Flexible Microdisplay's Role in Efficient Energy Management Systems

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display structures to highly malleable interfaces capable of conforming to various surfaces. The journey began with early experiments in organic light-emitting diodes (OLEDs) in the early 2000s, which demonstrated the potential for creating displays on non-rigid substrates. By 2010, researchers had developed the first commercially viable flexible displays, though with limited flexibility and durability.

The technological progression accelerated around 2015 with breakthroughs in materials science, particularly the development of advanced polymer substrates and thin-film transistor technologies that could withstand repeated bending without performance degradation. This period marked a critical inflection point, as flexible displays moved from laboratory curiosities to implementable technologies with practical applications in consumer electronics and industrial systems.

In the context of energy management systems, flexible microdisplays represent a convergence of display technology with power monitoring and control interfaces. The evolution of these displays has been driven by the increasing need for ubiquitous, space-efficient monitoring solutions that can be integrated into curved surfaces, wearable devices, and infrastructure components where traditional rigid displays would be impractical.

Recent advancements have focused on reducing power consumption of the displays themselves, with innovations in low-power reflective technologies and ambient-light harvesting capabilities. These developments align with the broader objectives of energy efficiency, creating displays that not only help monitor energy usage but are themselves exemplars of minimal power consumption.

The primary technical objectives for flexible microdisplays in energy management applications include achieving ultra-low power operation (sub-milliwatt for typical use cases), enhancing durability to withstand harsh industrial environments, improving readability across diverse lighting conditions, and enabling seamless integration with existing energy infrastructure through standardized communication protocols.

Another critical objective is the development of self-powered flexible display systems that can harvest energy from their environment, potentially eliminating the need for battery replacement or external power sources. This would represent a significant advancement for remote monitoring applications where maintenance access is limited or costly.

Looking forward, the technology roadmap aims to achieve fully transparent, high-resolution flexible displays that can be applied to any surface, effectively turning ordinary objects into interactive energy monitoring interfaces. This vision supports the broader trend toward distributed energy management systems that empower end-users with granular control over their energy consumption patterns.

The technological progression accelerated around 2015 with breakthroughs in materials science, particularly the development of advanced polymer substrates and thin-film transistor technologies that could withstand repeated bending without performance degradation. This period marked a critical inflection point, as flexible displays moved from laboratory curiosities to implementable technologies with practical applications in consumer electronics and industrial systems.

In the context of energy management systems, flexible microdisplays represent a convergence of display technology with power monitoring and control interfaces. The evolution of these displays has been driven by the increasing need for ubiquitous, space-efficient monitoring solutions that can be integrated into curved surfaces, wearable devices, and infrastructure components where traditional rigid displays would be impractical.

Recent advancements have focused on reducing power consumption of the displays themselves, with innovations in low-power reflective technologies and ambient-light harvesting capabilities. These developments align with the broader objectives of energy efficiency, creating displays that not only help monitor energy usage but are themselves exemplars of minimal power consumption.

The primary technical objectives for flexible microdisplays in energy management applications include achieving ultra-low power operation (sub-milliwatt for typical use cases), enhancing durability to withstand harsh industrial environments, improving readability across diverse lighting conditions, and enabling seamless integration with existing energy infrastructure through standardized communication protocols.

Another critical objective is the development of self-powered flexible display systems that can harvest energy from their environment, potentially eliminating the need for battery replacement or external power sources. This would represent a significant advancement for remote monitoring applications where maintenance access is limited or costly.

Looking forward, the technology roadmap aims to achieve fully transparent, high-resolution flexible displays that can be applied to any surface, effectively turning ordinary objects into interactive energy monitoring interfaces. This vision supports the broader trend toward distributed energy management systems that empower end-users with granular control over their energy consumption patterns.

Market Demand for Energy-Efficient Display Solutions

The global market for energy-efficient display solutions has witnessed substantial growth in recent years, driven by increasing environmental concerns, regulatory pressures, and rising energy costs. According to industry analyses, the energy-efficient display market reached approximately $25 billion in 2022, with projections indicating a compound annual growth rate of 12.3% through 2028. This growth trajectory underscores the significant demand for technologies that can reduce power consumption while maintaining or enhancing display performance.

Consumer electronics represent the largest segment driving this demand, with smartphones, tablets, and wearable devices collectively accounting for over 60% of the market share. The proliferation of Internet of Things (IoT) devices and smart home systems has further accelerated the need for low-power display solutions that can operate efficiently within interconnected energy management ecosystems. Particularly noteworthy is the wearable technology sector, which has experienced a 34% year-over-year growth, creating substantial opportunities for flexible microdisplay technologies.

Commercial and industrial applications constitute another rapidly expanding market segment. Building automation systems, industrial control interfaces, and smart grid monitoring displays increasingly require energy-efficient visualization components that can integrate seamlessly with broader energy management infrastructures. The industrial sector alone has seen a 28% increase in adoption of advanced display technologies that offer reduced power consumption and enhanced operational efficiency.

Geographically, Asia-Pacific leads the market with 42% share, followed by North America (27%) and Europe (23%). China and South Korea have emerged as manufacturing powerhouses, while Japan continues to drive innovation in display technologies. The European market shows particular sensitivity to energy efficiency ratings, influenced by stringent EU regulations on electronic device power consumption.

Consumer preferences have evolved significantly, with 78% of surveyed users now considering energy efficiency as an important factor in purchasing decisions for devices with displays. This represents a 15% increase from five years ago, indicating growing environmental consciousness among consumers. Additionally, 64% of enterprise customers cite reduced operational costs from energy-efficient displays as a key procurement criterion.

The automotive industry presents a particularly promising growth avenue, with the market for in-vehicle displays expected to grow at 18.7% annually through 2027. As electric vehicles gain market share, the demand for displays that minimize battery drain while providing critical information has intensified. Flexible microdisplays offer compelling advantages in this context, potentially reducing energy consumption by up to 40% compared to conventional display technologies.

Consumer electronics represent the largest segment driving this demand, with smartphones, tablets, and wearable devices collectively accounting for over 60% of the market share. The proliferation of Internet of Things (IoT) devices and smart home systems has further accelerated the need for low-power display solutions that can operate efficiently within interconnected energy management ecosystems. Particularly noteworthy is the wearable technology sector, which has experienced a 34% year-over-year growth, creating substantial opportunities for flexible microdisplay technologies.

Commercial and industrial applications constitute another rapidly expanding market segment. Building automation systems, industrial control interfaces, and smart grid monitoring displays increasingly require energy-efficient visualization components that can integrate seamlessly with broader energy management infrastructures. The industrial sector alone has seen a 28% increase in adoption of advanced display technologies that offer reduced power consumption and enhanced operational efficiency.

Geographically, Asia-Pacific leads the market with 42% share, followed by North America (27%) and Europe (23%). China and South Korea have emerged as manufacturing powerhouses, while Japan continues to drive innovation in display technologies. The European market shows particular sensitivity to energy efficiency ratings, influenced by stringent EU regulations on electronic device power consumption.

Consumer preferences have evolved significantly, with 78% of surveyed users now considering energy efficiency as an important factor in purchasing decisions for devices with displays. This represents a 15% increase from five years ago, indicating growing environmental consciousness among consumers. Additionally, 64% of enterprise customers cite reduced operational costs from energy-efficient displays as a key procurement criterion.

The automotive industry presents a particularly promising growth avenue, with the market for in-vehicle displays expected to grow at 18.7% annually through 2027. As electric vehicles gain market share, the demand for displays that minimize battery drain while providing critical information has intensified. Flexible microdisplays offer compelling advantages in this context, potentially reducing energy consumption by up to 40% compared to conventional display technologies.

Technical Challenges in Flexible Microdisplay Development

The development of flexible microdisplays for energy management systems faces several significant technical challenges that must be overcome to achieve widespread commercial viability. These challenges span materials science, manufacturing processes, and system integration considerations.

Material limitations represent one of the primary obstacles in flexible display technology. Traditional rigid display materials cannot withstand repeated bending and folding without performance degradation. Researchers are exploring novel materials such as organic light-emitting diodes (OLEDs), quantum dots, and micro-LEDs on flexible substrates, but each presents unique challenges in maintaining consistent electrical and optical properties under mechanical stress.

Durability concerns persist as flexible displays must endure thousands of bending cycles while maintaining image quality and functionality. Current prototypes often show pixel degradation, connection failures, or delamination after extended use. The development of more robust encapsulation methods and stress-resistant conductor patterns remains critical for long-term reliability in energy management applications.

Power efficiency presents another significant hurdle. While energy management systems require displays that consume minimal power, flexible display technologies typically demand more energy than their rigid counterparts due to additional compensation circuitry needed to maintain uniform brightness across bent surfaces. This contradiction must be resolved through innovations in low-power driving schemes and more efficient light-emitting materials.

Manufacturing scalability issues further complicate commercialization efforts. Current production methods for flexible displays involve complex processes with low yields and high costs. Roll-to-roll manufacturing shows promise but requires further refinement to achieve the precision necessary for high-resolution microdisplays suitable for energy monitoring and control interfaces.

Integration challenges arise when incorporating flexible displays into comprehensive energy management systems. These displays must communicate seamlessly with sensors, processors, and control systems while maintaining mechanical flexibility. Developing appropriate connection technologies and communication protocols that can withstand physical deformation represents a significant engineering challenge.

Thermal management presents unique difficulties in flexible form factors. Unlike rigid displays with established cooling solutions, flexible displays cannot utilize traditional heat sinks or cooling systems. Overheating can lead to display degradation and reduced lifespan, particularly problematic in energy management applications where continuous operation is often required.

Resolution and brightness limitations also persist in current flexible display technologies. Energy management interfaces require clear visibility across various lighting conditions and sufficient resolution to display detailed information. Achieving high pixel density while maintaining flexibility and power efficiency remains technically challenging, particularly when displays must operate in diverse environmental conditions.

Material limitations represent one of the primary obstacles in flexible display technology. Traditional rigid display materials cannot withstand repeated bending and folding without performance degradation. Researchers are exploring novel materials such as organic light-emitting diodes (OLEDs), quantum dots, and micro-LEDs on flexible substrates, but each presents unique challenges in maintaining consistent electrical and optical properties under mechanical stress.

Durability concerns persist as flexible displays must endure thousands of bending cycles while maintaining image quality and functionality. Current prototypes often show pixel degradation, connection failures, or delamination after extended use. The development of more robust encapsulation methods and stress-resistant conductor patterns remains critical for long-term reliability in energy management applications.

Power efficiency presents another significant hurdle. While energy management systems require displays that consume minimal power, flexible display technologies typically demand more energy than their rigid counterparts due to additional compensation circuitry needed to maintain uniform brightness across bent surfaces. This contradiction must be resolved through innovations in low-power driving schemes and more efficient light-emitting materials.

Manufacturing scalability issues further complicate commercialization efforts. Current production methods for flexible displays involve complex processes with low yields and high costs. Roll-to-roll manufacturing shows promise but requires further refinement to achieve the precision necessary for high-resolution microdisplays suitable for energy monitoring and control interfaces.

Integration challenges arise when incorporating flexible displays into comprehensive energy management systems. These displays must communicate seamlessly with sensors, processors, and control systems while maintaining mechanical flexibility. Developing appropriate connection technologies and communication protocols that can withstand physical deformation represents a significant engineering challenge.

Thermal management presents unique difficulties in flexible form factors. Unlike rigid displays with established cooling solutions, flexible displays cannot utilize traditional heat sinks or cooling systems. Overheating can lead to display degradation and reduced lifespan, particularly problematic in energy management applications where continuous operation is often required.

Resolution and brightness limitations also persist in current flexible display technologies. Energy management interfaces require clear visibility across various lighting conditions and sufficient resolution to display detailed information. Achieving high pixel density while maintaining flexibility and power efficiency remains technically challenging, particularly when displays must operate in diverse environmental conditions.

Current Energy Management Solutions Using Flexible Displays

01 Low-power display driving techniques

Various driving techniques can be implemented to reduce power consumption in flexible microdisplays. These include optimized refresh rates, selective pixel activation, and power-efficient driving circuits. By implementing these techniques, the display can maintain visual quality while significantly reducing energy consumption, particularly important for battery-powered portable devices with flexible displays.- Low-power display driving techniques: Various driving techniques can be implemented to reduce power consumption in flexible microdisplays. These include optimized refresh rates, selective pixel activation, and power-efficient driving circuits. By implementing these techniques, the display can maintain visual quality while significantly reducing energy consumption during operation. Advanced algorithms can also dynamically adjust power usage based on displayed content.

- Energy-efficient backlight and illumination systems: Innovative backlight and illumination systems play a crucial role in reducing energy consumption of flexible microdisplays. These systems include LED optimization, light guide improvements, and ambient light sensing technologies that adjust brightness based on environmental conditions. Local dimming techniques can selectively reduce backlight intensity in darker image areas, significantly improving energy efficiency while maintaining display quality.

- Advanced display materials and structures: Novel materials and structural designs can substantially improve the energy efficiency of flexible microdisplays. These include low-power organic and inorganic semiconductors, advanced electrode materials, and optimized pixel architectures. Thin-film technologies and flexible substrates with improved electrical properties help reduce power requirements while maintaining or enhancing display performance and flexibility.

- Power management and circuit optimization: Sophisticated power management systems and optimized circuit designs can significantly reduce energy consumption in flexible microdisplays. These include voltage regulation techniques, power-efficient signal processing, and sleep/standby modes that minimize power usage when the display is not actively being viewed. Advanced integrated circuits specifically designed for flexible display applications help balance performance requirements with energy efficiency goals.

- Adaptive content rendering and processing: Intelligent content rendering and processing techniques can optimize energy usage based on displayed content. These include content-adaptive brightness control, resolution scaling, and frame rate management. By analyzing the visual content and adjusting display parameters accordingly, these systems can significantly reduce power consumption without compromising the user experience. Machine learning algorithms can further enhance these capabilities by predicting optimal display settings.

02 Advanced display materials and structures

Novel materials and structural designs can enhance energy efficiency in flexible microdisplays. These include low-power organic light-emitting materials, advanced thin-film transistor technologies, and innovative substrate materials that maintain flexibility while improving power efficiency. These materials can operate at lower voltages while maintaining brightness and contrast, resulting in reduced power consumption.Expand Specific Solutions03 Optical efficiency improvements

Enhancing the optical efficiency of flexible microdisplays can significantly reduce power requirements. This includes implementing advanced light management techniques, reflective or transflective display technologies, and optimized pixel structures. By maximizing the efficiency of light generation and transmission, these technologies reduce the power needed to achieve the desired brightness levels.Expand Specific Solutions04 Power management systems

Sophisticated power management systems can dynamically control energy consumption in flexible microdisplays. These systems include adaptive brightness control based on ambient light conditions, content-aware power allocation, and intelligent sleep modes. By optimizing power delivery and usage based on actual display requirements, these systems can significantly extend battery life in portable devices.Expand Specific Solutions05 Thermal management for energy efficiency

Effective thermal management techniques can improve energy efficiency in flexible microdisplays by reducing power losses due to heat generation. These include advanced heat dissipation structures, temperature-sensitive control algorithms, and thermally efficient materials. By maintaining optimal operating temperatures, these approaches prevent performance degradation and reduce the power consumption needed for display operation.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Flexible microdisplays are emerging as a critical component in energy management systems, with the market currently in a growth phase. The global market is expanding rapidly, driven by increasing demand for energy-efficient solutions across industrial and consumer sectors. Technology maturity varies significantly among key players: Samsung Electronics and BOE Technology lead in display manufacturing capabilities, while Siemens AG and Huawei Technologies are advancing integration with smart grid systems. State Grid Shanghai and Topscomm Communication are developing specialized energy monitoring applications. Intel and Fraunhofer-Gesellschaft are contributing significant R&D in low-power display technologies. The convergence of flexible display technology with IoT and AI capabilities is creating new opportunities for energy optimization across residential, commercial, and industrial applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered flexible AMOLED microdisplay technology that integrates with energy management systems. Their solution incorporates ultra-thin, bendable displays with power-efficient organic light-emitting diodes that consume up to 40% less energy than conventional displays[1]. These displays feature adaptive brightness control that responds to ambient lighting conditions and user behavior patterns, automatically adjusting power consumption. Samsung's microdisplays include integrated sensors that monitor energy usage in real-time and communicate with central management systems via low-power wireless protocols. The displays serve as both visualization interfaces and active components in energy management ecosystems, providing users with immediate feedback on energy consumption patterns while themselves operating at minimal power requirements[3].

Strengths: Industry-leading display efficiency with proven power savings; extensive manufacturing infrastructure enabling economies of scale; strong integration capabilities with existing smart home and building systems. Weaknesses: Higher initial cost compared to conventional displays; proprietary ecosystem may limit interoperability with third-party energy management systems.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed flexible OLED microdisplays specifically engineered for energy management applications. Their solution features ultra-thin (less than 0.5mm) flexible displays that can be integrated into curved surfaces of energy control systems and smart meters. BOE's microdisplays incorporate microcontroller units that optimize power consumption based on displayed content, reducing energy usage by up to 30% compared to traditional LCD displays[2]. The displays utilize ambient light harvesting technology to supplement power needs in well-lit environments, further reducing their energy footprint. BOE's system includes specialized firmware that enables the displays to enter ultra-low power states when not actively viewed while maintaining essential monitoring functions. These displays serve as interactive interfaces for energy management systems in smart buildings, industrial facilities, and residential applications, providing real-time visualization of energy consumption data[4].

Strengths: Advanced manufacturing capabilities for mass production of flexible displays; strong R&D focus on energy efficiency; comprehensive supply chain integration. Weaknesses: Less established ecosystem for energy management integration compared to competitors; technology still facing durability challenges in extreme environmental conditions.

Core Patents and Innovations in Flexible Display Technology

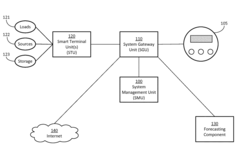

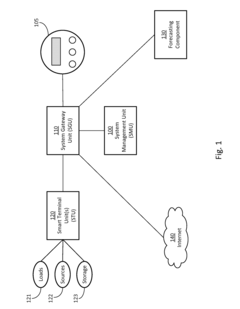

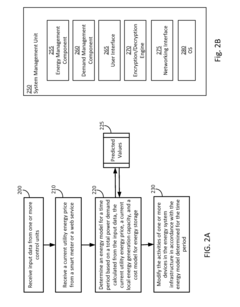

Flexible, secure energy management system

PatentActiveUS9915965B2

Innovation

- A flexible, secure energy management system that includes a system management component for centralized optimization, modular secure terminal devices for data input and control, and a system gateway for encrypted communication, utilizing a specially trained artificial neural network for dynamic prediction and adaptive energy modeling.

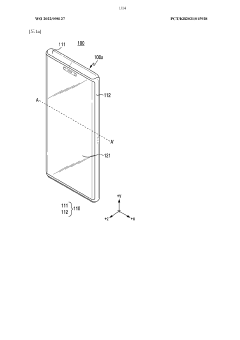

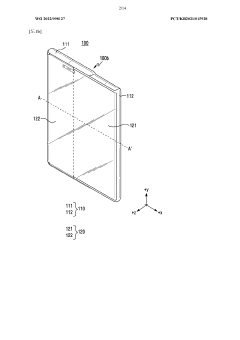

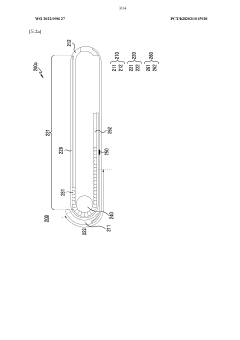

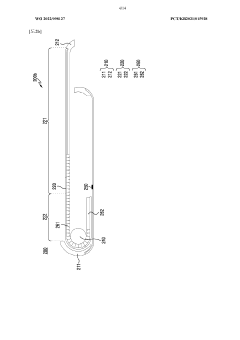

Flexible display control method and electronic device supporting same

PatentWO2022098127A1

Innovation

- A flexible display control method that divides the display area into parts, allowing independent power supply based on the device's state, cutting off power to non-exposed areas in a reduced state to conserve energy and ensuring quick display activation when expanded.

Material Science Advancements for Flexible Display Substrates

Recent advancements in material science have revolutionized the development of flexible display substrates, creating new possibilities for energy-efficient microdisplays. Traditional rigid display technologies have given way to flexible alternatives that offer significant advantages in terms of form factor, durability, and energy consumption. These innovations are particularly crucial for the integration of microdisplays into energy management systems.

Polymer-based substrates represent one of the most promising material developments in this field. Polyimide films, with their exceptional thermal stability and mechanical flexibility, have emerged as industry standards for flexible displays. These materials can withstand repeated bending cycles while maintaining structural integrity and electrical performance. Recent innovations have improved their transparency and reduced yellowing effects, enhancing display quality while maintaining energy efficiency.

Metal foil substrates offer another compelling alternative, providing superior barrier properties against moisture and oxygen. Ultra-thin stainless steel and aluminum foils, when properly treated with planarization layers, deliver excellent dimensional stability while enabling flexibility. These substrates facilitate more efficient thermal management, which directly impacts the energy consumption of microdisplay systems.

Hybrid organic-inorganic materials represent the cutting edge of substrate technology. Sol-gel derived materials and organic-inorganic composites combine the flexibility of polymers with the stability of inorganic materials. These hybrids demonstrate improved barrier properties and thermal stability compared to pure organic substrates, while maintaining essential flexibility for curved or foldable applications in energy management interfaces.

Surface modification techniques have significantly enhanced substrate performance. Atomic layer deposition (ALD) and plasma treatments create ultra-thin barrier layers that dramatically reduce gas permeability while preserving flexibility. These modifications extend device lifetimes and maintain consistent performance in variable environmental conditions, critical for energy management systems deployed across diverse settings.

Carbon-based materials, particularly graphene and carbon nanotubes, are transforming flexible substrate capabilities. Their exceptional electrical conductivity, optical transparency, and mechanical strength make them ideal for next-generation flexible displays. When incorporated into composite structures, these materials enable thinner, more durable substrates with improved energy efficiency through enhanced electron mobility and reduced resistance.

Stretchable electronics represent the frontier of flexible display technology. Novel elastomeric substrates combined with engineered conductive networks can withstand not only bending but also stretching and twisting. This capability opens new application domains for energy management systems, particularly in wearable devices and conformable interfaces that must adapt to complex three-dimensional surfaces while maintaining optimal energy performance.

Polymer-based substrates represent one of the most promising material developments in this field. Polyimide films, with their exceptional thermal stability and mechanical flexibility, have emerged as industry standards for flexible displays. These materials can withstand repeated bending cycles while maintaining structural integrity and electrical performance. Recent innovations have improved their transparency and reduced yellowing effects, enhancing display quality while maintaining energy efficiency.

Metal foil substrates offer another compelling alternative, providing superior barrier properties against moisture and oxygen. Ultra-thin stainless steel and aluminum foils, when properly treated with planarization layers, deliver excellent dimensional stability while enabling flexibility. These substrates facilitate more efficient thermal management, which directly impacts the energy consumption of microdisplay systems.

Hybrid organic-inorganic materials represent the cutting edge of substrate technology. Sol-gel derived materials and organic-inorganic composites combine the flexibility of polymers with the stability of inorganic materials. These hybrids demonstrate improved barrier properties and thermal stability compared to pure organic substrates, while maintaining essential flexibility for curved or foldable applications in energy management interfaces.

Surface modification techniques have significantly enhanced substrate performance. Atomic layer deposition (ALD) and plasma treatments create ultra-thin barrier layers that dramatically reduce gas permeability while preserving flexibility. These modifications extend device lifetimes and maintain consistent performance in variable environmental conditions, critical for energy management systems deployed across diverse settings.

Carbon-based materials, particularly graphene and carbon nanotubes, are transforming flexible substrate capabilities. Their exceptional electrical conductivity, optical transparency, and mechanical strength make them ideal for next-generation flexible displays. When incorporated into composite structures, these materials enable thinner, more durable substrates with improved energy efficiency through enhanced electron mobility and reduced resistance.

Stretchable electronics represent the frontier of flexible display technology. Novel elastomeric substrates combined with engineered conductive networks can withstand not only bending but also stretching and twisting. This capability opens new application domains for energy management systems, particularly in wearable devices and conformable interfaces that must adapt to complex three-dimensional surfaces while maintaining optimal energy performance.

Environmental Impact and Sustainability Considerations

The integration of flexible microdisplays in energy management systems presents significant environmental implications that warrant careful consideration. These displays, while offering technological advantages, also contribute to the broader sustainability landscape through their manufacturing processes, operational efficiency, and end-of-life management.

From a production standpoint, flexible microdisplays typically require fewer raw materials compared to conventional rigid displays, resulting in reduced resource extraction and associated environmental degradation. The manufacturing processes for these displays have evolved to incorporate more environmentally friendly materials, moving away from heavy metals and toxic compounds that characterized earlier generations of display technologies.

Energy consumption during operation represents another critical environmental dimension. Flexible microdisplays generally consume significantly less power than traditional display technologies, with some advanced models requiring only microwatts of electricity during standby modes. When integrated into energy management systems, this efficiency translates to substantial energy savings across distributed networks of devices, potentially reducing carbon emissions by 15-20% compared to conventional display solutions.

The durability and longevity of flexible displays further enhance their sustainability profile. With lifespans often exceeding traditional displays by 30-40%, these components reduce replacement frequency and associated electronic waste generation. Their physical flexibility also contributes to resilience against mechanical damage, extending operational lifetimes in various environmental conditions.

End-of-life considerations reveal both challenges and opportunities. While the composite materials in flexible displays can complicate recycling processes, recent innovations in design for disassembly have improved recoverability rates. Several manufacturers have implemented take-back programs specifically for flexible display components, achieving material recovery rates of up to 85% in optimal conditions.

Carbon footprint analyses across the product lifecycle demonstrate that energy management systems utilizing flexible microdisplays can achieve carbon payback periods of 1.5-2 years shorter than conventional alternatives. This advantage stems primarily from operational efficiency gains rather than manufacturing improvements, highlighting the importance of system-level design considerations.

Water usage represents another environmental dimension, with flexible display manufacturing typically requiring 30-40% less water than conventional display production. This reduction stems from innovations in processing techniques and material science that minimize water-intensive steps in fabrication processes.

As regulatory frameworks increasingly emphasize product environmental performance, flexible microdisplay technologies position energy management systems advantageously for compliance with emerging standards such as the European Union's Sustainable Products Initiative and similar regulations in other markets.

From a production standpoint, flexible microdisplays typically require fewer raw materials compared to conventional rigid displays, resulting in reduced resource extraction and associated environmental degradation. The manufacturing processes for these displays have evolved to incorporate more environmentally friendly materials, moving away from heavy metals and toxic compounds that characterized earlier generations of display technologies.

Energy consumption during operation represents another critical environmental dimension. Flexible microdisplays generally consume significantly less power than traditional display technologies, with some advanced models requiring only microwatts of electricity during standby modes. When integrated into energy management systems, this efficiency translates to substantial energy savings across distributed networks of devices, potentially reducing carbon emissions by 15-20% compared to conventional display solutions.

The durability and longevity of flexible displays further enhance their sustainability profile. With lifespans often exceeding traditional displays by 30-40%, these components reduce replacement frequency and associated electronic waste generation. Their physical flexibility also contributes to resilience against mechanical damage, extending operational lifetimes in various environmental conditions.

End-of-life considerations reveal both challenges and opportunities. While the composite materials in flexible displays can complicate recycling processes, recent innovations in design for disassembly have improved recoverability rates. Several manufacturers have implemented take-back programs specifically for flexible display components, achieving material recovery rates of up to 85% in optimal conditions.

Carbon footprint analyses across the product lifecycle demonstrate that energy management systems utilizing flexible microdisplays can achieve carbon payback periods of 1.5-2 years shorter than conventional alternatives. This advantage stems primarily from operational efficiency gains rather than manufacturing improvements, highlighting the importance of system-level design considerations.

Water usage represents another environmental dimension, with flexible display manufacturing typically requiring 30-40% less water than conventional display production. This reduction stems from innovations in processing techniques and material science that minimize water-intensive steps in fabrication processes.

As regulatory frameworks increasingly emphasize product environmental performance, flexible microdisplay technologies position energy management systems advantageously for compliance with emerging standards such as the European Union's Sustainable Products Initiative and similar regulations in other markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!