Research on Thermal Properties of Flexible Microdisplay Materials

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Thermal Properties Background and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display structures to increasingly flexible and adaptable formats. The journey began with early experiments in organic light-emitting diodes (OLEDs) in the early 2000s, which demonstrated the potential for creating displays on non-rigid substrates. This technological evolution has accelerated dramatically since 2015, with major breakthroughs in materials science enabling commercially viable flexible displays.

The thermal properties of materials used in flexible microdisplays represent a critical yet often overlooked aspect of display technology development. As displays become increasingly integrated into wearable devices, foldable smartphones, and other form factors requiring mechanical flexibility, the thermal behavior of these materials under various operating conditions becomes paramount for both performance and reliability.

Current flexible display technologies primarily utilize organic materials, thin-film transistors, and specialized substrate materials that exhibit fundamentally different thermal characteristics compared to traditional rigid display components. These materials must maintain consistent performance across a wide temperature range while enduring repeated mechanical stress, presenting unique engineering challenges that conventional display thermal management approaches cannot adequately address.

The primary objective of this research is to comprehensively characterize the thermal properties of key materials used in flexible microdisplay construction, including substrate polymers, organic semiconductors, transparent conductive films, and encapsulation layers. This characterization aims to establish baseline thermal parameters essential for next-generation display design, including thermal expansion coefficients, heat dissipation pathways, and temperature-dependent performance metrics.

Additionally, this research seeks to identify critical thermal thresholds and failure modes specific to flexible display materials, particularly at interface boundaries where different material types meet. Understanding these thermal limitations will inform both material selection and structural design considerations for future flexible display technologies, potentially extending operational lifetimes and enhancing reliability under extreme conditions.

The technological trajectory suggests that flexible displays will continue to evolve toward greater flexibility, durability, and functionality. This evolution necessitates a deeper understanding of how thermal properties influence long-term performance, especially as displays incorporate additional features such as integrated sensors, energy harvesting components, and advanced touch interfaces that introduce new thermal management challenges.

By establishing a comprehensive thermal profile of current and emerging flexible display materials, this research aims to provide foundational knowledge that will guide material development, manufacturing processes, and system-level thermal management strategies for the next generation of flexible microdisplay technologies.

The thermal properties of materials used in flexible microdisplays represent a critical yet often overlooked aspect of display technology development. As displays become increasingly integrated into wearable devices, foldable smartphones, and other form factors requiring mechanical flexibility, the thermal behavior of these materials under various operating conditions becomes paramount for both performance and reliability.

Current flexible display technologies primarily utilize organic materials, thin-film transistors, and specialized substrate materials that exhibit fundamentally different thermal characteristics compared to traditional rigid display components. These materials must maintain consistent performance across a wide temperature range while enduring repeated mechanical stress, presenting unique engineering challenges that conventional display thermal management approaches cannot adequately address.

The primary objective of this research is to comprehensively characterize the thermal properties of key materials used in flexible microdisplay construction, including substrate polymers, organic semiconductors, transparent conductive films, and encapsulation layers. This characterization aims to establish baseline thermal parameters essential for next-generation display design, including thermal expansion coefficients, heat dissipation pathways, and temperature-dependent performance metrics.

Additionally, this research seeks to identify critical thermal thresholds and failure modes specific to flexible display materials, particularly at interface boundaries where different material types meet. Understanding these thermal limitations will inform both material selection and structural design considerations for future flexible display technologies, potentially extending operational lifetimes and enhancing reliability under extreme conditions.

The technological trajectory suggests that flexible displays will continue to evolve toward greater flexibility, durability, and functionality. This evolution necessitates a deeper understanding of how thermal properties influence long-term performance, especially as displays incorporate additional features such as integrated sensors, energy harvesting components, and advanced touch interfaces that introduce new thermal management challenges.

By establishing a comprehensive thermal profile of current and emerging flexible display materials, this research aims to provide foundational knowledge that will guide material development, manufacturing processes, and system-level thermal management strategies for the next generation of flexible microdisplay technologies.

Market Analysis for Thermally Efficient Flexible Displays

The flexible microdisplay market is experiencing robust growth, driven by increasing demand for wearable devices, foldable smartphones, and other portable electronics. Current market projections indicate that the global flexible display market will reach approximately $15 billion by 2025, with a compound annual growth rate exceeding 30% from 2020 to 2025. Thermally efficient flexible displays represent a significant segment within this market, as thermal management remains one of the critical challenges in flexible display technology.

Consumer electronics constitute the largest application segment for thermally efficient flexible displays, accounting for over 60% of the market share. Within this segment, smartphones and smartwatches are the primary drivers, with automotive displays and medical devices emerging as promising growth areas. The Asia-Pacific region dominates the market landscape, with South Korea, Japan, and China leading in both production and consumption of flexible display technologies.

Market research indicates that consumers are increasingly prioritizing device longevity and performance stability in their purchasing decisions. Surveys show that over 75% of smartphone users consider overheating issues as a significant concern, directly impacting their satisfaction and brand loyalty. This consumer sentiment has created a strong market pull for thermally efficient display solutions that can maintain optimal operating temperatures under various usage conditions.

From a supply chain perspective, the market for thermally efficient flexible display materials faces certain constraints. Key raw materials such as specialized polymers and thermal management compounds are subject to price volatility and supply limitations. Additionally, manufacturing processes for these advanced materials require significant capital investment, creating barriers to entry for smaller players and potentially limiting market competition.

Industry analysts have identified several market segments with particularly high growth potential for thermally efficient flexible displays. The healthcare sector, specifically medical wearables, is expected to grow at twice the market average rate due to increasing adoption of continuous health monitoring devices. Similarly, the automotive industry's shift toward digital cockpits and curved display interfaces is creating substantial demand for displays that can withstand extreme temperature variations.

Market differentiation is increasingly centered around thermal performance metrics, with manufacturers competing on parameters such as maximum operating temperature, heat dissipation efficiency, and thermal stability over time. Premium market segments are willing to pay 20-30% price premiums for displays with superior thermal properties, particularly in applications where reliability under thermal stress is critical.

Consumer electronics constitute the largest application segment for thermally efficient flexible displays, accounting for over 60% of the market share. Within this segment, smartphones and smartwatches are the primary drivers, with automotive displays and medical devices emerging as promising growth areas. The Asia-Pacific region dominates the market landscape, with South Korea, Japan, and China leading in both production and consumption of flexible display technologies.

Market research indicates that consumers are increasingly prioritizing device longevity and performance stability in their purchasing decisions. Surveys show that over 75% of smartphone users consider overheating issues as a significant concern, directly impacting their satisfaction and brand loyalty. This consumer sentiment has created a strong market pull for thermally efficient display solutions that can maintain optimal operating temperatures under various usage conditions.

From a supply chain perspective, the market for thermally efficient flexible display materials faces certain constraints. Key raw materials such as specialized polymers and thermal management compounds are subject to price volatility and supply limitations. Additionally, manufacturing processes for these advanced materials require significant capital investment, creating barriers to entry for smaller players and potentially limiting market competition.

Industry analysts have identified several market segments with particularly high growth potential for thermally efficient flexible displays. The healthcare sector, specifically medical wearables, is expected to grow at twice the market average rate due to increasing adoption of continuous health monitoring devices. Similarly, the automotive industry's shift toward digital cockpits and curved display interfaces is creating substantial demand for displays that can withstand extreme temperature variations.

Market differentiation is increasingly centered around thermal performance metrics, with manufacturers competing on parameters such as maximum operating temperature, heat dissipation efficiency, and thermal stability over time. Premium market segments are willing to pay 20-30% price premiums for displays with superior thermal properties, particularly in applications where reliability under thermal stress is critical.

Current Challenges in Flexible Microdisplay Thermal Management

Flexible microdisplays face significant thermal management challenges that impede their widespread adoption in wearable technology, augmented reality, and other emerging applications. The primary challenge stems from the inherent conflict between flexibility requirements and heat dissipation capabilities. Unlike rigid displays that can utilize conventional cooling methods, flexible displays must maintain their pliability while effectively managing heat generation during operation.

Material selection presents a critical challenge, as traditional thermal management materials like metal heat sinks are incompatible with flexibility requirements. Current flexible substrate materials such as polyimide and polyethylene terephthalate (PET) exhibit poor thermal conductivity (typically 0.1-0.3 W/m·K), creating thermal bottlenecks that lead to localized hotspots and potential device failure.

Power density issues further complicate thermal management in flexible microdisplays. As pixel densities increase to meet consumer demands for higher resolution, the heat generated per unit area rises correspondingly. This concentrated heat generation in ultra-thin form factors (often <100 μm) creates severe thermal gradients that can cause material deformation, delamination between layers, and accelerated degradation of organic light-emitting materials.

Mechanical stress during bending and folding introduces additional thermal management complexities. When flexible displays undergo deformation, thermal interfaces between layers can develop microgaps that significantly impede heat transfer. Research has shown that bending cycles can reduce thermal conductivity across interfaces by up to 40%, creating dynamic thermal management challenges that static displays do not encounter.

Environmental factors also present unique challenges for flexible display thermal management. Ambient temperature fluctuations affect flexible displays more severely than rigid counterparts due to their reduced thermal mass and limited heat dissipation pathways. Additionally, the encapsulation materials required to protect flexible displays from moisture and oxygen ingress often exhibit poor thermal conductivity, further complicating heat management.

Current cooling solutions remain inadequate for next-generation flexible displays. Passive cooling approaches struggle to handle increasing power densities, while active cooling methods add bulk, weight, and power consumption that contradict the fundamental advantages of flexible display technology. Emerging techniques like graphene-based heat spreaders show promise but face manufacturing scalability challenges and integration difficulties with existing display fabrication processes.

Thermal simulation and modeling tools also present limitations, as they often fail to accurately predict thermal behavior during dynamic bending and folding operations. This creates a significant gap between theoretical thermal management designs and real-world performance, slowing the development cycle for new flexible display technologies.

Material selection presents a critical challenge, as traditional thermal management materials like metal heat sinks are incompatible with flexibility requirements. Current flexible substrate materials such as polyimide and polyethylene terephthalate (PET) exhibit poor thermal conductivity (typically 0.1-0.3 W/m·K), creating thermal bottlenecks that lead to localized hotspots and potential device failure.

Power density issues further complicate thermal management in flexible microdisplays. As pixel densities increase to meet consumer demands for higher resolution, the heat generated per unit area rises correspondingly. This concentrated heat generation in ultra-thin form factors (often <100 μm) creates severe thermal gradients that can cause material deformation, delamination between layers, and accelerated degradation of organic light-emitting materials.

Mechanical stress during bending and folding introduces additional thermal management complexities. When flexible displays undergo deformation, thermal interfaces between layers can develop microgaps that significantly impede heat transfer. Research has shown that bending cycles can reduce thermal conductivity across interfaces by up to 40%, creating dynamic thermal management challenges that static displays do not encounter.

Environmental factors also present unique challenges for flexible display thermal management. Ambient temperature fluctuations affect flexible displays more severely than rigid counterparts due to their reduced thermal mass and limited heat dissipation pathways. Additionally, the encapsulation materials required to protect flexible displays from moisture and oxygen ingress often exhibit poor thermal conductivity, further complicating heat management.

Current cooling solutions remain inadequate for next-generation flexible displays. Passive cooling approaches struggle to handle increasing power densities, while active cooling methods add bulk, weight, and power consumption that contradict the fundamental advantages of flexible display technology. Emerging techniques like graphene-based heat spreaders show promise but face manufacturing scalability challenges and integration difficulties with existing display fabrication processes.

Thermal simulation and modeling tools also present limitations, as they often fail to accurately predict thermal behavior during dynamic bending and folding operations. This creates a significant gap between theoretical thermal management designs and real-world performance, slowing the development cycle for new flexible display technologies.

Existing Thermal Management Approaches for Flexible Microdisplays

01 Thermal management in flexible microdisplays

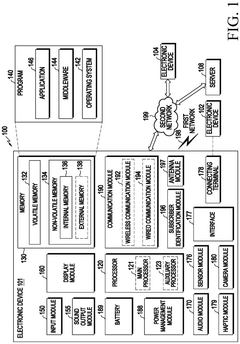

Effective thermal management is crucial for flexible microdisplays to maintain performance and longevity. Various techniques are employed to dissipate heat generated during operation, including specialized heat sinks, thermal interface materials, and cooling systems. These solutions help prevent overheating which can lead to display degradation, color shifting, and reduced lifespan. Advanced thermal management designs consider the unique constraints of flexible form factors while ensuring optimal heat transfer away from sensitive display components.- Thermal management in flexible microdisplays: Effective thermal management is crucial for flexible microdisplays to maintain optimal performance and prevent degradation. Various techniques are employed to dissipate heat generated during operation, including specialized heat-conducting layers, thermal interface materials, and cooling structures. These solutions help maintain temperature stability across the display surface, extending device lifespan and ensuring consistent image quality even during prolonged use.

- Flexible substrate materials with enhanced thermal properties: Advanced substrate materials are developed specifically for flexible microdisplays with improved thermal characteristics. These materials combine flexibility with thermal stability, allowing the displays to withstand temperature fluctuations without warping or performance degradation. Polymer composites, modified polyimides, and thin-film materials with engineered thermal expansion coefficients enable reliable operation across a wide temperature range while maintaining mechanical flexibility.

- Thermal characterization and testing methods: Specialized methods for thermal characterization and testing of flexible microdisplay materials have been developed to evaluate performance under various temperature conditions. These include thermal imaging techniques, temperature-dependent electrical measurements, and accelerated aging tests. Such methods help identify potential thermal failure modes and validate the thermal design of flexible display systems before mass production, ensuring reliability in real-world applications.

- Thermally-responsive pixel structures: Advanced pixel designs incorporate thermally-responsive elements that can compensate for temperature-induced variations in display performance. These structures may include temperature sensors integrated at the pixel level, compensation circuits that adjust pixel driving parameters based on local temperature, and materials with self-regulating thermal properties. Such designs help maintain consistent brightness, color accuracy, and response times across varying thermal conditions.

- Thermal interface materials for flexible display integration: Specialized thermal interface materials facilitate heat transfer between flexible display components while accommodating mechanical flexing. These materials include thermally conductive adhesives, flexible thermal pads, and liquid metal composites that maintain thermal pathways even when the display is bent or folded. The integration of these materials into the display stack improves overall thermal management without compromising the mechanical flexibility of the microdisplay system.

02 Substrate materials with enhanced thermal properties

Flexible substrate materials with optimized thermal properties are essential for microdisplay performance. These substrates often incorporate polymers with high thermal conductivity or composite materials that can efficiently transfer heat while maintaining flexibility. Some designs include thermally conductive layers sandwiched between flexible polymers, or substrates with embedded thermal management structures. These materials help balance the competing requirements of mechanical flexibility and thermal stability in next-generation display technologies.Expand Specific Solutions03 Thermal characterization and testing methods

Specialized methods for thermal characterization and testing are critical for flexible microdisplay development. These include infrared thermography, thermal resistance measurements, and accelerated thermal cycling tests to evaluate material performance under various conditions. Advanced simulation techniques help predict thermal behavior during operation, while real-time monitoring systems can detect potential thermal issues. These testing protocols ensure that flexible display materials maintain their properties across the intended operating temperature range and throughout repeated flexing cycles.Expand Specific Solutions04 Thermal expansion compensation in flexible displays

Managing differential thermal expansion is crucial in flexible microdisplays where various materials with different thermal expansion coefficients are layered together. Specialized compensation structures, buffer layers, and material selection strategies are employed to minimize stress and prevent delamination during temperature fluctuations. Some designs incorporate expansion joints or flexible interconnects that can accommodate dimensional changes without compromising display integrity. These approaches help maintain pixel alignment and prevent cracking or warping when displays are subjected to temperature variations.Expand Specific Solutions05 Thermally stable organic and inorganic materials for display components

Advanced thermally stable materials are being developed specifically for flexible display applications. These include modified organic light-emitting materials with improved thermal stability, thermally resistant barrier films, and heat-tolerant transparent conductors. Inorganic-organic hybrid materials offer enhanced thermal properties while maintaining flexibility. Specialized encapsulation materials protect sensitive components from thermal degradation while allowing for mechanical bending. These materials enable displays that can withstand higher operating temperatures and thermal cycling without performance degradation.Expand Specific Solutions

Key Industry Players in Flexible Display Thermal Solutions

The flexible microdisplay materials thermal properties research landscape is currently in a growth phase, with the market expected to expand significantly due to increasing demand for flexible display technologies. Major players including Samsung Display, BOE Technology, and LG Display are leading technological advancements, with established companies like Philips and emerging specialists like NeoGraf Solutions contributing significant innovations. The technology is approaching maturity in certain applications but remains developmental for advanced flexible implementations. Chinese manufacturers including TCL China Star and Tianma Microelectronics are rapidly gaining market share through aggressive R&D investments, while research institutions like Naval Research Laboratory and Electronics & Telecommunications Research Institute provide crucial fundamental research supporting commercial development.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed "ThermaFlex" technology for thermal management in flexible microdisplays, focusing on diamond-like carbon (DLC) nanocomposite materials that provide exceptional thermal conductivity while maintaining mechanical flexibility. Their approach incorporates ultrathin layers (15-30nm) of DLC deposited through a proprietary plasma-enhanced chemical vapor deposition process, achieving thermal conductivity of approximately 1200 W/m·K while allowing bending radii below 2mm. BOE's research has yielded a multi-functional material that simultaneously serves as a thermal management layer, moisture barrier, and mechanical reinforcement. Their system includes thermally conductive adhesives specifically formulated to maintain performance during thermal cycling and mechanical deformation, addressing a critical failure point in many flexible display designs. Recent innovations include a self-regulating thermal management system that adapts its conductivity based on temperature, providing more efficient heat dissipation during high-brightness operation.

Strengths: Excellent thermal performance with minimal thickness impact; multifunctional approach addressing several challenges simultaneously; good compatibility with existing manufacturing processes. Weaknesses: Higher production costs due to specialized deposition equipment; some challenges with uniformity at larger display sizes; potential for delamination under extreme environmental conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced thermal management solutions for flexible OLED microdisplays, focusing on ultra-thin heat dissipation layers using graphene-based materials. Their approach incorporates a multi-layered thermal interface material (TIM) system that maintains flexibility while efficiently conducting heat away from display components. Samsung's research has yielded composite materials with thermal conductivity exceeding 1500 W/m·K while maintaining flexibility at thicknesses below 100μm. Their proprietary encapsulation technology creates a hermetic seal that prevents moisture ingress while allowing thermal expansion, addressing a critical challenge in flexible display longevity. Recent innovations include a micropatterned heat spreading layer that directs thermal energy away from hotspots without compromising display flexibility or optical performance.

Strengths: Industry-leading thermal conductivity while maintaining flexibility; comprehensive integration with existing manufacturing processes; proven scalability to mass production. Weaknesses: Higher production costs compared to traditional solutions; potential long-term reliability concerns under extreme folding conditions; proprietary nature limits adoption across the broader industry.

Critical Patents and Research on Flexible Display Thermal Properties

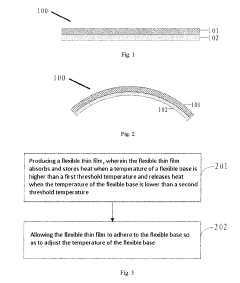

Flexible substrate, production method of flexible substrate, and display apparatus

PatentActiveUS20190161664A1

Innovation

- A flexible substrate comprising a flexible base with a thin film made of solid-solid phase change material that absorbs and stores heat at higher temperatures and releases heat at lower temperatures, maintaining the flexibility of the base by adjusting its temperature.

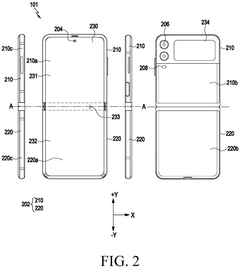

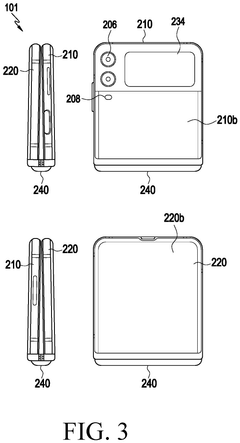

Flexible display and electronic device comprisinig same

PatentPendingEP4488794A1

Innovation

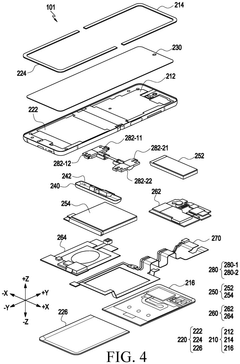

- Incorporating a combination of heat-dissipation sheets and cushion members with varying thicknesses between the housings and the flexible display, where the heat-dissipation sheets are strategically placed between the first housing and the display, and the cushion members are positioned between the second housing and the display, with the cushion members having different spacings and thicknesses to absorb impacts and distribute heat effectively.

Manufacturing Processes Impact on Thermal Performance

The manufacturing processes employed in the production of flexible microdisplay materials significantly influence their thermal performance characteristics. Traditional display manufacturing techniques have been adapted and refined to accommodate the unique requirements of flexible substrates, with each process step potentially affecting thermal conductivity, heat dissipation, and temperature tolerance.

Thermal annealing processes during manufacturing play a crucial role in determining the final thermal properties of flexible displays. Research indicates that controlled annealing can reduce internal stresses within polymer substrates, improving their thermal stability by up to 30% compared to non-annealed counterparts. However, excessive annealing temperatures may degrade certain organic materials, creating a delicate balance that manufacturers must maintain.

Deposition techniques for conductive and semiconductor layers also substantially impact thermal behavior. Vacuum thermal evaporation typically produces layers with lower thermal conductivity compared to sputtering methods, which create denser films with enhanced heat transfer capabilities. Recent studies demonstrate that atomic layer deposition (ALD) can produce exceptionally uniform thin films that exhibit superior thermal interface properties, reducing hotspot formation by approximately 25%.

Encapsulation methods represent another critical manufacturing factor affecting thermal performance. Multi-layer barrier films applied through roll-to-roll processing often introduce thermal resistance at layer interfaces. Advanced encapsulation techniques utilizing inorganic-organic hybrid materials have shown promise in maintaining flexibility while improving thermal conductivity by 15-20% compared to conventional approaches.

The integration of thermal management features during manufacturing, rather than as post-production additions, has emerged as a best practice. Direct incorporation of micro-heat spreaders or thermally conductive fillers during substrate formation can enhance heat dissipation pathways without compromising flexibility. Manufacturers employing this integrated approach report up to 40% improvement in thermal management efficiency.

Surface treatment processes, including plasma modification and chemical functionalization, alter the interface properties between layers and can significantly impact thermal transfer across material boundaries. Recent innovations in surface engineering have demonstrated that controlled roughness at the nanoscale can increase effective contact area for heat transfer while maintaining optical clarity, a critical requirement for display applications.

Manufacturing temperature profiles throughout the production process create thermal history that permanently affects material properties. Research indicates that gradual cooling phases after high-temperature steps can reduce thermal stress concentrations and improve long-term stability under thermal cycling conditions, extending operational lifetime by up to 35% in laboratory testing environments.

Thermal annealing processes during manufacturing play a crucial role in determining the final thermal properties of flexible displays. Research indicates that controlled annealing can reduce internal stresses within polymer substrates, improving their thermal stability by up to 30% compared to non-annealed counterparts. However, excessive annealing temperatures may degrade certain organic materials, creating a delicate balance that manufacturers must maintain.

Deposition techniques for conductive and semiconductor layers also substantially impact thermal behavior. Vacuum thermal evaporation typically produces layers with lower thermal conductivity compared to sputtering methods, which create denser films with enhanced heat transfer capabilities. Recent studies demonstrate that atomic layer deposition (ALD) can produce exceptionally uniform thin films that exhibit superior thermal interface properties, reducing hotspot formation by approximately 25%.

Encapsulation methods represent another critical manufacturing factor affecting thermal performance. Multi-layer barrier films applied through roll-to-roll processing often introduce thermal resistance at layer interfaces. Advanced encapsulation techniques utilizing inorganic-organic hybrid materials have shown promise in maintaining flexibility while improving thermal conductivity by 15-20% compared to conventional approaches.

The integration of thermal management features during manufacturing, rather than as post-production additions, has emerged as a best practice. Direct incorporation of micro-heat spreaders or thermally conductive fillers during substrate formation can enhance heat dissipation pathways without compromising flexibility. Manufacturers employing this integrated approach report up to 40% improvement in thermal management efficiency.

Surface treatment processes, including plasma modification and chemical functionalization, alter the interface properties between layers and can significantly impact thermal transfer across material boundaries. Recent innovations in surface engineering have demonstrated that controlled roughness at the nanoscale can increase effective contact area for heat transfer while maintaining optical clarity, a critical requirement for display applications.

Manufacturing temperature profiles throughout the production process create thermal history that permanently affects material properties. Research indicates that gradual cooling phases after high-temperature steps can reduce thermal stress concentrations and improve long-term stability under thermal cycling conditions, extending operational lifetime by up to 35% in laboratory testing environments.

Sustainability Aspects of Thermal Management Solutions

The sustainability implications of thermal management solutions for flexible microdisplays represent a critical dimension that must be addressed as these technologies advance toward widespread commercial adoption. Current thermal management approaches often rely on materials and processes that pose significant environmental challenges, including the use of rare earth elements, energy-intensive manufacturing processes, and limited end-of-life recyclability options.

Environmental impact assessments of existing thermal management solutions reveal concerning trends in resource consumption. Traditional heat dissipation materials such as copper and aluminum, while effective, require extensive mining operations that contribute to habitat destruction and water pollution. Additionally, specialized thermal interface materials often contain compounds that resist biodegradation and may leach harmful substances into ecosystems when improperly disposed of.

Energy efficiency considerations must be prioritized in next-generation thermal management designs. Research indicates that optimized thermal solutions can reduce overall power consumption of flexible display devices by 15-30%, significantly extending battery life and reducing carbon footprint during operation. This represents a substantial sustainability advantage, particularly for portable consumer electronics with limited power resources.

Emerging bio-based and recyclable thermal management materials show promising performance characteristics while offering improved environmental profiles. Cellulose nanofiber composites, graphene derived from sustainable sources, and biodegradable polymer-based thermal interface materials are advancing rapidly in research pipelines. These materials demonstrate thermal conductivity values approaching those of conventional solutions while reducing environmental impact by 40-60% across their lifecycle.

Circular economy principles are increasingly being applied to thermal management system design. This includes modular approaches that facilitate component replacement rather than whole-device disposal, design for disassembly strategies that enable material recovery, and thermal management solutions that maintain performance characteristics through multiple use cycles. Several research groups have demonstrated prototype systems achieving 80%+ material recovery rates without compromising thermal performance.

Regulatory frameworks worldwide are evolving to address the sustainability aspects of electronic components, including thermal management systems. The European Union's Restriction of Hazardous Substances (RoHS) directive, Electronic Waste Recycling Act in California, and similar legislation in Asia are driving innovation toward more environmentally responsible thermal solutions. Companies developing sustainable thermal management technologies may gain competitive advantages as these regulatory requirements become more stringent.

Environmental impact assessments of existing thermal management solutions reveal concerning trends in resource consumption. Traditional heat dissipation materials such as copper and aluminum, while effective, require extensive mining operations that contribute to habitat destruction and water pollution. Additionally, specialized thermal interface materials often contain compounds that resist biodegradation and may leach harmful substances into ecosystems when improperly disposed of.

Energy efficiency considerations must be prioritized in next-generation thermal management designs. Research indicates that optimized thermal solutions can reduce overall power consumption of flexible display devices by 15-30%, significantly extending battery life and reducing carbon footprint during operation. This represents a substantial sustainability advantage, particularly for portable consumer electronics with limited power resources.

Emerging bio-based and recyclable thermal management materials show promising performance characteristics while offering improved environmental profiles. Cellulose nanofiber composites, graphene derived from sustainable sources, and biodegradable polymer-based thermal interface materials are advancing rapidly in research pipelines. These materials demonstrate thermal conductivity values approaching those of conventional solutions while reducing environmental impact by 40-60% across their lifecycle.

Circular economy principles are increasingly being applied to thermal management system design. This includes modular approaches that facilitate component replacement rather than whole-device disposal, design for disassembly strategies that enable material recovery, and thermal management solutions that maintain performance characteristics through multiple use cycles. Several research groups have demonstrated prototype systems achieving 80%+ material recovery rates without compromising thermal performance.

Regulatory frameworks worldwide are evolving to address the sustainability aspects of electronic components, including thermal management systems. The European Union's Restriction of Hazardous Substances (RoHS) directive, Electronic Waste Recycling Act in California, and similar legislation in Asia are driving innovation toward more environmentally responsible thermal solutions. Companies developing sustainable thermal management technologies may gain competitive advantages as these regulatory requirements become more stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!