Flexible Microdisplay Integration in Smart Textile Manufacturing

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Microdisplay Background and Objectives

The integration of flexible microdisplays into textiles represents a transformative technological advancement at the intersection of electronics and textile manufacturing. This convergence has evolved from rudimentary LED implementations in fabrics to sophisticated display systems capable of rendering dynamic visual content directly on wearable surfaces. The trajectory of this technology has been shaped by parallel advancements in flexible electronics, conductive materials, and miniaturization techniques over the past decade.

Smart textiles with integrated display capabilities emerged initially in specialized military and medical applications, but recent technological breakthroughs have expanded potential use cases across consumer, industrial, and healthcare sectors. The fundamental objective of flexible microdisplay integration is to create seamless, comfortable, and durable display systems within textiles while maintaining the inherent properties of the fabric, such as flexibility, breathability, and washability.

Current technological objectives focus on overcoming several critical challenges: achieving higher resolution displays within the constraints of textile structures, improving power efficiency to enable practical wearable applications, enhancing durability against mechanical stress and environmental factors, and developing scalable manufacturing processes suitable for mass production. These objectives align with broader industry trends toward more intuitive human-computer interfaces and ubiquitous computing environments.

The evolution of flexible display technologies has been accelerated by innovations in organic light-emitting diodes (OLEDs), micro-LEDs, and electrophoretic displays, each offering distinct advantages for textile integration. Concurrently, advancements in conductive yarns, printable electronics, and flexible substrates have created new possibilities for embedding display functionality directly into the fabric structure rather than merely attaching rigid components to textile surfaces.

Research institutions and technology companies are increasingly focusing on developing complete ecosystems around smart textile displays, including specialized operating systems, user interaction paradigms, and application development frameworks. This holistic approach aims to transform smart textiles from novelty products into practical, everyday solutions with meaningful functionality.

The ultimate technical goal extends beyond mere visual display capabilities to create truly interactive textiles that can sense user inputs, display relevant information, and communicate with other devices within the Internet of Things (IoT) ecosystem. This vision requires interdisciplinary collaboration between textile engineers, electronics specialists, material scientists, and software developers to overcome the substantial technical barriers that currently limit widespread adoption.

Smart textiles with integrated display capabilities emerged initially in specialized military and medical applications, but recent technological breakthroughs have expanded potential use cases across consumer, industrial, and healthcare sectors. The fundamental objective of flexible microdisplay integration is to create seamless, comfortable, and durable display systems within textiles while maintaining the inherent properties of the fabric, such as flexibility, breathability, and washability.

Current technological objectives focus on overcoming several critical challenges: achieving higher resolution displays within the constraints of textile structures, improving power efficiency to enable practical wearable applications, enhancing durability against mechanical stress and environmental factors, and developing scalable manufacturing processes suitable for mass production. These objectives align with broader industry trends toward more intuitive human-computer interfaces and ubiquitous computing environments.

The evolution of flexible display technologies has been accelerated by innovations in organic light-emitting diodes (OLEDs), micro-LEDs, and electrophoretic displays, each offering distinct advantages for textile integration. Concurrently, advancements in conductive yarns, printable electronics, and flexible substrates have created new possibilities for embedding display functionality directly into the fabric structure rather than merely attaching rigid components to textile surfaces.

Research institutions and technology companies are increasingly focusing on developing complete ecosystems around smart textile displays, including specialized operating systems, user interaction paradigms, and application development frameworks. This holistic approach aims to transform smart textiles from novelty products into practical, everyday solutions with meaningful functionality.

The ultimate technical goal extends beyond mere visual display capabilities to create truly interactive textiles that can sense user inputs, display relevant information, and communicate with other devices within the Internet of Things (IoT) ecosystem. This vision requires interdisciplinary collaboration between textile engineers, electronics specialists, material scientists, and software developers to overcome the substantial technical barriers that currently limit widespread adoption.

Market Analysis for Flexible Display Textiles

The global market for flexible display textiles is experiencing significant growth, driven by increasing consumer demand for wearable technology that seamlessly integrates into daily life. Current market valuations indicate that the smart textile sector is expanding at a compound annual growth rate of 30% since 2020, with flexible display components representing one of the fastest-growing segments within this category.

Consumer electronics giants including Samsung, LG, and Apple have demonstrated strong interest in this technology, evidenced by their substantial patent portfolios related to flexible display integration with textiles. Market research indicates that early adopters are primarily found in fitness and healthcare sectors, where real-time biometric data visualization provides immediate value to users.

Regional analysis reveals that East Asia currently dominates manufacturing capacity for flexible microdisplays, with South Korea and Japan leading in production technology. However, European markets show the highest adoption rates for smart textiles in fashion and lifestyle applications, particularly in countries like Germany, France, and the Netherlands where fashion technology innovation hubs have emerged.

Price sensitivity remains a significant market barrier, with current manufacturing costs keeping flexible display textiles in the premium product category. Consumer surveys indicate willingness to pay a 40-60% premium for textiles with integrated display functionality compared to traditional smart textiles, but this acceptance decreases sharply beyond this threshold.

Market segmentation shows distinct application clusters emerging: health monitoring garments represent the largest current market share, followed by athletic performance wear, interactive fashion, and industrial/military applications. Each segment demonstrates different growth trajectories and price elasticity characteristics.

Supply chain analysis reveals potential bottlenecks in specialized materials production, particularly for transparent conductive materials and flexible encapsulation technologies. These constraints may impact market growth in the short term but are expected to resolve as manufacturing scales.

Competitive landscape assessment identifies three distinct business models emerging: vertically integrated manufacturers controlling the entire production process, specialized component suppliers focusing on microdisplay modules, and fashion brands partnering with technology providers through licensing arrangements.

Consumer adoption forecasts suggest that flexible display textiles will reach mainstream market penetration within 5-7 years, contingent upon achieving key price reduction milestones and demonstrating durability improvements through multiple wash cycles. Early market success will likely depend on establishing clear use cases that deliver tangible benefits beyond novelty appeal.

Consumer electronics giants including Samsung, LG, and Apple have demonstrated strong interest in this technology, evidenced by their substantial patent portfolios related to flexible display integration with textiles. Market research indicates that early adopters are primarily found in fitness and healthcare sectors, where real-time biometric data visualization provides immediate value to users.

Regional analysis reveals that East Asia currently dominates manufacturing capacity for flexible microdisplays, with South Korea and Japan leading in production technology. However, European markets show the highest adoption rates for smart textiles in fashion and lifestyle applications, particularly in countries like Germany, France, and the Netherlands where fashion technology innovation hubs have emerged.

Price sensitivity remains a significant market barrier, with current manufacturing costs keeping flexible display textiles in the premium product category. Consumer surveys indicate willingness to pay a 40-60% premium for textiles with integrated display functionality compared to traditional smart textiles, but this acceptance decreases sharply beyond this threshold.

Market segmentation shows distinct application clusters emerging: health monitoring garments represent the largest current market share, followed by athletic performance wear, interactive fashion, and industrial/military applications. Each segment demonstrates different growth trajectories and price elasticity characteristics.

Supply chain analysis reveals potential bottlenecks in specialized materials production, particularly for transparent conductive materials and flexible encapsulation technologies. These constraints may impact market growth in the short term but are expected to resolve as manufacturing scales.

Competitive landscape assessment identifies three distinct business models emerging: vertically integrated manufacturers controlling the entire production process, specialized component suppliers focusing on microdisplay modules, and fashion brands partnering with technology providers through licensing arrangements.

Consumer adoption forecasts suggest that flexible display textiles will reach mainstream market penetration within 5-7 years, contingent upon achieving key price reduction milestones and demonstrating durability improvements through multiple wash cycles. Early market success will likely depend on establishing clear use cases that deliver tangible benefits beyond novelty appeal.

Flexible Microdisplay Technology: Status and Barriers

Flexible microdisplay technology has evolved significantly over the past decade, transitioning from rigid glass-based displays to ultra-thin, bendable solutions that can be integrated into textiles. Current state-of-the-art flexible displays utilize organic light-emitting diode (OLED) and micro-LED technologies, which offer superior flexibility, low power consumption, and high brightness essential for wearable applications. These displays typically achieve bending radii of 1-5mm without performance degradation, representing a substantial improvement over earlier generations.

Despite these advancements, several critical barriers impede widespread integration into smart textiles. The foremost challenge remains durability under repeated mechanical stress. Current flexible displays can withstand approximately 100,000-200,000 folding cycles before significant performance degradation occurs—insufficient for textile applications that may undergo millions of flexing cycles throughout their lifetime. Environmental resilience presents another major obstacle, as exposure to moisture, temperature fluctuations, and washing processes can rapidly degrade display performance.

Manufacturing scalability constitutes a significant limitation, with current production methods predominantly relying on batch processing rather than roll-to-roll techniques compatible with textile manufacturing. This creates a fundamental mismatch between display and textile production paradigms, resulting in high integration costs and limited production volumes. The yield rates for flexible microdisplays remain below 70% at industrial scale, compared to over 90% for conventional rigid displays.

Power management represents another substantial barrier. While flexible displays have reduced power requirements compared to rigid counterparts, they still demand 50-100 mW/cm² during operation—challenging to supply through textile-integrated power sources. The interconnection between display components and textile substrates lacks standardization, with current solutions utilizing fragile conductive adhesives or mechanical connectors that create reliability vulnerabilities.

Resolution capabilities of flexible displays suitable for textile integration typically range from 100-300 PPI, significantly lower than the 500+ PPI available in rigid displays. This limitation restricts potential applications requiring detailed visual information. Additionally, color reproduction remains limited, with most textile-compatible displays achieving only 70-80% of the standard RGB color gamut.

The supply chain for flexible display materials presents further complications, with critical components like flexible encapsulation films and specialized conductive materials facing limited availability and high costs. These materials often require specialized handling procedures incompatible with standard textile manufacturing environments, creating additional integration challenges.

Despite these advancements, several critical barriers impede widespread integration into smart textiles. The foremost challenge remains durability under repeated mechanical stress. Current flexible displays can withstand approximately 100,000-200,000 folding cycles before significant performance degradation occurs—insufficient for textile applications that may undergo millions of flexing cycles throughout their lifetime. Environmental resilience presents another major obstacle, as exposure to moisture, temperature fluctuations, and washing processes can rapidly degrade display performance.

Manufacturing scalability constitutes a significant limitation, with current production methods predominantly relying on batch processing rather than roll-to-roll techniques compatible with textile manufacturing. This creates a fundamental mismatch between display and textile production paradigms, resulting in high integration costs and limited production volumes. The yield rates for flexible microdisplays remain below 70% at industrial scale, compared to over 90% for conventional rigid displays.

Power management represents another substantial barrier. While flexible displays have reduced power requirements compared to rigid counterparts, they still demand 50-100 mW/cm² during operation—challenging to supply through textile-integrated power sources. The interconnection between display components and textile substrates lacks standardization, with current solutions utilizing fragile conductive adhesives or mechanical connectors that create reliability vulnerabilities.

Resolution capabilities of flexible displays suitable for textile integration typically range from 100-300 PPI, significantly lower than the 500+ PPI available in rigid displays. This limitation restricts potential applications requiring detailed visual information. Additionally, color reproduction remains limited, with most textile-compatible displays achieving only 70-80% of the standard RGB color gamut.

The supply chain for flexible display materials presents further complications, with critical components like flexible encapsulation films and specialized conductive materials facing limited availability and high costs. These materials often require specialized handling procedures incompatible with standard textile manufacturing environments, creating additional integration challenges.

Current Integration Methods for Flexible Displays in Textiles

01 Flexible substrate technologies for microdisplays

Flexible substrates are essential components for creating bendable microdisplays. These substrates can be made from various materials such as polymers, thin glass, or metal foils that provide the necessary flexibility while maintaining structural integrity. The integration of display elements onto these flexible substrates requires specialized bonding techniques and stress management to ensure functionality during bending. Advanced manufacturing processes allow for the creation of ultra-thin substrates that can conform to curved surfaces while supporting the electronic components of the display.- Flexible substrate technologies for microdisplays: Flexible substrates are essential for creating bendable microdisplays. These substrates can be made from various materials such as polymers or thin glass that provide the necessary flexibility while maintaining structural integrity. The integration of display elements onto these flexible substrates requires specialized manufacturing techniques to ensure proper functionality even when the display is bent or folded. These technologies enable the development of curved, rollable, or foldable display devices that can be integrated into various applications.

- OLED technology for flexible displays: Organic Light Emitting Diode (OLED) technology is particularly suitable for flexible microdisplays due to its inherent thin and lightweight characteristics. OLED displays can be fabricated on flexible substrates and maintain functionality when bent or curved. The integration of OLED elements into flexible displays involves specialized manufacturing processes to ensure proper electrical connections and pixel alignment. This technology enables the creation of high-resolution, vibrant displays that can conform to non-flat surfaces.

- Interconnection technologies for flexible displays: Specialized interconnection technologies are crucial for maintaining electrical connectivity in flexible microdisplays during bending or folding. These include stretchable conductive materials, serpentine wiring patterns, and novel bonding techniques that can withstand repeated flexing without failure. The integration of these interconnection technologies ensures reliable signal transmission and power delivery throughout the flexible display system, even under mechanical stress conditions.

- Display driving mechanisms for flexible microdisplays: Specialized driving mechanisms are required for flexible microdisplays to maintain image quality during bending. These include thin-film transistor arrays that can operate while flexed, adaptive driving circuits that compensate for geometric distortions, and novel addressing schemes. The integration of these driving mechanisms with flexible display elements ensures consistent brightness, contrast, and color reproduction regardless of the display's physical configuration.

- Optical components for flexible display systems: Specialized optical components are essential for flexible microdisplay systems to maintain image quality when bent. These include flexible light guides, bendable backlighting systems, and deformable optical films that can redistribute light evenly across curved surfaces. The integration of these optical components with flexible display elements ensures uniform brightness and viewing angles, even when the display is not flat. These technologies enable the development of high-performance flexible displays for various applications.

02 OLED technology for flexible displays

Organic Light Emitting Diode (OLED) technology is particularly suitable for flexible microdisplays due to its inherently thin and flexible structure. OLED displays can be fabricated directly onto flexible substrates, eliminating the need for rigid backlighting components found in traditional LCD displays. The self-emissive nature of OLEDs allows for thinner display constructions with improved flexibility. Advanced OLED integration techniques include the use of specialized encapsulation methods to protect the organic materials from oxygen and moisture while maintaining flexibility.Expand Specific Solutions03 Interconnection technologies for flexible displays

Specialized interconnection technologies are crucial for maintaining electrical connectivity in flexible microdisplays during bending and folding operations. These include stretchable conductive materials, serpentine wiring patterns, and advanced bonding techniques that can withstand repeated flexing without failure. Innovative approaches such as liquid metal interconnects and conductive polymers provide both electrical conductivity and mechanical flexibility. The integration of these interconnection technologies with display elements requires precise alignment and attachment methods to ensure reliable performance under various bending conditions.Expand Specific Solutions04 Display driver integration for flexible microdisplays

The integration of display drivers with flexible microdisplays presents unique challenges that require specialized solutions. These include thin-film transistor arrays that can maintain performance while being bent, and driver ICs that can be mounted on flexible substrates. Advanced techniques such as chip-on-flex bonding and flexible printed circuit integration allow for the necessary electrical control while maintaining the overall flexibility of the display system. The placement and connection of these driver components must be carefully engineered to avoid stress concentration points that could lead to failure during flexing.Expand Specific Solutions05 Optical enhancement technologies for flexible displays

Various optical enhancement technologies can be integrated into flexible microdisplays to improve performance and viewing experience. These include flexible light management films, anti-reflection coatings that maintain effectiveness when bent, and specialized diffusers for uniform light distribution across curved surfaces. Color enhancement technologies such as quantum dot layers can be incorporated into flexible structures to improve color gamut. Additionally, specialized polarizers and compensation films can be integrated to maintain display quality at various viewing angles even when the display is in a non-flat configuration.Expand Specific Solutions

Industry Leaders in Smart Textile and Microdisplay Sectors

The flexible microdisplay integration in smart textile manufacturing market is currently in an early growth phase, characterized by significant R&D activity but limited commercial deployment. The global market size is projected to reach approximately $2.5 billion by 2027, with a CAGR of 15-20%. Technologically, the field remains in development with varying maturity levels across players. Leading companies like BOE Technology, Philips, and Intel are advancing commercial applications, while academic institutions including Zhejiang Sci-Tech University and Fudan University are driving fundamental research. Research centers like IMEC are bridging the gap between theoretical concepts and practical implementations, focusing on flexible electronics integration with textiles. Google and IBM are leveraging their expertise in software and AI to enhance the functionality of these smart textile systems.

Koninklijke Philips NV

Technical Solution: Philips has developed an innovative approach to flexible microdisplay integration in textiles through their "LuminousFiber" technology platform. This solution utilizes ultra-thin flexible OLED displays manufactured on polymer substrates with thickness below 50μm, allowing for seamless integration into various textile structures. Their manufacturing process incorporates specialized encapsulation techniques that protect the sensitive display components from environmental factors while maintaining flexibility and comfort. Philips' approach includes a distributed architecture where display modules are connected via conductive yarns that are woven directly into the fabric structure, eliminating the need for traditional rigid circuit boards. The display elements achieve brightness levels exceeding 300 nits while consuming minimal power through advanced pixel driving schemes. Their integration method includes proprietary bonding techniques that create reliable connections between the display components and textile substrates, maintaining functionality even after multiple washing cycles. Philips has also developed companion sensor systems that allow the integrated displays to respond to environmental conditions and user interactions, enabling applications in healthcare monitoring, personal safety, and fashion.

Strengths: Extensive experience in consumer electronics and healthcare applications; strong brand recognition for quality and reliability; established relationships with textile manufacturers. Weaknesses: Higher production costs compared to conventional displays; challenges with power distribution in larger textile displays; limited color reproduction in extreme bending conditions.

Intel Corp.

Technical Solution: Intel has developed a comprehensive flexible microdisplay integration platform called "Fabric Integration Technology" (FIT) specifically designed for smart textile applications. This solution leverages Intel's expertise in semiconductor miniaturization to create ultra-thin silicon-based display modules that can be directly incorporated into textile structures. The technology utilizes a specialized version of their low-power display architecture, modified to operate on flexible substrates with thickness under 75μm. Intel's approach incorporates a distributed processing architecture where multiple small display units work in coordination, reducing the need for bulky central controllers. Their manufacturing process includes proprietary bonding techniques that create reliable electrical connections between rigid components and flexible substrates, maintaining functionality even under repeated mechanical stress. The display modules employ microLED technology with specialized optical films that enhance visibility while maintaining flexibility. Intel has also developed companion power management ICs that optimize battery life for wearable applications, with intelligent power scaling based on display content and user activity patterns.

Strengths: Advanced semiconductor manufacturing capabilities; extensive experience with system-on-chip integration; strong partnerships with textile industry players for implementation. Weaknesses: Less experience with flexible display technologies compared to dedicated display manufacturers; higher component costs; challenges with heat dissipation in densely integrated textile applications.

Key Patents and Innovations in Textile Display Technology

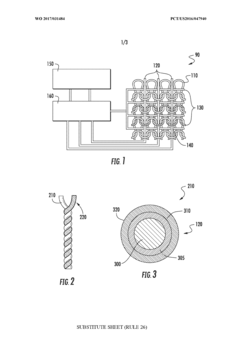

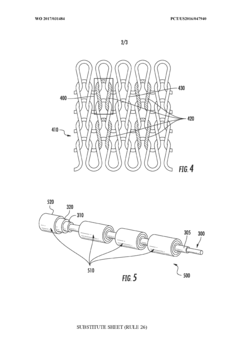

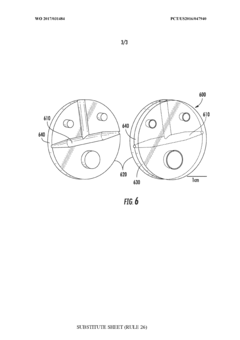

Direct integraton of individually controlled pixels into a knitted fabric matrix

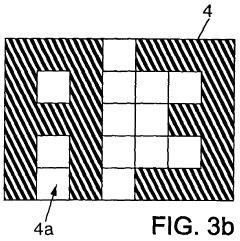

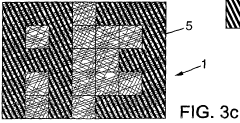

PatentWO2017031484A1

Innovation

- A flexible and scalable emissive fabric display with individually controllable pixels is achieved by integrating electroluminescent threads directly into a knitted matrix, where conductive and electroluminescent threads form pixels that can be controlled independently, allowing for dynamic information display and retention of fabric flexibility, with scalable and cost-effective production.

Flexible display

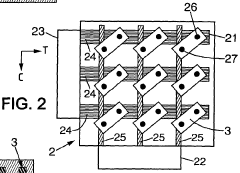

PatentWO2004100113A2

Innovation

- A flexible display comprising a flexible support with discrete light sources, a diffusing element to create a continuous light display, and a cover element for aesthetic integration, using a matrix arrangement of light-emitting diodes (LEDs) on a fabric substrate with conductive threads for signal transmission and power supply, allowing for adjustable pixel size and reduced power consumption.

Manufacturing Process Optimization for Scale Production

The optimization of manufacturing processes for scale production of flexible microdisplays in smart textiles requires systematic approaches to overcome current production bottlenecks. Current manufacturing methods typically involve batch processing with limited throughput, resulting in high unit costs that impede mass market adoption. To address these challenges, roll-to-roll (R2R) processing emerges as a promising solution, enabling continuous production of flexible displays on textile substrates.

R2R manufacturing can significantly increase production speeds from the current 0.5-2 m²/hour to potentially 20-50 m²/hour, representing a tenfold improvement in throughput. This approach requires precise tension control systems to maintain substrate stability during high-speed processing, with tolerance levels below ±0.05mm to ensure display functionality and pixel alignment.

Temperature management during manufacturing presents another critical optimization area. The integration of localized heating zones can reduce energy consumption by 30-40% compared to conventional methods while maintaining the precise thermal profiles required for organic semiconductor deposition. Advanced thermal modeling suggests optimal processing temperatures between 80-120°C for most flexible display materials, with controlled cooling rates of 2-5°C/minute to prevent thermal stress.

Automated quality control systems incorporating machine vision and AI-based defect detection can reduce rejection rates from current industry averages of 15-20% down to below 5%. These systems can identify microscopic defects at production speeds, enabling real-time process adjustments and significantly improving yield rates. Implementation of digital twin technology for production lines allows for virtual testing of process modifications before physical implementation, reducing downtime and optimization costs.

Material handling innovations, particularly in the realm of electrostatic discharge (ESD) management, are essential for reliable production. Advanced ionization systems integrated directly into production lines can maintain static charge below 100V, protecting sensitive display components while maintaining production speeds. Additionally, the development of specialized coating techniques for applying transparent conductive materials to textiles at speeds exceeding 10 m/minute represents a significant breakthrough for scale production.

Modular production line design enables manufacturers to scale operations incrementally, reducing initial capital expenditure while allowing for capacity expansion as market demand grows. This approach has demonstrated 25-30% lower setup costs compared to traditional fixed-capacity production lines, making the technology more accessible to mid-sized manufacturers entering the smart textile market.

R2R manufacturing can significantly increase production speeds from the current 0.5-2 m²/hour to potentially 20-50 m²/hour, representing a tenfold improvement in throughput. This approach requires precise tension control systems to maintain substrate stability during high-speed processing, with tolerance levels below ±0.05mm to ensure display functionality and pixel alignment.

Temperature management during manufacturing presents another critical optimization area. The integration of localized heating zones can reduce energy consumption by 30-40% compared to conventional methods while maintaining the precise thermal profiles required for organic semiconductor deposition. Advanced thermal modeling suggests optimal processing temperatures between 80-120°C for most flexible display materials, with controlled cooling rates of 2-5°C/minute to prevent thermal stress.

Automated quality control systems incorporating machine vision and AI-based defect detection can reduce rejection rates from current industry averages of 15-20% down to below 5%. These systems can identify microscopic defects at production speeds, enabling real-time process adjustments and significantly improving yield rates. Implementation of digital twin technology for production lines allows for virtual testing of process modifications before physical implementation, reducing downtime and optimization costs.

Material handling innovations, particularly in the realm of electrostatic discharge (ESD) management, are essential for reliable production. Advanced ionization systems integrated directly into production lines can maintain static charge below 100V, protecting sensitive display components while maintaining production speeds. Additionally, the development of specialized coating techniques for applying transparent conductive materials to textiles at speeds exceeding 10 m/minute represents a significant breakthrough for scale production.

Modular production line design enables manufacturers to scale operations incrementally, reducing initial capital expenditure while allowing for capacity expansion as market demand grows. This approach has demonstrated 25-30% lower setup costs compared to traditional fixed-capacity production lines, making the technology more accessible to mid-sized manufacturers entering the smart textile market.

Durability and Washability Considerations for Smart Textiles

The integration of flexible microdisplays into smart textiles introduces significant challenges regarding durability and washability. Traditional electronic components are inherently vulnerable to water, mechanical stress, and chemical exposure—all common factors in textile care. Current smart textile products typically withstand only 20-30 washing cycles before experiencing performance degradation, falling far short of conventional textile durability standards which expect 50+ washing cycles.

Encapsulation technologies represent the primary defense mechanism for embedded electronics. Advanced polymer-based encapsulants such as parylene and PDMS (polydimethylsiloxane) provide water-resistant barriers while maintaining flexibility. Recent developments in hydrophobic nano-coatings have demonstrated promising results, with some laboratory prototypes achieving IPX7 waterproof ratings while preserving textile breathability and tactile properties.

Mechanical stress during washing presents another critical challenge. Flexible microdisplays must withstand repeated bending, twisting, and compression forces in washing machines. Strain-resistant interconnect designs utilizing serpentine patterns and stretchable conductive materials have emerged as effective solutions. Studies indicate that strategically designed serpentine interconnects can withstand strain levels up to 30% without electrical failure, significantly improving washing cycle tolerance.

Temperature fluctuations during washing and drying processes pose additional concerns. Most flexible display technologies have operating temperature ranges of -20°C to 60°C, but washing temperatures can reach 90°C in sanitization cycles. Thermal management solutions incorporating phase-change materials and thermally resistant polymers are being developed to address this gap, though commercial implementation remains limited.

Chemical resistance presents perhaps the most complex challenge. Detergents, fabric softeners, and bleaching agents contain compounds that can degrade both electronic components and their protective encapsulation. Research into chemically resistant barrier materials has yielded promising results, with fluoropolymer-based coatings showing exceptional resistance to common laundry chemicals while maintaining flexibility.

Industry standards for washable electronics in textiles remain underdeveloped. The IPC-8921 standard for washable electronics provides some guidance, but specific protocols for flexible displays in textiles are still emerging. Leading manufacturers have established proprietary testing methodologies, creating inconsistency in durability claims across the market.

Future research directions include self-healing materials that can automatically repair minor damage from washing processes, removable display modules that can be detached before washing, and improved waterproof connectors specifically designed for textile integration. These innovations will be crucial for bridging the durability gap between conventional textiles and smart textile products with integrated microdisplays.

Encapsulation technologies represent the primary defense mechanism for embedded electronics. Advanced polymer-based encapsulants such as parylene and PDMS (polydimethylsiloxane) provide water-resistant barriers while maintaining flexibility. Recent developments in hydrophobic nano-coatings have demonstrated promising results, with some laboratory prototypes achieving IPX7 waterproof ratings while preserving textile breathability and tactile properties.

Mechanical stress during washing presents another critical challenge. Flexible microdisplays must withstand repeated bending, twisting, and compression forces in washing machines. Strain-resistant interconnect designs utilizing serpentine patterns and stretchable conductive materials have emerged as effective solutions. Studies indicate that strategically designed serpentine interconnects can withstand strain levels up to 30% without electrical failure, significantly improving washing cycle tolerance.

Temperature fluctuations during washing and drying processes pose additional concerns. Most flexible display technologies have operating temperature ranges of -20°C to 60°C, but washing temperatures can reach 90°C in sanitization cycles. Thermal management solutions incorporating phase-change materials and thermally resistant polymers are being developed to address this gap, though commercial implementation remains limited.

Chemical resistance presents perhaps the most complex challenge. Detergents, fabric softeners, and bleaching agents contain compounds that can degrade both electronic components and their protective encapsulation. Research into chemically resistant barrier materials has yielded promising results, with fluoropolymer-based coatings showing exceptional resistance to common laundry chemicals while maintaining flexibility.

Industry standards for washable electronics in textiles remain underdeveloped. The IPC-8921 standard for washable electronics provides some guidance, but specific protocols for flexible displays in textiles are still emerging. Leading manufacturers have established proprietary testing methodologies, creating inconsistency in durability claims across the market.

Future research directions include self-healing materials that can automatically repair minor damage from washing processes, removable display modules that can be detached before washing, and improved waterproof connectors specifically designed for textile integration. These innovations will be crucial for bridging the durability gap between conventional textiles and smart textile products with integrated microdisplays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!