Research on Advanced Material Usage in Flexible Microdisplay Development

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Materials Background and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display structures to increasingly flexible and adaptable formats. The journey began with early experiments in organic light-emitting diodes (OLEDs) in the late 1990s, which demonstrated the potential for creating displays on non-rigid substrates. This technological evolution has accelerated dramatically since 2010, with breakthroughs in materials science enabling unprecedented levels of flexibility while maintaining display performance.

The current trajectory of flexible microdisplay development is focused on achieving the perfect balance between mechanical flexibility, optical performance, and durability. Industry trends indicate a growing demand for displays that can be bent, folded, or even rolled while maintaining high resolution, color accuracy, and energy efficiency. This represents a significant departure from traditional display technologies and opens new possibilities for device form factors and user experiences.

Material innovation stands at the core of flexible microdisplay advancement. Traditional display materials like glass substrates and rigid silicon backplanes are being replaced by polymer-based alternatives, ultra-thin glass, and novel semiconductor materials. These innovations are complemented by developments in transparent conductive materials, encapsulation technologies, and flexible barrier films that protect sensitive electronic components from environmental factors.

The primary technical objectives in this field include developing materials with enhanced mechanical properties that can withstand repeated bending cycles without degradation, improving the optical characteristics of flexible substrates to match or exceed those of rigid displays, and creating manufacturing processes that enable cost-effective mass production of these advanced materials. Additionally, there is a focus on reducing the environmental impact of display materials through sustainable sourcing and improved recyclability.

From a historical perspective, flexible display technology has progressed through several distinct phases: initial proof-of-concept demonstrations, laboratory prototypes, limited commercial applications, and now the early stages of mainstream adoption. Each phase has been characterized by specific material innovations that addressed the limitations of previous approaches and expanded the potential applications of the technology.

The convergence of nanotechnology, polymer science, and semiconductor physics has created unprecedented opportunities for material innovation in this space. Research institutions and technology companies worldwide are exploring novel material combinations, including organic-inorganic hybrids, nanocomposites, and biomimetic structures inspired by naturally flexible biological materials. These explorations aim to overcome current limitations in flexibility, durability, and performance.

Looking forward, the field is moving toward truly conformable and stretchable displays that can adapt to complex three-dimensional surfaces or dynamic form factors. This evolution will require fundamental breakthroughs in material science, particularly in developing substrates and electronic components that can maintain functionality under extreme mechanical deformation while offering the visual quality consumers expect from modern displays.

The current trajectory of flexible microdisplay development is focused on achieving the perfect balance between mechanical flexibility, optical performance, and durability. Industry trends indicate a growing demand for displays that can be bent, folded, or even rolled while maintaining high resolution, color accuracy, and energy efficiency. This represents a significant departure from traditional display technologies and opens new possibilities for device form factors and user experiences.

Material innovation stands at the core of flexible microdisplay advancement. Traditional display materials like glass substrates and rigid silicon backplanes are being replaced by polymer-based alternatives, ultra-thin glass, and novel semiconductor materials. These innovations are complemented by developments in transparent conductive materials, encapsulation technologies, and flexible barrier films that protect sensitive electronic components from environmental factors.

The primary technical objectives in this field include developing materials with enhanced mechanical properties that can withstand repeated bending cycles without degradation, improving the optical characteristics of flexible substrates to match or exceed those of rigid displays, and creating manufacturing processes that enable cost-effective mass production of these advanced materials. Additionally, there is a focus on reducing the environmental impact of display materials through sustainable sourcing and improved recyclability.

From a historical perspective, flexible display technology has progressed through several distinct phases: initial proof-of-concept demonstrations, laboratory prototypes, limited commercial applications, and now the early stages of mainstream adoption. Each phase has been characterized by specific material innovations that addressed the limitations of previous approaches and expanded the potential applications of the technology.

The convergence of nanotechnology, polymer science, and semiconductor physics has created unprecedented opportunities for material innovation in this space. Research institutions and technology companies worldwide are exploring novel material combinations, including organic-inorganic hybrids, nanocomposites, and biomimetic structures inspired by naturally flexible biological materials. These explorations aim to overcome current limitations in flexibility, durability, and performance.

Looking forward, the field is moving toward truly conformable and stretchable displays that can adapt to complex three-dimensional surfaces or dynamic form factors. This evolution will require fundamental breakthroughs in material science, particularly in developing substrates and electronic components that can maintain functionality under extreme mechanical deformation while offering the visual quality consumers expect from modern displays.

Market Analysis for Flexible Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for portable, lightweight, and durable electronic devices. The global flexible display market was valued at approximately $23.1 billion in 2022 and is projected to reach $42.5 billion by 2027, growing at a CAGR of 13.0% during the forecast period. This substantial growth trajectory underscores the significant market potential for flexible microdisplay technologies.

Smartphones currently represent the largest application segment for flexible displays, accounting for over 40% of the market share. Major smartphone manufacturers have increasingly incorporated flexible display technologies into their flagship products, offering consumers innovative features such as foldable screens and edge-to-edge displays. This trend is expected to continue as manufacturers seek to differentiate their products in an increasingly competitive market.

Beyond smartphones, wearable devices constitute another rapidly expanding application area for flexible displays. The global wearable technology market is projected to grow at a CAGR of 15.9% from 2022 to 2027, with flexible displays playing a crucial role in this expansion. Smartwatches, fitness trackers, and augmented reality (AR) glasses are among the key products driving demand for flexible microdisplay technologies in the wearable segment.

The automotive industry has also emerged as a promising market for flexible display technologies. Advanced driver-assistance systems (ADAS), heads-up displays (HUDs), and in-vehicle infotainment systems increasingly incorporate flexible displays to enhance user experience and functionality. The automotive display market is expected to grow at a CAGR of 8.5% through 2027, presenting significant opportunities for flexible microdisplay technologies.

Geographically, Asia-Pacific dominates the flexible display market, accounting for approximately 45% of global market share. This regional dominance is attributed to the presence of major display manufacturers and electronic device producers in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer adoption rates for premium electronic devices featuring flexible displays.

Consumer preferences are increasingly shifting toward devices with larger screen-to-body ratios, improved durability, and enhanced portability. This shift has created substantial demand for flexible display technologies that can accommodate these preferences while maintaining high performance standards. Market research indicates that consumers are willing to pay premium prices for devices featuring flexible displays, suggesting strong market acceptance and growth potential.

The competitive landscape of the flexible display market is characterized by intense rivalry among key players such as Samsung Display, LG Display, BOE Technology, and Japan Display Inc. These companies are investing heavily in research and development to advance flexible microdisplay technologies and secure market leadership positions.

Smartphones currently represent the largest application segment for flexible displays, accounting for over 40% of the market share. Major smartphone manufacturers have increasingly incorporated flexible display technologies into their flagship products, offering consumers innovative features such as foldable screens and edge-to-edge displays. This trend is expected to continue as manufacturers seek to differentiate their products in an increasingly competitive market.

Beyond smartphones, wearable devices constitute another rapidly expanding application area for flexible displays. The global wearable technology market is projected to grow at a CAGR of 15.9% from 2022 to 2027, with flexible displays playing a crucial role in this expansion. Smartwatches, fitness trackers, and augmented reality (AR) glasses are among the key products driving demand for flexible microdisplay technologies in the wearable segment.

The automotive industry has also emerged as a promising market for flexible display technologies. Advanced driver-assistance systems (ADAS), heads-up displays (HUDs), and in-vehicle infotainment systems increasingly incorporate flexible displays to enhance user experience and functionality. The automotive display market is expected to grow at a CAGR of 8.5% through 2027, presenting significant opportunities for flexible microdisplay technologies.

Geographically, Asia-Pacific dominates the flexible display market, accounting for approximately 45% of global market share. This regional dominance is attributed to the presence of major display manufacturers and electronic device producers in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer adoption rates for premium electronic devices featuring flexible displays.

Consumer preferences are increasingly shifting toward devices with larger screen-to-body ratios, improved durability, and enhanced portability. This shift has created substantial demand for flexible display technologies that can accommodate these preferences while maintaining high performance standards. Market research indicates that consumers are willing to pay premium prices for devices featuring flexible displays, suggesting strong market acceptance and growth potential.

The competitive landscape of the flexible display market is characterized by intense rivalry among key players such as Samsung Display, LG Display, BOE Technology, and Japan Display Inc. These companies are investing heavily in research and development to advance flexible microdisplay technologies and secure market leadership positions.

Current Challenges in Flexible Microdisplay Materials

Despite significant advancements in flexible microdisplay technology, several critical material challenges continue to impede broader commercialization and performance optimization. The fundamental challenge lies in developing substrate materials that simultaneously offer mechanical flexibility, optical transparency, thermal stability, and dimensional stability under repeated bending cycles. Current polymer substrates such as polyimide (PI) and polyethylene terephthalate (PET) exhibit trade-offs between flexibility and thermal resistance, limiting processing options for subsequent layers.

Barrier layer materials present another significant hurdle, as flexible displays require exceptional moisture and oxygen barrier properties (water vapor transmission rates below 10^-6 g/m²/day) while maintaining flexibility. Traditional glass-based barriers are inadequate for flexible applications, while multilayer organic-inorganic hybrid structures often develop microcracks during flexing, compromising barrier integrity over time.

Transparent conductive electrodes (TCEs) face a critical conductivity-flexibility paradox. Indium tin oxide (ITO), the industry standard for rigid displays, becomes brittle when flexed, developing microcracks that increase resistance and create non-uniform current distribution. Alternative materials like silver nanowires, carbon nanotubes, and PEDOT:PSS show promise but struggle with long-term stability, uniform deposition, and integration with existing manufacturing processes.

For active matrix backplanes, traditional amorphous silicon (a-Si) and low-temperature polysilicon (LTPS) technologies are too brittle for flexible applications. Organic semiconductors and metal oxide semiconductors (particularly IGZO) offer better mechanical properties but face challenges in electron mobility, stability under environmental stresses, and compatibility with low-temperature processing required for polymer substrates.

Emissive layer materials, particularly in OLED-based microdisplays, encounter accelerated degradation when subjected to mechanical stress. The mechanical deformation can disrupt molecular packing and interfacial contacts, leading to reduced efficiency and shortened device lifetimes. Blue OLED emitters remain particularly problematic, with significantly shorter operational lifetimes than red and green counterparts.

Encapsulation technologies for flexible displays require fundamentally different approaches than those used in rigid displays. Thin-film encapsulation must maintain perfect barrier properties while accommodating repeated mechanical deformation, a requirement that current materials struggle to meet without developing defects over time.

Manufacturing integration presents perhaps the most complex challenge, as materials must not only perform individually but also maintain compatibility with adjacent layers and withstand sequential processing steps. The thermal budget limitations imposed by polymer substrates restrict processing options, while adhesion between dissimilar materials under mechanical stress remains problematic.

Barrier layer materials present another significant hurdle, as flexible displays require exceptional moisture and oxygen barrier properties (water vapor transmission rates below 10^-6 g/m²/day) while maintaining flexibility. Traditional glass-based barriers are inadequate for flexible applications, while multilayer organic-inorganic hybrid structures often develop microcracks during flexing, compromising barrier integrity over time.

Transparent conductive electrodes (TCEs) face a critical conductivity-flexibility paradox. Indium tin oxide (ITO), the industry standard for rigid displays, becomes brittle when flexed, developing microcracks that increase resistance and create non-uniform current distribution. Alternative materials like silver nanowires, carbon nanotubes, and PEDOT:PSS show promise but struggle with long-term stability, uniform deposition, and integration with existing manufacturing processes.

For active matrix backplanes, traditional amorphous silicon (a-Si) and low-temperature polysilicon (LTPS) technologies are too brittle for flexible applications. Organic semiconductors and metal oxide semiconductors (particularly IGZO) offer better mechanical properties but face challenges in electron mobility, stability under environmental stresses, and compatibility with low-temperature processing required for polymer substrates.

Emissive layer materials, particularly in OLED-based microdisplays, encounter accelerated degradation when subjected to mechanical stress. The mechanical deformation can disrupt molecular packing and interfacial contacts, leading to reduced efficiency and shortened device lifetimes. Blue OLED emitters remain particularly problematic, with significantly shorter operational lifetimes than red and green counterparts.

Encapsulation technologies for flexible displays require fundamentally different approaches than those used in rigid displays. Thin-film encapsulation must maintain perfect barrier properties while accommodating repeated mechanical deformation, a requirement that current materials struggle to meet without developing defects over time.

Manufacturing integration presents perhaps the most complex challenge, as materials must not only perform individually but also maintain compatibility with adjacent layers and withstand sequential processing steps. The thermal budget limitations imposed by polymer substrates restrict processing options, while adhesion between dissimilar materials under mechanical stress remains problematic.

Current Material Solutions for Flexible Microdisplays

01 Flexible substrate materials for microdisplays

Various flexible substrate materials can be used in the manufacturing of microdisplays to achieve flexibility. These materials include polymers, thin glass, and composite materials that can bend without breaking. The flexibility of these substrates allows for the creation of curved or foldable displays while maintaining optical performance. These materials must balance mechanical flexibility with stability to support the display components.- Flexible substrate materials for microdisplays: Various flexible substrate materials are being developed for use in microdisplays to achieve flexibility while maintaining display performance. These materials include polymeric films, thin glass, and composite materials that can bend without breaking. The substrates need to have specific properties such as high transparency, thermal stability, and compatibility with display manufacturing processes while enabling the flexibility required for next-generation display applications.

- Flexible electrode and conductive layer technologies: Advanced conductive materials are essential for flexible microdisplays, as traditional rigid electrodes would crack under bending stress. Innovations include transparent conductive oxides, metal nanowires, conductive polymers, and carbon-based materials like graphene that maintain conductivity while being mechanically flexible. These materials enable the creation of bendable circuits and electrodes that can withstand repeated flexing without performance degradation.

- Encapsulation and protection technologies for flexible displays: Flexible microdisplays require specialized encapsulation technologies to protect sensitive electronic components from environmental factors while maintaining flexibility. Advanced barrier films, thin-film encapsulation methods, and composite protection layers are being developed to provide effective moisture and oxygen barriers. These technologies must be thin and flexible enough to bend with the display while providing sufficient protection to ensure long-term reliability and performance.

- Novel backplane technologies for flexible displays: Flexible backplane technologies are critical for enabling bendable microdisplays. Innovations include organic thin-film transistors, oxide semiconductor TFTs, and low-temperature polysilicon that can be fabricated on flexible substrates. These technologies allow for the creation of active-matrix backplanes that maintain electrical performance while being mechanically flexible, enabling high-resolution flexible displays with good refresh rates and power efficiency.

- Manufacturing processes for flexible microdisplays: Specialized manufacturing processes have been developed to enable the production of flexible microdisplays. These include roll-to-roll processing, transfer techniques for delicate components, low-temperature deposition methods, and laser processing that are compatible with temperature-sensitive flexible substrates. These manufacturing innovations allow for cost-effective production of flexible displays while maintaining the precision required for high-resolution microdisplay applications.

02 Flexible electrode and conductive layer technologies

Advanced conductive materials are essential for flexible microdisplays, including transparent conductive oxides, metal nanowires, and conductive polymers. These materials maintain electrical conductivity while being able to withstand repeated bending and flexing. Specialized deposition techniques ensure uniform electrical properties across the flexible surface, allowing for consistent display performance even when the display is bent or folded.Expand Specific Solutions03 Encapsulation and protection technologies

Protective layers and encapsulation technologies are crucial for flexible microdisplays to prevent moisture and oxygen penetration while maintaining flexibility. These include thin-film encapsulation, barrier films, and hybrid organic-inorganic materials that provide environmental protection without compromising the display's ability to bend. Advanced sealing techniques ensure long-term reliability of flexible displays under various environmental conditions.Expand Specific Solutions04 Novel display technologies for flexible applications

Emerging display technologies specifically designed for flexible applications include organic light-emitting diodes (OLEDs), quantum dot displays, and electrophoretic displays. These technologies are inherently more compatible with flexible substrates compared to traditional LCD technology. The materials used in these displays can withstand mechanical stress while maintaining color accuracy, brightness, and contrast even when flexed.Expand Specific Solutions05 Manufacturing processes for flexible microdisplays

Specialized manufacturing processes have been developed for flexible microdisplays, including roll-to-roll processing, low-temperature deposition techniques, and laser patterning. These processes allow for the integration of electronic components onto flexible substrates without damaging the materials. Advanced bonding and lamination techniques ensure that all layers maintain proper adhesion even under repeated bending cycles, contributing to the overall durability of flexible displays.Expand Specific Solutions

Key Industry Players in Advanced Display Materials

The flexible microdisplay market is currently in a growth phase, characterized by increasing adoption across consumer electronics and wearable devices. The global market size is projected to expand significantly, driven by demand for lightweight, energy-efficient display solutions. Technologically, the field shows moderate maturity with established players like BOE Technology, Samsung Display, and LG Display leading commercial development, while companies such as TCL China Star and Tianma Microelectronics are rapidly advancing their capabilities. Research institutions including Industrial Technology Research Institute and Electronics & Telecommunications Research Institute are contributing fundamental innovations. Material science breakthroughs from JSR Corp and 3M are addressing key challenges in flexibility and durability, positioning this technology for mainstream adoption within the next 3-5 years.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible microdisplay material system centered around their OLED technology. Their approach utilizes ultra-thin flexible glass substrates with thicknesses below 100 micrometers, combined with proprietary low-temperature polysilicon (LTPS) backplanes that maintain electron mobility above 100 cm²/Vs even when flexed. BOE's material innovation includes specialized organic light-emitting materials optimized for microdisplay applications, achieving pixel densities exceeding 1000 PPI while maintaining flexibility. Their multi-layer thin film encapsulation (TFE) technology combines inorganic silicon nitride layers with organic polymer layers to achieve water vapor transmission rates below 10^-6 g/m²/day. BOE has also pioneered flexible transparent conductive materials based on silver nanowire networks that maintain conductivity when bent to radii below 3mm, essential for touch functionality in flexible microdisplays.

Strengths: Strong manufacturing infrastructure and scale that enables cost-effective production, with extensive experience in display technologies across multiple generations. Their government backing provides substantial R&D resources. Weaknesses: Relatively newer entrant to cutting-edge flexible display technologies compared to Korean competitors, with some technical gaps in the highest-performance materials and processes for microdisplays.

LG Display Co., Ltd.

Technical Solution: LG Display has developed proprietary P-OLED (Plastic OLED) technology for flexible microdisplays, utilizing a polyimide substrate that enables displays to bend and flex without damage. Their material innovation includes the development of "WOLED" (White OLED) with color filters that provides enhanced color accuracy and reduced power consumption. LG has pioneered advanced barrier films with multi-layer structures that achieve water vapor transmission rates below 10^-6 g/m²/day, critical for protecting sensitive organic materials in flexible displays. Their in-cell touch technology integrates touch sensors directly within the display structure, reducing thickness while improving touch response. LG has also developed specialized adhesives and optical bonding materials that maintain flexibility while ensuring durability through repeated bending cycles, with some materials capable of withstanding over 200,000 fold cycles without performance degradation.

Strengths: Expertise in large-scale OLED production that can be adapted to microdisplay applications, with strong vertical integration from materials to finished displays. Their WOLED technology offers manufacturing advantages for consistent quality. Weaknesses: Their flexible display technology has historically focused on larger displays, requiring significant adaptation for microdisplay applications with different material requirements at smaller scales.

Critical Material Innovations and Patents Analysis

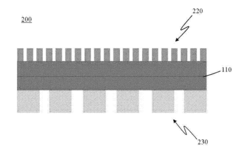

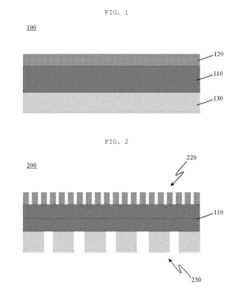

Flexible hybrid substrate for display and method for manufacturing same

PatentActiveUS20170171968A1

Innovation

- A flexible hybrid substrate comprising an ultra-thin glass plate with a first transparent thin film and a second transparent thin film made of transparent conductive polymer, such as silver nanowires or PEDOT-PSS, which are patterned and applied using roll-to-roll and wet coating methods to enhance flexibility and reduce brittleness, allowing for high-temperature processing and noise-blocking capabilities.

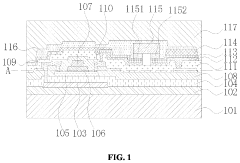

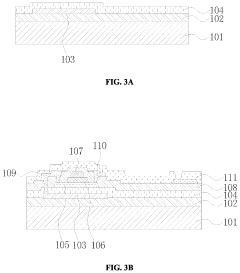

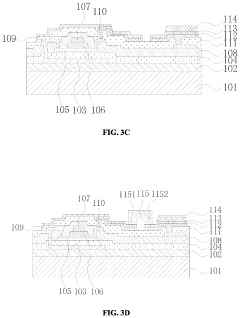

Flexible micro-led display panel and manufacturing method thereof

PatentActiveUS20220336525A1

Innovation

- A flexible micro-LED display panel design featuring a CPI-based substrate structure with a thin film transistor array, connecting electrode layers, micro-LED chips, and a flexible encapsulation layer, along with a second base substrate to control the neutral layer at the thin film transistor array, reducing wire disconnection risks and utilizing IGZO and Al—Nd materials for improved flexibility and barrier properties.

Manufacturing Process Optimization for Flexible Displays

The optimization of manufacturing processes for flexible displays represents a critical frontier in the advancement of flexible microdisplay technology. Current manufacturing approaches face significant challenges related to yield rates, cost efficiency, and scalability when incorporating advanced materials into production lines. Traditional display manufacturing techniques require substantial modification to accommodate the unique properties of flexible substrates and novel semiconductor materials.

Roll-to-roll (R2R) processing has emerged as one of the most promising manufacturing methodologies for flexible displays, offering continuous production capabilities that significantly reduce production time and material waste. Recent innovations in R2R technology have focused on improving registration accuracy and maintaining consistent material deposition across large surface areas. Thermal management during R2R processing remains particularly challenging when working with temperature-sensitive flexible substrates such as polyimide and polyethylene naphthalate (PEN).

Low-temperature deposition techniques have been developed specifically for flexible display manufacturing to address thermal constraints. Plasma-enhanced chemical vapor deposition (PECVD) operating at temperatures below 200°C has shown considerable promise for thin-film transistor (TFT) fabrication on flexible substrates. Similarly, solution-processing methods including inkjet printing and slot-die coating are gaining traction for their ability to precisely deposit active materials without subjecting substrates to excessive thermal stress.

Encapsulation processes have undergone significant refinement to ensure adequate protection of organic and inorganic components in flexible displays. Multi-layer barrier films incorporating alternating organic and inorganic layers have demonstrated superior performance in preventing oxygen and moisture penetration. Atomic Layer Deposition (ALD) has proven particularly effective for creating ultra-thin, defect-free barrier layers with water vapor transmission rates below 10^-6 g/m²/day.

Laser processing techniques have revolutionized patterning capabilities for flexible displays, enabling high-precision feature creation without mechanical contact that could damage delicate substrates. Femtosecond laser systems can achieve sub-micron resolution while minimizing the heat-affected zone, preserving the integrity of surrounding materials and structures.

Integration of in-line quality control systems utilizing machine vision and AI-based defect detection has substantially improved manufacturing yields. These systems can identify microscopic defects in real-time, allowing for immediate process adjustments and reducing waste. Advanced optical metrology tools capable of measuring layer thickness variations below 1nm have become essential components in flexible display production lines.

The transition from batch processing to fully continuous manufacturing remains an ongoing challenge, with hybrid approaches currently dominating industrial implementation. Industry leaders are investing heavily in developing fully integrated production lines that minimize handling steps between process stages, thereby reducing contamination risks and mechanical stress on flexible substrates.

Roll-to-roll (R2R) processing has emerged as one of the most promising manufacturing methodologies for flexible displays, offering continuous production capabilities that significantly reduce production time and material waste. Recent innovations in R2R technology have focused on improving registration accuracy and maintaining consistent material deposition across large surface areas. Thermal management during R2R processing remains particularly challenging when working with temperature-sensitive flexible substrates such as polyimide and polyethylene naphthalate (PEN).

Low-temperature deposition techniques have been developed specifically for flexible display manufacturing to address thermal constraints. Plasma-enhanced chemical vapor deposition (PECVD) operating at temperatures below 200°C has shown considerable promise for thin-film transistor (TFT) fabrication on flexible substrates. Similarly, solution-processing methods including inkjet printing and slot-die coating are gaining traction for their ability to precisely deposit active materials without subjecting substrates to excessive thermal stress.

Encapsulation processes have undergone significant refinement to ensure adequate protection of organic and inorganic components in flexible displays. Multi-layer barrier films incorporating alternating organic and inorganic layers have demonstrated superior performance in preventing oxygen and moisture penetration. Atomic Layer Deposition (ALD) has proven particularly effective for creating ultra-thin, defect-free barrier layers with water vapor transmission rates below 10^-6 g/m²/day.

Laser processing techniques have revolutionized patterning capabilities for flexible displays, enabling high-precision feature creation without mechanical contact that could damage delicate substrates. Femtosecond laser systems can achieve sub-micron resolution while minimizing the heat-affected zone, preserving the integrity of surrounding materials and structures.

Integration of in-line quality control systems utilizing machine vision and AI-based defect detection has substantially improved manufacturing yields. These systems can identify microscopic defects in real-time, allowing for immediate process adjustments and reducing waste. Advanced optical metrology tools capable of measuring layer thickness variations below 1nm have become essential components in flexible display production lines.

The transition from batch processing to fully continuous manufacturing remains an ongoing challenge, with hybrid approaches currently dominating industrial implementation. Industry leaders are investing heavily in developing fully integrated production lines that minimize handling steps between process stages, thereby reducing contamination risks and mechanical stress on flexible substrates.

Sustainability and Recyclability of Advanced Display Materials

The sustainability and recyclability of materials used in flexible microdisplays represent critical considerations in the development of next-generation display technologies. As environmental regulations become increasingly stringent worldwide, manufacturers must address the entire lifecycle of display products, from raw material sourcing to end-of-life management. Current flexible display technologies often incorporate rare earth elements, precious metals, and synthetic polymers that present significant environmental challenges.

Material selection for sustainable flexible microdisplays requires balancing performance requirements with environmental impact. Biodegradable polymers such as cellulose derivatives and polylactic acid (PLA) have emerged as promising substrates, offering comparable flexibility to conventional petroleum-based polymers while significantly reducing environmental footprint. These materials can decompose under controlled conditions, minimizing waste accumulation in landfills.

Recycling processes for advanced display materials have evolved substantially in recent years. Novel separation techniques utilizing supercritical fluid extraction can recover up to 95% of indium from indium tin oxide (ITO) layers, a significant improvement over conventional methods. Automated disassembly systems employing machine vision and precision robotics now enable more efficient recovery of valuable components from end-of-life displays, including flexible variants.

The industry has begun implementing design-for-recycling principles specifically for flexible display technologies. This approach includes modular construction, material labeling, and avoiding composite materials that complicate separation processes. Companies like Samsung and LG Display have established closed-loop manufacturing systems that reintegrate recovered materials into new production cycles, reducing virgin material requirements by approximately 30%.

Energy consumption during material processing represents another sustainability challenge. Advanced low-temperature deposition techniques for thin-film transistors and electrode materials have reduced energy requirements by up to 40% compared to conventional methods. Additionally, water-based processing for certain display components has decreased hazardous solvent usage, minimizing environmental contamination risks and improving workplace safety.

Regulatory frameworks worldwide increasingly mandate extended producer responsibility for electronic displays. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in Asia have accelerated industry adoption of recyclable materials and design practices. These frameworks have catalyzed innovation in material science, driving development of environmentally benign alternatives to traditional display materials.

Looking forward, emerging technologies such as self-healing materials and reversible adhesives promise to extend display lifespans and facilitate component recovery. Bioinspired materials derived from renewable sources represent another frontier in sustainable display development, potentially offering biodegradability without compromising performance characteristics essential for flexible microdisplay applications.

Material selection for sustainable flexible microdisplays requires balancing performance requirements with environmental impact. Biodegradable polymers such as cellulose derivatives and polylactic acid (PLA) have emerged as promising substrates, offering comparable flexibility to conventional petroleum-based polymers while significantly reducing environmental footprint. These materials can decompose under controlled conditions, minimizing waste accumulation in landfills.

Recycling processes for advanced display materials have evolved substantially in recent years. Novel separation techniques utilizing supercritical fluid extraction can recover up to 95% of indium from indium tin oxide (ITO) layers, a significant improvement over conventional methods. Automated disassembly systems employing machine vision and precision robotics now enable more efficient recovery of valuable components from end-of-life displays, including flexible variants.

The industry has begun implementing design-for-recycling principles specifically for flexible display technologies. This approach includes modular construction, material labeling, and avoiding composite materials that complicate separation processes. Companies like Samsung and LG Display have established closed-loop manufacturing systems that reintegrate recovered materials into new production cycles, reducing virgin material requirements by approximately 30%.

Energy consumption during material processing represents another sustainability challenge. Advanced low-temperature deposition techniques for thin-film transistors and electrode materials have reduced energy requirements by up to 40% compared to conventional methods. Additionally, water-based processing for certain display components has decreased hazardous solvent usage, minimizing environmental contamination risks and improving workplace safety.

Regulatory frameworks worldwide increasingly mandate extended producer responsibility for electronic displays. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in Asia have accelerated industry adoption of recyclable materials and design practices. These frameworks have catalyzed innovation in material science, driving development of environmentally benign alternatives to traditional display materials.

Looking forward, emerging technologies such as self-healing materials and reversible adhesives promise to extend display lifespans and facilitate component recovery. Bioinspired materials derived from renewable sources represent another frontier in sustainable display development, potentially offering biodegradability without compromising performance characteristics essential for flexible microdisplay applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!