Research on Flexible Microdisplay Integration with Quantum Dots

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Microdisplay Evolution and Objectives

Quantum dot (QD) technology has evolved significantly over the past two decades, transforming from a laboratory curiosity to a commercial reality in display applications. The journey began in the early 2000s with the first demonstrations of QD-enhanced LCD displays, where quantum dots were primarily used as color conversion layers. By 2010, the technology had advanced to enable more precise color control and enhanced brightness, leading to the first commercial QD-enhanced televisions entering the market around 2013.

The evolution accelerated dramatically between 2015-2020, with significant breakthroughs in QD stability, efficiency, and manufacturing processes. During this period, research shifted from cadmium-based QDs toward more environmentally friendly indium phosphide alternatives, addressing regulatory concerns while maintaining optical performance. Concurrently, integration methods evolved from QD films to on-chip solutions, enabling more compact and efficient designs critical for microdisplay applications.

The convergence of quantum dot technology with flexible display substrates represents a particularly promising frontier. Initial efforts focused on incorporating QDs into rigid microdisplays, but recent advances in materials science have enabled the integration of quantum dots with flexible substrates such as polyimide and ultrathin glass. This integration presents unique challenges related to thermal management, mechanical stress, and encapsulation requirements to prevent QD degradation during flexing operations.

The primary technical objectives in this field center around several key parameters. First is achieving high pixel density (>1000 PPI) while maintaining the superior color gamut (>90% Rec.2020) that QDs enable. Second is developing integration processes compatible with flexible substrates that can withstand repeated bending cycles (>100,000 cycles at 5mm radius) without performance degradation. Third is enhancing operational stability under variable environmental conditions, particularly humidity and temperature fluctuations that flexible devices frequently encounter.

Additional objectives include reducing power consumption to below 1W for full-display operation, critical for wearable applications, and developing scalable manufacturing processes that can transition from laboratory demonstrations to high-volume production. The ultimate goal is to create flexible microdisplays that combine the exceptional color performance of quantum dots with the form factor advantages of flexible substrates, enabling new product categories in AR/VR headsets, wearable displays, and foldable devices.

The technological trajectory suggests that within the next five years, we may see the first commercial products incorporating flexible QD microdisplays, with initial applications likely in premium wearable devices before expanding to broader consumer electronics markets.

The evolution accelerated dramatically between 2015-2020, with significant breakthroughs in QD stability, efficiency, and manufacturing processes. During this period, research shifted from cadmium-based QDs toward more environmentally friendly indium phosphide alternatives, addressing regulatory concerns while maintaining optical performance. Concurrently, integration methods evolved from QD films to on-chip solutions, enabling more compact and efficient designs critical for microdisplay applications.

The convergence of quantum dot technology with flexible display substrates represents a particularly promising frontier. Initial efforts focused on incorporating QDs into rigid microdisplays, but recent advances in materials science have enabled the integration of quantum dots with flexible substrates such as polyimide and ultrathin glass. This integration presents unique challenges related to thermal management, mechanical stress, and encapsulation requirements to prevent QD degradation during flexing operations.

The primary technical objectives in this field center around several key parameters. First is achieving high pixel density (>1000 PPI) while maintaining the superior color gamut (>90% Rec.2020) that QDs enable. Second is developing integration processes compatible with flexible substrates that can withstand repeated bending cycles (>100,000 cycles at 5mm radius) without performance degradation. Third is enhancing operational stability under variable environmental conditions, particularly humidity and temperature fluctuations that flexible devices frequently encounter.

Additional objectives include reducing power consumption to below 1W for full-display operation, critical for wearable applications, and developing scalable manufacturing processes that can transition from laboratory demonstrations to high-volume production. The ultimate goal is to create flexible microdisplays that combine the exceptional color performance of quantum dots with the form factor advantages of flexible substrates, enabling new product categories in AR/VR headsets, wearable displays, and foldable devices.

The technological trajectory suggests that within the next five years, we may see the first commercial products incorporating flexible QD microdisplays, with initial applications likely in premium wearable devices before expanding to broader consumer electronics markets.

Market Analysis for Flexible Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for portable, lightweight, and durable electronic devices. The global flexible display market was valued at approximately $23.1 billion in 2022 and is projected to reach $42.5 billion by 2027, growing at a CAGR of 13.0%. This growth trajectory is particularly significant for flexible microdisplay technologies integrated with quantum dots, which represent a high-value segment within the broader market.

Consumer electronics remains the dominant application sector, accounting for over 60% of the flexible display market. Smartphones and wearable devices are the primary drivers, with automotive displays and digital signage emerging as rapidly growing segments. The integration of quantum dots with flexible microdisplays is especially relevant for premium smartphones, AR/VR headsets, and automotive head-up displays, where high color accuracy and energy efficiency are paramount.

Regional analysis reveals that Asia-Pacific dominates the flexible display manufacturing landscape, with South Korea, Japan, China, and Taiwan collectively holding approximately 75% of production capacity. North America and Europe lead in research and development activities, particularly in advanced materials and quantum dot technologies, while also representing significant end-markets for premium devices incorporating these displays.

The market demonstrates strong segmentation based on technology types. OLED currently dominates with approximately 70% market share due to its maturity and established manufacturing infrastructure. However, quantum dot-enhanced flexible displays are experiencing the fastest growth rate at 28% annually, albeit from a smaller base. This growth is attributed to quantum dots' superior color performance, energy efficiency, and increasing cost-effectiveness as manufacturing processes improve.

Key market drivers include the expanding smartphone replacement cycle, growing adoption of wearable technology, increasing investment in AR/VR applications, and the automotive industry's shift toward digital cockpits. The COVID-19 pandemic initially disrupted supply chains but subsequently accelerated demand for personal electronic devices, creating a net positive effect on market growth.

Consumer preference analysis indicates willingness to pay a premium of 15-20% for devices featuring flexible displays with enhanced visual performance. This premium increases to 25-30% when quantum dot technology is incorporated, reflecting consumer recognition of the superior visual experience these displays provide.

Market challenges include high manufacturing costs, yield issues in flexible substrate production, and technical difficulties in achieving uniform quantum dot distribution in flexible formats. Despite these challenges, the convergence of flexible display technologies with quantum dots represents one of the most promising growth segments in the display industry.

Consumer electronics remains the dominant application sector, accounting for over 60% of the flexible display market. Smartphones and wearable devices are the primary drivers, with automotive displays and digital signage emerging as rapidly growing segments. The integration of quantum dots with flexible microdisplays is especially relevant for premium smartphones, AR/VR headsets, and automotive head-up displays, where high color accuracy and energy efficiency are paramount.

Regional analysis reveals that Asia-Pacific dominates the flexible display manufacturing landscape, with South Korea, Japan, China, and Taiwan collectively holding approximately 75% of production capacity. North America and Europe lead in research and development activities, particularly in advanced materials and quantum dot technologies, while also representing significant end-markets for premium devices incorporating these displays.

The market demonstrates strong segmentation based on technology types. OLED currently dominates with approximately 70% market share due to its maturity and established manufacturing infrastructure. However, quantum dot-enhanced flexible displays are experiencing the fastest growth rate at 28% annually, albeit from a smaller base. This growth is attributed to quantum dots' superior color performance, energy efficiency, and increasing cost-effectiveness as manufacturing processes improve.

Key market drivers include the expanding smartphone replacement cycle, growing adoption of wearable technology, increasing investment in AR/VR applications, and the automotive industry's shift toward digital cockpits. The COVID-19 pandemic initially disrupted supply chains but subsequently accelerated demand for personal electronic devices, creating a net positive effect on market growth.

Consumer preference analysis indicates willingness to pay a premium of 15-20% for devices featuring flexible displays with enhanced visual performance. This premium increases to 25-30% when quantum dot technology is incorporated, reflecting consumer recognition of the superior visual experience these displays provide.

Market challenges include high manufacturing costs, yield issues in flexible substrate production, and technical difficulties in achieving uniform quantum dot distribution in flexible formats. Despite these challenges, the convergence of flexible display technologies with quantum dots represents one of the most promising growth segments in the display industry.

Current Challenges in Flexible Quantum Dot Integration

Despite significant advancements in quantum dot technology for display applications, the integration of quantum dots (QDs) into flexible microdisplays presents several formidable challenges. The primary obstacle lies in maintaining quantum dot stability during the flexing process. When QD films undergo repeated bending and folding, the nanocrystal structure can deteriorate, leading to decreased quantum yield and color shift. This degradation significantly impacts display performance, particularly in applications requiring frequent folding or rolling.

Material compatibility issues represent another major hurdle. The integration of quantum dots with flexible substrates often involves complex interfaces between organic and inorganic materials. These interfaces can develop defects during fabrication or operation, creating pathways for oxygen and moisture penetration. Such penetration accelerates QD oxidation, resulting in diminished luminescence efficiency and shortened device lifespan.

The manufacturing scalability of flexible QD displays presents significant technical challenges. Current production methods for high-quality quantum dots typically involve solution processing techniques that are difficult to adapt to roll-to-roll manufacturing processes required for cost-effective flexible display production. The precise deposition of uniform QD layers on flexible substrates remains problematic at industrial scales, leading to inconsistent optical performance across the display area.

Encapsulation technology represents a critical bottleneck in flexible QD microdisplay development. Traditional rigid encapsulation methods provide excellent protection against environmental degradation but compromise flexibility. Conversely, highly flexible encapsulation materials often offer insufficient barrier properties against oxygen and moisture. This fundamental trade-off between flexibility and protection continues to challenge researchers and manufacturers alike.

Thermal management issues become particularly acute in flexible form factors. Quantum dot displays generate heat during operation, and efficient heat dissipation is crucial for maintaining performance and longevity. Flexible substrates typically exhibit lower thermal conductivity than rigid alternatives, potentially leading to localized heating that accelerates QD degradation and creates non-uniform display characteristics.

The integration of driving electronics with flexible QD layers presents additional complexity. Traditional thin-film transistor (TFT) backplanes may crack or delaminate under repeated flexing, disrupting electrical connections to the QD layer. While organic TFTs offer improved mechanical flexibility, they typically deliver lower performance in terms of switching speed and current density, limiting display refresh rates and brightness.

Achieving consistent color performance across different bending states remains an unresolved challenge. The optical properties of quantum dot films can vary with mechanical deformation, potentially causing visible color shifts during device operation. This phenomenon necessitates sophisticated compensation algorithms or novel material designs to maintain color accuracy throughout the display's operational range.

Material compatibility issues represent another major hurdle. The integration of quantum dots with flexible substrates often involves complex interfaces between organic and inorganic materials. These interfaces can develop defects during fabrication or operation, creating pathways for oxygen and moisture penetration. Such penetration accelerates QD oxidation, resulting in diminished luminescence efficiency and shortened device lifespan.

The manufacturing scalability of flexible QD displays presents significant technical challenges. Current production methods for high-quality quantum dots typically involve solution processing techniques that are difficult to adapt to roll-to-roll manufacturing processes required for cost-effective flexible display production. The precise deposition of uniform QD layers on flexible substrates remains problematic at industrial scales, leading to inconsistent optical performance across the display area.

Encapsulation technology represents a critical bottleneck in flexible QD microdisplay development. Traditional rigid encapsulation methods provide excellent protection against environmental degradation but compromise flexibility. Conversely, highly flexible encapsulation materials often offer insufficient barrier properties against oxygen and moisture. This fundamental trade-off between flexibility and protection continues to challenge researchers and manufacturers alike.

Thermal management issues become particularly acute in flexible form factors. Quantum dot displays generate heat during operation, and efficient heat dissipation is crucial for maintaining performance and longevity. Flexible substrates typically exhibit lower thermal conductivity than rigid alternatives, potentially leading to localized heating that accelerates QD degradation and creates non-uniform display characteristics.

The integration of driving electronics with flexible QD layers presents additional complexity. Traditional thin-film transistor (TFT) backplanes may crack or delaminate under repeated flexing, disrupting electrical connections to the QD layer. While organic TFTs offer improved mechanical flexibility, they typically deliver lower performance in terms of switching speed and current density, limiting display refresh rates and brightness.

Achieving consistent color performance across different bending states remains an unresolved challenge. The optical properties of quantum dot films can vary with mechanical deformation, potentially causing visible color shifts during device operation. This phenomenon necessitates sophisticated compensation algorithms or novel material designs to maintain color accuracy throughout the display's operational range.

Current Integration Methods for Flexible QD Microdisplays

01 Flexible substrate technologies for microdisplays

Flexible substrates are essential for creating bendable microdisplays. These substrates can be made from materials such as polyimide, polyethylene terephthalate (PET), or thin glass that provide mechanical flexibility while maintaining structural integrity. The manufacturing processes involve specialized deposition techniques that allow electronic components to be placed on these flexible materials without compromising performance. These substrates serve as the foundation for integrating quantum dot layers and other display components in a way that allows the entire device to bend without damage.- Flexible substrate technologies for microdisplays: Flexible substrates are essential for creating bendable microdisplays. These substrates can be made from materials such as polyimide, polyethylene terephthalate (PET), or thin glass that provide mechanical flexibility while maintaining structural integrity. The manufacturing processes involve specialized deposition techniques that allow electronic components to be integrated onto these flexible materials without compromising performance. These substrates serve as the foundation for flexible microdisplays with quantum dot integration, enabling applications in wearable technology and foldable devices.

- Quantum dot integration methods for display applications: Quantum dots can be integrated into microdisplays using various methods, including solution processing, printing techniques, and vapor deposition. These nanoscale semiconductor particles emit light at specific wavelengths when excited, providing vibrant colors with high efficiency. The integration process must ensure uniform distribution of quantum dots and proper encapsulation to prevent degradation. Advanced techniques allow for precise patterning of different quantum dot types to create RGB pixel arrays, enabling high-resolution flexible displays with enhanced color gamut and brightness.

- Protective encapsulation for quantum dot displays: Protective encapsulation is crucial for maintaining the performance and longevity of quantum dot-based flexible displays. Encapsulation layers shield quantum dots from oxygen and moisture, which can cause degradation and reduced efficiency. Advanced barrier films with multiple inorganic and organic layers provide effective protection while maintaining flexibility. Some encapsulation techniques incorporate self-healing materials that can repair minor damage to the protective layers. These protective systems are essential for ensuring the reliability of flexible microdisplays in various environmental conditions.

- Backplane and driving circuit designs for flexible displays: Specialized backplane and driving circuit designs are necessary for flexible quantum dot microdisplays. These circuits must maintain functionality while being subjected to bending and folding. Thin-film transistor (TFT) arrays made from materials like indium gallium zinc oxide (IGZO) or low-temperature polysilicon (LTPS) provide the necessary electronic control while remaining flexible. Advanced circuit layouts incorporate strain-relieving structures that prevent damage during flexing. These backplane technologies enable the active matrix addressing required for high-resolution quantum dot displays with minimal power consumption.

- Manufacturing processes for flexible quantum dot displays: Manufacturing flexible microdisplays with quantum dots requires specialized processes that combine traditional display fabrication with novel techniques. Roll-to-roll processing allows for continuous production of flexible displays on polymer substrates. Low-temperature deposition methods preserve the integrity of temperature-sensitive materials. Laser patterning and inkjet printing enable precise placement of quantum dots in pixel arrays. These manufacturing approaches must address challenges such as layer alignment, uniform quantum dot distribution, and yield management to produce commercially viable flexible microdisplays with consistent performance characteristics.

02 Quantum dot integration methods for display applications

Quantum dots can be integrated into microdisplays using various methods, including solution processing, inkjet printing, or photolithography. These nanoscale semiconductor particles emit specific wavelengths of light when excited, providing vibrant colors with high efficiency. The integration process must ensure uniform distribution of quantum dots to maintain consistent color performance across the display. Special encapsulation techniques are also employed to protect quantum dots from environmental factors while maintaining their optical properties in flexible display configurations.Expand Specific Solutions03 Backplane architecture for flexible quantum dot displays

Specialized backplane architectures are developed for flexible microdisplays that incorporate quantum dots. These backplanes typically use thin-film transistor (TFT) arrays that can withstand bending while maintaining electrical performance. Advanced circuit designs distribute power and signals efficiently across the flexible surface. The backplane must be engineered to provide stable electrical characteristics during flexing operations while interfacing effectively with the quantum dot emission layer to control brightness and color output.Expand Specific Solutions04 Encapsulation and protection technologies

Effective encapsulation is crucial for flexible quantum dot microdisplays to protect sensitive components from oxygen and moisture. Barrier films with multiple inorganic and organic layers are used to achieve low water vapor transmission rates while maintaining flexibility. Advanced sealing techniques ensure that the quantum dot materials remain stable during repeated bending cycles. These protective layers must be optically transparent to allow light emission while providing mechanical protection and environmental isolation.Expand Specific Solutions05 Manufacturing processes for flexible quantum dot displays

Specialized manufacturing processes have been developed for producing flexible microdisplays with quantum dots. These include roll-to-roll processing for continuous production, low-temperature deposition techniques that don't damage flexible substrates, and precision alignment methods for multilayer structures. Advanced patterning technologies enable high-resolution pixel formation on flexible surfaces. These manufacturing approaches focus on maintaining quantum dot performance while ensuring the display can withstand thousands of bending cycles without degradation.Expand Specific Solutions

Leading Companies in Quantum Dot Display Ecosystem

The flexible microdisplay integration with quantum dots market is currently in an early growth phase, characterized by significant R&D investments and emerging commercial applications. The global market size is projected to expand rapidly, driven by increasing demand for advanced display technologies in AR/VR, wearables, and automotive sectors. Technologically, major players demonstrate varying levels of maturity, with Samsung Display, BOE Technology, and TCL China Star leading with established quantum dot integration capabilities. Companies like Intel, Corning, and IBM contribute complementary technologies in semiconductor integration and materials science. Korean entities including Samsung Electronics, KAIST, and Korea Electronics Technology Institute show strong research foundations, while Chinese manufacturers like Tianma Microelectronics and HKC are rapidly advancing their capabilities. The ecosystem includes specialized players like Kateeva and E Ink Holdings who provide critical enabling technologies for flexible display manufacturing.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative approach to flexible quantum dot microdisplays using their "QLED Pro" technology. Their solution incorporates electroluminescent quantum dots (EL-QDs) directly into flexible backplanes manufactured with low-temperature polysilicon (LTPS) processes. BOE's technique involves depositing cadmium-free quantum dots through advanced patterning methods including photolithography and inkjet printing on ultra-thin polyimide substrates. Their displays achieve flexibility through a specialized mechanical structure that distributes strain evenly across the display surface, allowing for bend radii as small as 1mm without performance degradation[3]. BOE has also pioneered a unique barrier film technology that provides superior protection against oxygen and moisture penetration while maintaining flexibility, extending QD lifetime to over 10,000 hours in flexible configurations[4]. Their quantum dot formulation achieves color gamut coverage of approximately 114% NTSC while maintaining brightness levels suitable for AR/VR applications.

Strengths: Excellent color performance with cadmium-free materials, advanced manufacturing infrastructure, and established supply chain integration. Their flexible barrier technology provides superior environmental protection. Weaknesses: Higher power consumption compared to OLED alternatives, and challenges with achieving uniform quantum dot deposition across large flexible surfaces.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered flexible quantum dot microdisplay technology through their proprietary QD-OLED architecture. Their approach integrates quantum dots directly onto flexible substrates using inkjet printing methods, allowing for precise deposition of red and green QD color converters over blue OLED emitters. This creates self-emissive displays with exceptional color purity and flexibility. Their technology employs a unique pixel structure where blue light from OLEDs passes through quantum dot layers that convert it to pure red and green light, eliminating the need for color filters and improving energy efficiency by approximately 20%[1]. Samsung has also developed specialized encapsulation techniques to protect quantum dots from oxygen and moisture degradation, using multi-layer thin film encapsulation (TFE) with alternating inorganic and organic layers that maintain flexibility while providing effective barrier properties[2].

Strengths: Superior color volume (over 90% of BT.2020 color space), excellent viewing angles, and power efficiency. Their vertical integration from QD synthesis to display manufacturing provides manufacturing advantages. Weaknesses: Higher production costs compared to conventional displays, and challenges with blue OLED lifetime affecting long-term display performance.

Key Patents in Quantum Dot Flexible Display Technology

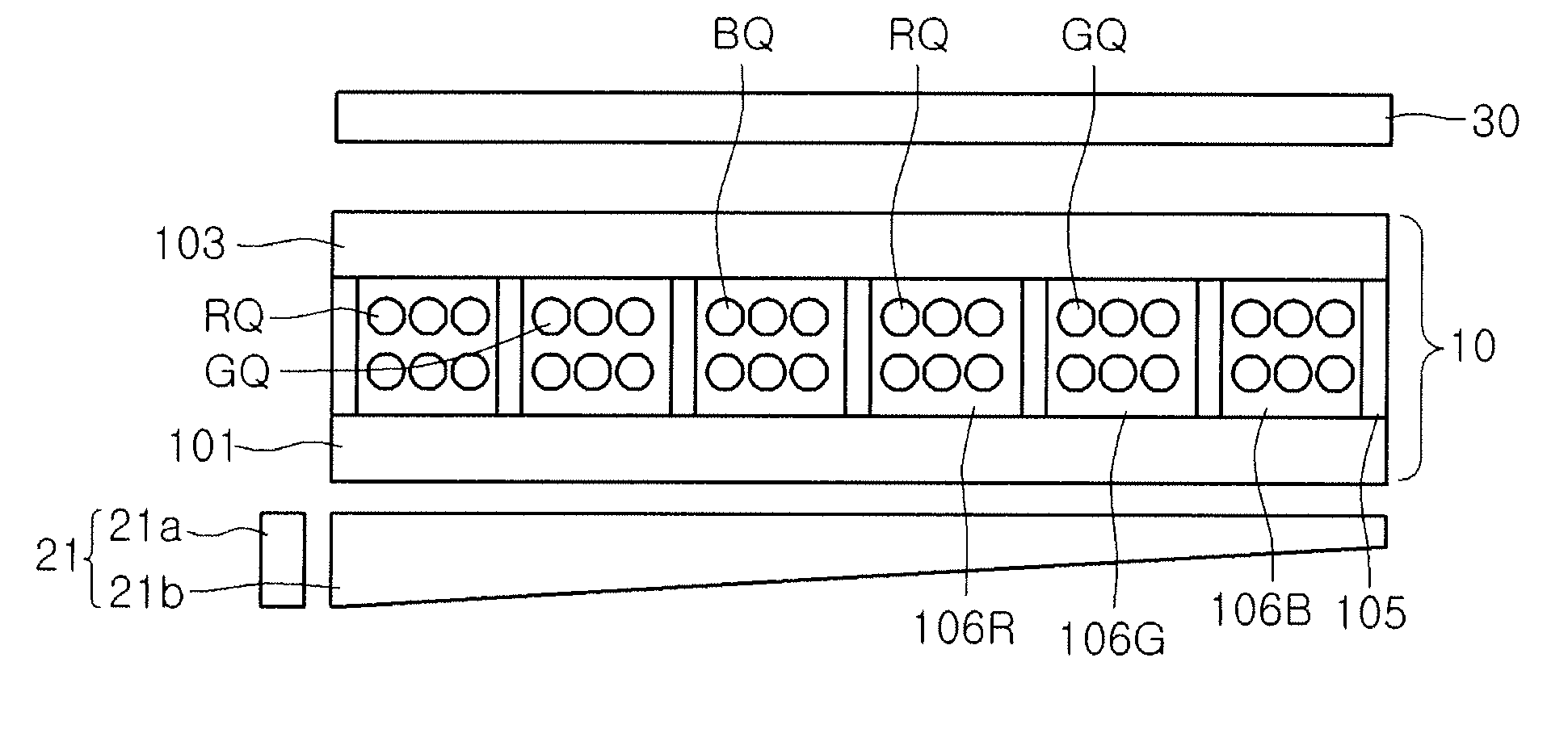

Display device

PatentWO2025080109A1

Innovation

- The display device incorporates a plurality of first electrode pads corresponding to light emitting regions, a second electrode pad, and light emitting elements electrically connected to the second electrode pad. These light emitting elements consist of semiconductor layers and active layers, with quantum dots in porous semiconductor layers to convert light colors, enhancing light emission efficiency.

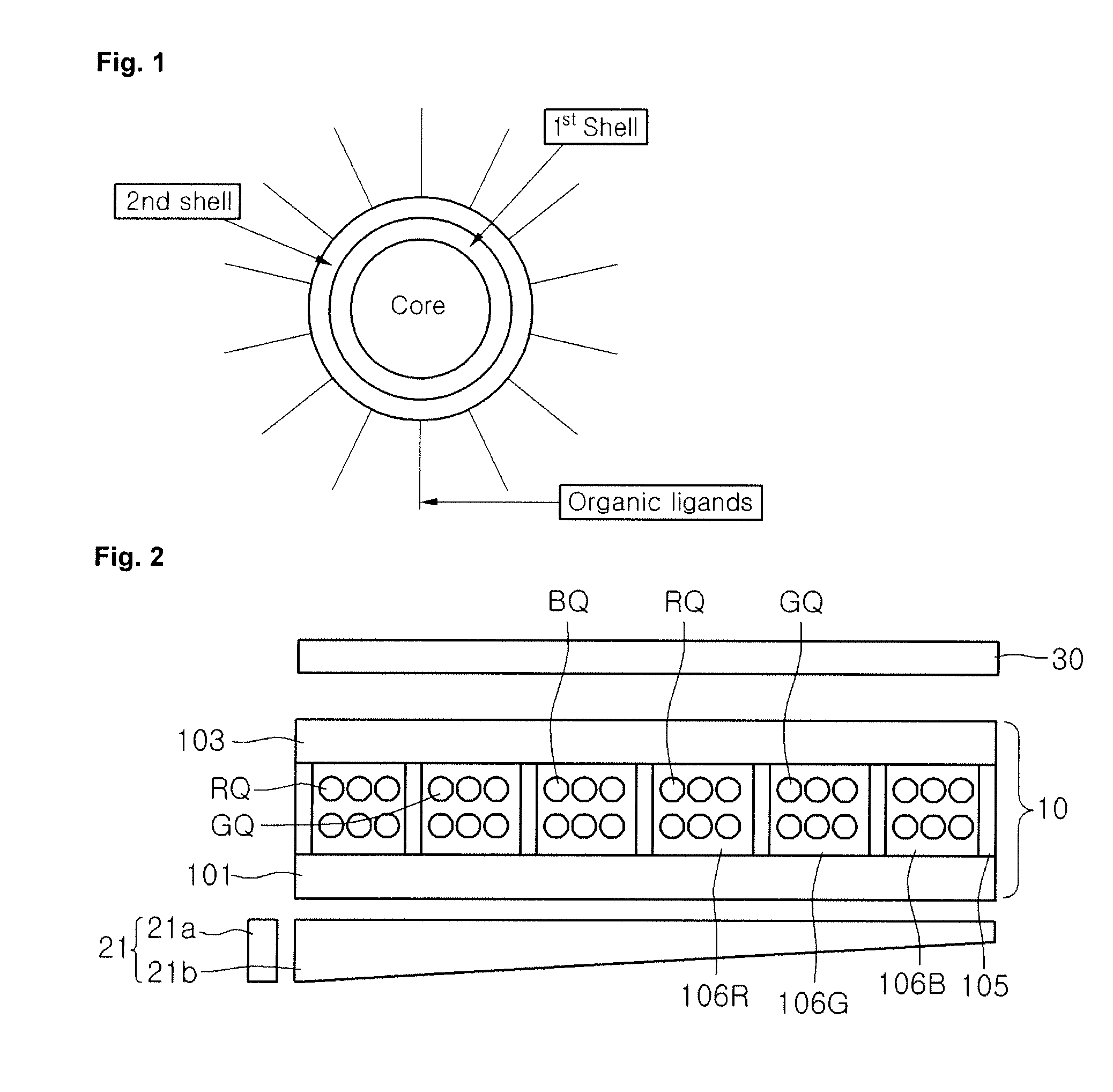

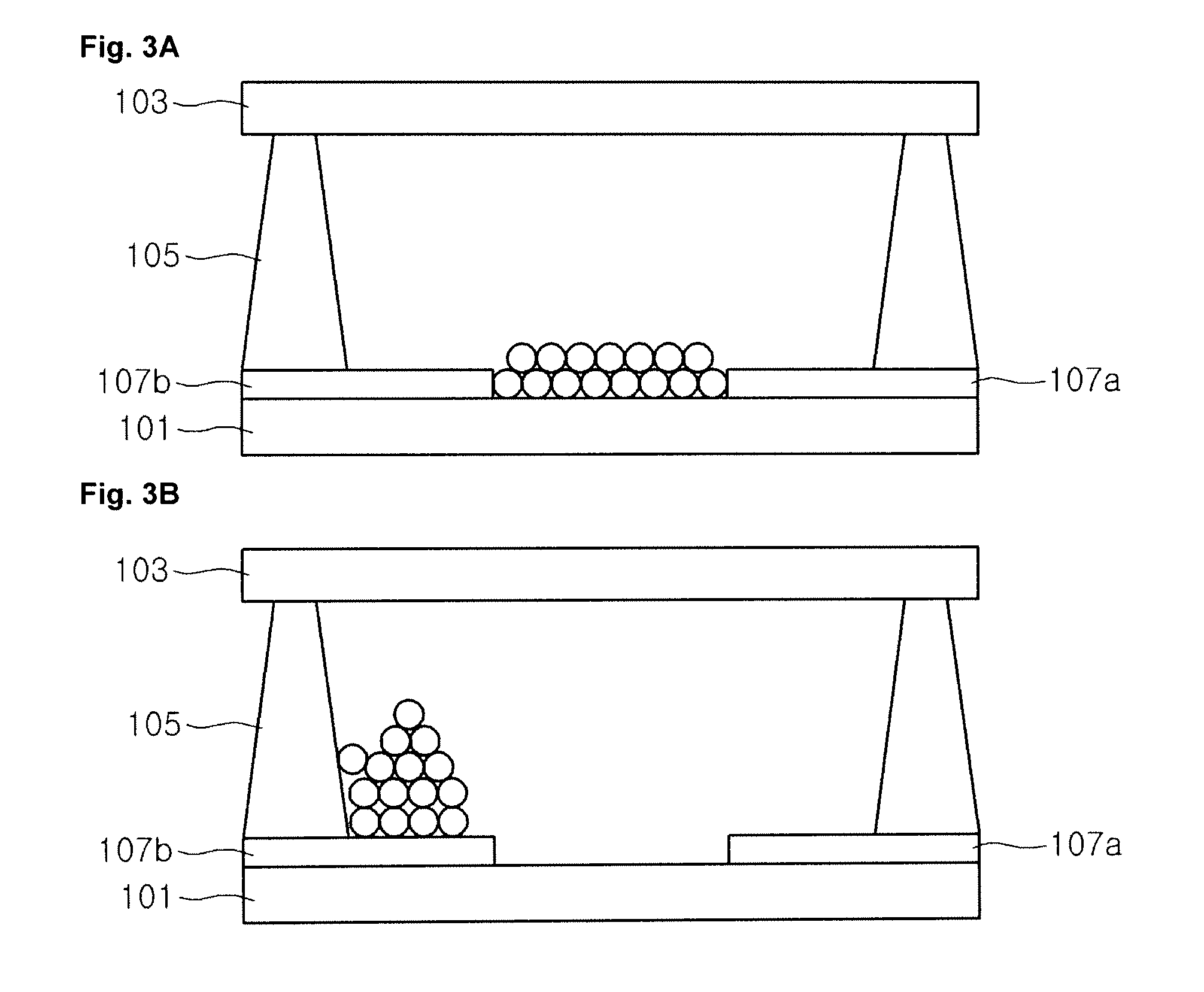

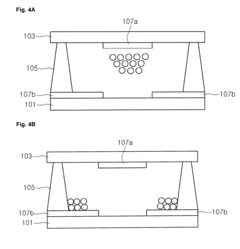

Display device using quantum dot

PatentInactiveUS20110089809A1

Innovation

- A display device utilizing quantum dots with specific core, shell, and organic ligand compositions, arranged between substrates with electrodes, to emit red, green, and blue light without the need for liquid crystals, color filters, or polarized panels, simplifying the structure and reducing costs.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for flexible microdisplays integrated with quantum dots presents significant challenges and opportunities for commercial viability. Current production methods primarily rely on batch processing techniques, which limit throughput and increase per-unit costs. Analysis of manufacturing data indicates that transitioning to roll-to-roll processing could potentially reduce production costs by 40-60%, though this approach requires substantial initial capital investment estimated at $15-25 million for a medium-scale production line.

Material costs represent approximately 35-45% of total production expenses, with quantum dot materials being particularly cost-intensive at $200-500 per gram depending on composition and quality specifications. The synthesis of quantum dots with consistent optical properties at industrial scale remains challenging, with typical batch-to-batch variation of 5-8% in emission wavelength requiring sophisticated sorting and binning processes that further impact costs.

Yield rates in current manufacturing processes average 65-75% for fully functional devices, with defects primarily occurring at the interface between quantum dot layers and flexible substrates. Statistical analysis of production data from leading manufacturers indicates that improving yield by just 10% could reduce overall costs by approximately 15-20%, highlighting the economic importance of process optimization.

Equipment depreciation constitutes 20-30% of production costs, with specialized deposition and patterning tools for quantum dot integration representing significant capital expenditures. The industry average for equipment lifetime is 3-5 years before major upgrades are required, necessitating continuous reinvestment to maintain competitive manufacturing capabilities.

Labor costs vary significantly by region, ranging from 5-8% of total production costs in highly automated facilities to 15-20% in regions with lower automation levels. Technical expertise requirements for quantum dot integration processes command premium wages, with specialized engineers earning 30-40% above industry averages for display manufacturing.

Economies of scale present a critical factor in cost reduction, with analysis showing that increasing production volume from 10,000 to 100,000 units monthly can reduce per-unit costs by approximately 30-35%. However, market demand uncertainty creates significant risk for capacity expansion investments, with current global demand estimated at 1.2-1.5 million units annually but projected to grow at 25-30% CAGR over the next five years.

Energy consumption in manufacturing processes averages 2.5-3.5 kWh per square inch of display area, with quantum dot processing accounting for approximately 40% of total energy requirements. Implementing energy efficiency measures could potentially reduce manufacturing costs by 3-5% while simultaneously improving environmental sustainability metrics.

Material costs represent approximately 35-45% of total production expenses, with quantum dot materials being particularly cost-intensive at $200-500 per gram depending on composition and quality specifications. The synthesis of quantum dots with consistent optical properties at industrial scale remains challenging, with typical batch-to-batch variation of 5-8% in emission wavelength requiring sophisticated sorting and binning processes that further impact costs.

Yield rates in current manufacturing processes average 65-75% for fully functional devices, with defects primarily occurring at the interface between quantum dot layers and flexible substrates. Statistical analysis of production data from leading manufacturers indicates that improving yield by just 10% could reduce overall costs by approximately 15-20%, highlighting the economic importance of process optimization.

Equipment depreciation constitutes 20-30% of production costs, with specialized deposition and patterning tools for quantum dot integration representing significant capital expenditures. The industry average for equipment lifetime is 3-5 years before major upgrades are required, necessitating continuous reinvestment to maintain competitive manufacturing capabilities.

Labor costs vary significantly by region, ranging from 5-8% of total production costs in highly automated facilities to 15-20% in regions with lower automation levels. Technical expertise requirements for quantum dot integration processes command premium wages, with specialized engineers earning 30-40% above industry averages for display manufacturing.

Economies of scale present a critical factor in cost reduction, with analysis showing that increasing production volume from 10,000 to 100,000 units monthly can reduce per-unit costs by approximately 30-35%. However, market demand uncertainty creates significant risk for capacity expansion investments, with current global demand estimated at 1.2-1.5 million units annually but projected to grow at 25-30% CAGR over the next five years.

Energy consumption in manufacturing processes averages 2.5-3.5 kWh per square inch of display area, with quantum dot processing accounting for approximately 40% of total energy requirements. Implementing energy efficiency measures could potentially reduce manufacturing costs by 3-5% while simultaneously improving environmental sustainability metrics.

Environmental Impact and Material Sustainability

The integration of quantum dots into flexible microdisplays raises significant environmental and sustainability concerns that warrant careful consideration. The manufacturing processes for quantum dots often involve toxic heavy metals such as cadmium, lead, and selenium, which pose substantial environmental risks if not properly managed. When these materials enter ecosystems through improper disposal or manufacturing waste, they can bioaccumulate in organisms and potentially enter the human food chain, causing long-term health impacts.

Production of flexible displays with quantum dot technology currently generates considerable electronic waste. The short lifecycle of consumer electronics, combined with the difficulty in separating quantum dot materials from other display components, creates challenges for recycling and proper end-of-life management. Current estimates suggest that less than 20% of quantum dot materials in displays are recovered through existing recycling processes.

Recent advances in green chemistry approaches have shown promise in developing more environmentally benign quantum dots. Heavy-metal-free alternatives using indium phosphide, zinc selenide, and carbon-based quantum dots are emerging as viable options with reduced toxicity profiles. These materials demonstrate comparable optical performance while significantly lowering environmental impact during both manufacturing and disposal phases.

Life cycle assessment studies indicate that flexible quantum dot displays could potentially reduce overall environmental footprint compared to traditional rigid displays if designed with sustainability in mind. The reduced material requirements, lower energy consumption during use, and potential for extended product lifespans through enhanced durability offer environmental advantages that may offset initial production impacts.

Material sourcing represents another critical sustainability consideration. Many rare earth elements and specialized materials required for quantum dot production face supply constraints and are often mined in regions with limited environmental regulations. Developing circular economy approaches for these materials, including recovery and reuse systems, will be essential for long-term sustainability of this technology.

Water usage in manufacturing processes presents additional environmental challenges. Current production methods for high-quality quantum dots can require significant quantities of ultrapure water and generate contaminated wastewater streams. Industry leaders are investigating closed-loop water systems and alternative synthesis methods that could reduce water consumption by up to 60% compared to conventional approaches.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers toward developing more sustainable quantum dot formulations and production processes that minimize environmental harm while maintaining technological performance.

Production of flexible displays with quantum dot technology currently generates considerable electronic waste. The short lifecycle of consumer electronics, combined with the difficulty in separating quantum dot materials from other display components, creates challenges for recycling and proper end-of-life management. Current estimates suggest that less than 20% of quantum dot materials in displays are recovered through existing recycling processes.

Recent advances in green chemistry approaches have shown promise in developing more environmentally benign quantum dots. Heavy-metal-free alternatives using indium phosphide, zinc selenide, and carbon-based quantum dots are emerging as viable options with reduced toxicity profiles. These materials demonstrate comparable optical performance while significantly lowering environmental impact during both manufacturing and disposal phases.

Life cycle assessment studies indicate that flexible quantum dot displays could potentially reduce overall environmental footprint compared to traditional rigid displays if designed with sustainability in mind. The reduced material requirements, lower energy consumption during use, and potential for extended product lifespans through enhanced durability offer environmental advantages that may offset initial production impacts.

Material sourcing represents another critical sustainability consideration. Many rare earth elements and specialized materials required for quantum dot production face supply constraints and are often mined in regions with limited environmental regulations. Developing circular economy approaches for these materials, including recovery and reuse systems, will be essential for long-term sustainability of this technology.

Water usage in manufacturing processes presents additional environmental challenges. Current production methods for high-quality quantum dots can require significant quantities of ultrapure water and generate contaminated wastewater streams. Industry leaders are investigating closed-loop water systems and alternative synthesis methods that could reduce water consumption by up to 60% compared to conventional approaches.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers toward developing more sustainable quantum dot formulations and production processes that minimize environmental harm while maintaining technological performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!