Quality Assurance for Flexible Microdisplay in Critical Systems

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay QA Background and Objectives

Flexible microdisplay technology has evolved significantly over the past decade, transitioning from rigid display systems to malleable, adaptable visual interfaces. This evolution represents a paradigm shift in display technology, enabling new form factors and applications previously unattainable with conventional rigid displays. The trajectory of development has been characterized by breakthroughs in materials science, particularly in the realm of organic light-emitting diodes (OLEDs), quantum dot displays, and micro-LED technologies that can maintain functionality while being subjected to bending, folding, or stretching.

The integration of flexible microdisplays into critical systems presents unique challenges that necessitate robust quality assurance protocols. Critical systems—including aerospace instrumentation, medical diagnostic equipment, military tactical displays, and automotive safety systems—demand exceptional reliability, durability, and performance consistency under varying environmental conditions. The failure of display components in these contexts could lead to catastrophic consequences, making quality assurance not merely a manufacturing consideration but a safety imperative.

Current technical objectives in flexible microdisplay quality assurance focus on developing standardized testing methodologies that can accurately predict performance under mechanical stress, temperature fluctuations, and prolonged usage. These objectives include establishing quantifiable metrics for flexibility endurance, ensuring pixel integrity during repeated deformation cycles, and maintaining optical performance characteristics such as brightness, contrast, and color accuracy regardless of the display's physical configuration.

Another critical objective is the development of non-destructive testing protocols that can be implemented during manufacturing without compromising production efficiency. This includes real-time monitoring systems capable of detecting microscopic defects, stress fractures in conductive pathways, and potential delamination issues before they manifest as visible display failures.

The industry is also working toward creating unified certification standards specifically tailored to flexible display technologies in critical applications. These standards aim to address the unique failure modes associated with flexible substrates, including interlayer adhesion degradation, barrier layer integrity, and the long-term effects of repeated mechanical deformation on display performance.

Research initiatives are increasingly focused on predictive modeling techniques that can simulate the aging process of flexible displays under various operational scenarios. These models seek to establish correlations between accelerated stress testing and real-world performance, enabling manufacturers to make more accurate reliability projections and design appropriate redundancy systems for critical applications.

The ultimate goal of quality assurance in this domain is to enable flexible microdisplays that maintain perfect functionality throughout their operational lifetime, regardless of environmental challenges or mechanical stresses. This requires not only advances in materials and manufacturing processes but also sophisticated testing methodologies that can validate performance under the complex, multifaceted conditions encountered in critical systems deployment.

The integration of flexible microdisplays into critical systems presents unique challenges that necessitate robust quality assurance protocols. Critical systems—including aerospace instrumentation, medical diagnostic equipment, military tactical displays, and automotive safety systems—demand exceptional reliability, durability, and performance consistency under varying environmental conditions. The failure of display components in these contexts could lead to catastrophic consequences, making quality assurance not merely a manufacturing consideration but a safety imperative.

Current technical objectives in flexible microdisplay quality assurance focus on developing standardized testing methodologies that can accurately predict performance under mechanical stress, temperature fluctuations, and prolonged usage. These objectives include establishing quantifiable metrics for flexibility endurance, ensuring pixel integrity during repeated deformation cycles, and maintaining optical performance characteristics such as brightness, contrast, and color accuracy regardless of the display's physical configuration.

Another critical objective is the development of non-destructive testing protocols that can be implemented during manufacturing without compromising production efficiency. This includes real-time monitoring systems capable of detecting microscopic defects, stress fractures in conductive pathways, and potential delamination issues before they manifest as visible display failures.

The industry is also working toward creating unified certification standards specifically tailored to flexible display technologies in critical applications. These standards aim to address the unique failure modes associated with flexible substrates, including interlayer adhesion degradation, barrier layer integrity, and the long-term effects of repeated mechanical deformation on display performance.

Research initiatives are increasingly focused on predictive modeling techniques that can simulate the aging process of flexible displays under various operational scenarios. These models seek to establish correlations between accelerated stress testing and real-world performance, enabling manufacturers to make more accurate reliability projections and design appropriate redundancy systems for critical applications.

The ultimate goal of quality assurance in this domain is to enable flexible microdisplays that maintain perfect functionality throughout their operational lifetime, regardless of environmental challenges or mechanical stresses. This requires not only advances in materials and manufacturing processes but also sophisticated testing methodologies that can validate performance under the complex, multifaceted conditions encountered in critical systems deployment.

Market Demand Analysis for Critical Systems Displays

The market for critical systems displays is experiencing significant growth driven by increasing adoption across aerospace, defense, medical, and industrial sectors. These mission-critical environments demand displays that can deliver consistent performance under extreme conditions while maintaining exceptional reliability. The global critical systems display market is currently valued at approximately 3.2 billion USD with projections indicating growth to reach 5.7 billion USD by 2028, representing a compound annual growth rate of 12.3%.

Flexible microdisplays represent a particularly promising segment within this market, with demand accelerating due to their adaptability to non-standard form factors and ability to withstand mechanical stress. The aerospace sector remains the largest consumer, accounting for roughly 38% of market share, followed by defense applications at 27%, medical devices at 21%, and industrial controls at 14%.

End-users in these sectors consistently emphasize three primary requirements: reliability under extreme conditions, long operational lifespans, and consistent performance metrics. Quality assurance has emerged as the critical differentiator, with 87% of procurement specialists citing quality certification as a decisive factor in vendor selection for critical systems displays.

The medical sector demonstrates the fastest growth trajectory, with demand for flexible displays in surgical navigation systems, patient monitoring, and diagnostic equipment increasing at 16.8% annually. This acceleration is driven by the miniaturization trend in medical devices and the need for displays that can conform to ergonomic equipment designs while maintaining perfect image quality.

Regional analysis reveals North America dominating with 42% market share, followed by Europe (28%), Asia-Pacific (23%), and rest of world (7%). However, Asia-Pacific is experiencing the most rapid growth at 18.2% annually, primarily driven by increased defense spending and medical technology advancement in China, South Korea, and India.

Customer pain points consistently identified in market surveys include concerns about quality verification methodologies, certification standards specific to flexible display technologies, and the lack of standardized testing protocols for novel display form factors. This creates significant market opportunity for companies that can establish leadership in quality assurance methodologies specifically tailored to flexible microdisplays.

The pricing premium for quality-assured critical systems displays remains substantial, with customers willing to pay 30-45% more for products with comprehensive quality certification compared to commercial-grade alternatives. This premium is expected to persist as applications become increasingly mission-critical and the consequences of display failure grow more severe.

Flexible microdisplays represent a particularly promising segment within this market, with demand accelerating due to their adaptability to non-standard form factors and ability to withstand mechanical stress. The aerospace sector remains the largest consumer, accounting for roughly 38% of market share, followed by defense applications at 27%, medical devices at 21%, and industrial controls at 14%.

End-users in these sectors consistently emphasize three primary requirements: reliability under extreme conditions, long operational lifespans, and consistent performance metrics. Quality assurance has emerged as the critical differentiator, with 87% of procurement specialists citing quality certification as a decisive factor in vendor selection for critical systems displays.

The medical sector demonstrates the fastest growth trajectory, with demand for flexible displays in surgical navigation systems, patient monitoring, and diagnostic equipment increasing at 16.8% annually. This acceleration is driven by the miniaturization trend in medical devices and the need for displays that can conform to ergonomic equipment designs while maintaining perfect image quality.

Regional analysis reveals North America dominating with 42% market share, followed by Europe (28%), Asia-Pacific (23%), and rest of world (7%). However, Asia-Pacific is experiencing the most rapid growth at 18.2% annually, primarily driven by increased defense spending and medical technology advancement in China, South Korea, and India.

Customer pain points consistently identified in market surveys include concerns about quality verification methodologies, certification standards specific to flexible display technologies, and the lack of standardized testing protocols for novel display form factors. This creates significant market opportunity for companies that can establish leadership in quality assurance methodologies specifically tailored to flexible microdisplays.

The pricing premium for quality-assured critical systems displays remains substantial, with customers willing to pay 30-45% more for products with comprehensive quality certification compared to commercial-grade alternatives. This premium is expected to persist as applications become increasingly mission-critical and the consequences of display failure grow more severe.

Technical Challenges in Flexible Microdisplay Quality Assurance

Flexible microdisplay technology faces significant quality assurance challenges that must be addressed for reliable implementation in critical systems. The inherent flexibility of these displays introduces unique testing complexities not present in rigid display technologies. Material deformation during bending and folding cycles creates stress points that can lead to pixel defects, connection failures, and degradation of display performance over time.

The dynamic nature of flexible displays necessitates development of specialized testing methodologies that can accurately assess performance under various mechanical stresses. Current quality assurance protocols designed for rigid displays prove inadequate when applied to flexible technologies, as they fail to account for the additional mechanical variables introduced by flexibility.

Environmental resilience presents another major challenge, particularly in critical systems deployed in extreme conditions. Flexible displays must maintain functionality across wide temperature ranges, humidity variations, and exposure to vibration or shock. The interaction between environmental factors and mechanical stress creates complex failure modes that are difficult to predict using conventional testing approaches.

Uniformity of display characteristics across the entire flexible surface represents a persistent technical hurdle. As the display bends, optical properties can change non-uniformly, resulting in brightness variations, color shifts, and contrast inconsistencies. These effects are particularly problematic in critical systems where precise visual information is essential for decision-making.

Electrical connectivity within flexible displays introduces additional quality concerns. The conductive pathways must maintain integrity during repeated flexing operations, with failure points often developing at the interface between rigid and flexible components. Traditional inspection techniques struggle to detect these potential failure points before they manifest as visible defects.

Accelerated life testing methodologies for flexible displays remain underdeveloped. The correlation between laboratory testing and real-world performance is not well established, making it difficult to accurately predict display lifespan in critical applications. This uncertainty creates significant risk for implementation in systems where failure could have severe consequences.

Miniaturization compounds these challenges, as flexible microdisplays must maintain quality standards while accommodating increasingly dense pixel arrangements and thinner form factors. The reduced scale intensifies the impact of even minor manufacturing variations, requiring exceptionally precise quality control processes.

Non-destructive testing techniques for flexible displays are limited in their ability to detect subsurface defects that may emerge over time. Advanced imaging technologies such as micro-CT scanning show promise but face resolution limitations when examining the multilayer structures typical in flexible display technology.

Human factors considerations add another dimension to quality assurance challenges, as visual perception of display quality can be affected by viewing angle, ambient lighting, and the specific curvature of the display during use. These subjective factors must be quantified and incorporated into objective quality metrics.

The dynamic nature of flexible displays necessitates development of specialized testing methodologies that can accurately assess performance under various mechanical stresses. Current quality assurance protocols designed for rigid displays prove inadequate when applied to flexible technologies, as they fail to account for the additional mechanical variables introduced by flexibility.

Environmental resilience presents another major challenge, particularly in critical systems deployed in extreme conditions. Flexible displays must maintain functionality across wide temperature ranges, humidity variations, and exposure to vibration or shock. The interaction between environmental factors and mechanical stress creates complex failure modes that are difficult to predict using conventional testing approaches.

Uniformity of display characteristics across the entire flexible surface represents a persistent technical hurdle. As the display bends, optical properties can change non-uniformly, resulting in brightness variations, color shifts, and contrast inconsistencies. These effects are particularly problematic in critical systems where precise visual information is essential for decision-making.

Electrical connectivity within flexible displays introduces additional quality concerns. The conductive pathways must maintain integrity during repeated flexing operations, with failure points often developing at the interface between rigid and flexible components. Traditional inspection techniques struggle to detect these potential failure points before they manifest as visible defects.

Accelerated life testing methodologies for flexible displays remain underdeveloped. The correlation between laboratory testing and real-world performance is not well established, making it difficult to accurately predict display lifespan in critical applications. This uncertainty creates significant risk for implementation in systems where failure could have severe consequences.

Miniaturization compounds these challenges, as flexible microdisplays must maintain quality standards while accommodating increasingly dense pixel arrangements and thinner form factors. The reduced scale intensifies the impact of even minor manufacturing variations, requiring exceptionally precise quality control processes.

Non-destructive testing techniques for flexible displays are limited in their ability to detect subsurface defects that may emerge over time. Advanced imaging technologies such as micro-CT scanning show promise but face resolution limitations when examining the multilayer structures typical in flexible display technology.

Human factors considerations add another dimension to quality assurance challenges, as visual perception of display quality can be affected by viewing angle, ambient lighting, and the specific curvature of the display during use. These subjective factors must be quantified and incorporated into objective quality metrics.

Current QA Frameworks for Flexible Display Systems

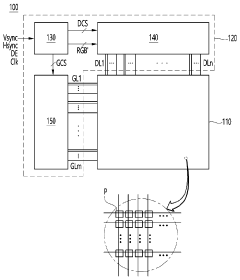

01 Optical inspection systems for flexible displays

Specialized optical inspection systems are used to detect defects in flexible microdisplays. These systems employ advanced imaging techniques to identify surface irregularities, pixel defects, and uniformity issues. The inspection process can be automated using machine vision algorithms that analyze captured images to identify quality issues that might not be visible to the human eye. These systems can operate at various stages of the manufacturing process to ensure consistent quality.- Optical inspection methods for flexible displays: Various optical inspection techniques are employed to ensure the quality of flexible microdisplays. These methods include automated visual inspection systems that can detect defects, irregularities, and inconsistencies in display panels. Advanced imaging technologies and computer vision algorithms analyze the optical properties of displays to identify issues such as dead pixels, color inconsistencies, or structural defects that might affect display performance or flexibility.

- Mechanical testing for flexible display durability: Mechanical testing procedures are crucial for evaluating the durability and reliability of flexible microdisplays. These tests assess the display's ability to withstand bending, folding, and other physical stresses without performance degradation. Testing methods include cyclic bend testing, impact resistance evaluation, and stress distribution analysis to ensure that the display maintains functionality and image quality even after repeated flexing or under various environmental conditions.

- Automated quality control systems for production: Automated quality control systems are implemented in the manufacturing process of flexible microdisplays to ensure consistent quality. These systems incorporate real-time monitoring, data analytics, and machine learning algorithms to detect defects during production. Automated inspection stations at various stages of manufacturing help identify issues early, reducing waste and ensuring that only high-quality displays reach the market.

- Electrical performance validation techniques: Electrical testing methodologies are essential for validating the performance of flexible microdisplays. These techniques assess parameters such as pixel response time, power consumption, signal integrity, and circuit functionality under various operating conditions. Specialized testing equipment and protocols are used to verify that the electrical components of the display maintain proper functionality despite the mechanical stresses associated with flexibility.

- Quality management systems and standards: Comprehensive quality management systems and standards are implemented to ensure consistent quality assurance for flexible microdisplays. These systems include standardized testing protocols, certification processes, and quality metrics specific to flexible display technology. Quality management frameworks incorporate traceability, documentation, and continuous improvement methodologies to maintain high standards throughout the product lifecycle, from design and manufacturing to distribution and customer support.

02 Mechanical testing for flexible display durability

Mechanical testing methods are essential for ensuring the durability and reliability of flexible microdisplays. These tests evaluate the display's performance under various stress conditions such as bending, folding, and stretching. Testing equipment can simulate real-world usage scenarios to measure the display's resistance to mechanical fatigue and identify potential failure points. This approach helps manufacturers establish quality standards for flexible displays that must maintain performance while being repeatedly flexed.Expand Specific Solutions03 Automated quality control systems

Automated quality control systems integrate hardware and software solutions to monitor and maintain the quality of flexible microdisplays throughout the production process. These systems collect real-time data from multiple inspection points and use statistical process control methods to identify trends and anomalies. Machine learning algorithms can be employed to improve defect detection accuracy over time. The automation of quality assurance processes reduces human error and increases production efficiency.Expand Specific Solutions04 Thermal and environmental testing

Thermal and environmental testing evaluates how flexible microdisplays perform under various temperature conditions and environmental factors. Test chambers simulate extreme temperatures, humidity levels, and other environmental stressors to ensure display functionality remains consistent across different operating conditions. These tests are particularly important for flexible displays that may be used in outdoor or harsh environments. Thermal imaging can also be used to identify potential hotspots or thermal management issues that could affect display quality and longevity.Expand Specific Solutions05 Quality management software and tracking systems

Specialized software solutions are used to manage the quality assurance process for flexible microdisplays. These systems track individual display units throughout the manufacturing and testing processes, maintaining comprehensive records of test results and quality metrics. The software can generate reports, identify recurring issues, and facilitate continuous improvement in manufacturing processes. Integration with supply chain management systems allows for traceability of components and finished products, which is essential for quality control and regulatory compliance.Expand Specific Solutions

Key Industry Players in Flexible Microdisplay Technology

The flexible microdisplay quality assurance market for critical systems is in a growth phase, with increasing demand driven by applications in aerospace, medical, and defense sectors. The market is projected to reach significant scale as adoption of flexible display technologies expands across critical applications. Technologically, the field is maturing with industry leaders Samsung Electronics, LG Display, and BOE Technology establishing strong positions through advanced manufacturing capabilities. Japanese players like Sony and Japan Display contribute specialized expertise, while research institutions such as ITRI provide innovation support. Companies like Siemens and Bosch are integrating these technologies into industrial and automotive applications, creating a competitive ecosystem balancing established manufacturers and emerging specialists focused on reliability and performance in demanding environments.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive Quality Assurance framework for flexible microdisplays used in critical systems. Their approach integrates automated optical inspection (AOI) systems with machine learning algorithms to detect microscopic defects in OLED flexible displays. The system employs high-resolution cameras and specialized lighting to capture surface anomalies as small as 1-2 microns. Samsung's QA protocol includes stress testing that simulates up to 200,000 fold cycles to ensure durability in mission-critical applications. Their proprietary "Real-time Defect Classification" (RDC) technology can identify and categorize over 20 different types of display defects with 99.7% accuracy, significantly reducing false positives compared to conventional methods. For critical systems implementation, Samsung employs redundant display modules with automatic failover mechanisms and continuous self-diagnostic routines that monitor display performance parameters including luminance stability, color accuracy, and response time variations.

Strengths: Industry-leading defect detection accuracy with proprietary AI algorithms; comprehensive fold-cycle testing methodology; integrated redundancy systems for critical applications. Weaknesses: Higher implementation costs compared to conventional QA systems; requires specialized training for operators; system calibration needs frequent updates to maintain detection accuracy.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered an advanced Quality Assurance framework specifically designed for flexible microdisplays in critical systems such as medical devices, aerospace controls, and defense applications. Their approach combines multi-stage inspection processes with specialized testing protocols for flexible OLED panels. The company's "Critical Systems Verification" (CSV) methodology incorporates environmental stress screening that tests displays under extreme temperature ranges (-40°C to +85°C), humidity variations, and vibration conditions exceeding MIL-STD-810 requirements. LG's proprietary "Micro-Defect Analysis System" employs laser-based scanning technology capable of detecting structural anomalies at the pixel level with resolution down to 0.5 microns. For ensuring reliability in critical applications, LG implements accelerated life testing that simulates 5-7 years of operational wear within a compressed timeframe, with continuous monitoring of electrical parameters, optical performance, and mechanical integrity. Their QA process includes specialized testing for EMI/EMC compliance to ensure display functionality remains uncompromised in electromagnetically noisy environments typical in critical systems.

Strengths: Comprehensive environmental testing exceeding military standards; high-precision defect detection at sub-micron levels; specialized protocols for critical system applications including medical and aerospace. Weaknesses: Extended QA process increases time-to-market; higher production costs passed to customers; system requires frequent recalibration when production materials or processes change.

Critical Testing Patents and Technical Literature Review

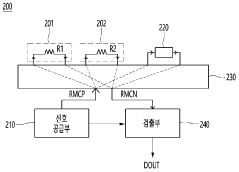

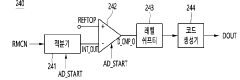

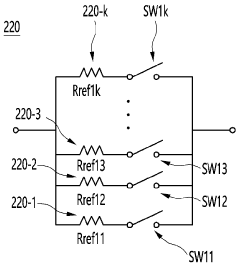

Crack detection device, crack detection method, and data driving device

PatentWO2024039117A1

Innovation

- A crack detection device and method that includes a signal supply unit, resistance adjustment unit, and path control unit to detect cracks by adjusting reference resistance values and selecting multiple paths for signal detection, allowing for accurate and quick identification of cracks in flexible display components.

Display device with micro cover layer and manufacturing method for the same

PatentPendingEP4598322A2

Innovation

- A flexible display apparatus with a micro-coating layer over the bend allowance section, encapsulation, and printed circuit film, along with specific configurations for wire traces and conductive lines to withstand bending stress, enhancing bonding and reducing stress on components.

Reliability Standards and Certification Requirements

Flexible microdisplays deployed in critical systems must adhere to stringent reliability standards and certification requirements to ensure operational safety and performance integrity. The International Electrotechnical Commission (IEC) has established IEC 62368-1 for safety of electronic equipment, while MIL-STD-810 provides environmental testing guidelines specifically relevant for military and aerospace applications where flexible displays are increasingly utilized.

For medical implementations, FDA 510(k) clearance is mandatory, with specific requirements outlined in IEC 60601-1 for medical electrical equipment safety. These standards emphasize rigorous testing protocols for flexible display components, including resistance to mechanical stress, temperature variations, and electromagnetic interference.

The automotive industry applies the Automotive Electronics Council's AEC-Q100 standard, which defines stress test qualifications for integrated circuits in automotive applications. Flexible displays in vehicle dashboards and heads-up displays must demonstrate reliability under extreme temperature conditions (-40°C to 125°C) and withstand vibration testing per ISO 16750.

Aviation systems incorporating flexible microdisplays must comply with DO-160 standards from RTCA, covering environmental conditions and test procedures for airborne equipment. Additionally, the FAA's Technical Standard Orders (TSO) provide minimum performance standards that manufacturers must meet for certification.

Certification processes typically involve third-party testing laboratories such as UL (Underwriters Laboratories), TÜV, or SGS. These organizations verify compliance through accelerated life testing, environmental stress screening, and failure mode analysis. For flexible displays, specialized tests include cyclic bend testing (typically 100,000+ cycles without performance degradation), humidity resistance (85% RH at 85°C for 1,000 hours), and impact resistance testing.

Emerging standards specifically addressing flexible display technology include the Flexible Display Standard Working Group's efforts to establish testing methodologies for mechanical durability. The JEDEC JESD22-B113 standard for board level cyclic bend testing has been adapted for flexible display applications, requiring displays to maintain functionality after repeated flexing operations.

Reliability qualification for critical systems also demands comprehensive documentation including Failure Modes and Effects Analysis (FMEA), Mean Time Between Failures (MTBF) calculations, and detailed test reports. Manufacturers must implement Statistical Process Control (SPC) methods to monitor production quality and ensure consistent reliability metrics across production batches.

As flexible display technology evolves, standards organizations are working to develop more specific requirements addressing unique characteristics such as folding endurance, crease visibility metrics, and pixel stability under mechanical stress. These emerging standards will be crucial for the wider adoption of flexible microdisplays in next-generation critical systems.

For medical implementations, FDA 510(k) clearance is mandatory, with specific requirements outlined in IEC 60601-1 for medical electrical equipment safety. These standards emphasize rigorous testing protocols for flexible display components, including resistance to mechanical stress, temperature variations, and electromagnetic interference.

The automotive industry applies the Automotive Electronics Council's AEC-Q100 standard, which defines stress test qualifications for integrated circuits in automotive applications. Flexible displays in vehicle dashboards and heads-up displays must demonstrate reliability under extreme temperature conditions (-40°C to 125°C) and withstand vibration testing per ISO 16750.

Aviation systems incorporating flexible microdisplays must comply with DO-160 standards from RTCA, covering environmental conditions and test procedures for airborne equipment. Additionally, the FAA's Technical Standard Orders (TSO) provide minimum performance standards that manufacturers must meet for certification.

Certification processes typically involve third-party testing laboratories such as UL (Underwriters Laboratories), TÜV, or SGS. These organizations verify compliance through accelerated life testing, environmental stress screening, and failure mode analysis. For flexible displays, specialized tests include cyclic bend testing (typically 100,000+ cycles without performance degradation), humidity resistance (85% RH at 85°C for 1,000 hours), and impact resistance testing.

Emerging standards specifically addressing flexible display technology include the Flexible Display Standard Working Group's efforts to establish testing methodologies for mechanical durability. The JEDEC JESD22-B113 standard for board level cyclic bend testing has been adapted for flexible display applications, requiring displays to maintain functionality after repeated flexing operations.

Reliability qualification for critical systems also demands comprehensive documentation including Failure Modes and Effects Analysis (FMEA), Mean Time Between Failures (MTBF) calculations, and detailed test reports. Manufacturers must implement Statistical Process Control (SPC) methods to monitor production quality and ensure consistent reliability metrics across production batches.

As flexible display technology evolves, standards organizations are working to develop more specific requirements addressing unique characteristics such as folding endurance, crease visibility metrics, and pixel stability under mechanical stress. These emerging standards will be crucial for the wider adoption of flexible microdisplays in next-generation critical systems.

Environmental Impact and Sustainability Considerations

The environmental footprint of flexible microdisplay manufacturing presents significant sustainability challenges that must be addressed as these technologies become increasingly prevalent in critical systems. Production processes for these displays typically involve rare earth elements, precious metals, and specialized chemicals that require energy-intensive extraction and processing methods. The environmental impact extends throughout the entire lifecycle, from raw material acquisition to end-of-life disposal, with particular concerns regarding the composite materials that make flexibility possible.

Manufacturing flexible displays generates substantial waste streams, including hazardous chemicals such as photoresists, etchants, and solvents. These substances require specialized handling and disposal protocols to prevent environmental contamination. Additionally, the high-purity water demands of microdisplay fabrication contribute to resource depletion in manufacturing regions, while the energy-intensive clean room environments necessary for production result in considerable carbon emissions.

Sustainability considerations must be integrated into quality assurance frameworks for flexible microdisplays, particularly for applications in critical systems where reliability and longevity are paramount. Implementing lifecycle assessment methodologies can quantify environmental impacts and identify opportunities for improvement. Design for environment (DfE) principles should guide material selection and manufacturing process optimization to reduce hazardous substance use and improve recyclability.

Emerging green chemistry approaches offer promising pathways to reduce environmental impact through substitution of hazardous materials with benign alternatives. Bio-based substrates and water-based processing techniques are showing potential to replace conventional petroleum-derived polymers and solvent-intensive methods. Additionally, closed-loop manufacturing systems that recover and reuse materials can significantly reduce waste generation and resource consumption.

For critical systems applications, extended producer responsibility programs become especially important, as these displays may contain valuable recoverable materials alongside potentially harmful components. Quality assurance protocols should therefore include end-of-life management considerations, ensuring that displays can be safely disassembled, with components either recycled or properly disposed of according to environmental regulations.

Energy efficiency during operation represents another crucial sustainability factor. Quality assurance testing should verify that flexible microdisplays meet stringent power consumption requirements, as energy usage during the operational phase often constitutes the largest environmental impact for electronic devices. Innovations in low-power display technologies and intelligent power management systems can substantially reduce lifetime carbon footprints while simultaneously extending battery life in portable critical systems.

Manufacturing flexible displays generates substantial waste streams, including hazardous chemicals such as photoresists, etchants, and solvents. These substances require specialized handling and disposal protocols to prevent environmental contamination. Additionally, the high-purity water demands of microdisplay fabrication contribute to resource depletion in manufacturing regions, while the energy-intensive clean room environments necessary for production result in considerable carbon emissions.

Sustainability considerations must be integrated into quality assurance frameworks for flexible microdisplays, particularly for applications in critical systems where reliability and longevity are paramount. Implementing lifecycle assessment methodologies can quantify environmental impacts and identify opportunities for improvement. Design for environment (DfE) principles should guide material selection and manufacturing process optimization to reduce hazardous substance use and improve recyclability.

Emerging green chemistry approaches offer promising pathways to reduce environmental impact through substitution of hazardous materials with benign alternatives. Bio-based substrates and water-based processing techniques are showing potential to replace conventional petroleum-derived polymers and solvent-intensive methods. Additionally, closed-loop manufacturing systems that recover and reuse materials can significantly reduce waste generation and resource consumption.

For critical systems applications, extended producer responsibility programs become especially important, as these displays may contain valuable recoverable materials alongside potentially harmful components. Quality assurance protocols should therefore include end-of-life management considerations, ensuring that displays can be safely disassembled, with components either recycled or properly disposed of according to environmental regulations.

Energy efficiency during operation represents another crucial sustainability factor. Quality assurance testing should verify that flexible microdisplays meet stringent power consumption requirements, as energy usage during the operational phase often constitutes the largest environmental impact for electronic devices. Innovations in low-power display technologies and intelligent power management systems can substantially reduce lifetime carbon footprints while simultaneously extending battery life in portable critical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!