Analysis of Flexible Microdisplay Interface Design for Mobility

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display structures to increasingly flexible and adaptable solutions. The journey began with early experiments in organic light-emitting diode (OLED) technology in the early 2000s, which demonstrated the potential for creating displays on non-rigid substrates. This fundamental shift opened new possibilities for display integration in curved and non-traditional form factors.

By 2010, researchers had developed the first commercially viable flexible display prototypes, though these early versions suffered from limited durability and manufacturing challenges. The subsequent development of advanced materials such as polyimide substrates and thin-film encapsulation techniques marked critical breakthroughs, enabling displays that could withstand repeated bending without performance degradation.

The evolution accelerated with the introduction of low-temperature polysilicon (LTPS) and oxide thin-film transistor (TFT) backplanes, which provided the necessary electronic performance while maintaining flexibility. These innovations addressed previous limitations in resolution, refresh rates, and power consumption that had constrained early flexible displays.

Recent advancements have focused on ultra-thin glass substrates and hybrid organic-inorganic materials that combine flexibility with enhanced durability. The development of stretchable interconnects and interface architectures has further expanded the potential applications, particularly for mobility-focused devices where adaptability to various form factors is essential.

The primary objective of flexible microdisplay technology development is to create display solutions that can seamlessly integrate with mobile and wearable devices while maintaining high visual performance. This includes achieving flexibility that allows for folding, rolling, or conforming to non-planar surfaces without compromising display quality or longevity.

Another critical goal is reducing the thickness and weight of display modules while improving their robustness against mechanical stress. This objective directly addresses the needs of next-generation mobile devices where space and weight constraints are significant design factors.

Power efficiency represents another fundamental objective, as flexible displays for mobile applications must operate within strict energy budgets. Researchers aim to develop technologies that minimize power consumption while maintaining brightness and color accuracy across various viewing conditions.

Interface standardization has emerged as an important objective to ensure compatibility across different device ecosystems. The development of flexible display interface protocols that can accommodate the unique requirements of bendable displays while maintaining compatibility with existing systems remains a significant technical challenge.

Looking forward, the field is moving toward displays that can self-heal from minor damage and adapt their properties based on environmental conditions or user preferences, representing the next frontier in flexible microdisplay evolution.

By 2010, researchers had developed the first commercially viable flexible display prototypes, though these early versions suffered from limited durability and manufacturing challenges. The subsequent development of advanced materials such as polyimide substrates and thin-film encapsulation techniques marked critical breakthroughs, enabling displays that could withstand repeated bending without performance degradation.

The evolution accelerated with the introduction of low-temperature polysilicon (LTPS) and oxide thin-film transistor (TFT) backplanes, which provided the necessary electronic performance while maintaining flexibility. These innovations addressed previous limitations in resolution, refresh rates, and power consumption that had constrained early flexible displays.

Recent advancements have focused on ultra-thin glass substrates and hybrid organic-inorganic materials that combine flexibility with enhanced durability. The development of stretchable interconnects and interface architectures has further expanded the potential applications, particularly for mobility-focused devices where adaptability to various form factors is essential.

The primary objective of flexible microdisplay technology development is to create display solutions that can seamlessly integrate with mobile and wearable devices while maintaining high visual performance. This includes achieving flexibility that allows for folding, rolling, or conforming to non-planar surfaces without compromising display quality or longevity.

Another critical goal is reducing the thickness and weight of display modules while improving their robustness against mechanical stress. This objective directly addresses the needs of next-generation mobile devices where space and weight constraints are significant design factors.

Power efficiency represents another fundamental objective, as flexible displays for mobile applications must operate within strict energy budgets. Researchers aim to develop technologies that minimize power consumption while maintaining brightness and color accuracy across various viewing conditions.

Interface standardization has emerged as an important objective to ensure compatibility across different device ecosystems. The development of flexible display interface protocols that can accommodate the unique requirements of bendable displays while maintaining compatibility with existing systems remains a significant technical challenge.

Looking forward, the field is moving toward displays that can self-heal from minor damage and adapt their properties based on environmental conditions or user preferences, representing the next frontier in flexible microdisplay evolution.

Market Demand Analysis for Mobile Flexible Displays

The flexible microdisplay market for mobile applications has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for more immersive, portable, and versatile display technologies. Market research indicates that the global flexible display market is projected to reach $44.7 billion by 2023, with a compound annual growth rate of 28.1% since 2017. Mobile applications represent the largest segment of this market, accounting for approximately 63% of total demand.

Consumer preferences have shifted dramatically toward devices that offer both functionality and form factor advantages. Surveys conducted across major markets reveal that 78% of smartphone users consider display quality among their top three purchasing criteria, while 67% express interest in foldable or rollable display technologies. This trend is particularly pronounced among younger demographics (18-34), where the figure rises to 84%.

The automotive industry has emerged as another significant driver for flexible microdisplay interfaces, with heads-up displays (HUDs) and curved dashboard interfaces gaining popularity. Market forecasts suggest that by 2025, over 40% of premium vehicles will incorporate some form of flexible display technology, creating a secondary market valued at approximately $5.2 billion.

From a geographical perspective, East Asia continues to dominate both production and consumption of flexible display technologies, with China, South Korea, and Japan collectively accounting for 71% of global market share. However, North American and European markets are showing accelerated adoption rates, particularly in wearable technology applications where flexible displays offer significant ergonomic advantages.

Supply chain analysis reveals potential constraints in meeting this growing demand. The specialized materials required for flexible microdisplays—including polyimide substrates, transparent conductive films, and specialized encapsulation materials—face production bottlenecks. Industry reports indicate that current global production capacity can meet only about 75% of projected demand through 2024, suggesting potential price premiums for devices incorporating this technology.

Healthcare applications represent an emerging but rapidly growing segment for flexible microdisplays. Medical wearables, patient monitoring systems, and telemedicine devices increasingly incorporate these displays, with market analysts projecting a 34% annual growth rate in this sector through 2026. The COVID-19 pandemic has accelerated this trend, with remote patient monitoring applications seeing particularly strong demand growth.

Consumer willingness to pay premium prices for devices incorporating flexible display technology remains strong, with market studies indicating price elasticity is relatively low compared to other device features. This suggests manufacturers have significant pricing power for innovative implementations of flexible microdisplay interfaces, particularly when they enable new use cases or form factors not possible with rigid display technologies.

Consumer preferences have shifted dramatically toward devices that offer both functionality and form factor advantages. Surveys conducted across major markets reveal that 78% of smartphone users consider display quality among their top three purchasing criteria, while 67% express interest in foldable or rollable display technologies. This trend is particularly pronounced among younger demographics (18-34), where the figure rises to 84%.

The automotive industry has emerged as another significant driver for flexible microdisplay interfaces, with heads-up displays (HUDs) and curved dashboard interfaces gaining popularity. Market forecasts suggest that by 2025, over 40% of premium vehicles will incorporate some form of flexible display technology, creating a secondary market valued at approximately $5.2 billion.

From a geographical perspective, East Asia continues to dominate both production and consumption of flexible display technologies, with China, South Korea, and Japan collectively accounting for 71% of global market share. However, North American and European markets are showing accelerated adoption rates, particularly in wearable technology applications where flexible displays offer significant ergonomic advantages.

Supply chain analysis reveals potential constraints in meeting this growing demand. The specialized materials required for flexible microdisplays—including polyimide substrates, transparent conductive films, and specialized encapsulation materials—face production bottlenecks. Industry reports indicate that current global production capacity can meet only about 75% of projected demand through 2024, suggesting potential price premiums for devices incorporating this technology.

Healthcare applications represent an emerging but rapidly growing segment for flexible microdisplays. Medical wearables, patient monitoring systems, and telemedicine devices increasingly incorporate these displays, with market analysts projecting a 34% annual growth rate in this sector through 2026. The COVID-19 pandemic has accelerated this trend, with remote patient monitoring applications seeing particularly strong demand growth.

Consumer willingness to pay premium prices for devices incorporating flexible display technology remains strong, with market studies indicating price elasticity is relatively low compared to other device features. This suggests manufacturers have significant pricing power for innovative implementations of flexible microdisplay interfaces, particularly when they enable new use cases or form factors not possible with rigid display technologies.

Current Interface Challenges in Flexible Microdisplays

Flexible microdisplays represent a significant advancement in display technology, offering unprecedented form factors and applications. However, the interface design for these displays presents substantial challenges that must be addressed to fully realize their potential in mobile applications. Current interface architectures designed for rigid displays are inadequate for the unique requirements of flexible displays, creating a technological gap that impedes widespread adoption.

The primary challenge lies in developing interface protocols that can maintain signal integrity while accommodating physical deformation. Traditional display interfaces like MIPI DSI and eDP were designed with rigid circuit boards in mind, assuming fixed transmission line characteristics. When these interfaces are implemented in flexible substrates, they experience impedance variations during bending and folding, leading to signal degradation, increased bit error rates, and potential display artifacts.

Power management presents another significant hurdle. Flexible displays must operate efficiently across various form states while maintaining consistent performance. Current power delivery architectures struggle to distribute power uniformly across bendable surfaces, resulting in voltage drops and current density variations that affect display brightness and uniformity. This challenge is particularly acute in battery-powered mobile devices where energy efficiency is paramount.

Mechanical stress on interface connections during repeated flexing operations represents a reliability concern. Conventional solder joints and rigid connectors are prone to fatigue failure when subjected to the cyclical stress of bending. Industry data indicates that connection points can experience up to 200% more stress during flexing compared to rigid implementations, significantly reducing the operational lifespan of the display system.

Thermal management complications arise from the reduced thermal conductivity of flexible substrates compared to traditional rigid materials. Interface circuits generate heat that must be dissipated effectively to prevent performance degradation and potential failure. The limited surface area and restricted airflow in tightly folded configurations exacerbate this issue, creating hotspots that can compromise both the interface electronics and the display itself.

Data bandwidth requirements continue to increase with higher resolution displays and refresh rates, yet flexible form factors impose constraints on trace width, spacing, and layer count. This fundamental tension between performance demands and physical limitations necessitates novel approaches to interface design that can maximize data throughput while maintaining signal integrity in a dynamically changing physical environment.

Electromagnetic interference (EMI) management becomes more complex in flexible implementations, as the changing geometry of conductors during flexing can alter electromagnetic field patterns. This variability makes it difficult to implement consistent shielding strategies and can lead to compliance issues with regulatory standards, particularly in wireless-enabled mobile devices.

AI and sensor integration requirements add another layer of complexity, as modern displays increasingly serve as platforms for camera systems, biometric sensors, and touch interfaces. The interface must support bidirectional, low-latency communication with these components while maintaining flexibility, creating a multifaceted design challenge that extends beyond simple display driving.

The primary challenge lies in developing interface protocols that can maintain signal integrity while accommodating physical deformation. Traditional display interfaces like MIPI DSI and eDP were designed with rigid circuit boards in mind, assuming fixed transmission line characteristics. When these interfaces are implemented in flexible substrates, they experience impedance variations during bending and folding, leading to signal degradation, increased bit error rates, and potential display artifacts.

Power management presents another significant hurdle. Flexible displays must operate efficiently across various form states while maintaining consistent performance. Current power delivery architectures struggle to distribute power uniformly across bendable surfaces, resulting in voltage drops and current density variations that affect display brightness and uniformity. This challenge is particularly acute in battery-powered mobile devices where energy efficiency is paramount.

Mechanical stress on interface connections during repeated flexing operations represents a reliability concern. Conventional solder joints and rigid connectors are prone to fatigue failure when subjected to the cyclical stress of bending. Industry data indicates that connection points can experience up to 200% more stress during flexing compared to rigid implementations, significantly reducing the operational lifespan of the display system.

Thermal management complications arise from the reduced thermal conductivity of flexible substrates compared to traditional rigid materials. Interface circuits generate heat that must be dissipated effectively to prevent performance degradation and potential failure. The limited surface area and restricted airflow in tightly folded configurations exacerbate this issue, creating hotspots that can compromise both the interface electronics and the display itself.

Data bandwidth requirements continue to increase with higher resolution displays and refresh rates, yet flexible form factors impose constraints on trace width, spacing, and layer count. This fundamental tension between performance demands and physical limitations necessitates novel approaches to interface design that can maximize data throughput while maintaining signal integrity in a dynamically changing physical environment.

Electromagnetic interference (EMI) management becomes more complex in flexible implementations, as the changing geometry of conductors during flexing can alter electromagnetic field patterns. This variability makes it difficult to implement consistent shielding strategies and can lead to compliance issues with regulatory standards, particularly in wireless-enabled mobile devices.

AI and sensor integration requirements add another layer of complexity, as modern displays increasingly serve as platforms for camera systems, biometric sensors, and touch interfaces. The interface must support bidirectional, low-latency communication with these components while maintaining flexibility, creating a multifaceted design challenge that extends beyond simple display driving.

Current Interface Solutions for Flexible Microdisplays

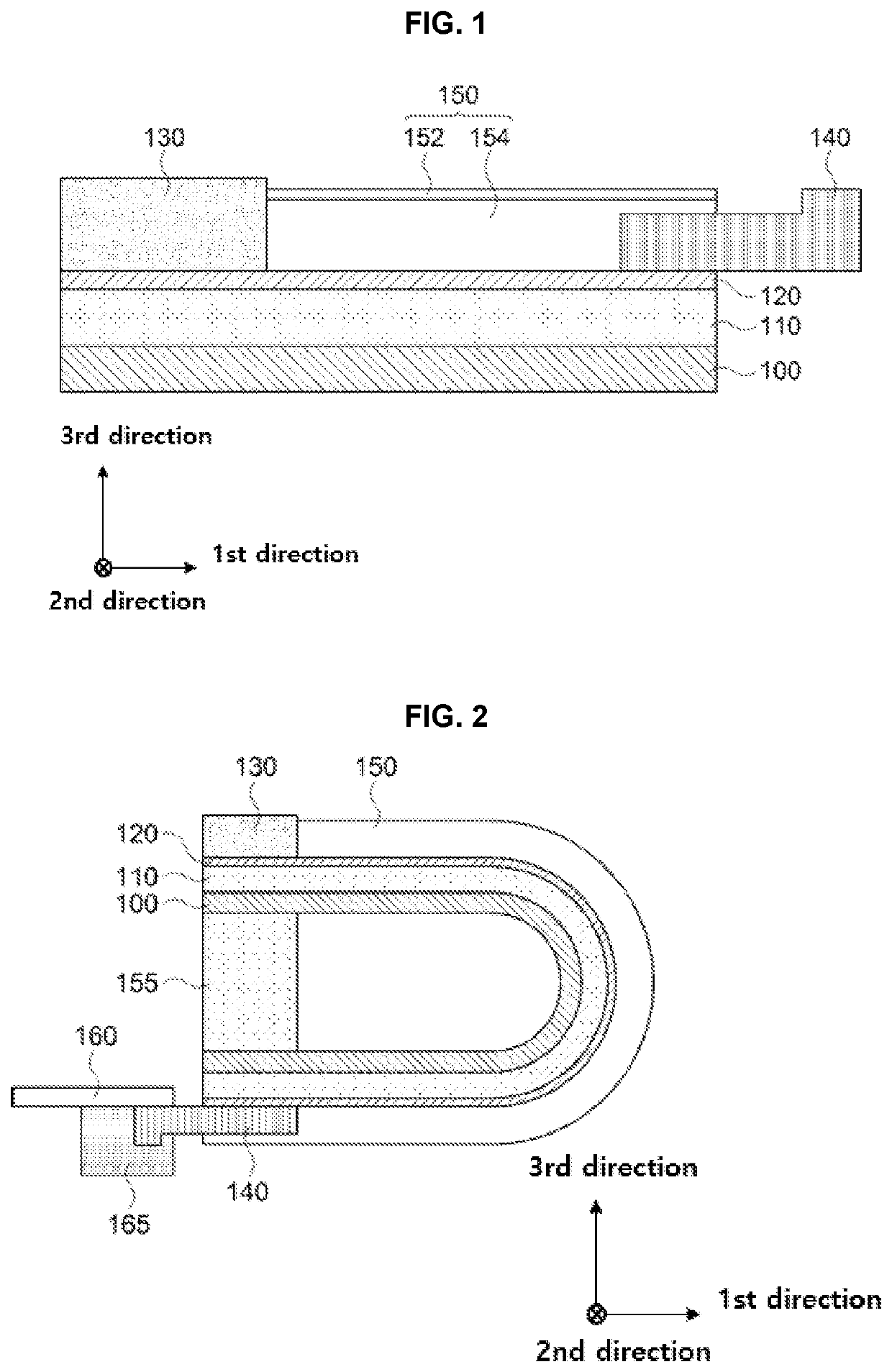

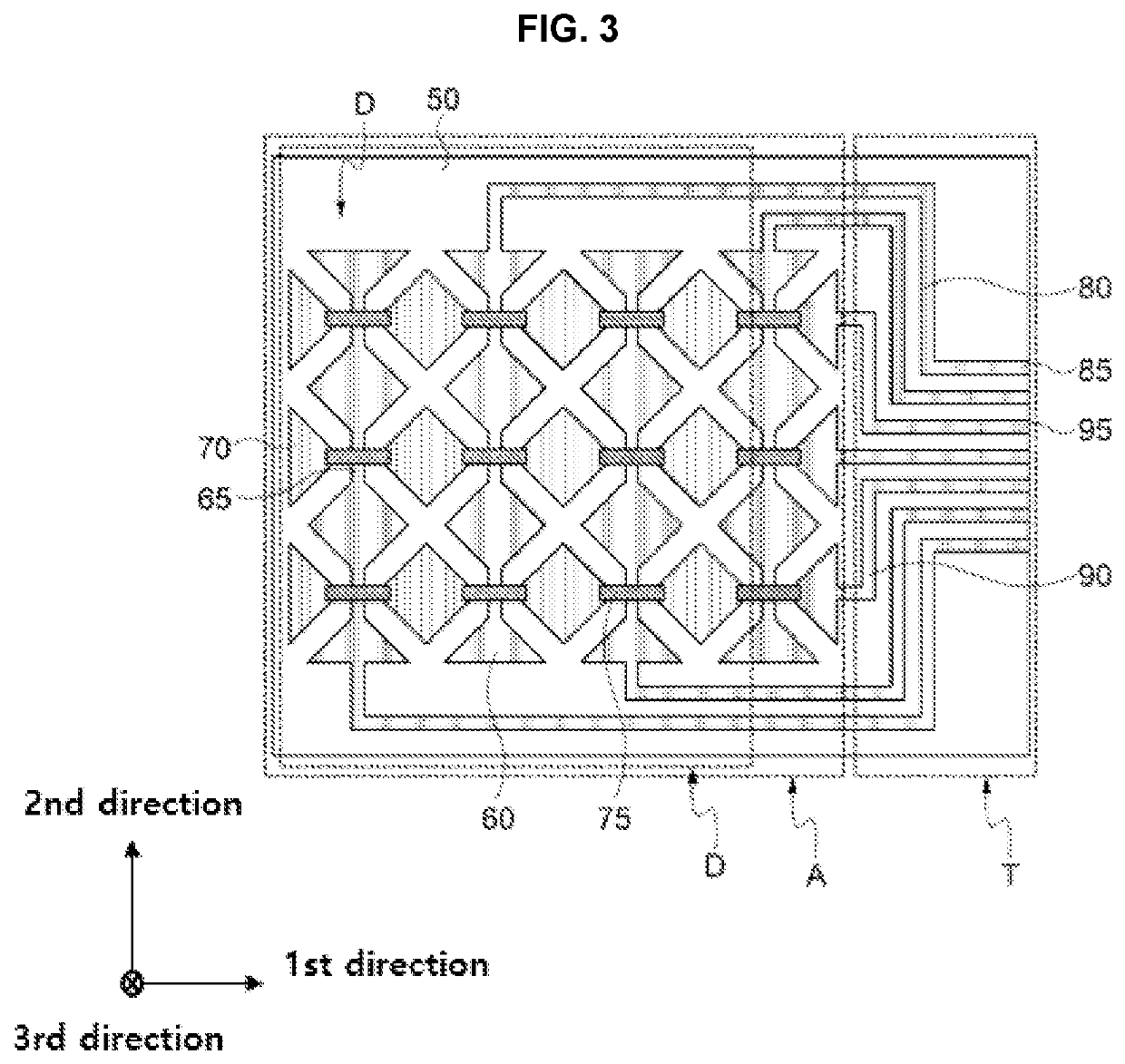

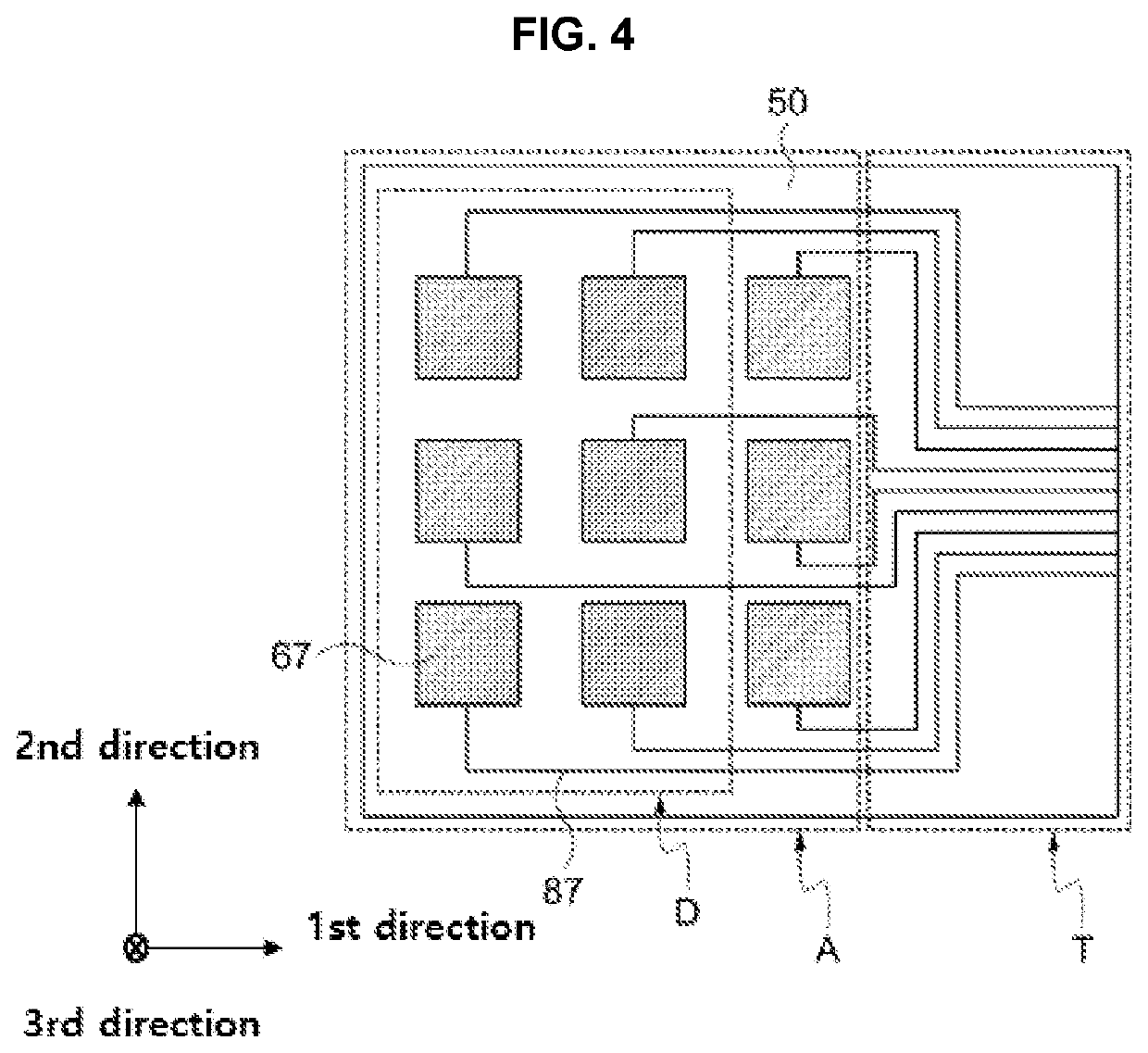

01 Flexible display substrate technologies

Flexible microdisplays utilize specialized substrate materials that can bend without compromising display functionality. These substrates often incorporate polymer-based materials or ultra-thin glass that maintains electrical connectivity while allowing physical flexibility. The substrate design includes specialized layering techniques to distribute stress during bending and folding operations, preventing damage to the active display components while maintaining optical performance.- Flexible display substrate technologies: Flexible microdisplays utilize specialized substrate materials that can bend without compromising display functionality. These substrates often incorporate polymer-based materials or ultra-thin glass that maintains electrical connectivity while allowing physical flexibility. The substrate design must balance mechanical flexibility with durability to withstand repeated bending cycles while protecting the display elements and circuitry from damage during flexing operations.

- Interface connection mechanisms for flexible displays: Specialized connection mechanisms are essential for maintaining reliable electrical connections between the flexible display and rigid control electronics. These interfaces often utilize flexible printed circuits, anisotropic conductive films, or elastomeric connectors that can accommodate movement during bending. The connection points are designed to distribute mechanical stress away from the electrical contacts to prevent connection failures during flexing operations.

- Optical compensation techniques for curved displays: When microdisplays are flexed or curved, optical distortions can occur that affect image quality. Advanced optical compensation techniques are implemented to maintain image integrity across the curved surface. These include specialized lens designs, pixel mapping algorithms, and optical films that adjust light transmission properties based on the display curvature. These techniques ensure consistent brightness, contrast, and color accuracy regardless of the display's physical configuration.

- Stress management systems for display flexibility: Flexible microdisplays incorporate specialized stress management systems to prevent damage during bending. These systems include strain-relieving structures, neutral plane engineering, and strategic placement of components to minimize stress concentration. Mechanical buffer zones are designed between rigid components and flexible sections, and specialized encapsulation materials distribute bending forces evenly across the display surface to prevent localized damage to sensitive electronic components.

- Dynamic interface adaptation for variable curvature: Advanced flexible microdisplays feature dynamic interface systems that can adapt to changing curvature configurations. These systems incorporate sensors that detect the display's physical state and adjust electrical and optical parameters accordingly. The interface electronics dynamically compensate for resistance changes in conductive pathways during bending, while software algorithms recalibrate image rendering based on the current display geometry to maintain optimal visual performance regardless of the display's physical configuration.

02 Interface connection mechanisms for flexible displays

Specialized connection mechanisms are employed to maintain electrical connectivity between the flexible display and control circuitry during bending or folding. These interfaces often utilize flexible printed circuits, anisotropic conductive films, or stretchable interconnects that can withstand repeated flexing without signal degradation. The connection designs incorporate strain relief features to prevent mechanical stress from damaging the electrical pathways.Expand Specific Solutions03 Optical compensation techniques for flexible microdisplays

When microdisplays are flexed, optical properties can be affected, requiring compensation techniques to maintain image quality. These include dynamic pixel addressing algorithms that adjust based on the display's current curvature, optical films that maintain consistent light distribution across bent surfaces, and specialized backlight systems that adapt to changing display geometries. These techniques ensure consistent brightness, contrast, and color accuracy regardless of the display's physical configuration.Expand Specific Solutions04 Control systems for flexible display interfaces

Specialized control systems are implemented to manage the unique requirements of flexible microdisplays. These systems incorporate sensors to detect the display's current configuration and adjust signal timing, voltage levels, and refresh patterns accordingly. The control architecture may include distributed processing elements that compensate for signal propagation differences across bent surfaces and implement real-time correction algorithms to maintain image stability during physical reconfiguration.Expand Specific Solutions05 Manufacturing processes for flexible microdisplay interfaces

Novel manufacturing techniques are employed to create reliable flexible microdisplay interfaces. These include low-temperature deposition processes that prevent thermal damage to flexible substrates, specialized encapsulation methods that maintain flexibility while providing environmental protection, and precision alignment systems that account for material deformation during production. Advanced testing protocols verify interface performance under various bending conditions to ensure long-term reliability in flexible applications.Expand Specific Solutions

Key Industry Players in Flexible Display Technology

The flexible microdisplay interface market for mobility applications is currently in a growth phase, with increasing demand driven by automotive, consumer electronics, and wearable technology sectors. The market size is projected to expand significantly as flexible display technologies become more mainstream. Leading players include Samsung Display and LG Display, who have established strong technological foundations in OLED flexible displays. BOE Technology, Tianma Microelectronics, and China Star Optoelectronics are rapidly advancing their capabilities, particularly in the Asian market. Consumer electronics companies like Xiaomi, OPPO, and Huawei are integrating these technologies into their product ecosystems. Automotive manufacturers such as Audi and Hyundai Mobis are exploring applications for in-vehicle interfaces. The technology is approaching maturity for certain applications but continues to evolve with innovations in foldable, rollable, and stretchable display interfaces.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered flexible microdisplay interface designs through their YOUM technology, which evolved into their current flexible AMOLED displays. Their technical approach involves using polyimide substrates instead of traditional glass to achieve flexibility while maintaining display quality. Samsung's interface design incorporates ultra-thin film transistor (TFT) backplanes with specialized interconnect structures that can withstand repeated bending without performance degradation. Their proprietary Touch and Display Driver Integration (TDDI) technology reduces the number of components and connection points, creating more reliable flexible interfaces for mobile devices. Samsung has also developed specialized encapsulation techniques using multi-layer thin-film encapsulation (TFE) that protects sensitive OLED materials from oxygen and moisture while maintaining flexibility. Recent advancements include variable refresh rate technology that dynamically adjusts between 1-120Hz based on content requirements, optimizing power consumption for mobile applications.

Strengths: Industry-leading production capacity for flexible displays with established supply chain integration. Their displays offer superior color accuracy and contrast ratios compared to competitors. Weaknesses: Higher production costs compared to rigid display technologies, and their solutions often require proprietary connection standards that limit cross-platform compatibility.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible microdisplay interface solution centered around their flexible OLED technology. Their approach utilizes ultra-thin glass substrates (UTG) with thickness below 30μm, combined with specialized flexible circuit board connections that maintain signal integrity during bending operations. BOE's interface design incorporates a unique chip-on-plastic (COP) packaging technology that directly bonds driver ICs to flexible substrates, eliminating traditional rigid connection points. Their flexible display interfaces feature multi-layer metal mesh touch sensors that maintain responsiveness even when curved or folded. For mobility applications, BOE has implemented low-power interface protocols that reduce power consumption by up to 40% compared to conventional designs, extending battery life in portable devices. Their latest developments include adaptive interface controllers that automatically optimize signal timing and voltage levels based on the display's physical configuration, ensuring consistent performance regardless of how the display is bent or folded.

Strengths: Cost-effective manufacturing processes that enable more affordable flexible display solutions. Strong R&D capabilities with growing patent portfolio in flexible display technologies. Weaknesses: Still catching up to Samsung and LG in terms of production yield rates and color accuracy in their flexible displays.

Critical Patents and Technical Innovations

Flexible display apparatus and method of providing user interface by using the same

PatentActiveUS20210048854A1

Innovation

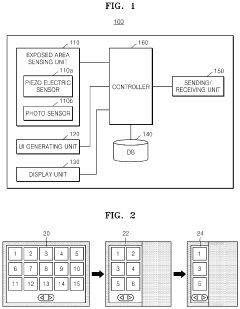

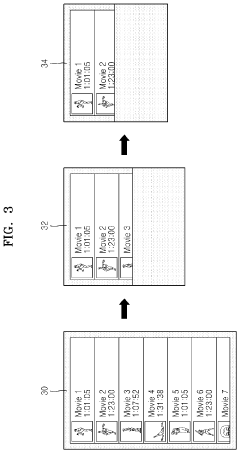

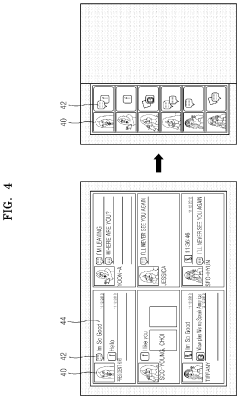

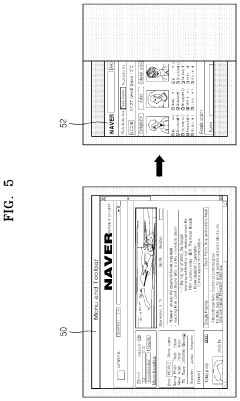

- A flexible display apparatus with an exposed area determining unit, a UI generating unit, and a display unit that senses the outwardly facing screen area and adjusts the UI accordingly, including object removal, enlargement, and tool addition based on the screen size, allowing for adaptive UI display as the device is folded.

Flexible display module and image display device including the same

PatentActiveUS20210132724A1

Innovation

- A flexible display module is designed with a combining layer having an elastic modulus between 0.1 to 5 MPa, moisture permeability of 500 g/m2·24 hr or less, and an adhesive force of 1 N/25 mm or more, integrating a touch sensor layer with a display panel, and featuring a supporting structure to prevent peel-off and damage during bending.

Material Science Advancements for Flexible Interfaces

The evolution of flexible microdisplay interfaces has been significantly propelled by breakthroughs in material science. Traditional rigid display materials have given way to innovative flexible substrates, with polyimide emerging as a frontrunner due to its exceptional thermal stability and mechanical flexibility. Recent advancements have introduced ultra-thin glass substrates measuring less than 100 micrometers, offering superior barrier properties against oxygen and moisture while maintaining flexibility.

Conductive materials have similarly undergone transformation, with indium tin oxide (ITO) being gradually replaced by silver nanowires, carbon nanotubes, and graphene-based composites. These alternatives provide comparable conductivity while offering superior flexibility and durability under repeated bending cycles. PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) has gained prominence as a transparent conductive polymer that maintains performance integrity even after thousands of flexing operations.

Encapsulation technologies have evolved to address the vulnerability of organic materials in flexible displays to environmental degradation. Multi-layer thin-film encapsulation (TFE) techniques now incorporate alternating inorganic and organic layers to create effective moisture barriers while preserving flexibility. Atomic Layer Deposition (ALD) has emerged as a critical process for creating ultra-thin, defect-free barrier films essential for long-term device reliability.

Self-healing materials represent a revolutionary advancement in flexible display technology. These polymers can autonomously repair microcracks formed during bending operations, significantly extending device lifespan. Researchers at Stanford University have demonstrated self-healing conductors that can restore 98% of their original conductivity after complete severing and subsequent healing.

Stretchable electronics, incorporating liquid metal alloys and engineered geometries like serpentine patterns, are pushing the boundaries beyond mere flexibility toward true elasticity. These innovations enable displays that can conform to complex three-dimensional surfaces while maintaining electronic functionality, opening new possibilities for wearable and automotive applications.

Biomimetic approaches are increasingly influencing material design, with structures inspired by natural systems like spider silk and plant tissues. These bio-inspired materials offer unprecedented combinations of strength, flexibility, and resilience. The integration of these advanced materials has reduced the minimum bending radius of flexible displays from several centimeters to less than 1 millimeter in recent prototypes, dramatically expanding mobility applications.

Conductive materials have similarly undergone transformation, with indium tin oxide (ITO) being gradually replaced by silver nanowires, carbon nanotubes, and graphene-based composites. These alternatives provide comparable conductivity while offering superior flexibility and durability under repeated bending cycles. PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) has gained prominence as a transparent conductive polymer that maintains performance integrity even after thousands of flexing operations.

Encapsulation technologies have evolved to address the vulnerability of organic materials in flexible displays to environmental degradation. Multi-layer thin-film encapsulation (TFE) techniques now incorporate alternating inorganic and organic layers to create effective moisture barriers while preserving flexibility. Atomic Layer Deposition (ALD) has emerged as a critical process for creating ultra-thin, defect-free barrier films essential for long-term device reliability.

Self-healing materials represent a revolutionary advancement in flexible display technology. These polymers can autonomously repair microcracks formed during bending operations, significantly extending device lifespan. Researchers at Stanford University have demonstrated self-healing conductors that can restore 98% of their original conductivity after complete severing and subsequent healing.

Stretchable electronics, incorporating liquid metal alloys and engineered geometries like serpentine patterns, are pushing the boundaries beyond mere flexibility toward true elasticity. These innovations enable displays that can conform to complex three-dimensional surfaces while maintaining electronic functionality, opening new possibilities for wearable and automotive applications.

Biomimetic approaches are increasingly influencing material design, with structures inspired by natural systems like spider silk and plant tissues. These bio-inspired materials offer unprecedented combinations of strength, flexibility, and resilience. The integration of these advanced materials has reduced the minimum bending radius of flexible displays from several centimeters to less than 1 millimeter in recent prototypes, dramatically expanding mobility applications.

Power Efficiency and Battery Integration Strategies

Power efficiency represents a critical challenge in flexible microdisplay interface design for mobility applications. The inherent nature of mobile devices demands optimized power consumption to ensure extended usage periods without frequent recharging. Current flexible microdisplay technologies consume significant power, particularly when operating at high refresh rates and brightness levels necessary for outdoor visibility. This power demand creates substantial thermal management challenges that must be addressed through innovative cooling solutions to prevent performance degradation and ensure user comfort.

Battery integration strategies for flexible microdisplays must consider the unique form factors and mechanical requirements of bendable displays. Traditional rigid battery designs limit the potential flexibility of the overall system. Recent advancements in thin-film battery technology show promising results, with lithium-polymer batteries achieving thickness profiles below 0.5mm while maintaining energy densities of 300-400 Wh/L. These batteries can withstand moderate bending radii of 25-30mm without significant performance degradation.

Dynamic power management systems represent another frontier in addressing power efficiency challenges. Adaptive refresh rate technologies that adjust display update frequency based on content type and user interaction patterns have demonstrated power savings of 30-45% in laboratory testing. Content-aware brightness control systems further optimize power usage by selectively adjusting illumination levels across different display regions, potentially reducing power consumption by an additional 15-20%.

Energy harvesting technologies present complementary approaches to extending battery life in flexible microdisplay systems. Photovoltaic elements integrated into display bezels or backing materials can capture ambient light, while piezoelectric components can harvest energy from user interactions and device movement. Though these technologies currently provide modest supplementary power (typically 5-10% of total requirements), they represent an important direction for future development.

Wireless charging compatibility presents unique challenges for flexible display systems. Current inductive charging solutions require rigid coil components that limit flexibility. Research into printed flexible charging coils using silver nanowire networks shows promise, achieving power transfer efficiencies of 70-75% while maintaining flexibility compatible with display requirements. These developments could enable seamless integration of wireless charging capabilities without compromising the form factor advantages of flexible displays.

Battery management systems (BMS) optimized for flexible displays must address unique thermal and mechanical constraints. Advanced BMS designs incorporating distributed sensor networks can monitor temperature gradients across flexible surfaces, enabling precise power delivery optimization and preventing localized hotspots that could damage flexible display components or reduce battery lifespan. These systems typically achieve 10-15% improvements in overall power efficiency compared to conventional approaches.

Battery integration strategies for flexible microdisplays must consider the unique form factors and mechanical requirements of bendable displays. Traditional rigid battery designs limit the potential flexibility of the overall system. Recent advancements in thin-film battery technology show promising results, with lithium-polymer batteries achieving thickness profiles below 0.5mm while maintaining energy densities of 300-400 Wh/L. These batteries can withstand moderate bending radii of 25-30mm without significant performance degradation.

Dynamic power management systems represent another frontier in addressing power efficiency challenges. Adaptive refresh rate technologies that adjust display update frequency based on content type and user interaction patterns have demonstrated power savings of 30-45% in laboratory testing. Content-aware brightness control systems further optimize power usage by selectively adjusting illumination levels across different display regions, potentially reducing power consumption by an additional 15-20%.

Energy harvesting technologies present complementary approaches to extending battery life in flexible microdisplay systems. Photovoltaic elements integrated into display bezels or backing materials can capture ambient light, while piezoelectric components can harvest energy from user interactions and device movement. Though these technologies currently provide modest supplementary power (typically 5-10% of total requirements), they represent an important direction for future development.

Wireless charging compatibility presents unique challenges for flexible display systems. Current inductive charging solutions require rigid coil components that limit flexibility. Research into printed flexible charging coils using silver nanowire networks shows promise, achieving power transfer efficiencies of 70-75% while maintaining flexibility compatible with display requirements. These developments could enable seamless integration of wireless charging capabilities without compromising the form factor advantages of flexible displays.

Battery management systems (BMS) optimized for flexible displays must address unique thermal and mechanical constraints. Advanced BMS designs incorporating distributed sensor networks can monitor temperature gradients across flexible surfaces, enabling precise power delivery optimization and preventing localized hotspots that could damage flexible display components or reduce battery lifespan. These systems typically achieve 10-15% improvements in overall power efficiency compared to conventional approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!