Why Flexible Microdisplays Are Vital for Next-gen Displays

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display paradigms to increasingly flexible solutions that enable novel form factors and applications. The journey began with traditional LCD and OLED technologies mounted on rigid substrates, which dominated the display market through the early 2000s. These conventional displays faced fundamental limitations in conformability, durability, and integration potential for next-generation devices.

The mid-2000s marked a pivotal shift with the introduction of plastic substrates replacing glass, allowing for thinner and more resilient display components. This period saw significant research investments from major technology corporations and academic institutions focused on overcoming the materials science challenges inherent in creating truly flexible displays that could maintain optical performance while being bent or folded.

By the 2010s, flexible OLED technology emerged as a commercial reality, with Samsung and LG introducing curved displays in consumer electronics. However, these early implementations offered limited flexibility and primarily served aesthetic purposes rather than enabling new functionality. The technical objectives during this phase centered on improving bend radius capabilities and addressing issues of pixel degradation under mechanical stress.

The current technological frontier focuses on microdisplay architectures specifically designed for flexibility from the ground up. These advanced systems integrate flexible backplanes, elastic interconnects, and strain-resistant light-emitting materials to create displays that can withstand repeated deformation while maintaining high resolution and color accuracy. MicroLED and advanced OLED technologies have become particularly promising platforms for flexible microdisplays due to their inherent thinness and efficiency.

The primary technical objectives driving flexible microdisplay development today include achieving sub-5mm bend radii without performance degradation, developing manufacturing processes suitable for mass production, extending operational lifetimes under repeated flexing conditions, and reducing power consumption to enable integration into wearable and portable devices with limited battery capacity.

Looking forward, the industry aims to develop fully rollable and foldable microdisplays with pixel densities exceeding 1000 PPI (pixels per inch), capable of withstanding over 200,000 fold cycles without visible degradation. Additional objectives include achieving transparency when desired, enabling variable opacity, and incorporating sensing capabilities directly into the display structure to create truly interactive surfaces.

These ambitious technical goals are driven by emerging application requirements in augmented reality, virtual reality, medical devices, automotive displays, and next-generation smartphones and wearables—all of which demand displays that can conform to non-planar surfaces while delivering exceptional visual performance.

The mid-2000s marked a pivotal shift with the introduction of plastic substrates replacing glass, allowing for thinner and more resilient display components. This period saw significant research investments from major technology corporations and academic institutions focused on overcoming the materials science challenges inherent in creating truly flexible displays that could maintain optical performance while being bent or folded.

By the 2010s, flexible OLED technology emerged as a commercial reality, with Samsung and LG introducing curved displays in consumer electronics. However, these early implementations offered limited flexibility and primarily served aesthetic purposes rather than enabling new functionality. The technical objectives during this phase centered on improving bend radius capabilities and addressing issues of pixel degradation under mechanical stress.

The current technological frontier focuses on microdisplay architectures specifically designed for flexibility from the ground up. These advanced systems integrate flexible backplanes, elastic interconnects, and strain-resistant light-emitting materials to create displays that can withstand repeated deformation while maintaining high resolution and color accuracy. MicroLED and advanced OLED technologies have become particularly promising platforms for flexible microdisplays due to their inherent thinness and efficiency.

The primary technical objectives driving flexible microdisplay development today include achieving sub-5mm bend radii without performance degradation, developing manufacturing processes suitable for mass production, extending operational lifetimes under repeated flexing conditions, and reducing power consumption to enable integration into wearable and portable devices with limited battery capacity.

Looking forward, the industry aims to develop fully rollable and foldable microdisplays with pixel densities exceeding 1000 PPI (pixels per inch), capable of withstanding over 200,000 fold cycles without visible degradation. Additional objectives include achieving transparency when desired, enabling variable opacity, and incorporating sensing capabilities directly into the display structure to create truly interactive surfaces.

These ambitious technical goals are driven by emerging application requirements in augmented reality, virtual reality, medical devices, automotive displays, and next-generation smartphones and wearables—all of which demand displays that can conform to non-planar surfaces while delivering exceptional visual performance.

Market Demand Analysis for Flexible Display Solutions

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible display market is projected to reach $15.5 billion by 2026, growing at a CAGR of 28% from 2021. This substantial growth reflects the shifting consumer preferences toward devices that offer enhanced portability, durability, and novel user experiences.

Consumer electronics represents the largest application segment for flexible microdisplays, with smartphones leading adoption. Major manufacturers have introduced foldable and rollable smartphones, responding to consumer desire for larger screen real estate without compromising device portability. Market surveys reveal that 67% of consumers express interest in foldable devices, with 42% willing to pay premium prices for this technology.

Wearable technology constitutes another significant market driver for flexible displays. The wearable device market is expanding rapidly, with smartwatches, fitness trackers, and augmented reality glasses requiring lightweight, conformable displays that can adapt to the human body's contours. Healthcare wearables particularly benefit from flexible displays, enabling continuous health monitoring through devices that can be comfortably worn for extended periods.

Automotive applications represent an emerging high-value market for flexible display technology. Modern vehicles increasingly incorporate curved displays in dashboards and entertainment systems, enhancing both aesthetics and functionality. Industry analysts predict that by 2025, premium vehicles will feature an average of 3-5 flexible displays, creating substantial demand for advanced microdisplay solutions.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub, while North America and Europe lead in technology innovation and premium market adoption. China has emerged as both a major producer and consumer of flexible display technologies, with domestic manufacturers rapidly closing the technology gap with established Korean and Japanese competitors.

Market challenges include price sensitivity among mainstream consumers and competition from alternative display technologies. Currently, flexible displays command a significant price premium over conventional rigid displays, limiting mass-market penetration. However, manufacturing economies of scale are gradually reducing this price differential, with production costs decreasing approximately 15% annually.

Consumer feedback indicates that durability remains a primary concern, with potential buyers expressing hesitation about the longevity of flexible display products. This highlights the need for continued material science innovation to improve folding endurance and scratch resistance while maintaining optical performance.

Consumer electronics represents the largest application segment for flexible microdisplays, with smartphones leading adoption. Major manufacturers have introduced foldable and rollable smartphones, responding to consumer desire for larger screen real estate without compromising device portability. Market surveys reveal that 67% of consumers express interest in foldable devices, with 42% willing to pay premium prices for this technology.

Wearable technology constitutes another significant market driver for flexible displays. The wearable device market is expanding rapidly, with smartwatches, fitness trackers, and augmented reality glasses requiring lightweight, conformable displays that can adapt to the human body's contours. Healthcare wearables particularly benefit from flexible displays, enabling continuous health monitoring through devices that can be comfortably worn for extended periods.

Automotive applications represent an emerging high-value market for flexible display technology. Modern vehicles increasingly incorporate curved displays in dashboards and entertainment systems, enhancing both aesthetics and functionality. Industry analysts predict that by 2025, premium vehicles will feature an average of 3-5 flexible displays, creating substantial demand for advanced microdisplay solutions.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub, while North America and Europe lead in technology innovation and premium market adoption. China has emerged as both a major producer and consumer of flexible display technologies, with domestic manufacturers rapidly closing the technology gap with established Korean and Japanese competitors.

Market challenges include price sensitivity among mainstream consumers and competition from alternative display technologies. Currently, flexible displays command a significant price premium over conventional rigid displays, limiting mass-market penetration. However, manufacturing economies of scale are gradually reducing this price differential, with production costs decreasing approximately 15% annually.

Consumer feedback indicates that durability remains a primary concern, with potential buyers expressing hesitation about the longevity of flexible display products. This highlights the need for continued material science innovation to improve folding endurance and scratch resistance while maintaining optical performance.

Current Technological Landscape and Barriers

The flexible microdisplay market is currently experiencing significant growth, with major technological advancements emerging from both established companies and innovative startups. Leading display manufacturers such as Samsung, LG Display, and BOE have made substantial investments in flexible OLED technology, which represents the most mature segment of the flexible display market. These companies have successfully commercialized flexible displays in consumer electronics, particularly in smartphones and wearable devices.

In terms of technological approaches, several competing technologies define the current landscape. OLED (Organic Light Emitting Diode) technology dominates the flexible display market due to its inherent flexibility, self-emissive properties, and excellent color reproduction. MicroLED technology is emerging as a promising alternative, offering higher brightness, longer lifespan, and potentially better flexibility than OLED. E-paper technologies, while limited in color reproduction and refresh rates, provide exceptional power efficiency for specific applications.

Despite these advancements, significant technical barriers persist in the development of truly flexible microdisplays. Material limitations represent a primary challenge, as substrate materials must simultaneously provide flexibility, durability, and compatibility with display manufacturing processes. Current plastic substrates often suffer from oxygen and moisture permeability issues that degrade organic materials in displays.

Manufacturing scalability presents another major hurdle. Traditional display fabrication techniques are optimized for rigid substrates, and adapting these processes for flexible materials introduces yield and quality control challenges. The industry is still developing cost-effective, high-volume production methods for flexible displays that maintain consistent performance.

Reliability and durability concerns also impede widespread adoption. Flexible displays must withstand thousands of bending cycles without performance degradation, while maintaining consistent optical properties throughout their operational lifetime. Current technologies often show visible degradation after repeated flexing, particularly at fold points where stress concentrates.

Power consumption remains problematic for many flexible display technologies. While flexibility enables new form factors, it often comes with energy efficiency trade-offs that limit battery life in portable devices. This is particularly challenging for high-resolution microdisplays intended for AR/VR applications, where power constraints are already significant.

Resolution limitations also persist in the flexible display space. Achieving the pixel densities required for near-eye applications (>1000 PPI) while maintaining flexibility presents significant technical challenges. The miniaturization of pixel structures must be balanced with maintaining high aperture ratios and managing heat dissipation in flexible substrates.

Geographically, Asia dominates flexible display manufacturing, with South Korea, Japan, China, and Taiwan housing most production facilities. Research institutions in North America and Europe contribute significantly to materials science innovations and next-generation display technologies, though commercial manufacturing remains concentrated in Asia.

In terms of technological approaches, several competing technologies define the current landscape. OLED (Organic Light Emitting Diode) technology dominates the flexible display market due to its inherent flexibility, self-emissive properties, and excellent color reproduction. MicroLED technology is emerging as a promising alternative, offering higher brightness, longer lifespan, and potentially better flexibility than OLED. E-paper technologies, while limited in color reproduction and refresh rates, provide exceptional power efficiency for specific applications.

Despite these advancements, significant technical barriers persist in the development of truly flexible microdisplays. Material limitations represent a primary challenge, as substrate materials must simultaneously provide flexibility, durability, and compatibility with display manufacturing processes. Current plastic substrates often suffer from oxygen and moisture permeability issues that degrade organic materials in displays.

Manufacturing scalability presents another major hurdle. Traditional display fabrication techniques are optimized for rigid substrates, and adapting these processes for flexible materials introduces yield and quality control challenges. The industry is still developing cost-effective, high-volume production methods for flexible displays that maintain consistent performance.

Reliability and durability concerns also impede widespread adoption. Flexible displays must withstand thousands of bending cycles without performance degradation, while maintaining consistent optical properties throughout their operational lifetime. Current technologies often show visible degradation after repeated flexing, particularly at fold points where stress concentrates.

Power consumption remains problematic for many flexible display technologies. While flexibility enables new form factors, it often comes with energy efficiency trade-offs that limit battery life in portable devices. This is particularly challenging for high-resolution microdisplays intended for AR/VR applications, where power constraints are already significant.

Resolution limitations also persist in the flexible display space. Achieving the pixel densities required for near-eye applications (>1000 PPI) while maintaining flexibility presents significant technical challenges. The miniaturization of pixel structures must be balanced with maintaining high aperture ratios and managing heat dissipation in flexible substrates.

Geographically, Asia dominates flexible display manufacturing, with South Korea, Japan, China, and Taiwan housing most production facilities. Research institutions in North America and Europe contribute significantly to materials science innovations and next-generation display technologies, though commercial manufacturing remains concentrated in Asia.

Current Technical Solutions for Flexible Microdisplays

01 Flexible substrate technologies for microdisplays

Various substrate materials and technologies are employed to create flexible microdisplays. These include polymer-based substrates, thin-film technologies, and specialized flexible materials that can withstand bending while maintaining display functionality. The flexibility of these substrates enables the development of bendable and foldable display devices that can conform to curved surfaces while maintaining optical performance.- Flexible substrate technologies for microdisplays: Various substrate technologies enable flexibility in microdisplays. These include polymer-based substrates, thin-film technologies, and specialized flexible materials that can bend without compromising display functionality. These substrates serve as the foundation for building flexible display components while maintaining electrical connectivity and optical performance under mechanical stress.

- Flexible electronic components and circuitry: Flexible electronic components are essential for creating bendable microdisplays. These include thin-film transistors (TFTs), flexible interconnects, and stretchable conductive materials that maintain functionality when bent or flexed. Advanced manufacturing techniques allow these components to withstand repeated bending cycles while preserving electrical performance and display quality.

- Display technologies optimized for flexibility: Various display technologies have been adapted for flexible applications, including OLED, LCD, and e-paper variants. These technologies incorporate specialized materials and structures that maintain image quality and brightness when bent. Innovations in pixel architecture and light-emitting materials enable displays to function properly even when not in a flat configuration.

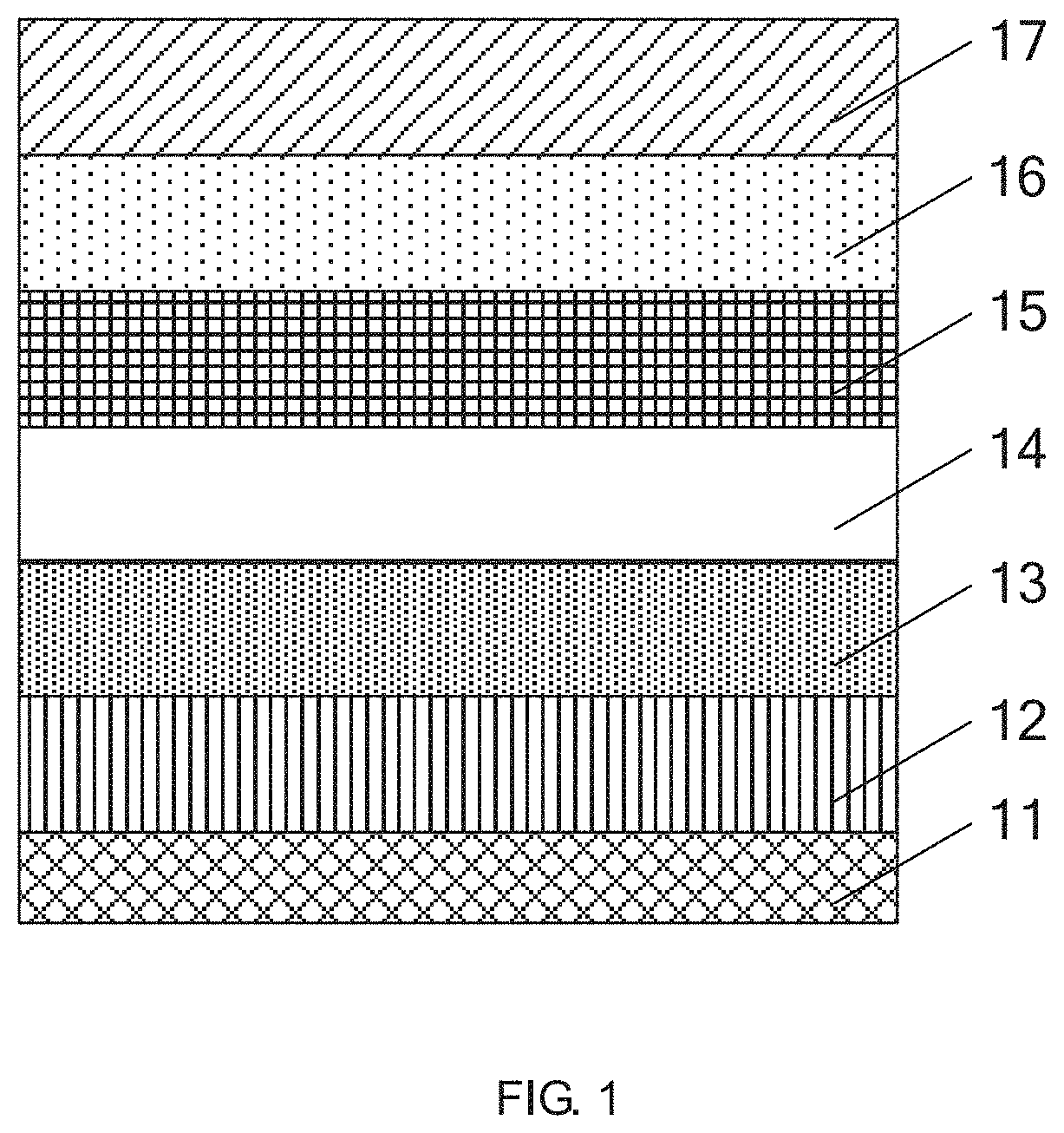

- Mechanical design for flexibility and durability: Specialized mechanical designs enhance the flexibility and durability of microdisplays. These include layered structures, neutral plane engineering, and strain-isolation techniques that protect sensitive components during bending. Advanced encapsulation methods and protective layers prevent damage from environmental factors while maintaining the display's ability to flex repeatedly.

- Testing and quality control for flexible displays: Specialized testing methodologies ensure the reliability of flexible microdisplays. These include bend testing, stress analysis, and accelerated aging tests to verify performance under various conditions. Advanced optical and electrical measurement techniques evaluate display quality during and after flexing, ensuring consistent performance throughout the product lifecycle.

02 Flexible display driving mechanisms

Specialized driving mechanisms are designed for flexible microdisplays to maintain image quality during bending. These include flexible thin-film transistors (TFTs), specialized electrode configurations, and circuit designs that can operate reliably when flexed. These driving mechanisms ensure consistent pixel addressing and image rendering even when the display is in a non-flat configuration.Expand Specific Solutions03 Optical components for flexible displays

Specialized optical components are developed for flexible microdisplays, including bendable light guides, flexible optical films, and deformable lens systems. These components maintain optical performance during bending and flexing operations, ensuring consistent image quality regardless of the display's physical configuration. The optical systems are designed to compensate for changes in light path that occur when the display surface is not flat.Expand Specific Solutions04 Flexible display materials and structures

Advanced materials and structural designs enable the creation of highly flexible microdisplays. These include specialized polymers, composite materials, and layered structures that provide both flexibility and durability. The materials are engineered to withstand repeated bending cycles while protecting sensitive electronic components and maintaining display performance. Some designs incorporate strain-relief mechanisms to prevent damage during flexing.Expand Specific Solutions05 Testing and quality control for flexible displays

Specialized testing methods and quality control procedures are developed for flexible microdisplays. These include bend testing equipment, optical performance measurement during flexing, and durability assessment techniques. The testing procedures ensure that flexible displays maintain their visual performance and electrical functionality throughout their expected lifetime of bending cycles and under various environmental conditions.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Flexible microdisplays are emerging as a critical technology for next-generation displays, with the market currently in a transitional growth phase. The global market is expanding rapidly, projected to reach significant scale as applications in wearables, foldable devices, and automotive displays gain traction. Technologically, the field is advancing from early-stage development toward commercial maturity, with key players demonstrating varying levels of expertise. Industry leaders like LG Display, Samsung Electronics, and BOE Technology have established strong positions through significant R&D investments, while companies such as Tianma Microelectronics and Innolux are rapidly advancing their capabilities. The ecosystem also includes specialized innovators like E Ink Holdings and Semiconductor Energy Laboratory, who are developing proprietary flexible display technologies to address specific market niches.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered flexible microdisplay technology through their P-OLED (Plastic OLED) solutions, which enable truly bendable and rollable displays. Their proprietary technology involves using plastic substrates instead of traditional glass, allowing for displays that can be bent, folded, or rolled while maintaining image quality. LG's technical approach includes specialized TFT backplanes on polyimide films that can withstand repeated mechanical stress without performance degradation. Their flexible microdisplays incorporate unique compensation algorithms that adjust pixel brightness and color accuracy when the display is bent or curved. LG has demonstrated commercial viability with products like their rollable OLED TV (SIGNATURE OLED R) and flexible smartphone displays, proving the scalability of their flexible microdisplay technology from small to large form factors.

Strengths: Industry-leading flexibility and durability metrics with displays capable of withstanding over 200,000 fold cycles; exceptional color accuracy maintained during bending; established mass production capabilities. Weaknesses: Higher production costs compared to rigid displays; some limitations in achieving extreme folding angles without visible creasing; power efficiency challenges in highly flexible configurations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible microdisplay technology centered around their Y-OCTA (Youm On-Cell Touch AMOLED) and UTG (Ultra Thin Glass) innovations. Their technical approach integrates touch sensors directly into the display panel rather than as a separate layer, significantly reducing thickness while enhancing flexibility. Samsung's flexible displays utilize a specialized low-temperature polycrystalline oxide (LTPO) backplane technology that enables variable refresh rates (from 1Hz to 120Hz) even in flexible configurations, dramatically improving power efficiency. Their Ultra Thin Glass technology provides a balance between flexibility and durability that plastic-only solutions cannot match, with glass layers as thin as 30 micrometers that can be bent while retaining glass's superior optical properties and scratch resistance. Samsung has implemented these technologies in commercial products including their Galaxy Z Fold and Z Flip series, demonstrating real-world application of flexible microdisplays in foldable smartphones.

Strengths: Superior display quality with higher brightness and color accuracy than competitors; innovative UTG technology provides better durability than plastic-only solutions; established ecosystem for mass production. Weaknesses: More limited folding radius compared to fully plastic solutions; higher manufacturing complexity due to ultra-thin glass handling requirements; premium pricing positioning limiting broader market adoption.

Core Patents and Breakthroughs in Flexible Display Technology

Flexible display panel and flexible display device

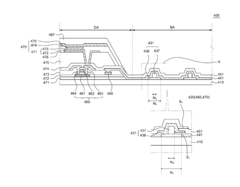

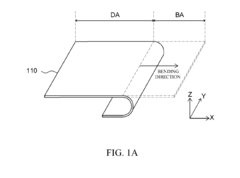

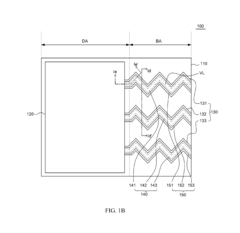

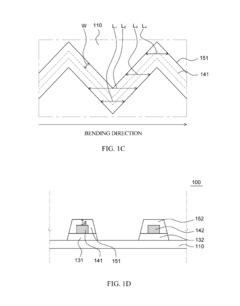

PatentActiveUS20210081063A1

Innovation

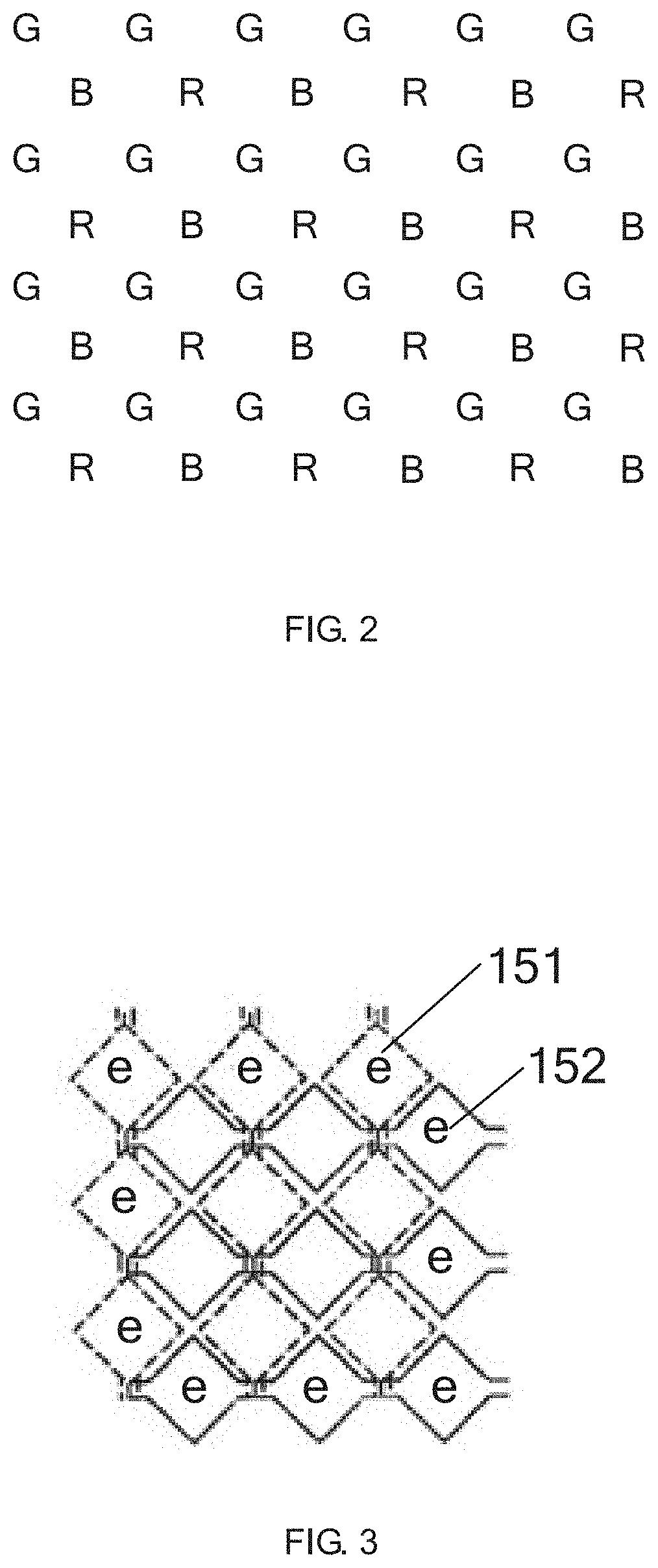

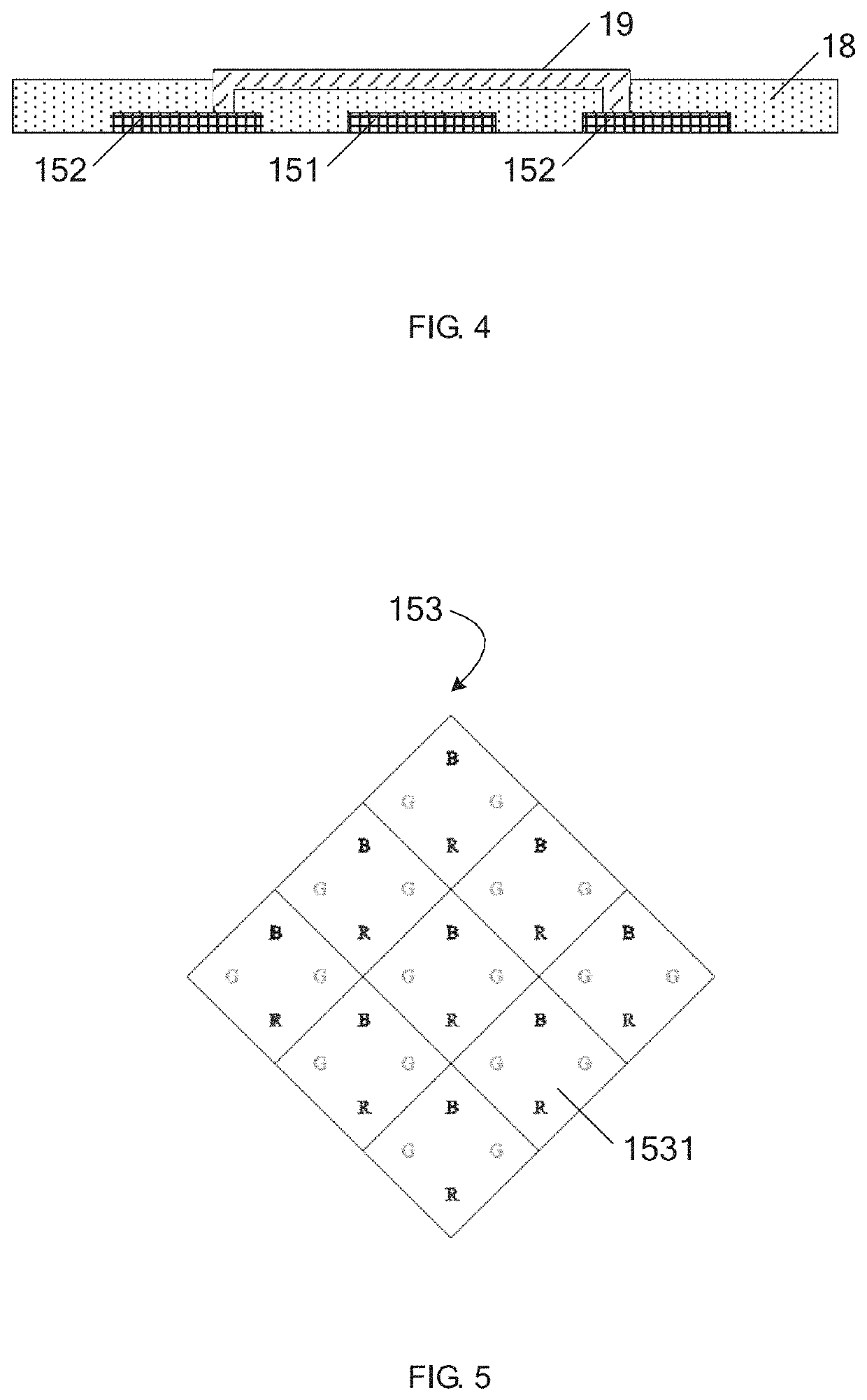

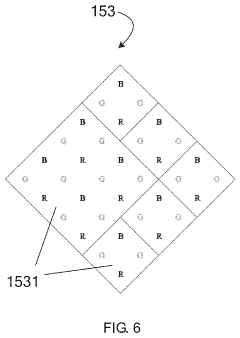

- Reducing the arrangement density of metal traces in the metal mesh and arranging them in gaps among sub pixels, with a higher transmittance achieved by not surrounding each sub pixel, and incorporating trace gaps in touch electrodes to minimize light shielding while maintaining optical uniformity.

Flexible Organic Light Emitting Display Device and Method for Manufacturing the Same

PatentActiveUS20170315399A1

Innovation

- A configuration featuring a flexible OLED display with a flexible substrate, where wires and insulating layers have trace patterns that match each other, reducing mechanical stress by separating individual insulating patterns to inhibit crack propagation, and using a cover glass to minimize visible edges and correct optical distortions.

Materials Science Advancements Enabling Flexibility

The evolution of flexible microdisplays represents a significant breakthrough in materials science, fundamentally transforming display technology capabilities. Traditional rigid display materials have given way to innovative flexible substrates, primarily through advancements in polymer science and thin-film technology. Polyimide has emerged as a leading substrate material due to its exceptional thermal stability, chemical resistance, and mechanical flexibility while maintaining dimensional stability under stress.

Significant progress in transparent conductive materials has been equally crucial, with indium tin oxide (ITO) alternatives becoming essential as conventional ITO exhibits microcracks when flexed. Silver nanowires, carbon nanotubes, and PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) have demonstrated superior flexibility while maintaining necessary conductivity properties for display applications.

The development of organic light-emitting materials has revolutionized flexible display technology. OLED (Organic Light-Emitting Diode) materials can be deposited on flexible substrates through low-temperature processes, eliminating the need for rigid glass substrates. Recent advancements in solution-processable OLED materials have further simplified manufacturing while improving performance metrics such as efficiency and color accuracy.

Thin-film encapsulation technologies represent another critical materials science breakthrough. These multi-layer barrier films protect sensitive organic materials from oxygen and moisture degradation while maintaining flexibility. Atomic Layer Deposition (ALD) techniques have enabled the creation of ultra-thin yet highly effective barrier layers measuring just nanometers thick, preserving display flexibility while extending operational lifetimes.

Stretchable electronics and interconnects have addressed the challenge of maintaining electrical connectivity during repeated flexing. Novel materials including liquid metal alloys, serpentine metal traces, and conductive polymers can withstand thousands of bending cycles without performance degradation. These materials accommodate mechanical strain while preserving electrical functionality across the display surface.

Nanocomposite materials have further enhanced flexible display capabilities by combining the properties of different materials at the nanoscale. These engineered materials exhibit customized characteristics including enhanced mechanical strength, improved barrier properties, and optimized optical performance while maintaining flexibility. Carbon nanomaterials, particularly graphene and carbon nanotubes, have demonstrated exceptional potential for flexible electronics due to their remarkable combination of electrical conductivity, optical transparency, and mechanical flexibility.

Significant progress in transparent conductive materials has been equally crucial, with indium tin oxide (ITO) alternatives becoming essential as conventional ITO exhibits microcracks when flexed. Silver nanowires, carbon nanotubes, and PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) have demonstrated superior flexibility while maintaining necessary conductivity properties for display applications.

The development of organic light-emitting materials has revolutionized flexible display technology. OLED (Organic Light-Emitting Diode) materials can be deposited on flexible substrates through low-temperature processes, eliminating the need for rigid glass substrates. Recent advancements in solution-processable OLED materials have further simplified manufacturing while improving performance metrics such as efficiency and color accuracy.

Thin-film encapsulation technologies represent another critical materials science breakthrough. These multi-layer barrier films protect sensitive organic materials from oxygen and moisture degradation while maintaining flexibility. Atomic Layer Deposition (ALD) techniques have enabled the creation of ultra-thin yet highly effective barrier layers measuring just nanometers thick, preserving display flexibility while extending operational lifetimes.

Stretchable electronics and interconnects have addressed the challenge of maintaining electrical connectivity during repeated flexing. Novel materials including liquid metal alloys, serpentine metal traces, and conductive polymers can withstand thousands of bending cycles without performance degradation. These materials accommodate mechanical strain while preserving electrical functionality across the display surface.

Nanocomposite materials have further enhanced flexible display capabilities by combining the properties of different materials at the nanoscale. These engineered materials exhibit customized characteristics including enhanced mechanical strength, improved barrier properties, and optimized optical performance while maintaining flexibility. Carbon nanomaterials, particularly graphene and carbon nanotubes, have demonstrated exceptional potential for flexible electronics due to their remarkable combination of electrical conductivity, optical transparency, and mechanical flexibility.

Environmental Impact and Sustainability Considerations

The environmental footprint of display technologies has become increasingly significant as consumer electronics proliferate globally. Flexible microdisplays offer substantial sustainability advantages compared to conventional rigid displays, primarily through reduced material usage and enhanced durability. The ultrathin nature of flexible display substrates requires significantly less raw material during manufacturing, potentially reducing resource extraction impacts by 30-45% compared to traditional glass-based displays.

Manufacturing processes for flexible microdisplays are evolving toward more environmentally friendly methods. Recent innovations include solvent-free lamination techniques and water-based processing that minimize hazardous chemical usage. Research from the Sustainable Electronics Initiative indicates that flexible display production can reduce toxic chemical use by up to 60% compared to conventional LCD manufacturing, substantially decreasing environmental contamination risks and worker exposure to harmful substances.

Energy efficiency represents another critical environmental advantage of flexible microdisplay technologies. The reduced weight and thickness of these displays translate to lower energy requirements during transportation and distribution. Additionally, many flexible display technologies, particularly those utilizing OLED or microLED elements, demonstrate 15-30% greater energy efficiency during operation compared to their rigid counterparts, contributing to reduced carbon emissions throughout product lifecycles.

End-of-life considerations further highlight the sustainability potential of flexible displays. Their inherent resistance to breakage extends product lifespans, potentially reducing electronic waste generation. When eventually discarded, the homogeneous material composition of many flexible displays simplifies recycling processes. Research from the Electronics Recycling Consortium suggests recovery rates for valuable materials from flexible displays could reach 75-85%, significantly higher than the 45-60% typically achieved with conventional displays.

Biodegradable substrate development represents a promising frontier in sustainable flexible display technology. Research teams at MIT and Stanford have demonstrated prototype displays utilizing cellulose-based substrates that can decompose under controlled conditions. While these technologies remain in early development stages, they point toward a future where display components could be designed for environmental decomposition rather than persistent waste.

Carbon footprint analyses conducted by the Green Electronics Council indicate that widespread adoption of flexible microdisplay technologies could reduce the display industry's carbon emissions by 12-18% by 2030. This reduction stems from combined benefits in manufacturing efficiency, extended product lifespans, and improved energy performance during use. As climate considerations increasingly influence technology development roadmaps, these sustainability advantages position flexible microdisplays as environmentally preferable alternatives to conventional display technologies.

Manufacturing processes for flexible microdisplays are evolving toward more environmentally friendly methods. Recent innovations include solvent-free lamination techniques and water-based processing that minimize hazardous chemical usage. Research from the Sustainable Electronics Initiative indicates that flexible display production can reduce toxic chemical use by up to 60% compared to conventional LCD manufacturing, substantially decreasing environmental contamination risks and worker exposure to harmful substances.

Energy efficiency represents another critical environmental advantage of flexible microdisplay technologies. The reduced weight and thickness of these displays translate to lower energy requirements during transportation and distribution. Additionally, many flexible display technologies, particularly those utilizing OLED or microLED elements, demonstrate 15-30% greater energy efficiency during operation compared to their rigid counterparts, contributing to reduced carbon emissions throughout product lifecycles.

End-of-life considerations further highlight the sustainability potential of flexible displays. Their inherent resistance to breakage extends product lifespans, potentially reducing electronic waste generation. When eventually discarded, the homogeneous material composition of many flexible displays simplifies recycling processes. Research from the Electronics Recycling Consortium suggests recovery rates for valuable materials from flexible displays could reach 75-85%, significantly higher than the 45-60% typically achieved with conventional displays.

Biodegradable substrate development represents a promising frontier in sustainable flexible display technology. Research teams at MIT and Stanford have demonstrated prototype displays utilizing cellulose-based substrates that can decompose under controlled conditions. While these technologies remain in early development stages, they point toward a future where display components could be designed for environmental decomposition rather than persistent waste.

Carbon footprint analyses conducted by the Green Electronics Council indicate that widespread adoption of flexible microdisplay technologies could reduce the display industry's carbon emissions by 12-18% by 2030. This reduction stems from combined benefits in manufacturing efficiency, extended product lifespans, and improved energy performance during use. As climate considerations increasingly influence technology development roadmaps, these sustainability advantages position flexible microdisplays as environmentally preferable alternatives to conventional display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!