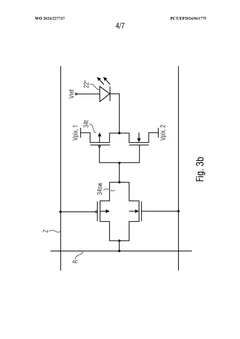

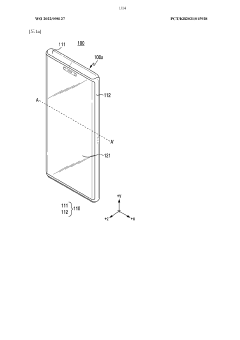

PatentWO2024227737A1

Innovation

- A microdisplay architecture with an integrated backplane that includes a pixel matrix control, image memory, and multiple interfaces, allowing for both memory-based and refresh rate-based operating modes, which simplifies system architecture, reduces power consumption, and adapts to various display technologies by integrating functionality and eliminating the need for external driver circuits.

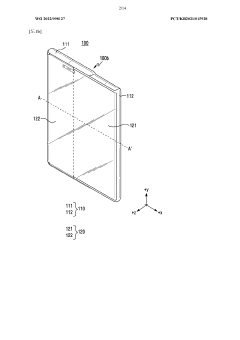

Flexible display control method and electronic device supporting same

PatentWO2022098127A1

Innovation

- A flexible display control method that divides the display area into parts, allowing independent power supply based on the device's state, cutting off power to non-exposed areas in a reduced state to conserve energy and ensuring quick display activation when expanded.

Environmental Impact and Sustainability Considerations

Flexible microdisplays represent a significant advancement in sustainable display technology, offering substantial environmental benefits throughout their lifecycle. The manufacturing process of these displays typically requires fewer raw materials compared to traditional rigid displays, reducing resource extraction impacts. Additionally, the thin-film technologies employed in flexible displays often utilize lower quantities of rare earth elements and toxic compounds, decreasing the environmental footprint of production.

Energy efficiency stands as one of the most compelling environmental advantages of flexible microdisplays. These displays consume significantly less power during operation, with some advanced OLED-based flexible displays achieving up to 40% energy savings compared to conventional LCD technologies. This reduced energy consumption directly translates to lower carbon emissions over the product lifecycle, particularly important as display technologies become increasingly ubiquitous in consumer and industrial applications.

The lightweight and durable nature of flexible displays contributes to sustainability through extended product lifespans and reduced transportation emissions. Their resistance to breakage and mechanical stress means fewer replacements and less electronic waste generation. When integrated into wearable technologies and IoT devices, these displays enable more efficient system-wide energy management through adaptive brightness and power-saving display modes.

End-of-life considerations also favor flexible microdisplays from a sustainability perspective. The simplified material composition of many flexible display technologies facilitates more effective recycling processes. Research indicates that up to 90% of materials in certain flexible display configurations can be recovered through specialized recycling techniques, compared to approximately 60% for conventional displays with more complex material integration.

The circular economy potential of flexible displays extends beyond recycling. Their modular design approach allows for easier component replacement and upgrades, reducing the need for complete device replacement. This design philosophy aligns with sustainable product development principles and helps address the growing electronic waste crisis facing the technology sector.

Looking forward, ongoing research into bio-based substrates and environmentally benign manufacturing processes promises to further enhance the sustainability profile of flexible microdisplays. Several leading manufacturers have committed to carbon-neutral production facilities for next-generation flexible display technologies, signaling industry recognition of both the environmental imperatives and market advantages of sustainable display solutions.

Energy efficiency stands as one of the most compelling environmental advantages of flexible microdisplays. These displays consume significantly less power during operation, with some advanced OLED-based flexible displays achieving up to 40% energy savings compared to conventional LCD technologies. This reduced energy consumption directly translates to lower carbon emissions over the product lifecycle, particularly important as display technologies become increasingly ubiquitous in consumer and industrial applications.

The lightweight and durable nature of flexible displays contributes to sustainability through extended product lifespans and reduced transportation emissions. Their resistance to breakage and mechanical stress means fewer replacements and less electronic waste generation. When integrated into wearable technologies and IoT devices, these displays enable more efficient system-wide energy management through adaptive brightness and power-saving display modes.

End-of-life considerations also favor flexible microdisplays from a sustainability perspective. The simplified material composition of many flexible display technologies facilitates more effective recycling processes. Research indicates that up to 90% of materials in certain flexible display configurations can be recovered through specialized recycling techniques, compared to approximately 60% for conventional displays with more complex material integration.

The circular economy potential of flexible displays extends beyond recycling. Their modular design approach allows for easier component replacement and upgrades, reducing the need for complete device replacement. This design philosophy aligns with sustainable product development principles and helps address the growing electronic waste crisis facing the technology sector.

Looking forward, ongoing research into bio-based substrates and environmentally benign manufacturing processes promises to further enhance the sustainability profile of flexible microdisplays. Several leading manufacturers have committed to carbon-neutral production facilities for next-generation flexible display technologies, signaling industry recognition of both the environmental imperatives and market advantages of sustainable display solutions.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of flexible microdisplays represents a critical factor in their widespread adoption for energy-efficient designs. Current production methods primarily utilize roll-to-roll (R2R) processing, which enables continuous fabrication of flexible display components on polymer substrates. This approach significantly reduces production time compared to traditional batch processing methods used for rigid displays, potentially lowering manufacturing costs by 30-40% at scale.

However, several manufacturing challenges persist that impact cost structures. Yield rates for flexible displays currently average 70-75%, considerably lower than the 85-90% achieved with established rigid display technologies. This yield gap directly translates to higher per-unit costs, with flexible microdisplays currently commanding a 2.5-3x premium over equivalent rigid alternatives in production environments.

Material selection presents another scalability consideration. While polyimide remains the dominant substrate material due to its thermal stability and mechanical properties, alternative materials like polyethylene naphthalate (PEN) and polyethylene terephthalate (PET) offer cost advantages but with performance trade-offs. The cost differential between these substrate options can impact final product pricing by 15-20%.

Equipment investment represents a significant barrier to market entry. Specialized deposition systems, patterning tools, and encapsulation equipment for flexible display manufacturing require capital investments ranging from $50-100 million for a production-scale facility. This high initial investment necessitates substantial production volumes to achieve cost competitiveness.

Economic analysis indicates that flexible microdisplays will reach price parity with conventional displays when production volumes exceed approximately 5 million units annually per manufacturing line. Current industry projections suggest this inflection point could occur within 3-5 years as demand for energy-efficient display solutions increases across consumer electronics, automotive, and wearable technology sectors.

Recent innovations in manufacturing processes, particularly in thin-film encapsulation techniques and low-temperature oxide semiconductor deposition, are gradually improving yield rates and reducing process complexity. These advancements, coupled with increasing demand for energy-efficient display solutions, are expected to drive manufacturing economies of scale that will ultimately reduce the cost premium associated with flexible microdisplay technologies.

However, several manufacturing challenges persist that impact cost structures. Yield rates for flexible displays currently average 70-75%, considerably lower than the 85-90% achieved with established rigid display technologies. This yield gap directly translates to higher per-unit costs, with flexible microdisplays currently commanding a 2.5-3x premium over equivalent rigid alternatives in production environments.

Material selection presents another scalability consideration. While polyimide remains the dominant substrate material due to its thermal stability and mechanical properties, alternative materials like polyethylene naphthalate (PEN) and polyethylene terephthalate (PET) offer cost advantages but with performance trade-offs. The cost differential between these substrate options can impact final product pricing by 15-20%.

Equipment investment represents a significant barrier to market entry. Specialized deposition systems, patterning tools, and encapsulation equipment for flexible display manufacturing require capital investments ranging from $50-100 million for a production-scale facility. This high initial investment necessitates substantial production volumes to achieve cost competitiveness.

Economic analysis indicates that flexible microdisplays will reach price parity with conventional displays when production volumes exceed approximately 5 million units annually per manufacturing line. Current industry projections suggest this inflection point could occur within 3-5 years as demand for energy-efficient display solutions increases across consumer electronics, automotive, and wearable technology sectors.

Recent innovations in manufacturing processes, particularly in thin-film encapsulation techniques and low-temperature oxide semiconductor deposition, are gradually improving yield rates and reducing process complexity. These advancements, coupled with increasing demand for energy-efficient display solutions, are expected to drive manufacturing economies of scale that will ultimately reduce the cost premium associated with flexible microdisplay technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!