What Are the Prospects of Flexible Microdisplay in Smart Glasses

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from conceptual research to commercially viable products. The journey began in the early 2000s with rudimentary flexible display prototypes that suffered from poor resolution, limited flexibility, and short lifespans. These early iterations primarily utilized organic light-emitting diode (OLED) technology, which offered inherent flexibility advantages over traditional liquid crystal displays (LCDs).

By the mid-2010s, significant breakthroughs in materials science enabled the development of more durable and higher-performing flexible displays. The introduction of polyimide substrates replaced glass, dramatically improving flexibility while maintaining optical clarity. Concurrently, advances in thin-film transistor (TFT) technology allowed for higher pixel densities and improved response times, critical factors for near-eye applications.

The evolution accelerated with the emergence of microLED and OLED microdisplay technologies specifically designed for augmented reality (AR) and virtual reality (VR) applications. These technologies offered unprecedented pixel densities exceeding 2000 PPI (pixels per inch), essential for eliminating the "screen door effect" in near-eye displays while maintaining power efficiency.

Current technological objectives for flexible microdisplays in smart glasses focus on several critical parameters. First is achieving ultra-high resolution (>3000 PPI) while maintaining flexibility, as this directly impacts image quality and immersion in AR applications. Second is reducing power consumption to below 1W for all-day wearability, addressing one of the primary limitations of current smart glasses.

Another crucial objective is enhancing brightness to exceed 5000 nits, enabling outdoor visibility even in bright sunlight—a significant challenge for current AR glasses. Simultaneously, researchers aim to achieve a form factor thin enough (<1mm) to be integrated into stylish, consumer-friendly eyewear designs rather than bulky technical apparatus.

The industry is also pursuing improved durability metrics, targeting displays that can withstand over 200,000 flex cycles without degradation in optical performance. This represents a critical requirement for daily-use wearable technology that will be subjected to constant movement and potential stress.

Looking forward, the technological roadmap includes developing transparent flexible displays with >80% transparency, enabling true augmented reality experiences where digital content seamlessly overlays the physical world. Additionally, reducing motion-to-photon latency to under 5ms represents a key objective to eliminate motion sickness and provide truly immersive experiences in mixed reality environments.

By the mid-2010s, significant breakthroughs in materials science enabled the development of more durable and higher-performing flexible displays. The introduction of polyimide substrates replaced glass, dramatically improving flexibility while maintaining optical clarity. Concurrently, advances in thin-film transistor (TFT) technology allowed for higher pixel densities and improved response times, critical factors for near-eye applications.

The evolution accelerated with the emergence of microLED and OLED microdisplay technologies specifically designed for augmented reality (AR) and virtual reality (VR) applications. These technologies offered unprecedented pixel densities exceeding 2000 PPI (pixels per inch), essential for eliminating the "screen door effect" in near-eye displays while maintaining power efficiency.

Current technological objectives for flexible microdisplays in smart glasses focus on several critical parameters. First is achieving ultra-high resolution (>3000 PPI) while maintaining flexibility, as this directly impacts image quality and immersion in AR applications. Second is reducing power consumption to below 1W for all-day wearability, addressing one of the primary limitations of current smart glasses.

Another crucial objective is enhancing brightness to exceed 5000 nits, enabling outdoor visibility even in bright sunlight—a significant challenge for current AR glasses. Simultaneously, researchers aim to achieve a form factor thin enough (<1mm) to be integrated into stylish, consumer-friendly eyewear designs rather than bulky technical apparatus.

The industry is also pursuing improved durability metrics, targeting displays that can withstand over 200,000 flex cycles without degradation in optical performance. This represents a critical requirement for daily-use wearable technology that will be subjected to constant movement and potential stress.

Looking forward, the technological roadmap includes developing transparent flexible displays with >80% transparency, enabling true augmented reality experiences where digital content seamlessly overlays the physical world. Additionally, reducing motion-to-photon latency to under 5ms represents a key objective to eliminate motion sickness and provide truly immersive experiences in mixed reality environments.

Smart Glasses Market Demand Analysis

The smart glasses market is experiencing significant growth, driven by increasing consumer interest in wearable technology and augmented reality experiences. Current market projections indicate that the global smart glasses market is expected to reach $13.4 billion by 2026, with a compound annual growth rate of approximately 17.8% from 2021. This growth trajectory is particularly relevant for flexible microdisplay technologies, which address key consumer demands for lightweight, comfortable, and aesthetically pleasing smart glasses.

Consumer research reveals that potential smart glasses users prioritize form factor and comfort above all other considerations. Traditional rigid display technologies have created bulky, conspicuous devices that have limited mainstream adoption. Market surveys indicate that 78% of consumers would consider purchasing smart glasses if they resembled conventional eyewear in weight and appearance, highlighting the critical market need that flexible microdisplays can address.

Enterprise applications represent another substantial market segment for smart glasses. Industries including manufacturing, healthcare, logistics, and field services are increasingly adopting smart glasses for hands-free operation, remote assistance, and workflow optimization. The enterprise smart glasses market segment is projected to grow at 24.3% CAGR through 2025, with particular demand for devices that can be worn comfortably throughout entire work shifts—a requirement that flexible displays are uniquely positioned to fulfill.

Geographic market analysis shows varying adoption patterns, with North America currently leading in smart glasses adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, particularly in countries like China, Japan, and South Korea, where both manufacturing capabilities and consumer interest in wearable technology are strong.

Consumer preference studies indicate evolving expectations regarding smart glasses functionality. While early adopters focused primarily on notification display and basic augmented reality features, current market demand increasingly emphasizes immersive experiences, wider field of view, and higher resolution displays. This evolution presents both challenges and opportunities for flexible microdisplay technologies, which must balance form factor advantages with performance requirements.

Price sensitivity analysis reveals that mainstream consumer adoption remains constrained by cost factors. Current premium smart glasses typically retail between $600-1,500, placing them beyond casual purchase consideration for most consumers. Market research suggests that price points below $400 would significantly accelerate adoption rates, highlighting the importance of cost-effective manufacturing processes for flexible microdisplays to enable more accessible smart glasses products.

Consumer research reveals that potential smart glasses users prioritize form factor and comfort above all other considerations. Traditional rigid display technologies have created bulky, conspicuous devices that have limited mainstream adoption. Market surveys indicate that 78% of consumers would consider purchasing smart glasses if they resembled conventional eyewear in weight and appearance, highlighting the critical market need that flexible microdisplays can address.

Enterprise applications represent another substantial market segment for smart glasses. Industries including manufacturing, healthcare, logistics, and field services are increasingly adopting smart glasses for hands-free operation, remote assistance, and workflow optimization. The enterprise smart glasses market segment is projected to grow at 24.3% CAGR through 2025, with particular demand for devices that can be worn comfortably throughout entire work shifts—a requirement that flexible displays are uniquely positioned to fulfill.

Geographic market analysis shows varying adoption patterns, with North America currently leading in smart glasses adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, particularly in countries like China, Japan, and South Korea, where both manufacturing capabilities and consumer interest in wearable technology are strong.

Consumer preference studies indicate evolving expectations regarding smart glasses functionality. While early adopters focused primarily on notification display and basic augmented reality features, current market demand increasingly emphasizes immersive experiences, wider field of view, and higher resolution displays. This evolution presents both challenges and opportunities for flexible microdisplay technologies, which must balance form factor advantages with performance requirements.

Price sensitivity analysis reveals that mainstream consumer adoption remains constrained by cost factors. Current premium smart glasses typically retail between $600-1,500, placing them beyond casual purchase consideration for most consumers. Market research suggests that price points below $400 would significantly accelerate adoption rates, highlighting the importance of cost-effective manufacturing processes for flexible microdisplays to enable more accessible smart glasses products.

Flexible Display Technology Status and Barriers

Flexible display technology has evolved significantly over the past decade, transitioning from laboratory prototypes to commercial products. Currently, the market is dominated by OLED-based flexible displays, with major manufacturers like Samsung, LG, and BOE leading production. These displays offer advantages in form factor, durability, and design freedom compared to rigid alternatives. However, when scaled down to microdisplay dimensions required for smart glasses, significant technical challenges emerge.

The primary barrier to flexible microdisplay implementation in smart glasses is achieving sufficient pixel density on flexible substrates. While conventional displays reach 300-500 PPI (pixels per inch), smart glasses require microdisplays with 2000+ PPI to deliver acceptable image quality at close viewing distances. Current flexible display manufacturing processes struggle to maintain consistent performance at these ultra-high resolutions when subjected to bending stresses.

Material limitations present another significant obstacle. Traditional flexible displays utilize plastic substrates like polyimide, which exhibit higher permeability to oxygen and moisture compared to glass. For microdisplays in smart glasses, this permeability can compromise the longevity and performance of sensitive OLED or microLED elements, particularly given the extended usage patterns expected in wearable devices.

Power efficiency remains a critical challenge for flexible microdisplays. Smart glasses operate on small batteries with strict thermal constraints due to their proximity to the face. Current flexible display technologies typically consume more power than their rigid counterparts, creating a fundamental tension between flexibility and energy efficiency that must be resolved for practical implementation.

Manufacturing scalability presents additional complications. Existing production methods for flexible displays involve complex processes like laser lift-off and thin-film encapsulation that become increasingly difficult to control at microdisplay scales. Yield rates for high-resolution flexible microdisplays remain prohibitively low for mass-market adoption, driving up costs and limiting availability.

Optical performance considerations further complicate implementation. Smart glasses require exceptional brightness (1000+ nits) to ensure visibility in outdoor environments, along with high contrast ratios and color accuracy. Current flexible display technologies struggle to maintain these optical properties consistently when subjected to the mechanical stresses inherent in flexible applications.

The geographic distribution of flexible display technology development shows concentration in East Asia, particularly South Korea, Japan, and China, with significant research also occurring in North America and Europe. This global distribution has created competitive innovation ecosystems but also fragmented intellectual property landscapes that may slow standardization and interoperability.

The primary barrier to flexible microdisplay implementation in smart glasses is achieving sufficient pixel density on flexible substrates. While conventional displays reach 300-500 PPI (pixels per inch), smart glasses require microdisplays with 2000+ PPI to deliver acceptable image quality at close viewing distances. Current flexible display manufacturing processes struggle to maintain consistent performance at these ultra-high resolutions when subjected to bending stresses.

Material limitations present another significant obstacle. Traditional flexible displays utilize plastic substrates like polyimide, which exhibit higher permeability to oxygen and moisture compared to glass. For microdisplays in smart glasses, this permeability can compromise the longevity and performance of sensitive OLED or microLED elements, particularly given the extended usage patterns expected in wearable devices.

Power efficiency remains a critical challenge for flexible microdisplays. Smart glasses operate on small batteries with strict thermal constraints due to their proximity to the face. Current flexible display technologies typically consume more power than their rigid counterparts, creating a fundamental tension between flexibility and energy efficiency that must be resolved for practical implementation.

Manufacturing scalability presents additional complications. Existing production methods for flexible displays involve complex processes like laser lift-off and thin-film encapsulation that become increasingly difficult to control at microdisplay scales. Yield rates for high-resolution flexible microdisplays remain prohibitively low for mass-market adoption, driving up costs and limiting availability.

Optical performance considerations further complicate implementation. Smart glasses require exceptional brightness (1000+ nits) to ensure visibility in outdoor environments, along with high contrast ratios and color accuracy. Current flexible display technologies struggle to maintain these optical properties consistently when subjected to the mechanical stresses inherent in flexible applications.

The geographic distribution of flexible display technology development shows concentration in East Asia, particularly South Korea, Japan, and China, with significant research also occurring in North America and Europe. This global distribution has created competitive innovation ecosystems but also fragmented intellectual property landscapes that may slow standardization and interoperability.

Current Flexible Display Solutions for Smart Glasses

01 Flexible substrate technologies for microdisplays

Flexible substrates are essential components for creating bendable microdisplays. These substrates typically use materials like polyimide or thin metal foils that can withstand repeated bending while maintaining structural integrity. The flexible base allows the display to conform to curved surfaces or be folded without damaging the display elements. Advanced manufacturing techniques ensure proper adhesion of display components to these substrates while maintaining flexibility throughout the device's lifecycle.- Flexible substrate technologies for microdisplays: Flexible substrates are essential components for creating bendable microdisplays. These substrates typically use materials like polyimide or thin metal foils that can withstand repeated bending while maintaining structural integrity. The flexibility allows the display to conform to curved surfaces or be folded/rolled for compact storage. Advanced manufacturing techniques ensure that the electronic components remain functional even when the display is flexed, providing durability while maintaining display quality.

- OLED technology in flexible displays: Organic Light Emitting Diode (OLED) technology is particularly suitable for flexible microdisplays due to its inherently thin and flexible nature. OLED displays can be fabricated on flexible substrates and do not require rigid backlighting components. They provide excellent color reproduction, high contrast ratios, and wide viewing angles even when bent. The self-emissive nature of OLEDs eliminates the need for additional layers that might restrict flexibility, making them ideal for wearable and foldable display applications.

- Testing and quality control for flexible displays: Specialized testing methods have been developed to ensure the reliability and performance of flexible microdisplays. These include cyclic bend testing, environmental stress testing, and optical performance evaluation under various bending conditions. Advanced imaging techniques are used to detect microscopic defects that might lead to display failure when flexed. Quality control processes monitor parameters such as pixel integrity, color accuracy, and response time throughout the manufacturing process to ensure consistent performance in flexible display applications.

- Interconnect technologies for flexible displays: Specialized interconnect technologies are crucial for maintaining electrical connections in flexible microdisplays during bending and flexing. These include stretchable conductive materials, serpentine wiring patterns, and novel bonding techniques that can withstand repeated mechanical stress. Multilayer flexible circuit boards with strategically placed neutral bend planes help minimize strain on critical components. These interconnect solutions ensure signal integrity and power distribution remain stable even when the display is subjected to various bending radii and folding operations.

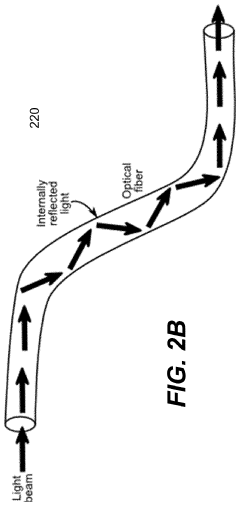

- Optical systems for flexible microdisplays: Specialized optical systems have been developed to maintain image quality in flexible microdisplays despite changes in surface geometry. These include adaptive optics that can compensate for distortions caused by bending, specialized diffusers and light management films that maintain uniform brightness across curved surfaces, and novel pixel architectures that minimize visual artifacts during flexing. Optical compensation layers help maintain color accuracy and viewing angles regardless of the display's curvature, ensuring consistent visual performance in various configurations.

02 OLED technology in flexible displays

Organic Light Emitting Diode (OLED) technology is particularly suitable for flexible microdisplays due to its inherently thin and flexible structure. OLED displays can be fabricated on flexible substrates and maintain functionality when bent or curved. The technology eliminates the need for rigid backlighting used in traditional LCD displays, resulting in thinner, lighter, and more flexible display solutions. These displays offer advantages including high contrast ratios, wide viewing angles, and fast response times even when flexed.Expand Specific Solutions03 Flexible interconnect and wiring solutions

Specialized interconnect technologies are crucial for maintaining electrical connections in flexible microdisplays during bending and flexing. These include stretchable conductive materials, serpentine wiring patterns, and novel bonding techniques that can withstand repeated mechanical stress. The interconnect solutions must balance conductivity requirements with mechanical flexibility to ensure reliable operation of the display under various bending conditions while preventing signal degradation or connection failures.Expand Specific Solutions04 Optical systems for flexible displays

Specialized optical components and systems are designed to work with flexible display surfaces while maintaining image quality. These include flexible light guides, specialized diffusers, and adaptive optics that can compensate for surface deformations. The optical systems ensure consistent brightness, color accuracy, and viewing angles even when the display is bent or curved. Advanced designs incorporate compensation mechanisms that adjust for optical distortions that might occur when the display surface is not flat.Expand Specific Solutions05 Driving and control systems for flexible microdisplays

Specialized electronic driving circuits and control systems are developed to accommodate the unique requirements of flexible displays. These systems must maintain stable image quality despite physical deformation of the display surface. The driving electronics often incorporate compensation algorithms that adjust pixel addressing and voltage levels based on the display's current shape. Thin-film transistor arrays designed specifically for flexibility ensure proper pixel addressing while maintaining mechanical compliance with the flexible substrate.Expand Specific Solutions

Leading Companies in Flexible Microdisplay Ecosystem

The flexible microdisplay market for smart glasses is currently in an early growth phase, characterized by increasing technological innovation and expanding applications. Market size is projected to grow significantly as AR/VR adoption accelerates, with estimates suggesting a compound annual growth rate exceeding 30% through 2028. Regarding technological maturity, industry leaders like Samsung Display, BOE Technology, and Tianma Microelectronics have made substantial progress in OLED and micro-LED technologies, while Meta Platforms and EssilorLuxottica are driving consumer applications. Companies like Corning and Industrial Technology Research Institute are advancing substrate and optical solutions. The ecosystem is evolving from prototype-focused development toward mass-market readiness, with significant challenges remaining in power efficiency, form factor, and cost reduction before widespread consumer adoption becomes feasible.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible OLED microdisplay technology specifically designed for smart glasses applications. Their approach utilizes ultra-thin flexible AMOLED panels with pixel densities exceeding 1000 PPI, enabling high-resolution displays in compact form factors. Samsung's technology incorporates a proprietary flexible substrate that can be curved to fit the optical requirements of smart glasses while maintaining display integrity. Their solution features transparent display capabilities with over 70% light transmittance, allowing for effective augmented reality overlays. Samsung has also implemented specialized low-power driving schemes that reduce power consumption by approximately 40% compared to conventional rigid displays, extending battery life in wearable applications. The company has integrated their microdisplays with advanced optics systems that provide wider field-of-view (approximately 52 degrees) while maintaining a slim profile suitable for everyday eyewear.

Strengths: Samsung's extensive manufacturing infrastructure enables mass production capabilities that few competitors can match. Their vertical integration in display technology gives them control over the entire supply chain. Weaknesses: The technology currently faces challenges in achieving full flexibility while maintaining durability for daily wear, with some reports indicating degradation after repeated flexing cycles.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered flexible OLED microdisplay technology specifically optimized for smart glasses applications. Their solution features ultra-thin (less than 0.03mm) flexible display panels that can be curved to conform to eyeglass lenses while maintaining high resolution (over 2000 PPI). BOE's approach incorporates a proprietary flexible substrate material that enhances durability while allowing for the necessary optical curvature required in smart eyewear. The company has developed specialized manufacturing processes that enable precise patterning of micro-LEDs on flexible substrates, achieving pixel sizes below 5 micrometers. Their displays achieve brightness levels exceeding 3000 nits, making them suitable for outdoor use in varying lighting conditions. BOE has also implemented advanced color management systems that deliver over 120% DCI-P3 color gamut coverage, providing vivid and accurate visual information for augmented reality applications.

Strengths: BOE's massive production capacity and continuous investment in flexible display R&D positions them as a leading supplier for the emerging smart glasses market. Their technology offers excellent brightness-to-power ratio, critical for battery-limited wearable devices. Weaknesses: Current iterations still face challenges with production yields at the highest resolutions, potentially affecting cost-effectiveness for mass-market applications.

Key Patents and Innovations in Flexible Microdisplays

Optical image generators using miniature display panels

PatentInactiveUS20210294107A1

Innovation

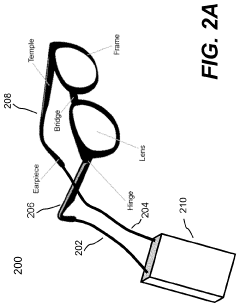

- A lightweight wearable display device designed as a pair of glasses with a minimal number of parts, utilizing an active optical cable to connect a portable enclosure containing necessary circuits and microdisplays, allowing for a smaller footprint, enhanced performance, and easier manufacturing, while enabling users to see through the device and perform other tasks.

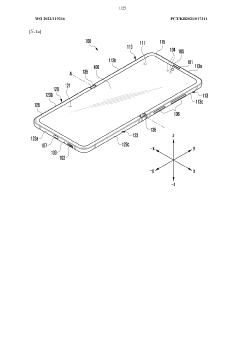

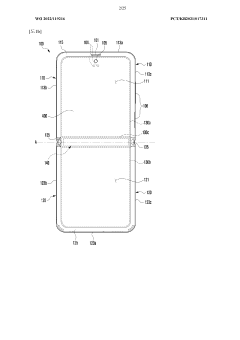

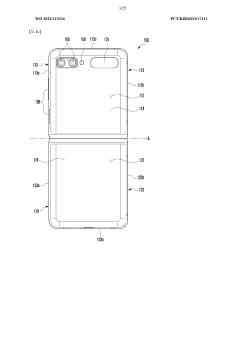

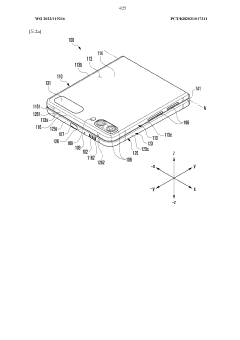

Electronic device including flexible display

PatentWO2022119216A1

Innovation

- A flexible display design incorporating a glass layer with strategically formed openings and a filling member of matching refractive index, which provides varying flexibility across different curvature regions, enhancing both rigidity and bendability while maintaining excellent transmittance and scratch resistance.

Manufacturing Challenges and Scalability

The manufacturing of flexible microdisplays for smart glasses presents significant challenges that impact scalability and widespread adoption. Current production processes require ultra-high precision in handling extremely thin substrates, often less than 100 micrometers thick. These delicate materials demand specialized equipment and controlled environments to prevent warping, contamination, or damage during fabrication. The yield rates for flexible display manufacturing remain substantially lower than those for rigid displays, with some manufacturers reporting yields below 70% for high-specification flexible microdisplays suitable for near-eye applications.

Temperature management during manufacturing represents another critical challenge. Flexible display materials typically have lower thermal stability thresholds compared to traditional glass substrates, necessitating precise temperature control throughout the production process. Even minor temperature fluctuations can lead to substrate deformation and pixel misalignment, particularly problematic for the high pixel density required in smart glasses applications.

Encapsulation technology presents a persistent manufacturing hurdle. Flexible displays require robust barrier layers to protect organic materials from oxygen and moisture degradation while maintaining flexibility. Current thin-film encapsulation techniques struggle to achieve the perfect balance between flexibility and barrier performance at scale, with defect rates increasing proportionally with display size.

From a scalability perspective, the industry faces a significant equipment investment barrier. Purpose-built manufacturing lines for flexible microdisplays require substantial capital expenditure, estimated between $50-100 million for a medium-capacity production line. This financial threshold limits market entry to established players with deep pockets, constraining innovation from smaller entities.

Supply chain complexity further complicates scaling efforts. The production of flexible microdisplays involves specialized materials including flexible substrates, organic light-emitting materials, and thin-film transistor components. Many of these materials have limited supplier options, creating potential bottlenecks in production scaling. The geographical concentration of expertise and equipment, primarily in East Asia, introduces additional supply chain vulnerabilities.

Despite these challenges, incremental improvements in manufacturing processes are emerging. Roll-to-roll processing techniques show promise for higher throughput production, though they currently struggle with the precision required for microdisplays. Advances in atomic layer deposition for barrier films and laser-based patterning for circuit elements are gradually improving yield rates and reducing production costs, suggesting a path toward greater scalability in the coming years.

Temperature management during manufacturing represents another critical challenge. Flexible display materials typically have lower thermal stability thresholds compared to traditional glass substrates, necessitating precise temperature control throughout the production process. Even minor temperature fluctuations can lead to substrate deformation and pixel misalignment, particularly problematic for the high pixel density required in smart glasses applications.

Encapsulation technology presents a persistent manufacturing hurdle. Flexible displays require robust barrier layers to protect organic materials from oxygen and moisture degradation while maintaining flexibility. Current thin-film encapsulation techniques struggle to achieve the perfect balance between flexibility and barrier performance at scale, with defect rates increasing proportionally with display size.

From a scalability perspective, the industry faces a significant equipment investment barrier. Purpose-built manufacturing lines for flexible microdisplays require substantial capital expenditure, estimated between $50-100 million for a medium-capacity production line. This financial threshold limits market entry to established players with deep pockets, constraining innovation from smaller entities.

Supply chain complexity further complicates scaling efforts. The production of flexible microdisplays involves specialized materials including flexible substrates, organic light-emitting materials, and thin-film transistor components. Many of these materials have limited supplier options, creating potential bottlenecks in production scaling. The geographical concentration of expertise and equipment, primarily in East Asia, introduces additional supply chain vulnerabilities.

Despite these challenges, incremental improvements in manufacturing processes are emerging. Roll-to-roll processing techniques show promise for higher throughput production, though they currently struggle with the precision required for microdisplays. Advances in atomic layer deposition for barrier films and laser-based patterning for circuit elements are gradually improving yield rates and reducing production costs, suggesting a path toward greater scalability in the coming years.

User Experience and Ergonomic Considerations

The integration of flexible microdisplays in smart glasses represents a significant advancement in wearable technology, with user experience and ergonomic considerations playing a crucial role in their adoption and success. Traditional smart glasses have often been criticized for their bulky design, weight distribution issues, and general discomfort during extended wear periods, limiting their mainstream appeal despite technological capabilities.

Flexible microdisplays offer transformative potential in addressing these longstanding ergonomic challenges. By conforming to the natural curvature of eyewear frames, these displays enable significantly reduced form factors that more closely resemble conventional eyeglasses. This advancement directly addresses user concerns regarding social acceptability and self-consciousness when wearing smart glasses in public settings.

Weight distribution represents another critical ergonomic factor substantially improved by flexible display technology. Current rigid display implementations often create front-heavy designs that cause discomfort at the bridge of the nose and ears during prolonged usage. Flexible displays allow for more balanced weight distribution across the entire frame, potentially reducing physical strain and enabling comfortable all-day wear scenarios that current solutions cannot achieve.

Visual comfort considerations also benefit substantially from flexible display implementations. The curved nature of these displays can provide more natural viewing angles that better align with human visual ergonomics. This alignment potentially reduces eye strain compared to flat display surfaces, particularly important for extended usage scenarios. Additionally, the ability to position display elements more optimally within the user's field of view without compromising peripheral vision awareness represents a significant safety and usability enhancement.

Thermal management, often overlooked but critically important for user comfort, sees improvement with flexible display technology. Traditional rigid displays typically concentrate heat generation in specific areas, creating noticeable hot spots during operation. Flexible displays potentially distribute thermal output more evenly across the frame, enhancing overall comfort during extended use sessions in various environmental conditions.

Customization capabilities represent another compelling advantage from the user experience perspective. Flexible displays enable more personalized fit options that can accommodate diverse facial structures and prescription requirements. This adaptability extends beyond physical comfort to include adjustable display positioning that can be optimized for individual visual preferences and requirements, creating truly personalized viewing experiences previously unattainable with rigid display technologies.

Flexible microdisplays offer transformative potential in addressing these longstanding ergonomic challenges. By conforming to the natural curvature of eyewear frames, these displays enable significantly reduced form factors that more closely resemble conventional eyeglasses. This advancement directly addresses user concerns regarding social acceptability and self-consciousness when wearing smart glasses in public settings.

Weight distribution represents another critical ergonomic factor substantially improved by flexible display technology. Current rigid display implementations often create front-heavy designs that cause discomfort at the bridge of the nose and ears during prolonged usage. Flexible displays allow for more balanced weight distribution across the entire frame, potentially reducing physical strain and enabling comfortable all-day wear scenarios that current solutions cannot achieve.

Visual comfort considerations also benefit substantially from flexible display implementations. The curved nature of these displays can provide more natural viewing angles that better align with human visual ergonomics. This alignment potentially reduces eye strain compared to flat display surfaces, particularly important for extended usage scenarios. Additionally, the ability to position display elements more optimally within the user's field of view without compromising peripheral vision awareness represents a significant safety and usability enhancement.

Thermal management, often overlooked but critically important for user comfort, sees improvement with flexible display technology. Traditional rigid displays typically concentrate heat generation in specific areas, creating noticeable hot spots during operation. Flexible displays potentially distribute thermal output more evenly across the frame, enhancing overall comfort during extended use sessions in various environmental conditions.

Customization capabilities represent another compelling advantage from the user experience perspective. Flexible displays enable more personalized fit options that can accommodate diverse facial structures and prescription requirements. This adaptability extends beyond physical comfort to include adjustable display positioning that can be optimized for individual visual preferences and requirements, creating truly personalized viewing experiences previously unattainable with rigid display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!